This article will teach about laser protective film and its role in laser cutting and welding. Ultimately, you will understand how these films keep you and your laser equipment safe. Sit back and read on!

What Are Laser Protective Films?

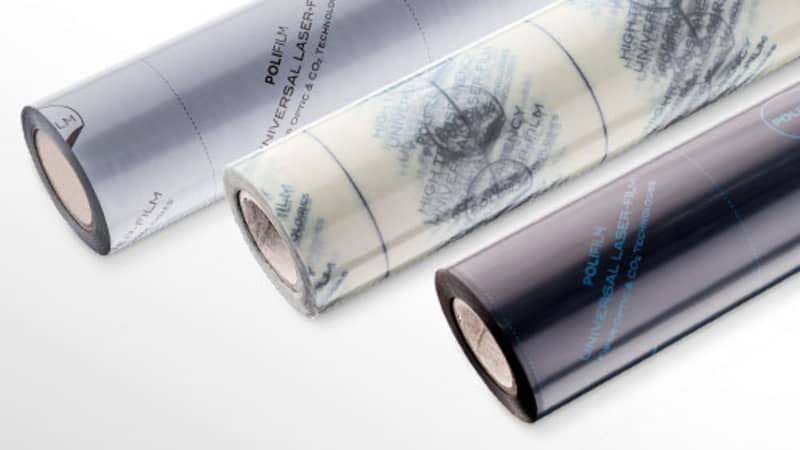

Laser protective film is a specialized protection film that provides safety against laser radiation. These films come in various sizes and styles and can be customized to meet different needs. You can also apply them to various equipment and surfaces, as they can block specific wavelengths of radiation.

Laser protective film is essential for someone who uses laser equipment for business or personal use. They help prevent damage to the skin and eyes as well as any damage to the equipment, especially when working high-power machines such as 40kW fiber laser cutters in your business.

This saves you from any costly equipment damages and potential health risks. On top of it, as these films work as a barrier against laser radiation, it reduces the risks of accidents and increases the overall life of the equipment.

How Laser Protective Films Work and What Makes Them Effective?

Laser protective film reflects or absorbs laser radiation, so they don’t harm you or the equipment. As a result, these films act as a barrier between you, your equipment, and the harmful radiation. But how are they so effective? This is how:

- Laser Parameters: defining the laser parameters ensures that you are using the right protective film for the laser you are working with. This is because laser films come in a variety of parameters to counter radiations of different wavelengths, power intensity, and exposure time.

- Material Composition: another factor behind the effectiveness of laser-protective film is the material composition. These films are made from materials that have high reflectivity or absorption coefficients. As a result, they have the ability to handle specific laser wavelengths and power.

- The angle of Incidence: laser protective film provides peak performance when the angle of incidence is perpendicular to the film’s surface.

- Film Thickness: the film thickness is a measure of its optical density. The higher the optical density, the more amount of light the film can reflect or absorb.

The Different Types of Laser Protective Films Available

You can find a wide variety of laser protective films on the market. However, we will only talk about the most prominent ones:

Coated Films

Coated laser protective film is designed for applications where it comes across high-intensity laser radiation. These include laser welding and laser cutting. They come in a variety of compositions and thicknesses to ensure adequate protection against harmful radiation.

Their go-to mechanism is to reflect laser light away from the film’s surface, ensuring that it does not pass through and cause any damage.

Tinted Films

These types of laser protective films have tints that help absorb high-intensity laser beams. They come with varying levels of tinting depending on the intensity and power of the laser you are working with. A good example of their use includes protection for protective lenses for laser cutting and welding machines.

Laminated Films

Laminated films are more costly than the other two types because they have multiple layers for multipurpose protection. For instance, a laminated protective film can have an outer layer of abrasion-resistant material for protection against scratches.

At the same time, it can have an inner layer that helps block varying laser wavelengths. Hence, laminated films come in handy for high-risk applications where equipment failure can lead to serious consequences. A good example would be the aerospace industry.

Benefits of Laser Protective Films

Laser protection films are a worthwhile investment for businesses mainly for their invaluable benefits such as:

Increased Safety

Workplace safety is a crucial factor for any manufacturing plant. Laser protective films help ensure they increase safety for the workers as well as the equipment. Blocking harmful radiation reduces the risk of skin burns, eye damage, and other injuries.

On top of it, laser protective films also prevent damage to any part of the equipment where the laser is not supposed to reach.

The Laser Institute of America conducted a case regarding the use of laser film eyewear. They concluded that these films significantly reduced eye injuries in the facilities where workers operated high-intensity laser machines.

Cost Savings

Businesses can save a ton using laser protection films for their equipment. Sensitive equipment such as windows and lenses need effective protection against laser radiation.

As a result, using these films reduces the need for costly replacements and repairs. Moreover, they also help reduce production downtime and equipment failure. This comes in handy when working alongside an automated laser-cutting system.

UK’s National Laser User’s Facility found in a study that laser protective films significantly reduce the need for repair, replacements, and maintenance.

Regulatory Compliance

Many authorities require the use of laser protective films around the use of laser equipment.

One of these authorities is the Occupational Safety and Health Administration, which demands that all workers must have protective laser film equipment for protection against radiation. Businesses that comply with this can avoid fines and penalties.

Applications of Laser Protective Films

The manufacturing, healthcare, and research industries are the most prominent users of laser protection films. Here are some examples of how these industries utilize them:

- In healthcare, laser protective films are used in various medical applications such as laser surgery, dermatology, and ophthalmology. These films help protect patients and medical staff from harmful laser radiation.

- Research: Laser protection films are commonly used in laser spectroscopy and imaging to protect researchers and equipment from high-intensity laser radiation. For instance, in laser-induced fluorescence (LIF) imaging, the films protect the camera from laser radiation.

- In the manufacturing industry, laser protection films are commonly used in the laser cutting process and welding processes. These films can protect workers from laser radiation and prevent damage to the equipment.

- Construction: Laser protective films are also used in construction applications such as laser cutting and marking on surfaces like steel, glass, and ceramics. These films can protect workers from laser radiation and reduce the risk of accidents and injuries.

What Should You Consider When Choosing Laser Protective Films?

Not sure what to consider getting the right laser protective film for your needs? Don’t worry. We have made it easy for you. Just keep the following in mind:

- Power Density: laser protection films come with varying specifications. As a result, they can withstand different power densities effectively. Ensure you get the correct specification for your fiber laser power density, which is the amount of power per unit area it emits.

- Optical Density: this factor determines the amount of light the film can block. The higher the optical density, the more radiation it can block. Ensure you get the right optical density for your working laser.

- Wavelength: laser machines can generate fiber laser machine radiations of different wavelengths. To ensure maximum protection against radiation, you must work with a protective film that is designed to withstand the specific wavelength in question.

- Exposure Time: The length of time a worker or equipment is exposed to laser radiation is also critical. The laser protective film should be able to withstand the exposure time without degrading or losing effectiveness.

- Certification: When choosing a fiber laser protective film, it’s important to ensure that it meets relevant safety standards. For this, it must have a certification that assures the film has been independently tested and verified to provide adequate protection for your production process.

Installation and Maintenance of Laser Protective Films

If you want to use laser protective films to their full potential, you must install and maintain them properly. Here are some general tips to keep in mind:

- Regular visual inspection to ensure there are no unordinary wear and tear. If there are, go for a timely replacement.

- Replacement schedule for the film to ensure you get maximum protection from the radiation.

- For installation, get a qualified person to do the job to align the film properly.

- Regularly clean the film. You can use a lint-free cloth and a mild solution or the manufacturer-recommended products.

Conclusion

In conclusion, laser protective films are essential to any workplace that utilizes laser equipment. They are highly effective at preventing damage to both equipment and personnel by protecting against harmful laser radiation.

Choosing the right film requires careful consideration of various factors, including wavelength, power density, and exposure time. By using laser protective films, businesses can ensure the safety of their workers, prevent equipment damage, and ultimately save money.

Baison Laser is an all-around laser machine manufacturer that works on the following principles: efficiency, quality, and safety. Your worker’s safety is as important to us as it is to you.

Source highly safe laser machines from us and stay in line with regulatory compliance to avoid injuries and equipment failure. Contact us today.