Laser marking or engraving is an important production process that is often ignored. Different products need different types of labeling. Product information, QR codes, product content, warning, logos, and other information about the product need to be marked or engraved.

In this article, we will discuss laser marking. We will see how laser marking or laser engraving is a superior way of marking products and how it can help manufacturers to track and identify products throughout their life cycle. Before we get into the detail, let’s take a deeper look at what laser marking is.

What is Laser Marking, and How Does it Work?

Laser marking is the process of etching, engraving, or marking of logos, product information, codes, serial numbers, or model numbers on a product. Compared to any other way of marking, laser markers are effective, time-saving, efficient, and produce permanent markings on different materials.

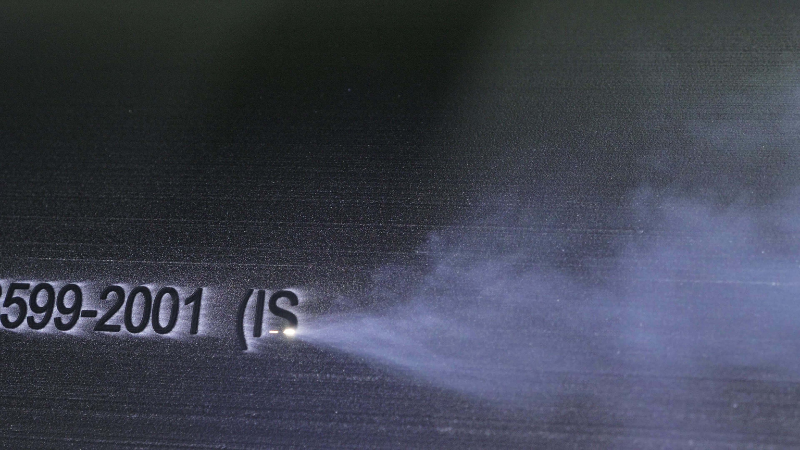

Laser marking uses laser energy to create a laser beam that scratches, melts, discolors, peels, oxidizes, or cuts surfaces. Laser marking is useful in more than one way. Not only is it the better way of labeling or marking the product, but it also ensures unique and permanent marks are made on the product that can lead to better production quality.

Laser marking uses a laser beam to mark or engrave materials such as metal, plastic, glass, and ceramics. The laser beam creates a permanent mark on the material’s surface by either removing or changing the material’s properties.

The process works by directing a high-powered laser beam at the material, which creates a localized heat source that vaporizes or oxidizes the surface layer of the material. The laser beam can be precisely controlled and directed to create fine and detailed marks, including text, logos, barcodes, and serial numbers.

Laser Marking for Automatic Manufacturing

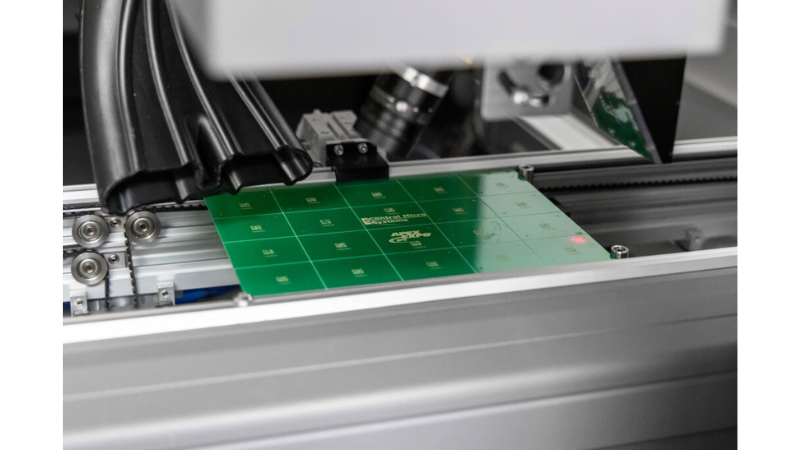

Laser marking has been useful for quality control as it can mark permanent product identification numbers on material surfaces. These laser markers are an essential part of automated processes.

They can be added to the manufacturing process, adding product data and unique identification of the product and its parts. The process helps assemble the end product and gives unique identification and serial numbers to the parts. It can increase product quality and efficiency.

Laser Marking for Data Tracking

Data tracking is an essential part of the manufacturing process. It allows manufacturers to control production quality by tracking raw materials and finished products. It enables the manufacturers to trace the products in the supply chain. It’s particularly essential for pharmaceutical and food products.

Data tracking and data marking are closely related in the manufacturing process. By using data tracking software, manufacturers can monitor various aspects of the production process. Manufacturers can identify issues and where in the supply chain the products are. They can use that information to optimize the production process.

Laser Marking vs. Other Marking Methods

There are some other methods of marking other than laser machines. Some of these are:

Laser Marking vs. Dot Peen Marking

Dot peen marking is the process of marking the surface of the material with small dots. The process involves using a computer-controlled stylus, or pin, to create a series of closely spaced, indented dots on the material’s surface. These dots can be used to create text, barcodes, logos, and other designs.

Dot peen marking is efficient, but if we compare it with laser marking, it cannot match its efficacy, durability, and precision. It cannot produce sharp lines, clear graphics, and high-quality laser marking. The marking is shallower and less precise.

Electrochemical Etching vs. Laser Marking

Also known as electrolytic etching or electro-etching. It uses an electric current and an electrolyte solution to dissolve the material and create permanent markings on the surface. It uses a stencil or mask to protect the surface of the material while an electric current is applied to create a chemical reaction that etches the surface.

Electrochemical etching is often used to mark conductive materials such as metal. It’s also an inexpensive marking method as it does not involve buying heavy machines.

Electrochemical is a useful method of marking, but if we compare the quality with laser marking, it needs more finesse, the complexity of design, and the quality of laser marking. Laser machines are also fast compared to them; electrochemical etching takes a long time.

Inkjet Marking vs. Laser Marking

It’s like printing, where information is sprayed on base material with an inkjet printer. Inkjet marking is suitable for marking on various materials, including paper, cardboard, plastics, and metals. It is more commonly used in packaging industries to label products.

Inkjet marking can produce high-quality images, but more is needed to permanently label products like laser marking. Its color changes with exposure to light and water. It’s a cost-effective way to label things on a lower production level.

However, It is ineffective and cannot be used aerospace and automotive industries to label product numbers and other information clearly and permanently.

Chemical Etching vs. Laser Marking

This method involves applying a chemical solution to the material’s surface, which removes the top layer of the material to create the desired marking. Chemical etching is often used for marking metal and glass.

Chemical etching effectively engraves high-quality images on the surface, but it is a slow process compared to laser marking. It also involves the use of chemicals that can be hazardous to handle.

Knowing the differences between laser marking and other methods, you can learn how to choose fiber laser marking machines.

9 Ways Laser Marking Can Improve Production Quality

Here is how laser marking can improve production quality.

1. Permanent Identification Numbers

Automobile, aerospace, and other high-end industries require producing parts that need identification, batch numbers, model numbers, and serial numbers. These numbers are important for as long as the life of the final product.

If you need to change the parts or re-assemble, identification or serial number is essential. Only laser marking machines can produce high-quality, precise, and clear marking that is permanent.

2. Fully Automated System

Laser machines require less manual intervention compared to other marking systems. They are the need of the hour for the high production industries and can label products fully automatedly. The marking results are accurate even with less labor cost. That increases productivity, saves time, and positively affects product quality.

3. Tailor Made Laser Systems

Laser systems are fully automated. They allow the manufacturers to change the design or content of labeling very quickly as a computer software file directs the laser beam. The change of design, images, or data is easy.

4. Improve Traceability

Laser marking can create unique identification codes, serial numbers, and barcodes on products. This makes tracking and tracing products throughout the supply chain easier, helping to prevent counterfeiting, reduce warranty claims, and ensure product authenticity.

5. High Precision Production Data

As we have compared it with other methods of marking or labeling, laser marking is a high-precision method. It can create very detailed marks on various materials. It can mark both minute signs and difficult images with precision.

The high-resolution images and accuracy of designs make it suitable for applications where you need precise, clear, and permanent markings.

6. Non-Contact and Versatility

Laser marking is a non-contact method of creating labels. It means that no machine or part of the machine is required to make physical contact with the material being marked. This makes it ideal for marking delicate or fragile materials that other marking methods may damage.

Laser marking can be used to mark various materials, including metals, plastics, ceramics, glass, and paper. It can also create different types of markings, such as barcodes, logos, text, and images, making it a versatile marking method.

7. Permanent Marking

Laser marking does not fade or wear off with time. It is the best choice for lifetime labeling. Laser markings are highly durable and resistant to wear, corrosion, and fading. They can withstand exposure to light, water, or extreme weather conditions.

8. Speed and Efficiency

Another big advantage of laser marking is that it beats any other way of marking or labeling in speed and efficiency. It’s a fast method that is suitable for the automated manufacturing process. It can also be automated, further improving its speed and efficiency.

9. Reduced Waste and Product Costs

As it’s a no-contact labeling method, it does not produce any waste. The Method also saves labor costs and can mark many products where other marking methods take a lot of time. The laser marking machines can be expensive but reduce production code and labor costs.

Conclusion

In conclusion, laser marking machines are far better than other labeling methods. They are efficient, time-saving, and accurate, which suits high-end industries. Laser marking also ensures the durability and permanence of marks on various materials, making it a popular choice for high-quality marking and labeling of products.

And versatility allows for creating of complex and intricate designs that would be difficult or impossible to achieve with other marking methods. They also offer a faster marking speed, reducing production time and increasing productivity.

Invest in Baison Laser Marking Machines to Revolutionize your Marking Process

If you are looking for a reliable and efficient way to mark your products with precision and accuracy, Baison‘s laser marking machines are the solution. Our state-of-the-art technology can mark various materials, including metal, plastic, and more.

We offer a free application evaluation to help you choose the laser machine that suits your needs. Contact us today to learn more about Baison’s laser marking machines.