In this comprehensive guide, we’ll explore the top industrial laser cutting machines on the market, delve into their features, and provide you with the information you need to choose the right one for your needs. Whether you’re a small business looking to scale up production or a large manufacturer in need of a reliable machine for your assembly line, this guide will help you navigate the world of industrial laser cutters.

What is an Industrial Laser Cutting Machine?

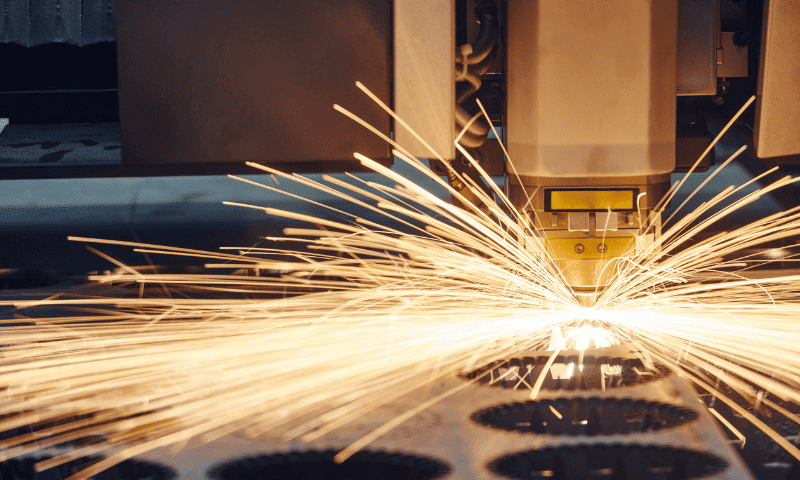

Industrial laser cutting machines utilize fiber lasers for precise and efficient cutting. These machines are ideal for a wide range of materials like metal, plastic, and wood. With their high accuracy and repeatability, fiber laser cutting machines offer unmatched precision in cutting processes.

But that’s not all – they also enable the creation of complex designs and intricate patterns with ease. This process of fiber laser machine cutting is replacing many plasma cutting applications as well as waterjet and punching applications in the sheet metal and fabrication job shop.

Understanding Laser Cutting

An industrial laser cutting machine is a high-powered and precise tool used in manufacturing and fabrication industries to cut various materials with the help of a laser beam from fiber lasers, diode lasers, and CO2 lasers. The machine utilizes a focused laser beam from the laser cutting head to melt, burn, or vaporize the material being cut, resulting in a clean and accurate cut.

The laser beam, generated by various types of laser heads such as fiber laser, CO2 laser, and diode laser, is guided by computer numerical control (CNC) technology. This allows for precise control and automation of the cutting process. Industrial laser cutting technology is commonly used in industries like automotive, aerospace, electronics, and signage to cut materials such as metal, wood, plastics, textiles optical fibers, and composites.

Benefits of Industrial Laser Cutters

Compact Size: Fits into Limited Workspace

The best laser cutter, including fiber laser and CO2 laser, offers maximum power in a compact size that easily fits into limited workspaces. With its space-saving design, this industrial laser cutting machine, suitable for engraving machines and cutters, allows you to maximize your available area. Therefore, you don’t need to worry about finding an extra room or rearranging your workspace.

Versatile: Handles a Variety of Materials

This top-notch laser cutter, also known as an engraver, is versatile and can handle a wide range of materials. Whether it’s wood, metal, acrylic, or even fabric, this machine delivers accurate cuts on various surfaces. So say goodbye to the hassle of switching between different tools for different materials from now on.

Cost-effective Solution: Compared to Traditional Cutting Methods

Choosing a piece of industrial laser equipment for your business is a cost-effective solution. Unlike traditional cutting methods that may require multiple tools and extensive manual labor, this laser cutter streamlines the manufacturing process down. Just save time and money by investing in a reliable and efficient machine that provides precise cuts without breaking the bank.

Easy-to-use Interface: Requires Minimal Training

You don’t have to be an expert to operate this machine effectively. The best laser cutter features an intuitive interface that requires minimal training. Its user-friendly design ensures that you can start producing high precision cuts with ease.

By selecting industrial laser cutting machines for your business, you gain access to numerous advantages. These cutting-edge devices utilize laser technology for precise and efficient cutting, making them ideal for a wide range of materials like metal, plastic, and wood. Industrial laser cutting machines, such as fiber laser machines and CO2 laser cutters, provide the versatility you need to meet your business requirements. Whether it’s for laser engraving machine part, marking, or intricate cutting tasks, these powerful lasers have got you covered.

Top 5 Industrial Laser Cutting Machines

You want the best laser cutter that suits your needs. With several reputable machines available in the market, it’s essential to consider the top equipment options. Here are five outstanding choices worth considering.

Dual Platforms Sheet Metal & Tube Laser Cutting Machine

- Patented Climbing Exchange Platform: More accurate as it allows the laser cutting head to cut without changing the z-axis.

- Fully Enclosed Machine Design: A fully enclosed design with an advanced ventilation system makes it cleaner.

- Energy-saving Tech: Energy consumption can be reduced by 15-20% compared to similar products.

This industrial laser cutter machine, also known as a laser engraver, is renowned for its versatility and wide range of applications. It takes advantage of the strengths prevalent in both platforms: short processing times for large ranges or possible tubes, as well as cutting through thicker materials with an increased power level. With its fiber laser cutters, this machine is a perfect laser engraving machine, for various cutting and engraving tasks.

All-round Tube Laser Cutting Machine

- Full Stroke Professional Pneumatic Chuck: The intelligent and stable chucking system makes your cutting more accurate.

- Dynamic and Precise: The dynamic combination of chuck and laser head allows you to cut more flexibly.

- Zero Tail Material to Reduce Waste: Three chuck design allows you not to waste a centimeter of the tube.

The all-around tube laser cutting machine has been a breakthrough in the industry. It uses solid-state lasers that allow for higher power laser short processing times and high-volume production, even on heavier tubes or thicker materials, to ensure you can always afford excellent quality!

CO2 Laser Cutting Machines

- Suitable for use with wood, plastic, metal, and many more materials

- Engraves and cuts without the use of sharp blades

- Able to engrave surfaces with incredible accuracy.

The Baison CO2 laser cutters are available in 1500W and 2500W laser power options. When working with metal materials, this laser cutter is ideal. It guarantees precise cuts on delicate and thin materials while maintaining efficiency. The laser cutter equipment ensures accuracy and productivity.

Coil-fed Laser Blanking System

- Zero-Delay Cutting: Removing time-latent material transport processes with direct-from-coil cutting.

- Full-Spectrum Automation: Material handling automation can save time that would have been spent transporting materials, sorting, and more.

- Implement Flexible Changes: It alleviates the need for bending tools while allowing for agile production modifications.

Automation is key to increasing productivity in any business. Coil-fed laser blanking systems at Baison are a flexible solution for any-sized manufacturing operation. These equipment are ideal for saving space, reducing material costs, and expediting productivity. Whether you need lasers or other machines, Baison has the equipment you need to streamline your operations.

Superior Sheet Metal Laser Cutting Machine

- Super Quick and Reliable Cutting: High-powered advanced laser generators give you lightning-fast laser cutting speed and stability.

- Improved Edge Quality: Equipped with an advanced cutting head for more precise cutting.

- Higher Efficiency of Energy Utilization: Cut through thick sheets easily without worrying about energy expenditure.

The Biason Superior sheet metal cutting machine will revolutionize production pipelines with its rapid processing times and top-tier quality, even when contouring complex shapes in thick materials. It features an intelligent assistant system that reduces operating costs while increasing productivity – giving you the edge over your industry!

By considering these top industrial laser cutting machines, such as Coil-fed Laser Blanking System, you can make an informed decision that aligns with your business needs. Whether it’s versatility, speed, or material-specific requirements, there is a laser cutter out there to suit your unique needs.

Factors to Consider When Buying an Industrial Laser Cutting Machine

When choosing an industrial laser cutting machine for your business, there are several key factors to consider, such as a laser resonator and laser system. These factors will help you make an informed decision and ensure that the lasers, machines, and other laser cutters that you choose meet your specific needs. Let’s take a look at some of the most important factors to consider when selecting a fiber laser cutting machine.

1. Power and Performance

The power and performance of an industrial laser cutting machine play a crucial role in determining its cutting capabilities maximum thickness and speed. Consider the laser power options of laser cutters available and their corresponding power output. This will help you determine whether the machine can handle the material thickness you require.

2. Precision and Accuracy

Precision and accuracy are vital when using fiber laser cutters. Look for machines that offer high precision levels, as this will ensure clean cuts without any errors or deviations. Pay attention to features such as automatic focusing systems or advanced motion control technology, which contribute to improved precision with lasers.

3. Ease of Use

An easy-to-use industrial laser cutting machine can save you time and effort in your business operations. Look for intuitive user interfaces, software compatibility, and convenient control panels that allow for the smooth operation of lasers. Consider if the machine offers any automation features that streamline processes.

4. Price and Value

While the price of a laser cutter is always a consideration, it’s essential to evaluate the overall value of the industrial laser cutting machine beyond its initial cost. Take into account factors such as maintenance requirements, durability, warranty coverage, and customer support services provided by the manufacturer.

By carefully considering these factors – power and performance, precision and accuracy, ease of use, and price/value – you’ll be able to choose an industrial fiber laser cutting machine that meets your business requirements effectively.

How Industrial Laser Cutters Are Used in Manufacturing

Laser cutters have become indispensable tools in the manufacturing industry, revolutionizing the way materials are cut and engraved. With their versatility and precision, these industrial machines offer numerous benefits for manufacturers across various sectors.

Cutting and Engraving Materials

Some materials like copper called reflective metals and one called conductive materials are hard to cut, but fiber laser cutting machines are perfect for these materials. Industrial laser cutters excel at cutting a wide range of materials, from metal sheets to reflective metals and even ferrous metals.

They effortlessly slice through substrates with remarkable accuracy, allowing manufacturers to create intricate designs and shapes. Laser cutting fiber machines can engrave surfaces with exceptional detail, adding personalization or identification marks to products. The use of fiber lasers has revolutionized the laser cutting industry.

Increasing Production Efficiency

By adopting industrial laser cutters, manufacturers can significantly enhance production efficiency. These machines operate at high speed while maintaining consistent quality, reducing processing time and increasing output rates. With larger working areas available on modern laser cutting machines, multiple pieces cut thick materials can be processed simultaneously, further boosting productivity.

In the medical field alone, laser cutting technology has enabled the precise fabrication of medical devices that adhere to strict specifications. This advancement has not only expedited production but also improved patient care by ensuring accurate and reliable equipment.

Overall, choosing a perfect laser cutting machine for your business unlocks a myriad of possibilities in the manufacturing realm. From streamlining operations to expanding capabilities for diverse applications like metal sheets processing or medical applications – these versatile tools empower manufacturers to stay competitive in today’s fast-paced market.

Safety Tips for Using Industrial Laser Cutters

Although industrial laser cutting machines offer many benefits, there are some safety considerations that need to be noted in order to work better.

Wear appropriate protective gear such as safety glasses and gloves: When operating an industrial laser cutting machine, it is crucial to prioritize your safety. One of the first steps you should take is to wear the necessary protective gear.

This includes safety glasses and gloves, which will shield your eyes and hands from potential hazards. By equipping yourself with these essentials, you can minimize the risk of accidents or injuries while working with the right laser cutter yourself.

Ensure proper ventilation to prevent inhalation of fumes: Another important aspect of laser safety is ensuring proper ventilation in your workspace. Laser cutting generates fumes that may be harmful if inhaled. To safeguard your health, it is essential to have adequate airflow and ventilation systems in place. This will effectively remove any potentially hazardous fumes from the environment, keeping you safe while operating the machine.

Regularly inspect the machine for any potential hazards or malfunctions: To maintain a safe working environment with your industrial laser cutter, it is crucial to regularly inspect your industrial laser cutter for any potential hazards or malfunctions.

Conducting routine checks will help identify issues before they escalate into serious problems. Look out for loose components, damaged wiring, or signs of wear and tear. By promptly addressing these issues, you can prevent accidents and ensure the smooth operation of the machine.

Follow manufacturer guidelines on safe operating procedures: Lastly, always adhere to the manufacturer’s guidelines on safe operating procedures when using an industrial laser cutting machine. These guidelines are designed to prioritize user safety and provide instructions on how to operate the equipment correctly. Familiarize yourself with these guidelines thoroughly before using the crystal laser cutter machine and strictly follow them during operation.

By following these safety tips when using an industrial laser cutter for your business, you can protect yourself from potential harm and create a secure working environment.

FAQs

Q: How do I determine which industrial laser cutting machine is best suited for my business?

Finding the right laser machine involves assessing factors from many laser machine companies like budget, required specifications (such as power output or bed size), laser resonator, desired materials compatibility, and customer reviews or testimonials from similar businesses.

Q: Can industrial laser cutting equipment be used for materials other than metal?

Yes, industrial laser cutting machines can work with a variety of materials such as wood, acrylic, fabric, plastic, and even certain types of stone. However, it is essential to check the plasma cutting machine’s specifications to ensure compatibility with your desired material.

Q: Are there any additional costs associated with owning an industrial laser cutting machine?

Apart from the initial purchase cost, you should consider expenses like maintenance, replacement parts, electricity consumption, and potential training or support services. Evaluating these costs will help you calculate the overall investment required.

Conclusion

We’ve explored the exciting world of industrial laser cutters, highlighting their benefits, key features, and their invaluable role in manufacturing. Which feature of the industrial laser cutter do you find most appealing for your production needs? Share your thoughts in the comments section. If you’re ready to enhance your manufacturing processes with precision and efficiency, explore our range of high-quality laser cutters at Baison Laser.

Choosing the Right Laser cutting machine in Baison for Your Business

So why wait? Embrace the power of industrial laser cutters and witness firsthand how they transform your manufacturing processes into efficient and precise operations. To make the most informed decision possible, thoroughly research each option, consider your business’s unique needs, consult laser machine experts if necessary, and weigh all factors before making a purchase.

Baison is one of the excellent fiber laser technology and machine companies that offers one-on-one expert guidance and free evaluations that can help you find the high-quality fiber laser cutter and CO2 laser machine made from world-class, high-quality components. Move your finger to contact us for help now!