CNC machining processes are becoming increasingly common in many manufacturing processes. Computer numerical control machines are a great resource for lowering your operating costs and increasing the quality of your products.

The idea behind these machines is to take human error out of the equation when it comes to making parts with large numbers of features. However, because there are so many moving parts, some problems can arise outside of your control.

You can also do things yourself to avoid problems before they happen or fix them as soon as they occur. In this article, we’ll cover common CNC machine problems and how you can address them without CNC machine tool operators’ expertise.

What Is a CNC Machine?

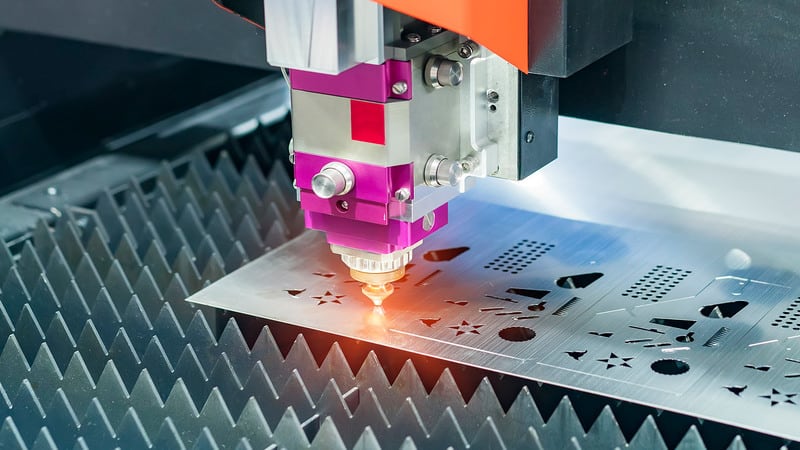

A CNC machine, or computer numerical control, is a machine that uses a computer to control its functions. CNC machines cut, drill, and milled materials such as wood or metal in three dimensions. They can be found in aerospace, automotive, construction, medical and more.

A typical CNC machine consists of an X-Y table that moves along two axes: left/right (X), and up/down (Y). The table can also tilt, rotate and swivel around its central axis to allow you to work on curved surfaces if needed.

The most common type of CNC mill will have two or three motors driving each axis. It happens while being controlled by your favorite CAD software program via G-code instructions. The signal tells it exactly how far along those axes should move at any given time during operation–hence the term “computer numerical control.

CNC machines are used by designers to create prototypes or finished products with fewer resources. The machine tools are also used by hobbyists who want to build their own projects at home without being expert CNC machine tools or operators.

How Does CNC Machining Work?

A CNC machine is a computer-controlled machine tool that uses a programmable controller to automatically move, cut and manipulate the material.

In this case, the word “computer” refers not to the device but rather to the tool holder and its ability to calculate and control movement based on user input.

CNC machines use numerical control (NC) methods for programming their operations. These methods involve using a series of codes written into the software that tells your machine where it needs to go next so that it can complete its task accurately and efficiently. This is why CNC stands for “computer numerical control.”

CNC machining has become increasingly popular over the years due to its ability to save companies money. This happens while producing high-quality products at an amazing pace and these cutting tools’ benefits don’t stop there.

7 Common Problems with CNC Machines

Here are some common CNC machine problems and their solutions:

1. Mechanical Issues

Worn-out parts can cause many problems with your CNC machine. If you’re experiencing poor performance or the machine is not cutting as expected, you will likely need to replace some worn-out parts. You may also want to check for misalignment issues and improper lubrication at this point as well.

2. Electrical Problems

Electrical issues can cause all sorts of problems with your CNC machine including faulty wiring, motor issues, or problems with the controller itself (such as incorrect programming code).

Electrical problems can be difficult to diagnose because so many different components are involved. But they often involve either incorrectly setting parameters in software or just plain bad wiring practices (like running power cables under high-wear areas).

3. Programming Errors

The most common type of CNC machine problem is a programming error. This and machine tool errors can be caused by incorrect tool paths, code, and parameter settings.

Programming errors can cause your machine to fail or not run at all, so it’s important to know how to fix them if you have this problem.

4. Environmental Factors

Environmental factors like temperature changes, humidity, and dust can affect the performance of your CNC machine.

A temperature change can cause components to expand or contract, which may result in damage if not properly compensated for during operation.

High humidity levels can cause condensation inside the enclosure or other parts of the system that may lead to short circuits or damaged components over time (especially relays).

Dust particles on sensors can interfere with detection systems causing false signals which could result in poor quality cuts or even cause damage to internal components.

5. Poor or Improper Maintenance

Proper maintenance is important to keep your CNC machine performing well and safely. Maintenance should be done regularly, by a qualified person, at the right time.

Dirt and dust can build up on the machine’s moving parts over time, causing them to wear out faster than they normally would.

Worn-out lubricants will increase friction between machine parts (like gears). This may lead to other problems, such as machine failures like overheating or motor jams/failures. It happens due to excessive stress on these components caused by poor lubrication levels during operation.

6. Improper Settings or Tools

If your CNC machine is not set up incorrectly, it may not be able to perform its intended functions correctly.

This can lead to problems with the quality and accuracy of your workpiece or machine tools and damage or wear on the tooling used by your machine.

If you’re having trouble with your CNC machine, the first thing to do is check the programming. This can include problems with:

- Inappropriate toolpaths (such as cutting too deep or too shallow)

- Incorrect code, such as a carriage moving in the wrong direction or at an incorrect velocity

- Parameters that are set incorrectly (such as feed rates)

7. Poor or Improper Programming

Many of the problems that arise from poor programming are due to improper settings, such as incorrect toolpaths or cuts made at an angle instead of straight across a piece of material.

In addition to this, there may also be some issues with faster speeds than what was intended for certain parts of your project.

If this happens, you may need to make adjustments so that everything fits into place correctly before moving forward with any further work on your project.

How to Fix the Problems in CNC Machines?

CNC machines are one of the most important tools in every manufacturer’s shop. They can help make the manufacturing process of your work easier, faster, and more efficient.

However, if you’re having problems with your own CNC machine tools, it’s important to take care of them so you can make sure everything runs smoothly. If your CNC machine is giving you problems, here are some tips on how to fix them:

First, use a multimeter to check the power supply. If it’s not getting enough voltage, the problems could be caused by any number of things, from worn-out fuses to an open circuit breaker.

Next, check that your spindle is properly connected to the power supply, not damaged wires or cables. If there are no visible signs of damage, try swapping out cables for a new set that is known to be good. If this doesn’t solve the problem, then try replacing fuses or resetting breakers on your circuit board until you find the source of the issue.

Finally, check that your motor is connecting with the power supply properly and not damaged any wires or cables. If there are no visible signs of damage, try swapping out cables for a new set that is known to be good.

If this doesn’t solve the problem, then try replacing fuses or resetting breakers on your circuit board until you find the source of the issue.

What Should You Consider While Choosing a CNC Machine?

It’s true; there are a lot of things to consider when choosing a CNC machine. Luckily, we’ve got you covered. Check out our top tips for making sure you get the best deal possible!

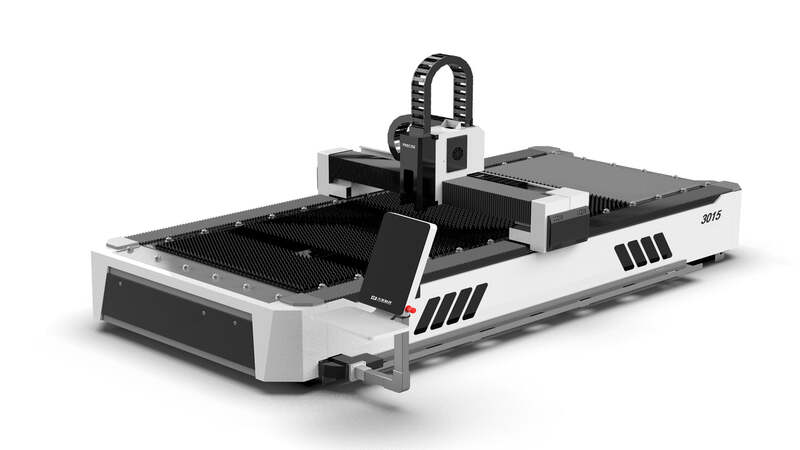

Size of the Machine

If you’re looking for something that can handle big projects, then bigger is better. But smaller ones will work fine if you just need something for smaller jobs and prototypes.

Type of Work it Will Handle

Suppose your business is all about one type of thing (like woodworking). In that case, you might want to look into a machine specializing in milling machines for that kind of work over one that does everything from sewing to plastics manufacturing.

Cost

You want to make sure you get what you pay for and that your machine lasts as long as possible so that any initial investment pays off in the long run. This means keeping up with maintenance and making sure any parts are replaced on time so they don’t break down later!

Budget

When it comes to choosing the right CNC machine, budget is one of the most important factors. If you have a limited budget, then you might have to settle for a low-end machine while if you have ample funds at your disposal, then you can go for a high-end model.

Machine Features

If you are looking to buy a CNC machine tool, then it is important that you consider all its features as well as its specifications before making your final decision. The more features that come with the CNC machine tool’s display and its specifications play an important role in determining whether or not it will be able to meet all your requirements for machining purposes.

Maintenance

You should also consider how much maintenance will be required by your CNC machine over time. This will help determine how much money you need to pay for repairs or replacement parts when they break down due to wear and tear from regular use over time.

Conclusion

The CNC machine is a powerful tool that can help you to create your own projects. Knowing how to use it correctly is important so you don’t waste time or money on repairs.

By checking the common problems in CNC machines and knowing how to fix them, we hope this article has helped give you some insight into this complex world. Please contact us if you have any questions about your machine or want to help troubleshoot an issue. Baison will provide you with perfect solutions.