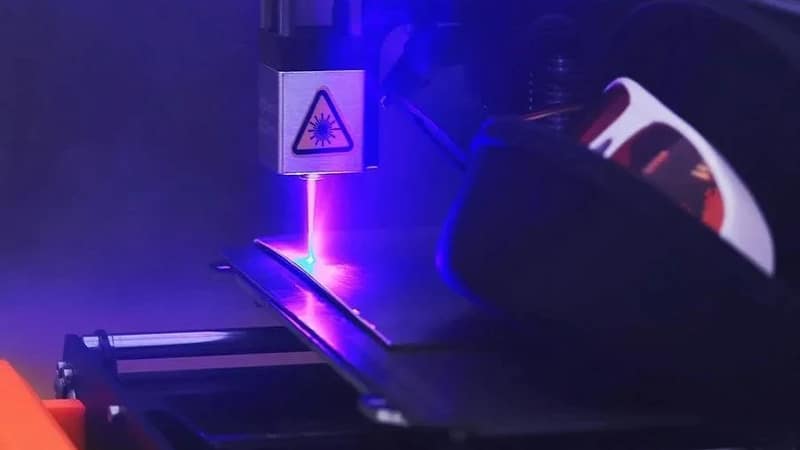

What Is a 40kW Fiber Laser Cutter?

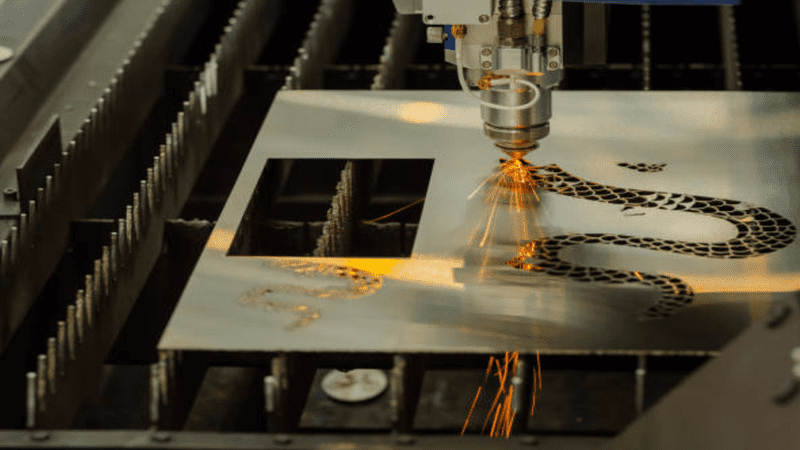

As the name suggests, a 40kW fiber laser cutter can generate a high-power laser beam with an output of 40,000 watts. With such an incredible force, it can cut through thick materials that other laser cutters fail to work on.

Moreover, it is a heavy-duty machine with precision metal cutting at its core, suitable for businesses that require fast yet precise outputs.

It uses a range of fiber optic cables that help with precision cutting by guiding the laser beam to the cutting head. As a result, the whole power output is focused on a small spot which it cuts through. Moreover, it can also cut through denser and thicker materials faster than other low-powered laser cutters.

How Does a 40kW Fiber Laser Cutter Work?

Here is how a 40kW fiber laser machine works:

Laser Generation

40kW fiber laser cutting machines generate a laser beam from a series of diodes that power the fiber optic cable atoms. This creates a highly powerful laser-cutting beam output.

Laser Beam Direction

The machine also has fiber lasers and a cutting head which is solely responsible for directing the laser beam to the target.

Here the target is a small spot that the machine recognizes using a lens for precision. This helps focus all the energy onto a single spot for absolutely fine cutting.

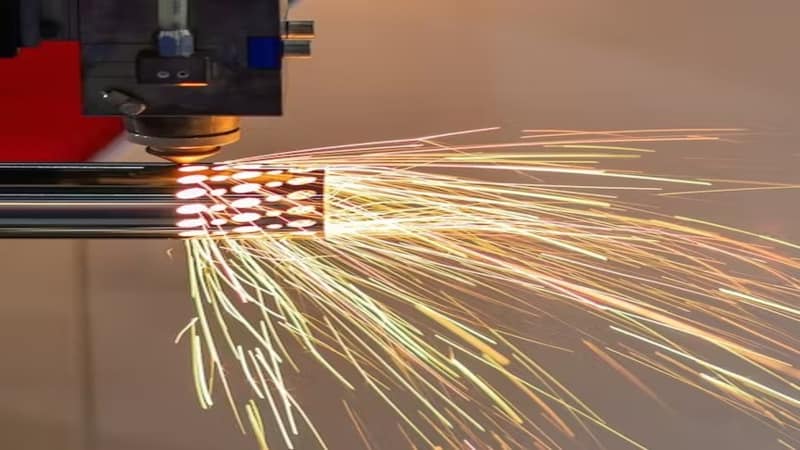

Material Absorption

Once the focused laser beam lands on the material, it gets absorbed into the material. This absorption helps evaporate or melt the material, cutting it into the desired shape.

Efficient Cutting

A 40kW fiber laser cutter is known for its high cutting speed and precision. All credit goes to the high power output that quickly melts the material by focusing all the energy on the target spot.

It saves time, all the while making sure there is no lack of cutting accuracy. Hence, it helps cut materials into complex shapes with ease and in less time.

In summary, a 40kW fiber laser machine generates a high-energy laser beam focusing on a small spot for precision metal cutting. The whole process is quick and efficient, which helps businesses achieve higher outputs in no time.

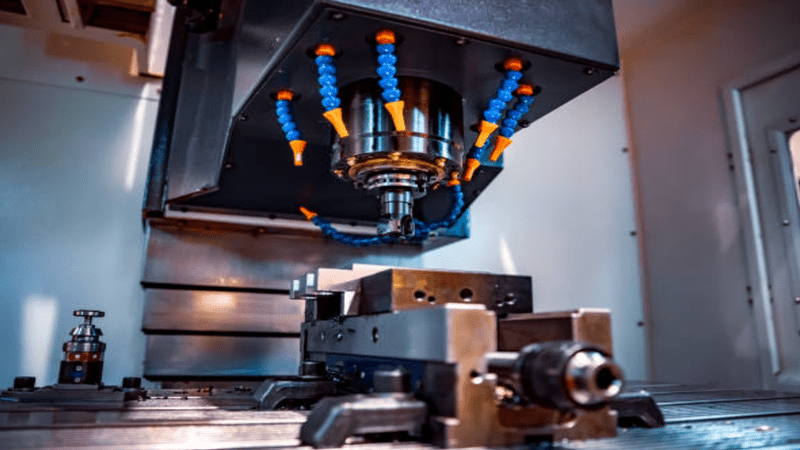

What Are the Key Components of a 40kW Fiber Laser Cutter?

A 40kW fiber laser cutter comes packed with various components for high-speed precision cutting. However, these can vary from brand to brand, but some fundamental parts are found in all 40kW laser cutters. These include:

- Laser Source: the source helps generate the fiber laser beam that does the cutting. The source works alongside the fiber optic cables which together generate a high-energy beam.

- Cutting Head: as the fiber laser sources generate a high-energy beam, it needs direction to do the metal cutting. That is where the cutting head comes in with its lens. It uses the lens to focus the laser beam on the right spot on the cutting material. It can move the laser beam in several directions for complex cuttings.

- Beam Delivery System: while the laser source generates the beam, and the cutting head directs it, the beam delivery system ensures that the beam is adequately transmitted through the laser source to the cutting head. It does so with the help of a bundle of fiber optic cables.

- Control System: just like any other computer has a CPU as its brain, laser cutting machines have a control system that works as its brain. It has software that helps translate the inputs given to the machine into instructions. It then helps the machine follow the cutting instructions as commanded.

- Cooling System: it only makes sense to have a cooling system in a 40kW fiber laser cutter because of the high amounts of energy it generates. The cooling system helps ensure that the machine operates at an optimal temperature at all times, even if you are doing long cutting sessions.

- Workpiece Support: this is where all the cutting takes place. It is a platform where the cutting material is placed sturdily so that it does not move while the high-powered laser beam moves across.

What Are the Differences Between a 40kW Fiber Laser Cutter and Other Laser Cutters?

A 40kW fiber laser cutting machine has several differences when compared to other laser cutters. The prominent ones include:

- Versatility: a 40kW fiber laser machine allows businesses to cut through various materials. This includes heavy-duty metals as well as plastics and other composite materials.

- Maintenance: typically, a laser cutting machine requires high maintenance. However, that is not the case with a 40kW fiber laser machine, as they are known for being low-maintenance machines due to their simple designs. You can also invest in a fiber laser cleaning machine.

- Speed and Power: a 40kW fiber laser cutting machine has significantly higher speeds and power outputs compared to other laser cutters. Hence, it is more efficient for businesses to work with.

- Operating Costs: due to the high efficiency of a 40kW fiber laser machine, it requires less cost for operation.

What Are the Benefits of Using a 40kW Fiber Laser Cutter?

A 40kW fiber laser cutting machine standouts in a variety of ways:

Cutting Accuracy

It offers excellent metal cutting accuracy thanks to the powerful laser beam and precise metal cutting system. This reduces the need for secondary operations, as the first cuts are always clean.

Cuts Through Dense Materials

A 40kW fiber laser produces such high amounts of energy that it can cut through a wide range of dense and thick materials.

Speed and Versatility

A 40kW fiber laser machine not only offers high cutting speeds. It also offers versatility alongside it. This means it can cut a wide range of materials with the same speed, saving time for business and creating higher outputs.

What Is the Thickness Range of the 40kW Fibre Laser Cutter Cutting Material?

Even though a 40kW fiber laser cutting machine can cut through a wide range of thick and dense materials, the exact thickness range depends on the material in question. Let’s look at some of these materials and their thickness ranges:

- Copper: it can cut through copper materials as thick as 12mm

- Mild Steel: it can cut through mild steel, which is as thick as 40mm

- Aluminum: it can cut through aluminum as thick as 25mm

- Brass: it can cut through brass that is up to 12mm thick

- Stainless Steel: it can cut through 25mm thick stainless steel.

These are just general estimations. The real thickness range can vary from machine to machine and brand to brand.

What Should You Consider When Choosing a 40kW Fiber Laser Cutter?

40kW fiber laser cutters don’t come at a low cost. As a result, it is a big business decision when purchasing one. Hence, it would help if you considered the following factors before finalizing the purchase:

- Manufacturers Reputation: this does not mean that the manufacturer is a big name in the industry. What’s more important is that the manufacturer offers support and service post-purchase. This helps because 40kW laser equipment is a highly technical machine, and you will need manufacturer support at one point or another.

- Machine Size and Capability: This is important because you don’t want to get a machine so big that it does not fit your production facility. On top of it, check for the cutting capabilities so that you get the right laser-cutting machine for the materials you need to cut.

- Efficiency: this includes both price and working capacity. You must cross-check the prices from different brands and compare the features. Prices can vary significantly from manufacturer to manufacturer. However, it is a big investment, so don’t waste your money by trying to get a cheaper, low-quality model.

- Safety Features: laser cutters with 40,000 outputs need good safety features to work around, so make sure the machine you get has them.

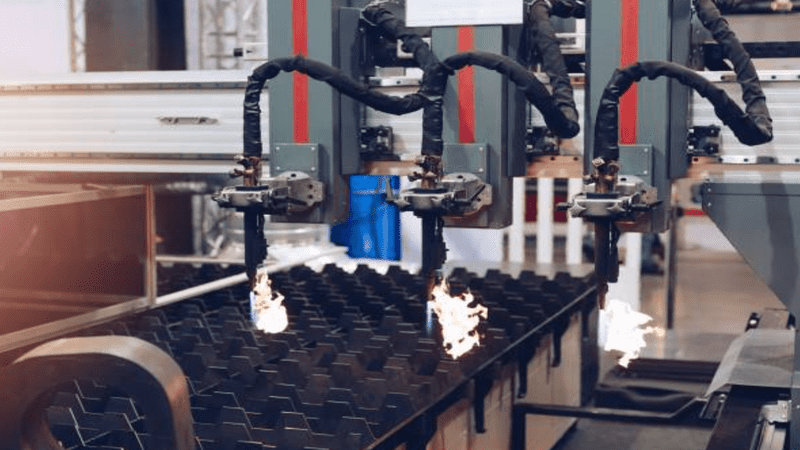

The Application of Using a 40kW Fiber Laser Cutter

You will find the use of 40kW fiber laser cutters in a wide range of heavy-duty industries. The most common ones include:

- Power and Energy Generation Industry

- Automotive and Aerospace Industry

- Industrial Equipment Manufacturing Industry

- Marine Industry

These industries require a potent laser beam from a 40kW fiber laser cutting machine. Hence, they readily use services from this machine to speed up business and deliver them with precise cutting with no room for error.

Some good examples of businesses that have used 40kW fiber laser machines include:

Rolls-Royce

The luxury car maker that also manufactures jet engines uses 40kW fiber laser cutters in their manufacturing process. It helps them do complex cutting precisely and quickly.

Caterpillar

This mining industry giant uses a 40kW fiber laser cutting machine to cut through thick materials for higher product quality and accuracy.

Trumpf

This is another german company that manufactures heavy-duty machine tools. They use 40kW fiber laser cutters to cut and design these tools for various industries worldwide.

Conclusion

To conclude, a 40kW fiber laser cutting machine has made its mark in the industry with its efficiency and high power. Its ability to cut through various thick and dense materials makes it a suitable choice for business worldwide. On top of it, it helps save time by being extremely accurate and fast. This machine is for you if you are a business lacking in orders because of slow and imprecise cutting.

At Baison, we offer technologically advanced fiber laser-cutting machines at affordable prices. Our engineers have ensured that the machines are highly safe for use and serve the purpose of businesses looking for speedy solutions to complex fiber laser cutting machines. Request an instant quote.