According to Future Market Insights, in the decade from 2022 to 2032, the global laser cutting machine market will grow at a CAGR of 5.8%. As the market changes, manufacturers pursue technological innovation and perfection. The 5-axis laser machine was born at this time.

The 5-axis laser cutter is a remarkable manufacturing tool that pushes the boundaries of traditional laser cutting and engraving practices. While your standard 3-axis laser cutter can cut flat and simple designs, its 5-axis big brother can accomplish the same tasks with higher precision and at faster speeds.

What is 5-axis Laser Cutting?

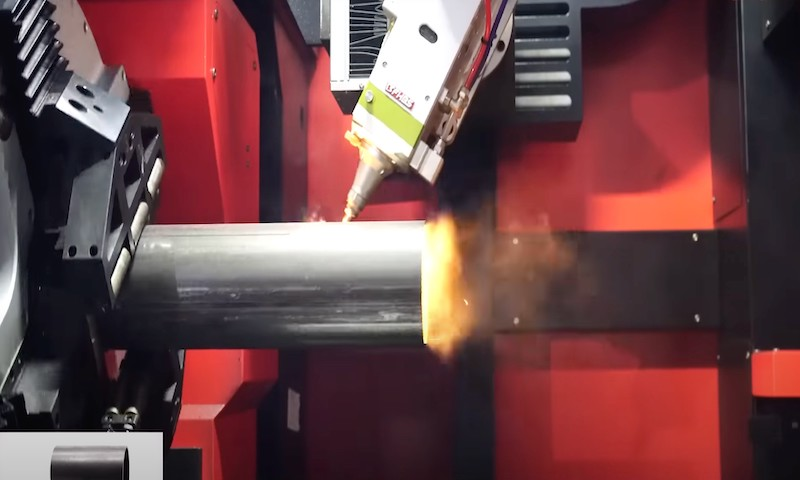

5-axis laser cutting is an advanced CNC (computer numerical controlled) manufacturing process that involves moving the laser head in five axes around the workpiece to cut and shape the material from different angles.

Allowing operators to cut complex parts in one swift step and removing the need to dismount, reorient, and remount the workpiece after every laser pass.

Moving in more directions enables a high degree of flexibility and cutting precision, improving the cutting process and enabling 3D (three-dimensional) cutting.

A standard 3-axis laser cutting machine can only cut metal parts in a 2D motion. Essentially limiting operators to cutting flat sheets of metals. With a multi-axis laser cutter, like a 5-axis machine, operators can cut 3D shapes out of metal blocks by moving around the workpiece in 5 axes.

The laser cutting head in a 5-axis laser cutting machine moves in the following axes.

- X-Axis: Horizontal Motion – Left and Right.

- Y-Axis: Horizontal Motion – Front and Back.

- Z-Axis: Vertical Motion – Up and Down.

- A-Axis: Horizontal Rotation – Spinning in the X-Axis.

- B-Axis: Horizontal Rotation – Spinning in the Y-Axis.

| Number of Axes | X-axis Motion | Y-axis Motion | Z-axis Motion | A-axis Rotation | B-axis Rotation | C-axis Rotation |

|---|---|---|---|---|---|---|

| 2-axis Cutter | ✅ | ✅ | ||||

| 3-axis Cutter | ✅ | ✅ | ✅ | |||

| 4-axis Cutter | ✅ | ✅ | ✅ | ✅ | ||

| 5-axis Cutter | ✅ | ✅ | ✅ | ✅ | ✅ | |

| 5-axis Cutter | ✅ | ✅ | ✅ | ✅ | ✅ | |

| 6-axis Cutter | ✅ | ✅ | ✅ | ✅ | ✅ | ✅ |

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

How Does a 5-axis Laser Cutting Machine Work?

A 5-axis laser cutting machine is a complex device that involves a lot of prep work and pre-cutting setup to ensure the best performance. But once you have made all the necessary preparations, the cutting process is as simple as installing your chosen material in the workpiece and pressing a button.

Following are the basic setup and cutting steps of a 5-axis laser cutting machine.

Step 1 – Vise Installation

Laser cutting machines have a solid metal bed that is a basis for all cutting operations. A mechanical vise must be installed to securely mount workpieces (materials) to the work bed.

Check the specifications of your 5-axis laser cutting machine and look for the vise recommendations. The manufacturer has tested and approved these vises for the select laser cutter.

Simply place the vice on the work bed and screw it into the base.

Step 2 – Tool Installation

Most multi-axis cutting machines support multiple cutting tool selection. The machine can automatically switch from one tool to another during cutting.

For laser cutting, you are limited to one tool at a time but can stop the machine and manually install a different cutting head.

The change in the laser head shifts the machine’s working distance, depth focus, and beam wavelength.

Step 3 – Set Tool Center to Zero

Next, we inform the CNC processor in the 5-axis laser cutter about the zero positions. Typically, this is done by replacing the laser head with a measuring probe.

The operator ensures the measuring probe touches the workbench and the edges of the vise and dials in a zero value into the machine. This way, the laser cutter will know not to exceed the cutting limit and accidentally cut into the vise or the work bed.

Step 4 – Mounting the Material to the Vise

Once the laser cutter is set up and all machine parts are working properly, we can mount the working material to the vise.

Select an optimal orientation for the workpiece so the laser can easily make the desired cuts at virtually any angle.

Tightly secure the workpiece to the vise before starting the cutting process.

Step 5 – Load Cutting Program

Laser-cutting machines use specific coding languages to translate computer designs into laser cutting. Check all the supported programs and file formats with your machine’s manufacturer.

Once you have the program details, you can load it into the laser cutter using a USB cable, memory card, or flash device.

Step 6 – Run Program

Now select and run the program using the laser cutting machine’s interface. If you have an overly complex part geometry or a particularly large design, you must split the cutting process into two parts.

Step 7 – Extract the Finished Part

Wait for the machine to make the desired cuts, engravings, or markings, and then hit the open door button on the laser cutting machine interface.

Carefully unfasten the vise grip and gently remove the finished part.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

6 Amazing Benefits of 5-axis Laser Cutting

Following are some of the most important benefits of a 5-axis laser cutter.

1. 3D Laser Cutting

One of the most significant advantages of a 5-axis machine is 3D laser cutting complex shapes and contours with precision.

This flexibility is impossible with 2-axis or 3-axis machines, which are limited to flat designs and simple shapes.

2. Minimal Material Waste

Since the cutting process is combined into one step, the laser can cut parts with a higher mechanical precision, reducing material waste.

With 2-axis and 3-axis machines, much material is wasted because the machine cannot efficiently move the laser head.

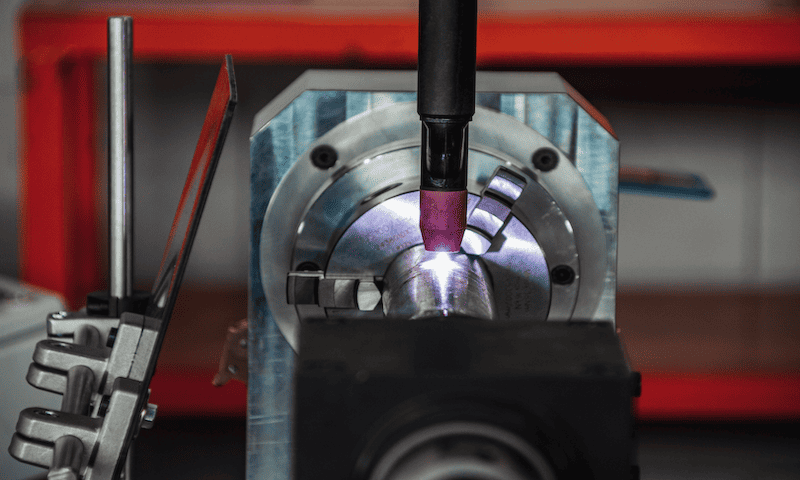

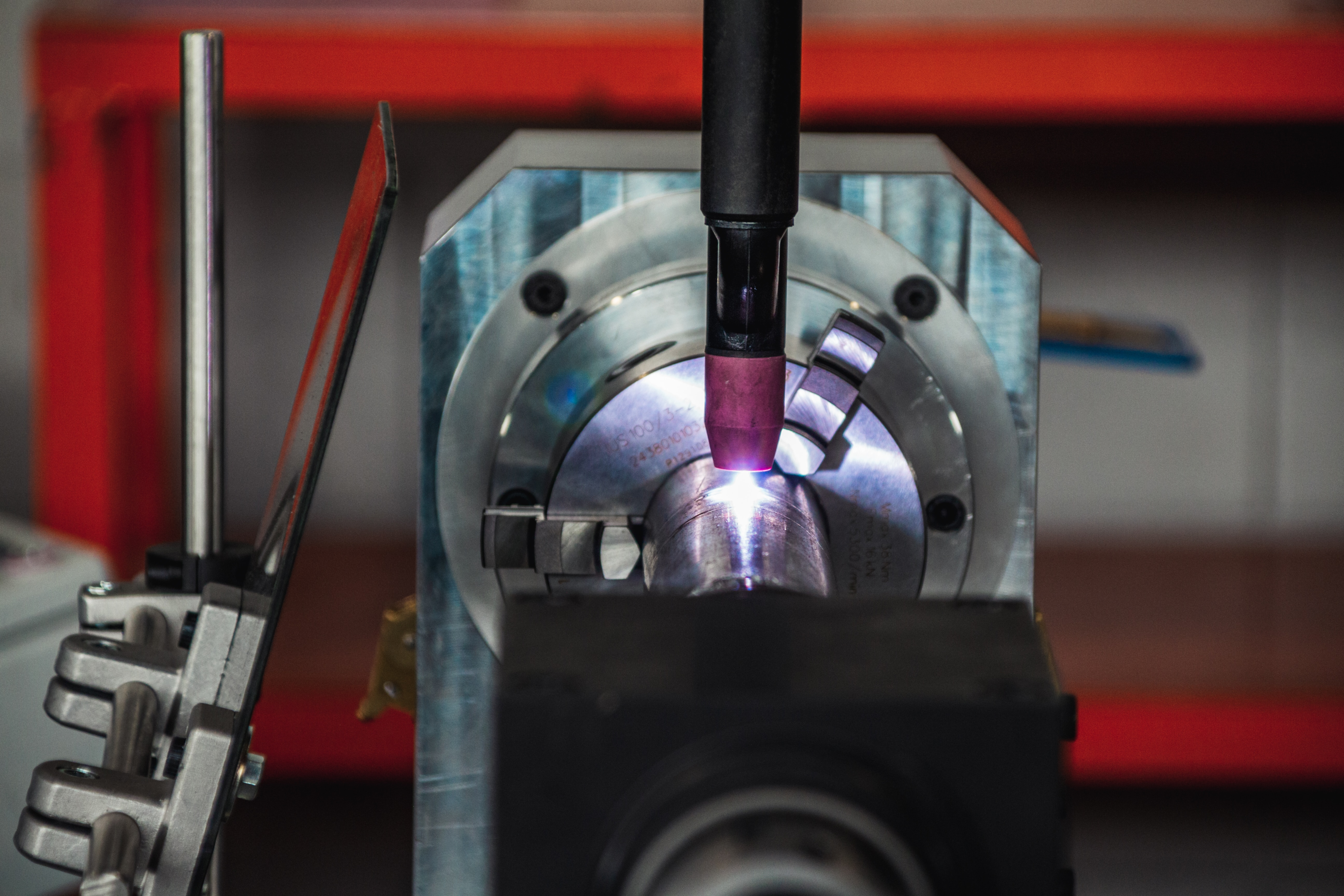

3. Gas Assistance

Due to the nature of laser cutting, a multi-axis laser cutting machine is inherently premium. As such, it enjoys quality-of-life features like gas assistance. A nozzle jets oxygen or nitrogen at the cutting spot, preventing flare-ups and improving cutting efficiency.

A high-energy laser beam can result in volatile metals like magnesium catching fire. Hence, a gas jet is needed to minimize burning and optimize the cutting accuracy and precision.

4. Better Accuracy and Precision

All CNC machines enjoy high cutting accuracy and precision. However, 5-axis laser cutting can further improve those capabilities by supporting multiple setups.

Multiple setups mean that the machine can cut parts irrespective of workpiece orientation. You can mount your workpiece upside down, tilted to one side, or at an angle, and it will not affect the laser cutting.

5. Improved Cutting Efficiency

Laser cutting is a fast process that enables quick and close tolerances on complex parts with the press of a button. But 3-axis machines introduce unwanted slowdowns in the process as they often require multiple laser passes and workpiece reorientation.

The time wasted in unmounting and then remounting a workpiece results in an overall lower cutting efficiency.

6. Reduced Production Costs

When you are making high-quality laser-cut parts at a breakneck speed with excellent accuracy and precision, it will improve your production rate.

A higher production rate means more parts per day, resulting in lower operational costs, making 5-axis laser cutters particularly beneficial for businesses that deal in large-volume manufacturing.

Click here to learn about how laser cutting machines save costs for your projects.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Applications and Industries

The flexibility and versatility of multiaxis machining make it ideal for high-precision work and quick turnarounds.

Following is a short list of industries with the biggest uptake in 5-axis laser cutting.

| Industry | Application |

|---|---|

| Aerospace | Aircraft Hull, Wings, Engine Parts, Turbine Blades, etc. |

| Automotive | Car Chassis, Suspension System, Door Panels, Interior Design, Engine Parts, etc. |

| Medical | Metal Implants, Medical Equipment Manufacturing, Surgical Tools, etc. |

| Marine | Ship Constructions, Precision Cutting Joints, Turbine Parts, etc. |

| Jewelry | Cleanup, Marking, Engraving, Precision Cutting, etc. |

| R&D | Rapid Prototyping, Rough Samples, etc. |

| Construction | Precision Cut parts for Cranes, Excavators, Loaders, Sanitation Machines, etc. |

Tips for Choosing the Right 5-axis Laser Cutter

The trick to choosing the right 5-axis laser cutter is understanding your business requirements. You need a laser cutter that suits your current production needs and can match future expansion.

1. Production Requirements

Assess your current production capacity and business needs. If you’re struggling to meet your current production goals with 3-axis laser cutters, then it’s time to upgrade to a 5-axis model.

2. Future Proofing

Future-proofing refers to buying over-spec equipment right now to have enough power for future expansion and production increase.

A 5-axis machine also serves as an investment into the future of your business. Allowing you to grow and expand into other production sectors.

3. Ease of Operation

When choosing a 5-axis laser cutter, check if it is easy to operate or if the manufacturer provides operator training. A complex operating procedure can hinder your production output when you shift to the new 5-axis laser setup.

4. Return on Investment

ROI, or return on investment, is a business term that refers to the number of years it takes to recover your initial monetary investment. If you buy an expensive 5-axis laser cutter today, see how long it would take for that machine to pay off its initial price and start generating revenue.

5. Buy From a Reputable Brand

Always buy from a reputable brand (manufacturer). If you’re unsure about the manufacturer’s reputation and capabilities, a quick email to their support staff for quotes or advice is a good first step. Contact Baison now for a quick consultation!

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. How Many Axis Does a Laser Cutter Have?

A standard laser cutter has a 3-axis of motion. The laser head can move in the X, Y, and Z directions. Higher performance machines come with 4-axis, 5-axis, and 6-axis.

2. What is the Z-axis on a Laser Cutter?

The Z-axis on a laser cutter refers to the up and down motion of the laser head, which is responsible for the cutting depth, among other things.

3. Is Laser Cutting CNC Controlled?

Yes, all laser cutting machines (except handheld laser cutters) have CNC controllers that enable their high accuracy and precision.

4. How Many Axes Do You Need for 3D Laser Cutting?

3D laser cutting requires a machine with at least 4-axis of motion. XYZ motion and the ability to rotate around one axis.

Conclusion

5-axis laser cutting machines are versatile manufacturing tools that enable operators to cut metal parts with three-dimensional motion and increased accuracy. While 3-axis laser cutters are great for flat 2D operations, they struggle with complex parts and geometry. Multi-axis laser cutters are an excellent choice for small businesses looking to expand their business and large ones looking to optimize their production.

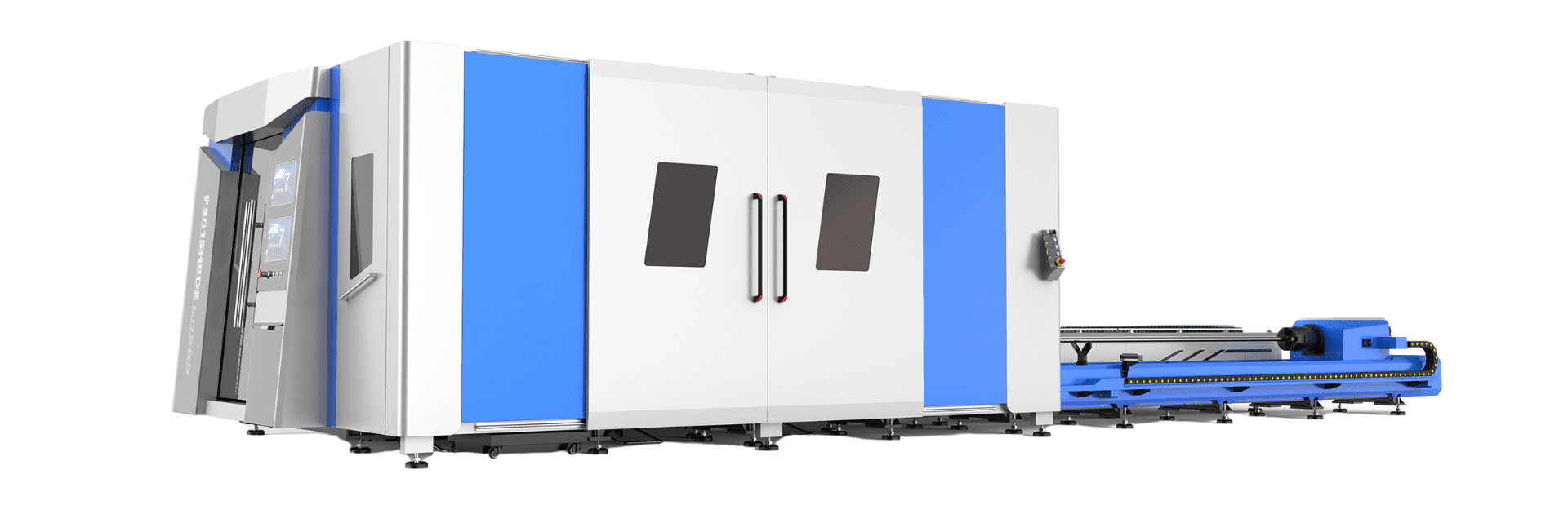

Unleash the Potential of Laser Cutting with Baison Laser!

Baison is a leading manufacturer and supplier of high-quality industrial laser-cutting equipment with over two decades of experience in the global market. Our exceptional CO2 and Fiber laser cutting machines implement state-of-the-art technology in a neat and compact package.

We offer FREE Application Evaluation and Customer Training to help you maximize your business’ potential.

Unleash your Potential with Baison. Contact us Now!