The shipbuilding industry needs laser-cutting machines for their high speed and precision. Learn more about how laser-cutting is revolutionizing the shipbuilding industry.

Shipbuilding is the heart of international trade and economy. It’s also the heart of the defense line for any country. It’s a huge industry with a growing need for technological precision and innovation.

Laser cutting machines and welding machines quickly replace any welding or cutting machines and are becoming monumental in enhancing production quality while controlling the price. Such an important industry as shipbuilding requires cutting precision and the speed that only laser machines can provide.

This article will discuss how laser cutting and welding machines are becoming essential for the shipbuilding industry. Let’s take a look at laser technology first.

What Is Laser Technology?

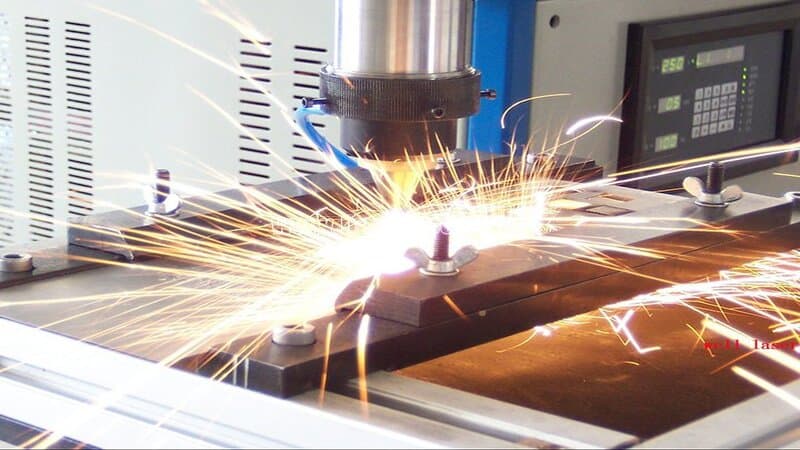

Laser cutting technology is monumental in shipbuilding, and many industries require precise welding and cutting mediums. A laser machine is equipped with high-power energy to generate a laser beam.

The laser beam is narrow enough to cut or weld the area only where it is directed, but it is more powerful than any other cutting method. When directed at the workpiece, it heats the material within a fraction of the time, vaporizing it. It’s the most efficient, high-quality, safe technology for industrial use.

Shipbuilding requires lots of parts and components to be built and joined together. It requires exact alignment and high accuracy that only laser-cutting machines can provide.

The laser equipment works with a narrow beam, works on even thick materials, and cuts them with the ease and precision the shipbuilding industry needs. It’s a thermal cutting technique that uses a narrow beam to follow the design. The laser beam is amplified through lenses that heat and vaporize the material.

These machines are highly effective for cutting thick metal plates and tubes and are equally precise in cutting thin and delicate materials. The laser cutting machines provide a control system to set the parameters.

Benefits of Using Laser Cutting in the Shipbuilding Industry

Let’s look at some of the benefits of laser processing:

1. Precise Cutting

The high-power lasers come with a highly focused and narrow beam. They are controlled by a software program that moves the beam on the workpiece according to set parameters. The room for error is almost zero. These machines can work on even complex designs or thicknesses of material with precision.

Shipbuilding requires lots of sheets, tubes, pipes, and smaller components to be assembled in the final design. This calls for high precision in the cutting process only laser-cutting machines can provide.

2. Versatility

Such a complex industry as shipbuilding involves more than just handling one or two types of metals. Some numerous parts and pieces are to be separately built. These materials can be steel, carbon steel, aluminum, composites, alloys, spring steel, and other challenging metals and alloys with different properties and may require different cutting parameters.

A laser cutting machine gives you enough power to handle tough materials and the flexibility to adjust the cutting parameters to suit all types of material. It works well for glass, PVC, rubber, and wood materials.

3. Productivity

Shipbuilding is a highly growing industry. It’s a million-dollar industry that is steadily picking up as the demand grows. Increasing seaborne trade, growing population, and the fast delivery trend have given customers new purchasing power.

This has drastically increased the need for high demand in the shipbuilding industry. Laser-cutting machines work way faster than traditional machines. They offer speed and power that can almost double the production rate or even more.

You may want to learn the difference between laser cutting and traditional methods, read this blog post.

4. Complex Shapes and Designs

Shipbuilding requires dealing with complex shapes and designs. Modern structures require intricate designs to meet the advanced design. Innovation requires more complex designs, optimized structures, and improved hydrodynamics that only laser-cutting machines can provide.

5. Safe

Laser-cutting machines are built on modern designs and principles. International regulations and environmental policies must be considered in any industry, including shipbuilding. Laser-cutting machines are perfectly safe not only for manual workers operating the machine but also for the environment.

6. Low Production Cost and Waste Reduction

Industries are growing, and there is a growing demand to keep prices in check. That is only possible with laser-cutting machines. They can work fast and increase the production rate. Also, they are precise in cutting and welding, which reduces material waste.

The precision and accuracy of designs require no need for rework. The maximum material loss and manual labor reduction are all factors that contribute towards keeping the production cost in check.

7. Streamline Production System

Laser machines can be fully automatic. They can be integrated seamlessly with another production line. They have a digital system and computer-aided software that allows you to not only keep track of the different shipbuilding processes but also make it possible to integrate the existing system with emerging technologies.

Do you want to learn more about the advantages and disadvantages of laser cutting? Click the button below!

Application of Laser Cutting Technology in the Shipbuilding Industry

Laser-cutting technology has ensured precision and speed in the shipbuilding industry. Here are several applications of laser cutting in the shipbuilding industry:

1. Plate Cutting

The shipbuilding industry is almost based on cutting raw materials. Sheet cutting is essential for building the basic structure of ships like hulls, decks, and bulkheads. And other structural components.

And its different parts. It includes cutting complex shapes and designs of different metals. It may include cutting stainless steel, aluminum, different alloys, and ship construction materials.

2. Tube and Pipe Cutting

Sheets may have limited density, but tube and pipe cutting. It may include laser cutting plates, drilling holes or other complex shapes into thick pipes and cutting, drilling holes, making ventilation systems, or other pipe-related activities. Laser-cutting machines cut thick and tough metal pipes and tubes with precision.

3. Panel Cutting and Slotting

Cutting panels and slithering is another important application in shipbuilding. It includes cutting doors, windows, openings, hatches, and other entrance points into a ship. It requires working on exact measurements so that everything assemblies nicely.

4. Structural Components

Besides the basic structure of a ship that requires cutting metal sheets and numerous components, they are vital for the overall ship design. It can include brackets, panels, support systems, or other components made with different materials.

Each component and material may require different cutting parameters and special design measurements to be followed precisely for the overall ship structure.

5. Interior Components

Besides some structural components, numerous small and big interior components require cutting and fabrication. It may involve heating or cooling systems, exhausts, ducting, and other components.

6. Repair and Maintenance

The basic structure, maintenance, and repair of existing parts and components require laser-cutting machines. It includes repairing existing parts, retrofitting, improving designs to some existing ones, or replacing some parts with new and better ones.

What Is Laser Welding Technology?

Besides cutting, another important sector in metal fabrication is laser welding technology. Welding is essential to industries like shipbuilding, where many metal pieces must be combined for the basic ship structure.

Welding means joining two or more metal pieces together. Traditional welding, like arc welding, requires excessive physical effort, pressure, and proper technique. Laser welding machines are modern machines that do not require any pressure or physical effort while welding.

These are precise machines that work effortlessly even if the operator is not skilled enough, as they require very minimum physical effort. Laser hybrid welding machines give high-quality welding, especially for types of welding like T-joints pipe joining or butt and fillet welds, or complex joint configurations that are easy to perform by laser welding machines.

Why Is Laser Beam Welding Important in Shipbuilding?

Laser welding has numerous benefits. These high-quality machines are fast and can cope with the rapid production volume of the shipbuilding industry. Besides these, they are efficient and require less manual handling as in other traditional welding techniques.

Laser welding processes work with high-quality beams. Just like laser cutting, the contact zone of the laser beam and material is on-spot and very narrow. The concentrated energy of the laser only affects the part where it is directed without distortion or material loss.

These powerful welding machines are equipped with high-power energy that can melt even the hardest of materials in a fraction of the time.

Benefits of Using Laser Welding Technology in the Shipbuilding Industry

Here are a few benefits of laser welding technology in the shipbuilding industry:

1. High Precision and Accuracy

Laser welding machines give full control for welding different metals and materials and provide high-precision manufacturing. The focused beam is controlled by a computer software program that already has the design. It does not require any manual handling.

The narrow beam moves on the path and can follow complex designs and patterns. It gives an accuracy that is difficult to achieve with other welding methods.

2. High Welding Speed

A great advantage of laser welding machines is the high welding speeds of these machines with accuracy. Shipbuilding is a fast-growing industry, and the required production volume has also increased due to the pandemic years.

Laser welding machines can work day and night and are way faster than other manual machines. They can also be automated to improve their speed further and help the manufacturers keep up the production volume.

3. Welding of Dissimilar Material

As we have already discussed, the shipbuilding industry requires processing different material types. They require joining dissimilar materials together as well.

Joining dissimilar materials is tricky and challenging, especially when you want to maintain the weld quality. Laser welding machines are capable of welding. Laser welded joints are strong, requiring not much edge preparation.

How Is Laser Welding Used in Shipbuilding?

The welding process refers to joining two or more metal pieces together. Laser welding machines are highly useful in the shipbuilding industry. Shipbuilding requires welding several metal sheets and pipes. It is essential not only for a ship’s structural design, but also for several components, for the exhaust system, ventilation, and several other systems.

Laser machines are not only user-friendly and fast, but their weld quality is also superior to any other welding technique. They are also safe as they require less manual power. It works well not only for the most challenging material in a fraction of the time, but it is also perfect for perfectly joining very thin and challenging materials.

Shipbuilding requires joining dissimilar materials, pipes and tubes, metal sheets, and other components. They can work nonstop with accuracy and precision and can follow the most complex designs and shapes with precision and accuracy.

Not only do laser welding machines play a monumental role in the construction of ship structures, their designs, compartments, and several small and big components, but they can also be used for regular maintenance and repairs. They allow precise localized repairs and can be used to repair cracks, joints, and other damaged areas.

The shipbuilding industry cannot afford welding imperfections. They must employ strict quality control and advanced welding techniques to minimize imperfections.

Common Welding Imperfections in Shipbuilding

Laser welding machines can weld different types of material with precision. Here are some challenges that welders may feel in the shipbuilding industry:

1. Lack of Fusion

A major problem welders face is the lack of fusion. It happens when the workpiece does not fuse adequately with the base material. Almost the whole ship structure depends on strong welding. A laser cutting machine can fuse even dissimilar materials with perfection.

2. Porosity

It is another imperfection that the shipbuilding industry faces. It happens when gas pockets or voids form while welding two materials. Porosity may cause cracks and weak joints.

3. Welding Cracks

It happens when the heat affects the surrounding materials. The laser beam is highly focused and heats only the area where it is directed. It does not affect the surrounding material. The laser beams can melt and join the most challenging materials like steel springs, carbon steel, or aluminum.

4. Undercut

An undercut or groove is formed at the edge of the weld joints. Undercuts can reduce welding strength. We have also prepared an article for you evaluating welded joints.

5. Distortion

Distortion also happens while welding sensitive materials. Excessive heat can melt or distort the surrounding materials. Distortion can affect the dimensional accuracy, weakening the structure or ship.

Trends and Suggestions of Laser Cutting in the Shipbuilding Industry

Laser machines are the ultimate solution for cutting or welding in the shipbuilding industry. They provide manufacturers with the speed and accuracy to join and cut tough metal pieces.

The computer software system guides the laser beam and controls its movements to follow complex designs and patterns. Here are a few suggestions for optimizing the laser machines.”

1 – Monitoring and Quality Control

Shipbuilding requires high-precision technology to meet the latest trends in the industry. Proper monitoring and quality control are crucial to ensure the quality and consistency of laser machines. Do you want to know how laser welding monitoring works?

2 – Qualified Staff

Though laser machines are highly accurate and can be fully automated, manufacturers still need highly qualified staff to adjust parameters, understand the properties of raw materials, and use the laser machines safely to their maximum capacity.

With the correct parameters like speed, power, beam quality, and spot size, operators can ensure no anomalies, imperfections, or distortions in the raw material or finished products.

3 – Collaboration and Knowledge Sharing

Collaboration within the industry can be helpful both ways. Industry can benefit from shared experiences, learning, and best practices. This shared effort can lead to better innovations in the shipbuilding industry.

4 – Investing in Advanced Laser Systems

Investing in advanced laser systems is the only solution to increase production volume, keep costs in check, and ensure high quality. As the industry requires cutting, welding, and fabricating many metals, fiber laser cutting and welding machines are the solution.

These machines are equipped with high power and offer the speed and precision that the industry needs. Investing in the right system can help manufacturers ensure quality and increase productivity.

Conclusion

In summary, laser cutting and welding technologies have significantly propelled shipbuilding forward, offering unprecedented precision and efficiency. This leap in innovation not only streamlines production but also opens the door to new design frontiers, ultimately benefiting both the economy and the environment. As the industry continues to evolve with these technologies, the future of shipbuilding looks both robust and sustainable.

Go Into Shipbuilding with Baison!

Shipbuilding is a highly demanding industry with growing precision, speed, and accuracy needs. Laser machines are built on the latest technology and harness laser power to cut or weld the material.

Baison offers state-of-the-art laser cutting and laser welding machines. We offer laser systems that are user-friendly and modern ready to cope with the growing production demands in the industry. We provide a range of laser machines that suit small, medium, and large industries’ production needs.

Contact us to get more information!