Laser cutting has revolutionized how we shape and customize materials, and its precision and efficiency are unparalleled in acrylic and plexiglass. This guide will delve into the art of laser cutting these materials, providing valuable insights and practical tips. Whether you’re a seasoned professional or a beginner, you can benefit from this guide.

What is Laser Cutting?

Laser cutting is a precise technique that uses a laser ray to cut through different materials. It is more accurate than traditional cutting methods because it melts or vaporizes the material, leaving a clean cut.

Laser cutting machines, also known as laser cutters, are used for various purposes like processing, engraving, and creating intricate designs. They use a focused laser beam that can be controlled very precisely.

Compared to traditional cutting methods, laser cutting has many advantages. It is exact and great for detailed cuts and delicate designs. Lasers can be cut through various materials like acrylic, wood, metal, and fabric, making them useful in manufacturing, signage production, and hobbies.

When using lasers for cutting, it’s essential to consider the concept of “laser kerf“. Laser kerf refers to the width of material that is removed during cutting. It’s crucial to remember this when designing projects requiring precise measurements.

Benefits of Laser Cutting Acrylic and Plexiglass

Compared to conventional cutting methods, laser technology has numerous advantages for cutting plastic sheets, including acrylic cutting and plexiglass cutting. Let’s delve into the various benefits that this craft machine engraving method offers.

- High accuracy: Laser cutting has higher precision and can achieve precise cutting. Traditional cutting methods often create minor errors in the cutting process, while laser cutting is based on laser beams that accurately target the cutting position, resulting in higher precision.

- Fast cutting: Laser cutting is faster than traditional cutting methods and can quickly complete the entire cutting process. Traditional cutting methods often require adding some material to the material or other methods to achieve cutting, while laser cutting can directly cut the material, saving time and costs.

- Industrial level: Laser cutting is an industrial-level cutting method with advanced equipment and technology that can better satisfy industrial needs. Applying automated equipment can achieve high-efficiency production processes and improve production efficiency and product quality.

- Environmentally friendly and sustainable: Laser cutting is more environmentally friendly and sustainable than traditional cutting methods, as it does not require chemical materials to achieve cutting, thus having a smaller impact on the environment. In addition, laser cutting can efficiently use energy, reducing energy consumption and emissions and achieving both economical and eco-friendly production.

- Clear-cutting results: Laser cutting can produce clear-cutting results, with the cutting surface being flat and smooth, allowing for easier subsequent processing such as painting, edge band, etc.

Choosing the Right Laser Cutter

Choosing the appropriate laser cutter machine is essential for achieving a prosperous laser-cut acrylic endeavor. Consider the following important aspects: machine parts, sheets, and inches.

Power Requirements

The laser power required for cutting acrylic or plexiglass sheets depends on the thickness of the material. Laser power also requirements vary depending on whether you’re cutting thicker sheets of acrylic or plexiglass. To ensure satisfaction, choosing a laser acrylic cutter with enough power for the parts you are working with is important.

Precision Control

Intricate designs require precise control. Look for a machine with excellent precision control to achieve intricate and detailed cuts on colored plexiglass and acrylic parts. This will allow you to bring your creative ideas to life using versatile and durable acrylic material.

Easy Setup Features

Streamline your workflow by opting for a machine with convenient features like autofocus or adjustable bed height. These functions simplify setup and save valuable time during the preparation process for working with colored plexiglass, acrylic parts, and inch measurements.

When browsing for suitable options for machine-made acrylic parts, keep an eye out for terms such as “laser engraver,” “CNC laser,” or “fusion maker.” These keywords can help you find relevant colored acrylic or plexiglass that meet your requirements, whether for a one-inch or larger size.

When comparing different models of laser cutting machines, consider factors like engraving speeds, type of CO2 wattage, and the quality of the machine parts. These specifications can significantly impact the efficiency and quality of your projects, especially when working with colored acrylic parts made from acrylic material.

When cutting acrylic or plexiglass, it is important to consider the power requirements, precision control, and ease of setup of the laser cutter machine. You can confidently select the perfect laser cutter machine for your acrylic cutting needs by carefully evaluating these factors. This versatile tool can unlock creativity and explore endless possibilities with precision-cut acrylic parts.

Learning Top 5 Cutting Technologies

We will compare and analyze five cutting-edge technologies here. From a high-level perspective, these five cutting technologies have a wide range of capabilities and are widely used in various industrial sectors. However, laser cutting stands out for its high precision and accurate cutting ability. Next, we will detail the specific advantages of laser cutting and why it is the preferred choice for many applications.

1. High-speed Laser Cutting

This is a method used for cutting small parts in large quantities at high speeds. It is perfect for batch-processing tasks and is used extensively in the automotive, aerospace, and medical industries.

High-speed Laser Cutting is suitable for cutting thin materials and can achieve accuracy levels of +-0. 1mm. High-speed Laser Cutting is a cost-effective and time-saving solution for batch processing and production of small parts.

2. Water Jet Cutting

This method relies on a high-pressure jet of water to cut through materials. A water jet cutter offers a better finish and high accuracy for cutting thick materials compared to other methods.

Water Jet Cutting is commonly used in the construction and mining industries for massive projects and can cut materials with a thickness of 50mm or more. Water Jet Cutting can also be used for CNC programming and is a flexible solution for cutting a wide range of materials including metal, glass, and plastics.

We have prepared an article for you about laser cutting and water jet cutting.

3. CNC Routing

This method is similar to Water Jet Cutting but uses a cutting tool rather than a high-pressure stream of water. CNC Routing allows for the creation of intricate and detailed patterns on the surface of materials.

It is perfect for low to medium-volume production of parts and offers precise cutting capabilities with an accuracy of +-0. 1mm. CNC Router can also be used for CNC programming and is a flexible solution for cutting a wide range of materials including metal, glass, and plastics.

4. Hand-held Laser Cutting

This method uses a handheld laser cutter to cut through materials by hand. It offers ultimate flexibility, allowing for free-form cutting and multiple copies of the same design.

Hand-held Laser Cutting is a cost-effective and time-saving solution for low-volume production and is perfect for prototyping and model-making. Hand-held Laser Cutting can also be used for CNC programming and is a flexible solution for cutting a wide range of materials including plastic, wood, and acrylic.

5. Hot Knife Cutting

This technique uses a hot knife to cut through the material. The knife is heated to a high temperature, and then it is passed through the material to produce a clean, high-quality cut.

The advantage of this technique is that it allows for hand-held cutting and can be used in places where large-scale cutting machines are not available. The ability to cut in a straight line freehand, offers flexibility compared to other methods. The disadvantage of this technique is that it has a limited cutting height compared to other techniques.

Why Choose Laser Cutting to Cut Acrylic and Plexiglass?

Compared to other cutting technologies, laser cutting offers several key advantages. The first advantage is its precision and speed; it uses a highly focused beam of light to deliver extremely high energy to the material being cut, making it possible to achieve excellent accuracy even with small features.

Additionally, laser cutting can be achieved in a fraction of the time compared to traditional methods like water jet cutting or plasma cutting, making it particularly popular for high-volume production.

Another advantage of laser cutting is its versatility; because it uses light as the primary cutting source, it can cut a diverse range of materials including steel, wood, and plastics. This makes laser cutting a highly versatile cutting technology that can be applied to a wide range of applications.

How to Laser Cut Acrylic and Plexiglass: A Step-by-Step Guide

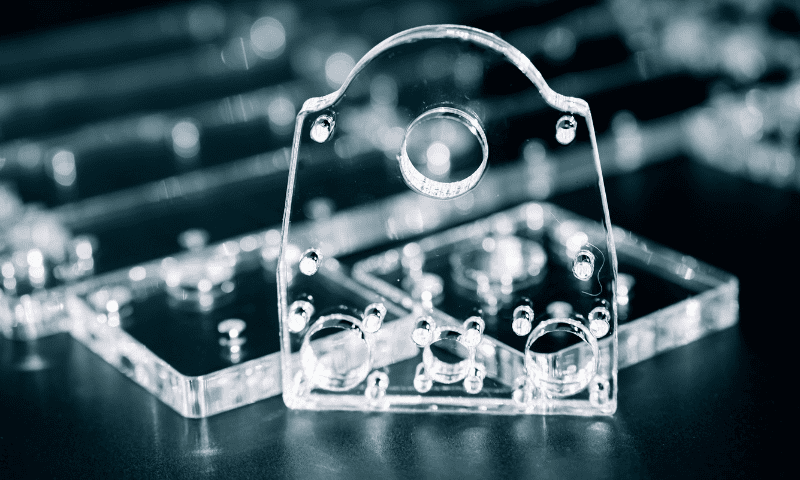

Laser cutting is a convenient and precise way to create intricate designs and shapes. Acrylic and plexiglass are two popular materials used for laser cutting due to their durability, transparency, and versatility. Below is a comprehensive step-by-step guide on how to laser cut and engrave these materials the right way.

1. Preparing the Material

Before you start the laser cutting acrylic and plexiglass process, it’s essential to prepare the material properly. Here are the important steps to consider:

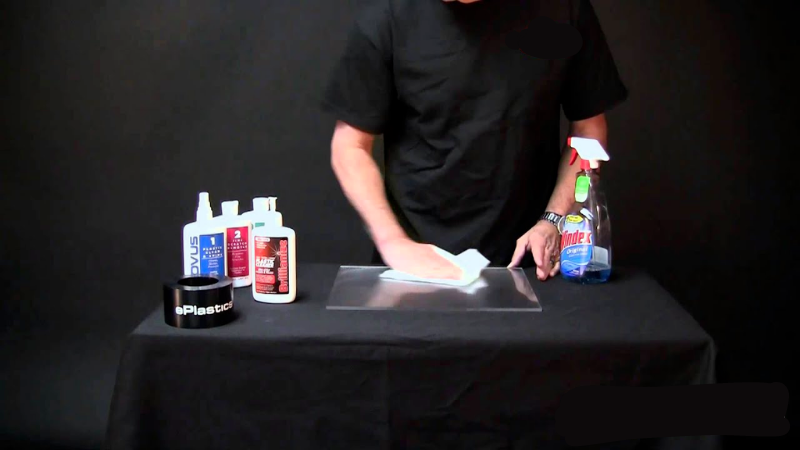

Cleaning and Deburring the Material

- Remove any protective film or packaging material from the material surface.

- Clean the surface of the material using a dry cloth or brush to remove any dust or dirt particles.

- If there are any rough edges from the manufacturing process, deburr them using a deburring tool or sandpaper to ensure a smooth cutting surface. Use a utility knife to remove any excess material along the edges if a deburring tool isn’t available.

Choosing the Right Material

There are various types of acrylic and plexiglass available, each with its own unique characteristics and properties. You need to choose the right type of acrylic sheets for your products. Here are the common types of acrylic and plexiglass to choose from:

- Acrylic: Acrylic is a clear and transparent plastic material that is commonly used in the construction, advertising, and fashion industries. It has a smooth surface and can be easily etched with a laser beam. There are different types of acrylic available, including cast acrylic and extruded acrylic. Choose the right type of acrylic.

- Plexiglass: Plexiglass is a type of acrylic that is similar to glass. With the help of a laser beam, Plexiglass can be turned into a wide range of intricate designs, graphics, and logos. Plexiglass is also available in various colors and thicknesses.

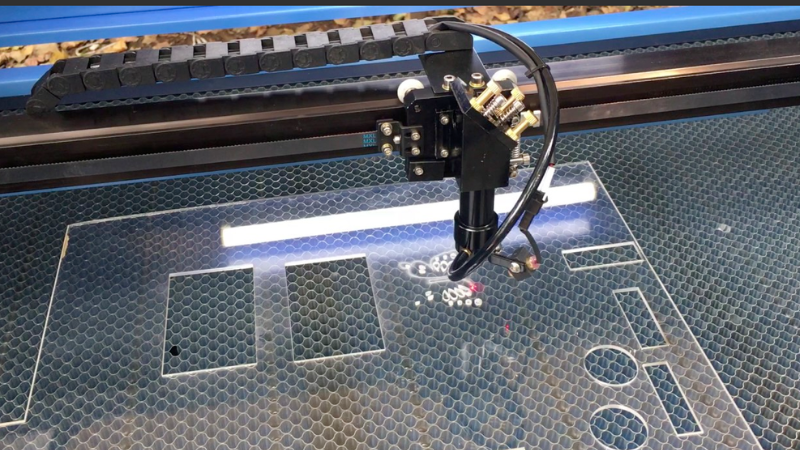

2. The Cutting Process

After preparing the material and setting up the laser cutter, you’re ready to start the cutting process. Below are the steps to follow:

Setting Up the Job

- Load the material into the laser cutter’s work table.

- Choose the appropriate settings for your material and design.

- Set the desired number of copies and the desired cutting width.

- Aligning the laser cutter correctly ensures the cut line follows the intended path on the material.

- Preview the job and make any necessary adjustments to ensure a high-edge quality.

Starting the Cut

- Use the keyboard or touchscreen interface to start the cutting process.

- Observe the cutting process and make any necessary adjustments to the speed or power settings.

- When the cutting process is complete, your design should be etched on the material.

Laser cutting acrylic and plexiglass can be a simple and precise method to create intricate designs and shapes. By following instructions on material preparation, setting up the laser cutter and the cutting process, and performing cleanup properly, you can achieve high-quality results.

Safety Equipment

To stay safe while working with laser cutting acrylic, use the right protective gear. Here’s what you need:

- Wear special goggles to protect your eyes from dangerous radiation when using laser machines.

- Use heat-resistant gloves to handle hot acrylic pieces and protect yourself from burns and chemicals.

- Make sure you have good ventilation to remove fumes that can be harmful if inhaled.

By following these safety tips, you can reduce the risks of working with laser cutting acrylic. Remember to prioritize your safety by using the right gear and having proper ventilation.

Tips for Achieving the Best Results

- Adjust the laser beam focus based on the thickness of the acrylic sheet.

- Set the power and speed appropriately for the thickness and density of the sheet.

- Ensure all safety features are working and wear proper protective equipment.

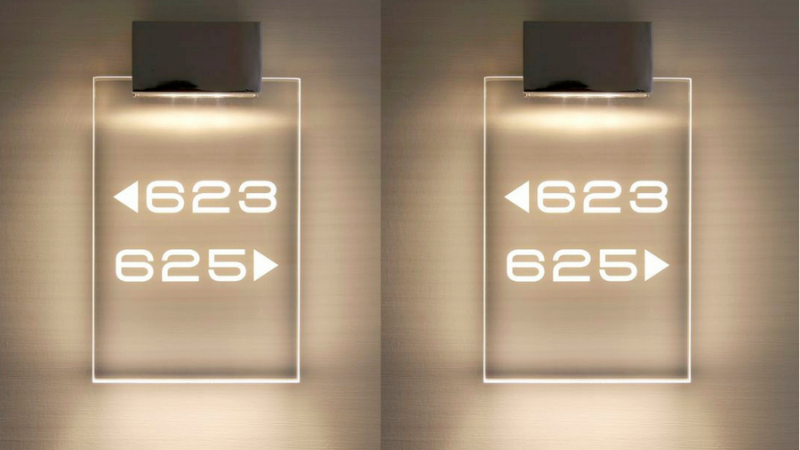

- Laser cutting acrylic is versatile and perfect for DIY projects like signs and home decor.

- Consider factors like sheet thickness and desired cutting speed to find optimal parameters for laser cutting acrylic.

Conclusion

The article introduces five cutting techniques, but when cutting acrylic and plexiglass we recommend choosing laser cutting! Laser cutting acrylic and plexiglass has many benefits, like precise designs and clean edges. It’s versatile and efficient, making it great for signs, jewelry, and home decor. We also explain in detail the process of laser cutting acrylic and plexiglass with a laser cutter.

Having a rudimentary knowledge of laser cutting techniques will allow you to confidently delve into this process for your diverse undertakings.

Ready to Get a Laser Cutting Machine for Acrylic and Plexiglass?

If you’re ready to explore the endless possibilities of laser cutting, don’t hesitate to reach out to Baison Laser today. Our team of experts is always ready to help you find the perfect solution for your needs, whether it’s a laser cutter or one of their other amazing products.

With Baison Laser, you can trust that you’ll receive high-quality, reliable products with the best after-sales support in the industry. So why wait? Visit Baison Laser today and explore our range of laser cutters, materials, and accessories. We promise you won’t be disappointed!