Understanding Fiber-Coupled Laser Diodes: The Ultimate Guide

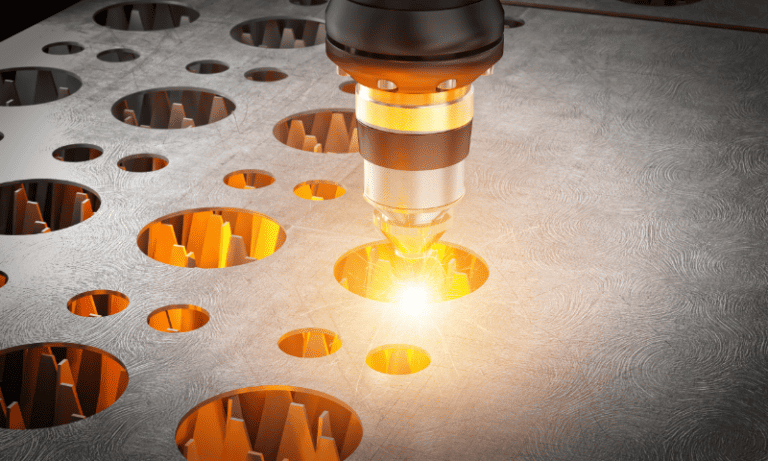

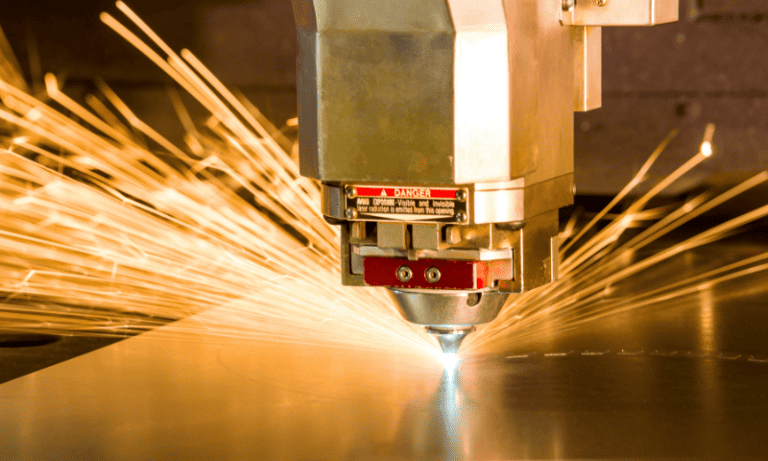

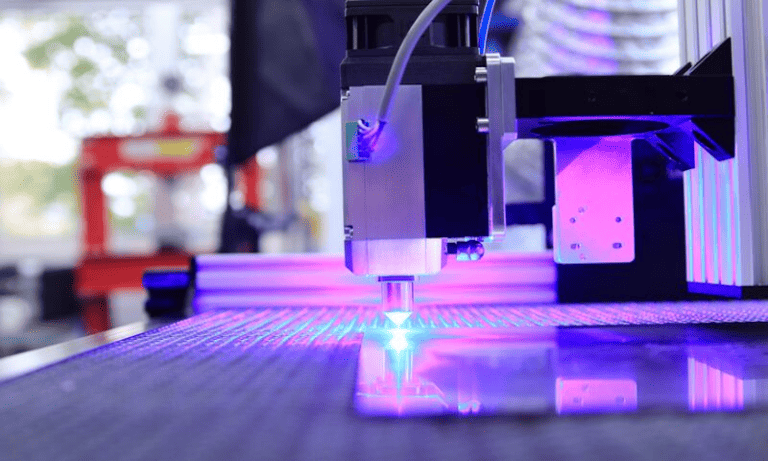

Fiber-coupled laser diodes are gaining popularity due to their versatility across industries. With this article, we will explore the principle types, applications, and the reasons that make them supremely useful. The knowledge will guide businesses to harness the power of laser diodes along with getting apt support from Baison Laser.