In the fabric design and crafting world, laser cutters have emerged as a game-changing alternative, revolutionizing how businesses approach fabric production. However, choosing the best laser cutter for your fabric projects can be a real challenge. Why? Because laser power, cost, brand, and material compatibility all play an equally important role in finding the ideal machine and finding the right combination is crucial.

What is a Fabric Laser Cutter?

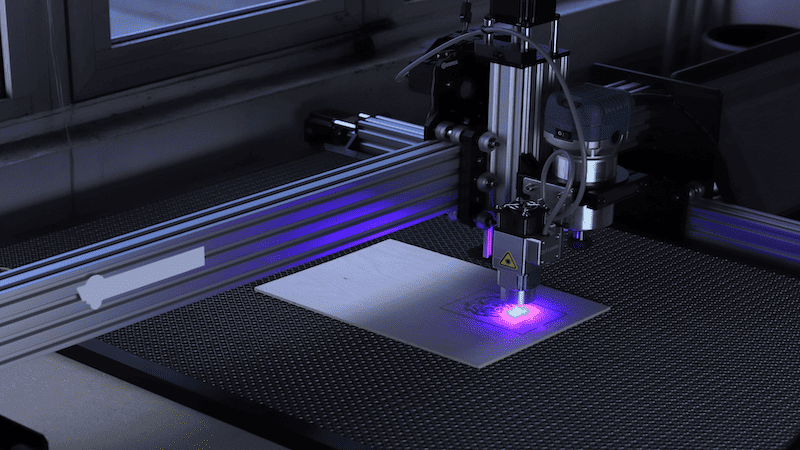

Fabric laser cutters are automatic cutting machines that use a low-power laser beam to cut through fabrics and other materials without burning the edges.

You will typically see a 10-40W laser in fabric laser cutting machines compared to the 500-3000W lasers in metal cutters.

Lasers output large amounts of energy into a micrometer-sized point on the fabric, all in a fraction of a second. This results in the fabric material burning at the point of laser contact and creating a nice, cleanly cut edge.

Since fabric cutters use low-power lasers and the laser only makes contact with the material for less than a second, the resultant heat doesn’t radiate to the rest of the material. Hence, there is a negligible chance of fabric damage.

Fabric laser cutters are compatible with several common materials like cotton, felt, denim fabric, lace, silk, and more. Some fabric laser cutting machines also offer material compatibility with paperboard, plywood, acrylic, and other thin sheets of softer materials.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

6 Huge Benefits of Fabric Laser Cutters

Laser cutters offer several features and benefits over traditional cutting methods for fabric. Following is a short list of the most prominent benefits of using fabric laser-cutting machines.

1 – Suitable for Small Business Owners

Traditional fabric-cutting machines are very large, expensive, and require special training to use. Contrarily, laser cutters are affordable, small, easy to use, and user-friendly.

Any small business owner can get an entry-level fabric laser cutter and be up and running in a matter of hours.

2 – Fast and Accurate Cuts

Lasers are highly accurate cutting devices with very tight tolerances. A cutting job that would take a person an hour to complete can be done in a matter of minutes and with higher accuracy using laser cutting.

3 – Reliable and Precise

Any type of mass-production clothing work demands all fabrics be cut with extreme precision. As fabric cutters are computer controlled, they can consistently repeat cuts with practically zero variance.

4 – Automating Tedious Tasks

Small to medium-sized custom businesses often lack the personnel to handle large orders. Tedious tasks like pattern making and design engraving take up too much time. As a result, the overall productivity of the business takes a nosedive.

With automatic fabric laser cutting machines, all the repetitive and tedious tasks can be offloaded to the machine while the employees work on finishing the clothes.

5 – Cuts Clean Edges

Some materials are more difficult to cut than others. Loose threads and burs can end up ruining the overall look and aesthetic of your clothes.

Laser cutters gently melt the edges as they cut through the fabric, creating an even and clean look.

6 – Excellent for Complex Pattern Work

Lasers are particularly effective at handling complex patterns. Most fabric laser cutting machines have an accuracy of up to 0.005 in. Laser-cutting machines provide businesses with more versatility and flexibility in their designs.

Intricate designs greatly benefit from the fabric laser cutter’s computer-controlled laser head.

Top 5 Fabric Laser Cutter

Choosing the ideal laser-cutting machine can be a real challenge. Even veterans can get overwhelmed by so many brands, configurations, and price points.

So we have taken the time to highlight the best laser cutters available right now, from budget options to allrounders to top-tier laser cutting machines.

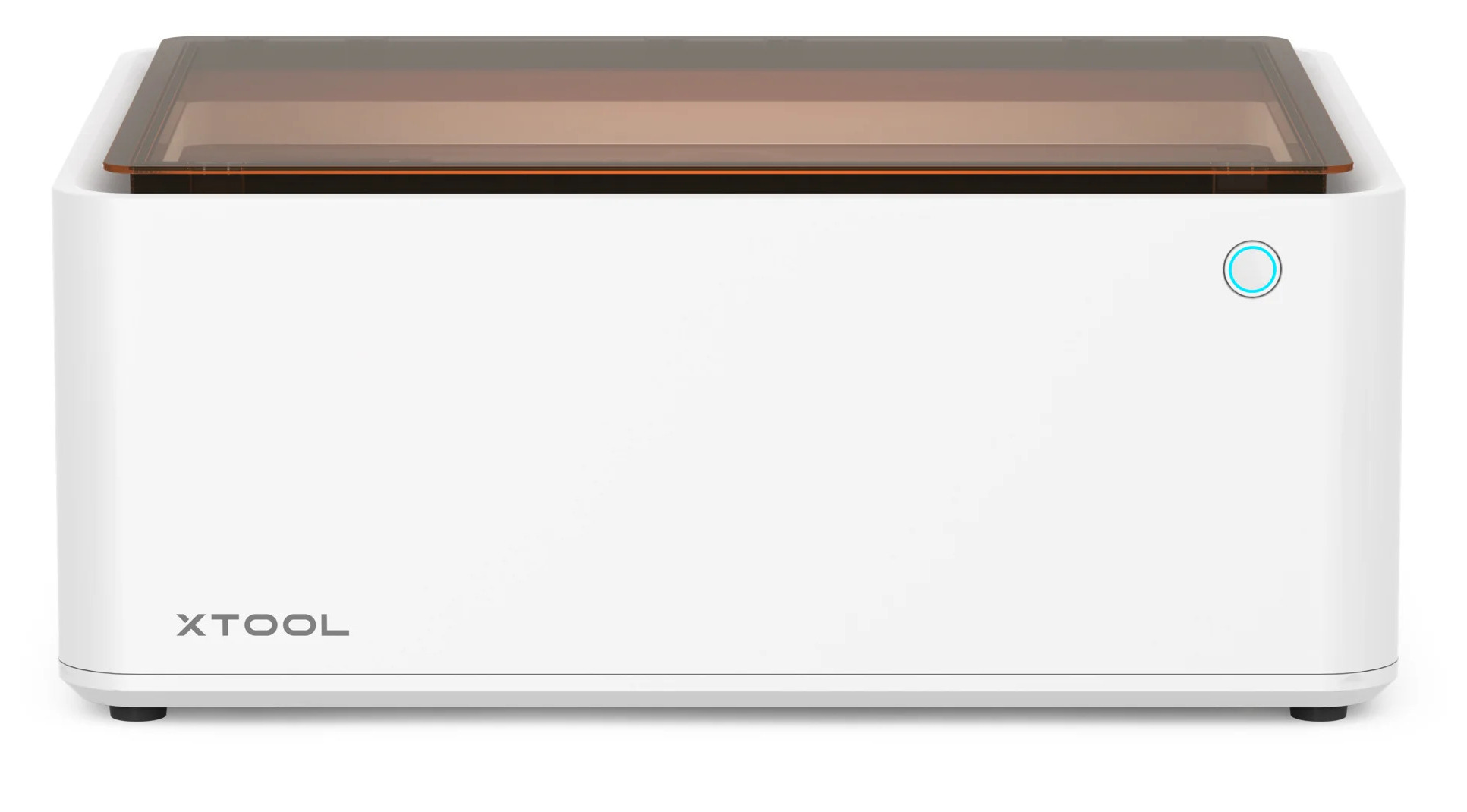

1 – xTool M1

xTool is a supplier of small-scale laser cutting machines focused on the hobbyist and small business market. Their M1 is a compact laser and blade-cutting machine that comes in 5W and 10W models.

At a sub $1000 price, this tiny machine is a productivity beast. Between the laser cutter and the blade option, the M1 can cut through hundreds of different non-metal materials.

xTool’s biggest benefit might be its accessories bundle. You can get additional items like a rotary attachment for engraving cylinders, raisers to improve material compatibility, replacement blades, and more.

If you’re not interested in the blade-cutting solution, go for the xTool D1 Pro laser engraver and cutter. This is a pure laser machine with up to a 20W laser option.

For beginners, the M1 is one of the best laser cutters in the market, especially at this price point.

2 – Flux Beamo

Flux is selling one of the most powerful and versatile laser cutters available right now. It manages to fit a massive 30W CO2 laser inside a compact body. It can cut through fabrics of up to 9mm thickness with ease.

Additionally, it supports common image formats that will help beginners make their masterpieces without any hassle. Just load up your JPG, PNG, SVG, or DXF file into the machine, and it will take care of the rest.

At a price of roughly $2200, it is a little expensive, especially for its work area of 300x210mm. At best, you are looking at cutting/engraving an A4 fabric sheet.

To Flux’s credit, it does offer larger Beambox and Beambox Pro models that can handle much larger projects. But they also come with a higher price tag.

The Flux Beamo is a fine balance between performance and functionality. It is an enthusiast-level machine that is bound to make you happy. If price is not an issue, this might be the best laser cutter for you.

3 – OMTech DF K40 40W

If you’re looking for something powerful and versatile but within your budget, OMTech’s got you covered. Their DF K40 has a massive 40W laser, capable of cutting and engraving a wide range of materials at a reasonably high cutting speed.

All of this at the very low, low price of $600. At nearly half the price of the M1, it has four times as much power. However, OMTech has had to make several compromises to hit this low price point.

To put things bluntly, it’s not a very attractive or well-designed machine. It has a very industrial 80s look compared to its competitors’ modern and sleek designs.

The DF K40 is a very versatile laser cutter with excellent laser engraving offerings. This is a great budget option for businesses involved in fabric, wood, and acrylic designs.

4 – Glowforge Plus

Let’s move on from reasonable budgets and power outputs to top-tier machines. Glowforge laser cutter options are premium, sleek, and versatile. Their Glowforge Plus starts at $50000, with the air filter attachment costing another $1300.

For this price, you do get the best laser fabric cutter available on the market. It has one of the largest work areas and supports a wide range of laser engraving and cutting materials.

Thanks to its active cooling system, glowforge laser machines are designed to run all day long. Whether it’s laser cutting fabric, multiple layers, synthetic fabric, solid wood, or even engraving metals and ceramics, this machine can do it all.

It’s not only one of the best laser cutters but also one of the best laser engravers commercially available. Glowforge is the ideal solution for business owners who need laser-cut and engraved fabrics, woods, acrylics, and more.

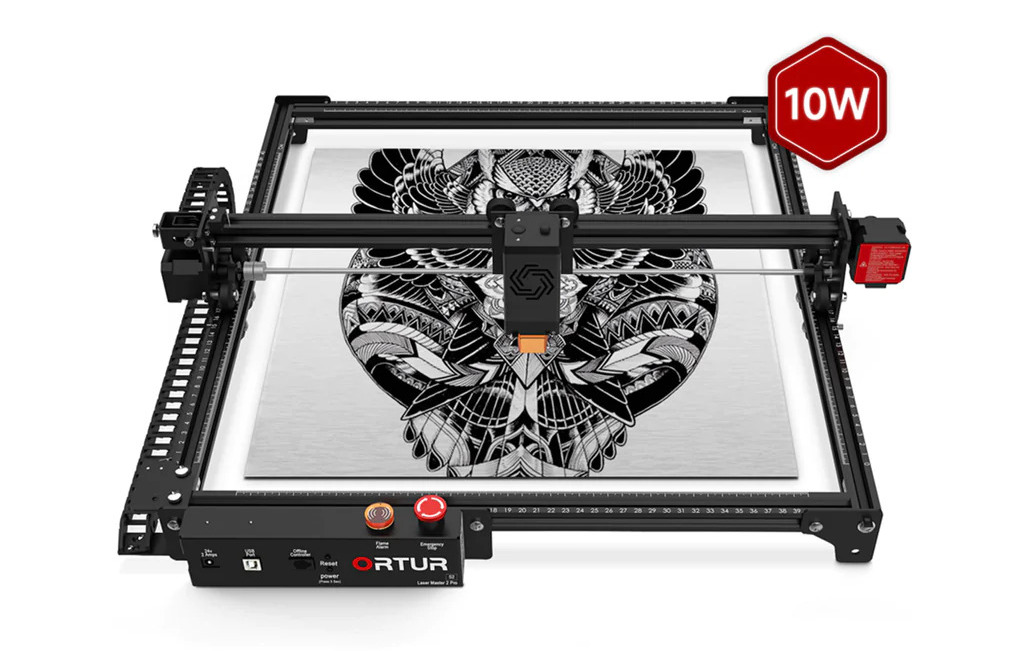

5 – Ortur Laser Master 2

Our final pick is the Ortur Laser Master 2, a budget laser cutting and engraving machine with an impressive 10W diode laser. Ortur offers all this and more at just $450.

This is more of a DIY (do it yourself) option for buyers who don’t mind getting their hands dirty setting up a laser cutting (fabric, wood, and acrylic) machine. Ortur ships you a kit that you have to assemble yourself.

The benefit of DIY is that you can swap out the laser head (laser tube) for a different one, according to your needs. Not everyone needs this type of laser machine, but those who can take full advantage of it are bound to be satisfied by the price and performance.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Factors to Consider When Buying a Fabric Laser Cutter

When choosing a fabric laser-cutting machine, you should be aware of a few metrics that can make or break your business.

Here is a quick list of factors you should consider before selecting a fabric laser cutter.

1 – Power and Performance

Fabric lasers aren’t known for their laser power. 10-40W is a standard range for most commercially available fabric lasers. While higher-power laser cutters are more appealing, you should always choose one that best suits your business needs.

Low-wattage lasers are less versatile as they cannot cut through thicker materials like leather. But if your clothing business doesn’t have leather products, you don’t have to forgo the extra cash for a higher-wattage laser cutter.

This article summarizes in detail information about the cost of laser cutting. Instead, it would be more practical to get two low-power laser cutters and improve your overall production volume.

2 – Precision and Accuracy

Fabric laser cutting machines all operate on the same computer-controlled model. However, the quality of the parts used to make up the laser cutter can significantly impact the performance of the laser cutter.

Low-quality gears, belts, and motors can reduce machine accuracy. Always check the manufacturer-provided specifications before you buy a laser cutter.

On average, you pay more for ultimate precision and accuracy cutting because high-quality laser cutters use high-quality and expensive parts.

3 – Ease of Use

Your employees already have a lot on their plate. The last thing they should be doing is worrying about their laser cutter.

A fabric laser cutter is a tool to help make your work easier and more efficient. Getting an easy-to-use machine will reduce training overhead. Your employees will only require a quick overview before starting their work.

Look for laser cutters with simple touch interfaces, minimum maintenance needs, and easy fabric removal mechanisms.

4 – Size and Weight

For smaller businesses, the size of a machine is much more concerning than the cost. Any business can save up the funds to get one or two laser cutters. But the spatial cost of incorporating them into your existing floor space is a major hurdle.

Smaller compact machines can only process small pieces of cloth at a time. But you have the benefit of buying and setting up multiple machines in a small space.

Additionally, if your factory has space constraints, you want a lightweight machine that can be easily moved around after use.

5 – Price and Value

Consider the price-to-value proposition of a fabric laser cutter. These machines are generally not expensive, but the return on investment is subject to your business’s needs.

A cheaper machine seems attractive until you realize it doesn’t cut fabrics fast enough. In such a situation, the value you get from the machine is not worth the small price you paid.

On the other hand, if you get an expensive state-of-the-art laser-cutting machine but don’t use it regularly. Then you have simply overspent.

Find a healthy balance between price and productivity to ensure you’re getting the best laser cutter.

Safety Tips for Using Fabric Laser Cutters

Fabric laser machines are generally very safe since they use low-power lasers and are hidden behind a protective glass door.

However, there are still some safety considerations that everyone should consider before getting a laser cutting machine.

1. Proper Ventilation

Fumes are the most dangerous part of a laser system. Natural fabrics are fairly safe to laser-cut, but synthetic fabrics can produce harmful fumes.

Ensure that you have a well-ventilated and spacious workspace. An air pump or similar air assist device is crucial for more confined spaces.

All laser fabric cutters mentioned above come with an air-assist device to prevent hazardous situations.

2. Safety Goggles

Even at low power, Lasers can damage the eyes if stared at directly. Safety goggles should always be worn when dealing with lasers, especially if you’re using open-concept laser cutters like the Ortur.

3. Emergency Shutoff

Using a higher-power laser on a thin and flammable material like paper or wood can quickly result in a fire. However, many laser-cutting machines have safety measures designed to prevent such situations.

An emergency shutoff system like turning off the main power supply is the responsibility of a business owner.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Conclusion

Fabric cutting solutions have seen a major uplift with the introduction of user-friendly compact laser-cutting systems. Before, you had to invest in a massive die-stamping process to get fabric cutouts and patterns, but now you can get a modest laser cutter and get similar results at home.

Choosing between the several hundred commercially available options can be daunting. The key to choosing the best laser cutter is outlining your project needs and selecting one accordingly.

The second biggest selection criteria are the ease of use and feature set. Finally, remember that the laser wattage and material compatibility mostly determine machine cost.

Take your Projects to the Next Level with Baison Laser

Baison Laser is a lead manufacturer and supplier of fiber laser solution systems. For the past two decades, we have shipped high-quality metal laser cutters to over 100 countries and regions.

Our fiber lasers are best in class and go through rigorous testing before being shipped to you. Browse our diverse catalog to find the right laser cutting machine for your project. Take advantage of our FREE customer training and application evaluation programs.

So don’t miss out on this amazing opportunity, and Contact us Now!