Lasering reflective metal materials can be a challenge. In this blog post, we’ll go over the basics of working with reflective metals and how to get the best results when lasering them. By following these tips, you’ll be able to produce clean and precise laser cuts on reflective metal materials every time.

What Makes a Metal Highly Reflective?

Before examining how a laser beam cuts reflective metal materials, we must read what makes a metal highly reflective. Both silver and aluminum are considered some of the most highly reflective materials. They are mainly used in windows, jewelry, sunglasses, and mirrors.

Reflective metals which are hard to cut using lasers include bronze, gold, bronze, and copper. Although not generally considered reflective metal, stainless, mild steel exhibits reflective properties when completed with a mirror polish. This behavior by stainless steel can be troublesome, and typically, the supplied plastic coated on the cut side is used to minimize the risk when cutting stainless steel.

Problems With Laser Cutting Reflective Metals

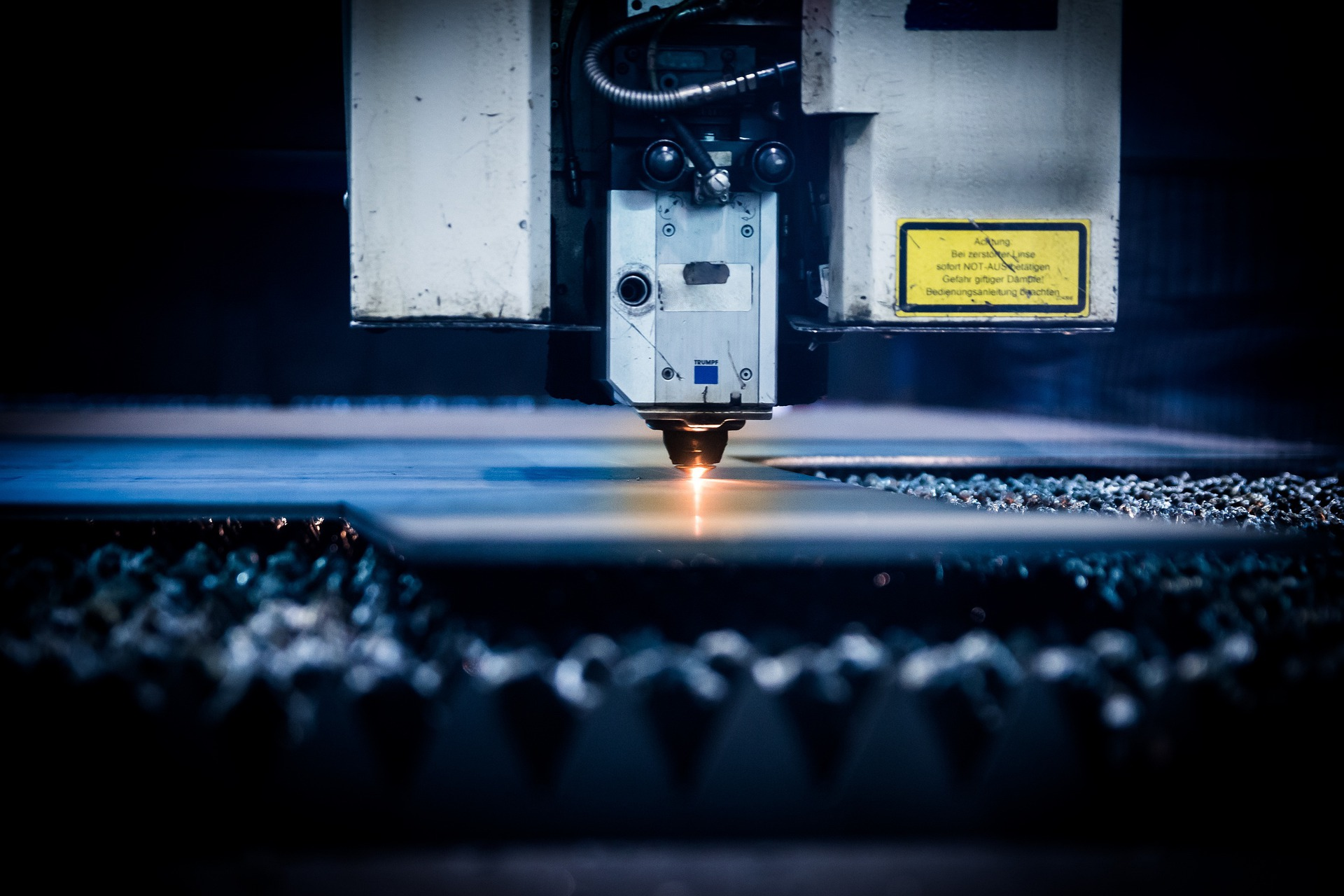

A laser beam quickly melts the surface to initiate an efficient cutting process when opting for optimized optics, laser lens, and cutting procedures. Using non-optimal process parameters or the wrong optical setup choice can affect laser dwelling with solid metal. Excessive reflection leads to inefficiency of potential damage and cutting reflective metals process to optics.

The crucial stage in metal cutting is the initial stage of the process. When the cut is established, the laser beam engages with molten metal. All the stages, especially the piercing stage, are the most important as laser processing engages with solid metal.

Why is Reflective Metals Laser Cutting so Difficult?

Both copper and brass have low infrared laser absorption, which makes metals hard to cut. Such metals are well-known reflectors of infrared laser light, specifically when the metals are in a solid state.

The infrared laser light makes cutting reflective materials and the optimized laser cutting process challenging. It is also called the damaging reflective beam. In its solid state, copper reflects more than 95% infrared radiation. Thereby, reflective metals decrease the efficiency of the laser cutting process, and the cutting speed deteriorates considerably.

When metals warm, copper and brass reflectivity decreases. The reflectivity drops sharply when such metals melt. For copper, it should reduce to 70% during its molten state. Therefore, laser cutting brass or cutting copper is quite tricky.

What Materials Are Suitable for Laser Cutting?

Although laser cuts an extensive range of materials, you should know what properties of different materials make them the best fit for laser cutting. Some materials do demand extra attention during laser cutting.

Here are different reflective materials laser cutting examples:

1. Metals

From stainless to non-ferrous, laser cutters can cut all metal types. Other reflective metals are harder to cut. In these cases, fiber lasers are a better option.

The metal thickness can be up to 30mm. The maximum thickness is dependent on the laser or waterjet cutting service. It differentiates based on the laser’s power and the machine operator’s skills.

2. Wood

Multiple wood types, such as MDF and plywood, are well-suited for cutting. However, you should remember that resin or oils can catch fire during laser cutting.

3. Paper and Cardboard

Paper and cardboard are well-suited for laser cutting. They are used to make intricate laser-cut wedding invitations.

4. Plastics

Lucite, PMMA, and acrylic are all see-through plastics. They leave an impressive finish after they are laser-cut. The edges of these plastics are melted, so they seem polished.

5. POM

POM is another plastic that can be cut by laser. It is often used to make gears, sliding elements, and medical instruments.

What Materials Are Not Suitable for Laser Cutting?

Although it may look like lasers can cut anything, including reflective metals, many materials are unsuitable for laser and waterjet cutting. Mainly, it would be best if you did not try to cut different plastics.

Here’s a list of materials not suitable for laser cutting:

1. PVC

Cutting polyvinyl chloride (PVC) produces toxic fumes and acids that harm the operator or machine and the laser cutter.

2. Polycarbonate

Under 1mm, polycarbonate is good to cut. Polycarbonates absorb infrared radiation used to cut materials. Laser cutting should be avoided for thicker materials as it leaves patches of discoloration.

3. ABS (Acrylonitrile butadiene styrene)

ABS plastic is a thermoplastic polymer used for 3D printing. The hot laser beam makes the material vaporize. ABS tends to melt, leaving a cut not up to the mark.

4. Polystyrene and Polypropylene Foam

Both polystyrene and polypropylene foam catch fire easily. Since heat is created due to friction during laser cutting, using PPF as laser cutting material is foolhardy. Laser cutting has other problems as well; the fire should be enough to stop you from cutting.

5. Coated Carbon Fiber

Although you may cut carbon fiber, not when it is coated, when you try to cut coated carbon fiber, its coating will release a mixture of toxic fumes. These gases are dangerous when inhaled by someone not wearing a breathing mask. The toxic fumes can lead to different lung complications, including lung cancer.

6. Food

Laser cutting is not meant for cutting meat, bread, or dough. Laser cutters can contaminate food with harmful substances. Although there are specialized lasers for food, they are commonly used for direct labeling. For instance, they are used for putting product information or designs to reduce the use of plastic packaging.

Methods for Successful Laser Cutting of Reflective Materials

The following parameters are to be followed when reflective metals laser cutting like copper and brass:

1. Cut Speed

The cutting speed is usually applied when a material is in its highest meditative state at high beam energy levels. If you doubt, you can initiate the stable cutting process at a slower pace which the process can support. Using the cutting equipment, you can allow enough time for the piercing hole to be through before pushing the beam to initiate the cut.

2. Position

Set focus position to the surface for cutting and piercing, keeping trimmed quality in mind. It reduces the surface material interacting with the beam during the initial stages. You can increase power density, resulting in faster melting of the reflective metal.

3. Power Setting

Using maximum peak power for cutting and piercing decreases the time the metals are in their reflective condition.

4. Cutting Gas

Oxygen at high pressure is generally used as cutting gas when cutting and piercing reflective metals such as copper. This increases the reliability of the process. When you use oxygen, the copper oxide formation decreases reflectivity.

Conclusion

For the best reflective metal laser cutting experience, you should opt for modern machines or fiber laser technology. They are the latest technology that uses laser light and laser delivery systems. A laser head or laser beam rapidly overcomes the cutting process, making the cutting process faster. Fiber optic lasers and fiber laser cutters are affordable for cutting thin reflective sheets through significantly more laser energy.

Elevate Your Laser Cutting Efficiency with Baison Laser!

Ready to tackle the challenge of laser cutting reflective metal materials? Baison Laser is here to guide you every step of the way. Baison laser cutting machine has a stable, efficient, and safe cutting head, suitable for thick and thin plate cutting. Get the best guidance via our website to improve your productivity NOW!