The Properties of Wood

In laser cutting wood, a careful understanding of wood properties is vital to achieving precise results. Moisture content is a critical factor; overly dry wood becomes brittle and susceptible to burning, while overly moist wood generates excess smoke and charring. Striking the right moisture balance is essential.

Density and hardness vary among wood species, affecting the power settings required for clean cuts. Grain orientation plays a role too, with cuts parallel to the grain typically demanding less power. Resin content should be considered, as some woods release natural resins during cutting. Thickness and size influence the process, with thicker or larger pieces requiring more time and adjustment. Lastly, the surface finish impacts the precision of laser cutting, with smoother surfaces resulting in cleaner cuts.

These properties guide the choice of wood and inform laser settings for optimal outcomes, ensuring that laser-cut wood projects are not only efficient but also yield high-quality results.

What Are the Advantages of Laser Cutting Wood?

Laser cutting wood offers a multitude of advantages that make it an ideal method for woodworking:

Precision

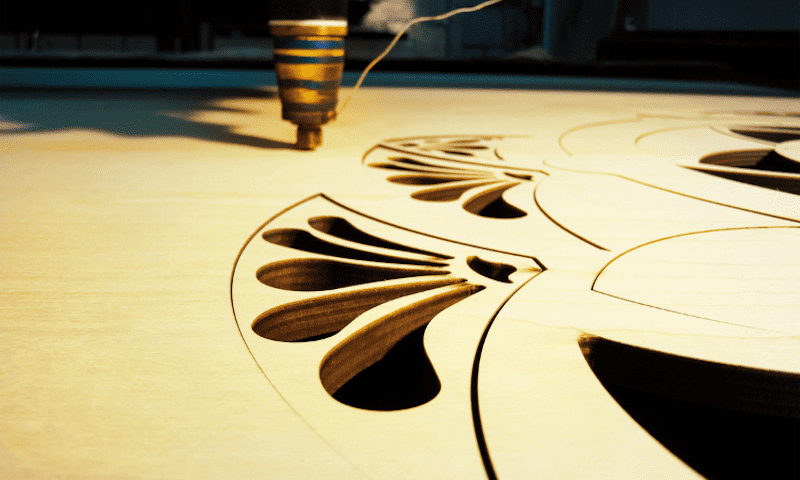

These machines have a great laser focus that delivers unparalleled precision, allowing for intricate designs and detailed cuts. Keep in mind that getting these cuts is not possible with traditional woodworking tools.

Efficiency and Versatility

Laser cutting is remarkably efficient, saving substantial time compared to manual woodworking processes. This makes it suitable for both small-scale business and large-scale projects. Also, laser cutting can be applied to a wide array of wood types and thicknesses, making it a versatile tool for diverse applications.

Clean Cuts

When executed correctly, laser cutting produces clean, smooth cuts with minimal splintering or tear-out, imparting a professional finish to projects.

Minimal Waste and Cost Efficiency

Laser cutting is renowned for its minimal material wastage, making it the most cost-effective solution for woodworking. The precise cutting patterns maximize wood utilization, significantly reducing both material costs and environmental impact. This sustainability-minded approach aligns with the growing need for eco-friendly woodworking practices.

Reduced Maintenance and Laser Performance

Laser cutting equipment requires minimal maintenance compared to traditional woodworking tools. There’s no need for the labor-intensive tasks of blade sharpening or complex setups. This streamlined maintenance directly contributes to the overall efficiency of the woodworking process.

Design Flexibility

Laser cutting provides exceptional design flexibility, allowing woodworkers to explore unique shapes, intricate patterns, and detailed engraving. This design versatility, coupled with lasers’ ability to work with a wide range of materials, opens up a world of creative possibilities. Woodworkers can experiment with diverse wood types, thicknesses, and artistic concepts, making laser-cut wood an ideal choice for intricate custom projects.

Do You Have Any Questions?

Let Us Solve Your Problem

The Different Types of Lasers Used for Cutting Wood

Understanding the various types of lasers used for cutting wood is essential for achieving precise and clean cuts while minimizing the risk of burning. Here are the types of lasers that cut materials.

CO2 Lasers

These lasers are the most common choice for wood-cutting applications. They operate by directing high-powered CO2 laser beams onto the wood surface. This technology excels at achieving intricate designs and delicate details on wood materials. The CO2 laser’s versatility makes it suitable for a wide range of wood types and thicknesses.

However, one important consideration when using CO2 lasers for wood cutting is the generation of heat. The intense heat produced during the cutting process can elevate the risk of burning if not meticulously controlled. Therefore, operators must pay close attention to the laser’s settings, including laser power and cutting speed. The correct laser settings, especially speed and power settings, can help to strike the right balance between precision and the prevention of burn marks.

Proper ventilation is another crucial aspect of working with CO2 laser cutters on wood. Adequate ventilation helps dissipate smoke and fumes generated during the cutting process, reducing the chances of combustion and ensuring a safer working environment. Additionally, material selection is critical when using a CO2 laser cutter on wood. Choosing woods with lower resin content can help mitigate the risk of igniting volatile compounds in the wood.

Fiber Lasers

Fiber lasers are gaining prominence in the field of wood cutting due to their efficiency and exceptional precision. Unlike CO2 lasers, fiber lasers utilize a fiber-optic cable to deliver the laser beam to the cutting surface. This method results in cleaner cuts with significantly less heat generation, making fiber lasers an optimal choice for preventing burning, especially when working with delicate or prone-to-burning woods.

Fiber lasers have a reputation for their accuracy, making them an excellent choice for intricate woodwork. Whether you’re crafting detailed patterns or working on projects that demand a high level of precision, fiber lasers are well-suited to the task. Furthermore, the reduced heat output means that fiber lasers are less likely to discolor the wood, preserving the material’s natural beauty.

The choice of laser wavelength is a crucial factor in laser cutting wood. Different wavelengths interact with wood in varying ways. Shorter wavelengths, such as those produced by fiber lasers, are more readily absorbed by wood, resulting in cleaner cuts with less burning. On the other hand, CO2 lasers with longer wavelengths are prone to generating more heat, which can increase the likelihood of burning.

You can learn more about the differences between CO2 laser and fiber laser technology in this article.

Do You Have Any Questions?

Let Us Solve Your Problem

Methods for Preventing Burning from Laser Cutter

Several mistakes can leave burn marks. By keeping the following things in mind, beginners can achieve the fewest burn marks on wood or even avoid burn marks completely if they practice. Achieving pristine laser cuts in wood on several key factors, including the laser’s performance and proper techniques. To ensure the best results, you need to practice the following methods:

Laser Beds and Smooth Coating

Utilize laser beds with smooth coatings to reduce air bubbles that can affect cutting precision. Smooth bed surfaces promote even material support and minimize discrepancies in laser focus, making a huge difference in the quality of your cuts.

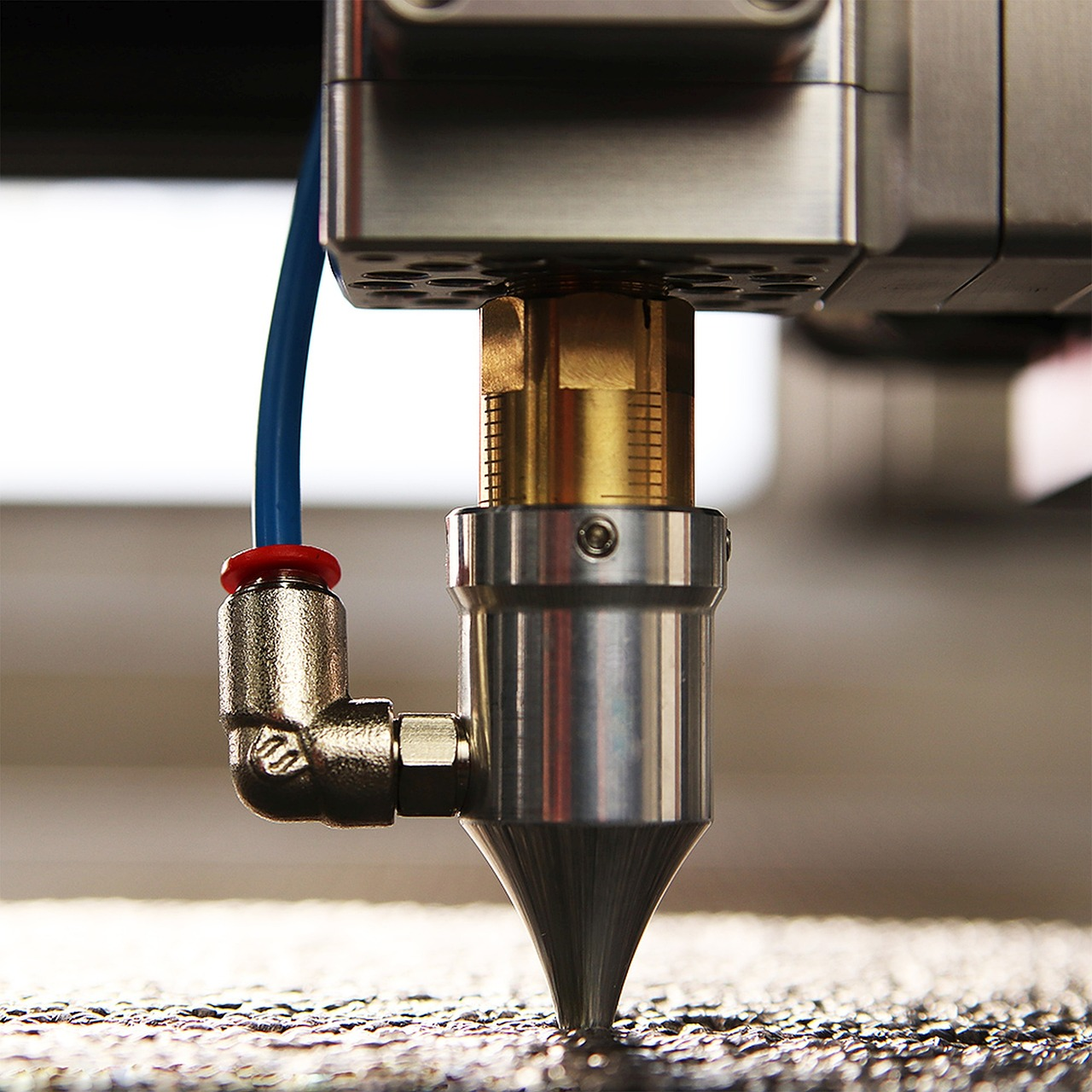

Proper Ventilation with Compressed Air

Maintaining proper ventilation, coupled with compressed air, effectively dissipates the smoke produced during laser cutting. This combination not only safeguards your health but also enhances the longevity of your equipment. Clean air circulation ensures that your laser’s performance remains consistent.

Masking Tape and Application Tape

Applying masking tape to wood surfaces acts as a protective barrier, shielding against burning and scorching. When selecting tape, opt for low-residue varieties to prevent adhesive residue on the wood. Additionally, consider using application tape to facilitate smoother and more precise application, especially when working with intricate designs or multiple pieces.

Leverage Air Assist

If available, use the air assist function in your laser cutting equipment. It directs a stream of air over the cutting area, cooling the wood and preventing burning. Air assist also aids in clearing away debris and smoke, further enhancing the quality of your cuts.

Test Cuts for Precision

Prior to your final project, perform power speed tests and check cuts on scrap wood. This essential step allows you to fine-tune settings and ensure a burn-free outcome. Experimenting with various parameters can make a significant difference in achieving the desired results.

Optimal Focus Adjustment

Precise focus adjustment is crucial for clean laser cuts in wood. It allows you to find the ideal focal length for your wood type and thickness, ensuring accurate cuts without burning or scorching. Experiment with focus settings on test pieces for optimal results.

Control Cutting Speed

Monitoring and adjusting the laser’s cutting speed is essential. The right speed prevents incomplete cuts and excessive heat buildup. Regularly fine-tune the cutting speed to match the wood’s characteristics, ensuring efficient and precise laser cutting.

Applications of Laser Cutting Wood

Now that you know how to prevent burn marks, let’s explore the diverse applications of this versatile technology:

Custom Signage

Laser-cut wood is ideal for crafting custom signs featuring intricate fonts and designs, suitable for both commercial and personal purposes.

Architectural Models

Architects and model makers employ laser-cut wood to create detailed scale models of buildings and landscapes, effectively showcasing design concepts.

Home Decor

Laser-cut wood transforms into stunning home decor items, including decorative panels, lampshades, and wall art. The precision of laser cutting machines offers limitless design possibilities.

Jewelry and Accessories

Crafters fashion unique jewelry pieces such as earrings, pendants, and bracelets from laser-cut wood, imparting a natural and artistic dimension to fashion accessories.

Furniture Design

Designers and woodworkers utilize laser cutting to introduce intricate patterns and details to furniture pieces, infusing a touch of elegance into their creations.

FAQs

1. How Can You Reduce The Risk of Fire During Your Laser Cut?

Reducing the risk of fire during laser cutting is paramount. The process of laser engraving commences by selecting materials with lower flammability and maintaining proper ventilation to disperse fumes. Regularly maintain your laser cutter and ensure the availability of fire safety equipment. Avoid leaving the machine unattended, and establish clear emergency protocols for a swift response.

2. How do You Get Rid of Laser Burns on Wood?

Eliminating laser burns from wood entails various methods. Sanding can effectively address superficial burns, while deeper marks may require the application of wood filler or wood bleach. As an alternative, concealing burning marks can be achieved by staining or painting the material surface to match its natural tone.

3. How do You Mask Wood for Laser Cutting?

To mask wood for laser cutting, carefully apply adhesive masking material, ensuring secure adhesion. After laser cutting, meticulously remove the masking material to reveal the pristine areas, effectively safeguarding the wood beneath.

4. Do Burn Marks from Laser go away?

Burn stains resulting from laser cutting typically persist. While techniques like sanding, wood filler, wood bleach, or staining can reduce their appearance, the extent of success depends on the severity of the burns and the wood type.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

Laser cutting wood presents a world of creative opportunities and precision in craftsmanship. To fully harness this potential, it’s essential to understand the properties of the wood you’re working with, as different woods react differently to laser cutting due to varying densities, grain patterns, and resin contents. Choosing the right type of laser machine, whether CO2 or fiber, based on your project’s requirements prevents wood burning.

Keep in mind, to prevent burning and damage during laser engraving, applying a layer of furniture polish to the wood surface acts as a protective barrier. This simple yet effective technique safeguards your project, and after engraving, any residual polish can be easily removed with a solution of plastic and mineral spirits. Or you can simply practice other burning prevention methods discussed above.

Mastering Burn-Free Laser Woodcutting!

Are you seeking to prevent wood burning during laser cutting? Connect us. At Baison Laser, we provide expert guidance to help you make informed decisions and choose the best products. We have an array of products that help you select products for your type of process for engraving wood. So, don’t wait and contact us today!