Curious about laser marking machine costs? Before diving in, it’s essential to grasp the factors that influence these expenses. Our comprehensive guide breaks down these cost components, from the initial investment to maintenance, ensuring an informed decision aligned with your needs and budget. Let’s dive in and discover everything you need to know about laser marking machine costs!

The Basics of Laser Marking

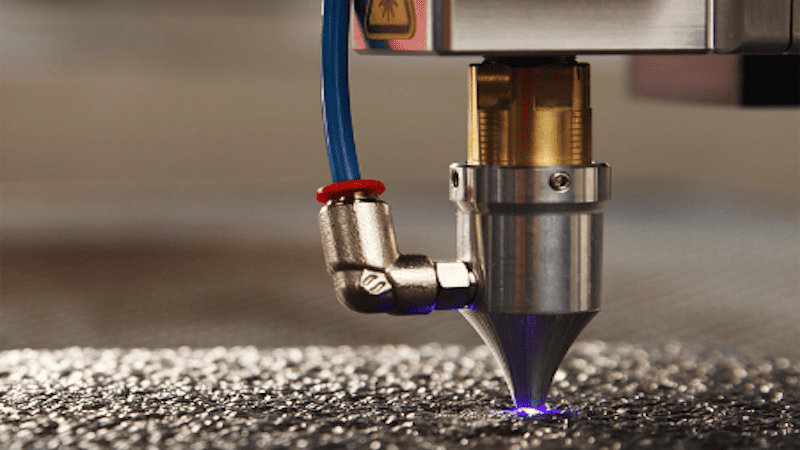

Laser marking is a widely used process by the use of CNC (Computer Numerical Controlled) technology for creating permanent marks or designs on various materials. It involves using a laser beam to etch or engrave the surface, resulting in high-quality and precise markings. The process involves using a laser beam for convex engraving.

Let’s delve into the fundamentals of laser marking:

Definition and Explanation of the Laser Marking Process

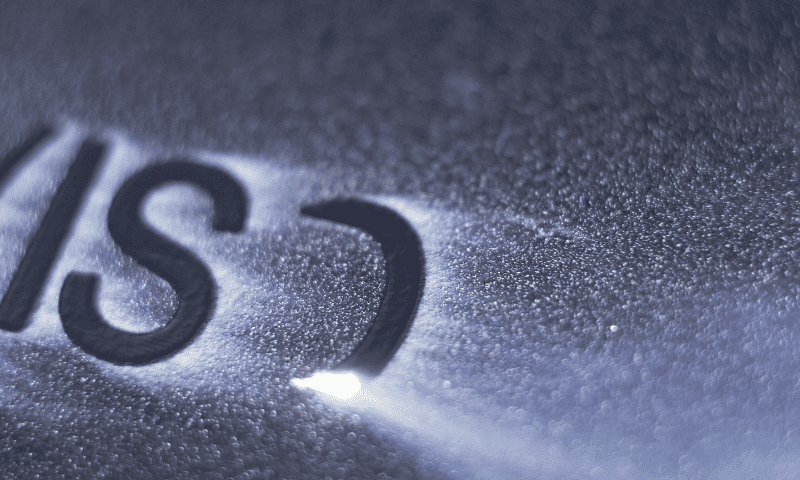

Laser marking, also known as laser engraving, is a non-contact method that utilizes focused laser beams from a laser engraver to alter the material surface properties by cutting marks using lasers. By directing the laser onto the target area, it generates heat, causing oxidation or vaporization of the material surfaces.

This laser etching process leaves behind permanent marks that are resistant to fading or wearing off. Color laser marking is achieved using laser markers, which create a vibrant marking effect.

Advantages and Limitations of Laser Marking Technology

Laser marking technology, using lasers and engraving machines, offers numerous benefits that make it popular across industries. The use of lasers enables precise laser cutting and marking.

- High precision: The most significant advantage of laser marking is enables intricate designs with fine details.

- Permanent markings: Resistant to fading, abrasion, and chemicals.

- Non-contact process: Minimizes damage to delicate materials.

- Versatility: Applicable on various surfaces including metals, plastics, ceramics, etc.

However, there are certain limitations worth considering:

- Cost: Prices vary depending on factors such as power output and system complexity.

- Speed: The time required for larger or more complex designs may be longer.

- Material compatibility: Some materials may not respond well to laser marking.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Types of Laser Marking Machines

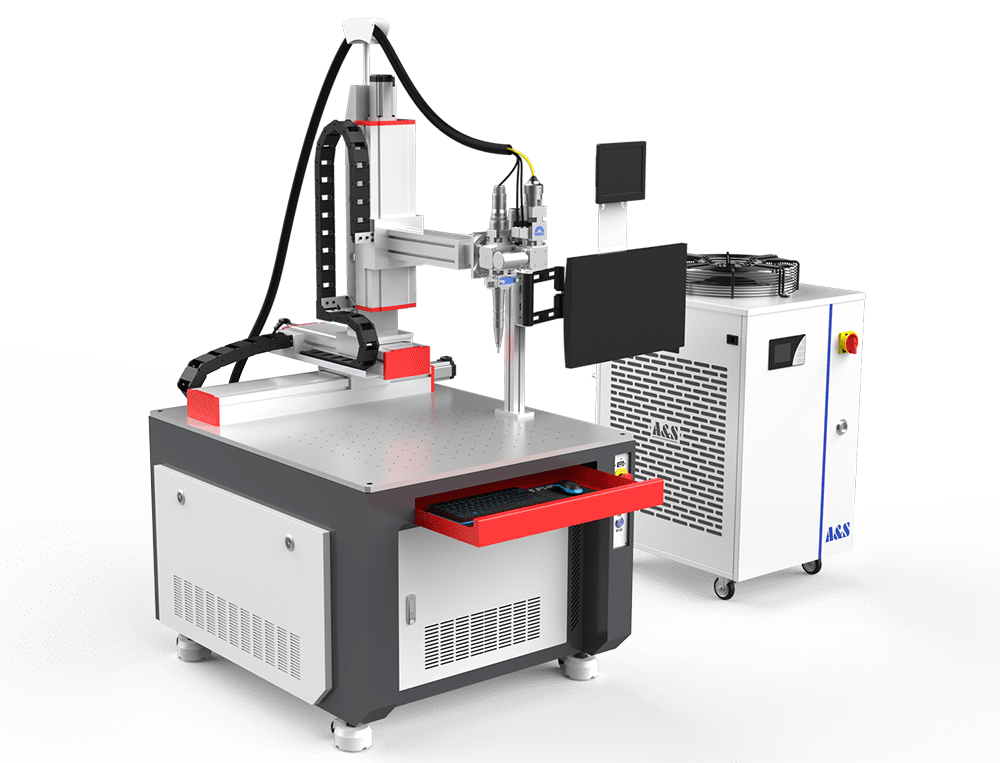

There are various types of laser marking machines available in the market, each with its own unique features and capabilities. Here is an overview of different types.

- Fiber Laser Marking Machines: These laser machines use fiber lasers to create precise and permanent markings on a variety of materials. (You can read this blog post to learn about materials suitable for fiber laser marking.) They are known for their high speed, accuracy, and durability.

- CO2 Laser Marking Machines: These machines utilize CO2 lasers to engrave or mark non-metallic materials such as wood, acrylic, glass, and plastics. They are commonly used in industries like signage making and packaging.

- Nd: YAG Laser Marking Machines: Nd: YAG lasers are suitable for marking materials like metal parts and certain plastics. They provide excellent beam quality and can be used for deep engraving or surface marking.

Factors Affecting Laser Marking Machine Cost

The cost of a laser marking machine, used for engraving and marking surfaces, can vary based on several factors such as the type of lasers used. Here are the key factors that influence the price.

1. Type and Power of the Laser Source

The type and power of the laser source used in a marking machine play a significant role in determining its cost. Different types of lasers, such as fiber, or CO2, have varying price ranges. Higher power lasers generally come at a higher cost due to their increased capabilities and efficiency.

2. Additional Features and Customization Options

Laser marking machines offer various additional features and customization options that can impact their price. These may include advanced software capabilities, rotary attachments for cylindrical objects, autofocus systems, or integrated barcode scanners. Each added feature or customization option adds to the overall cost.

3. Maintenance, Service, and Operational Costs

When considering the cost of a laser machine, it is essential to take into account ongoing expenses such as maintenance costs, service contracts, and operational costs. Laser sources, such as fiber lasers used in engraving machines and marking machines, may require periodic replacement or maintenance to ensure optimal performance. Operational costs like electricity consumption should be considered.

Factors like the thermal effect on materials being marked also affect the choice of laser technology for specific applications but do not directly impact the machine’s cost.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Cost of a Laser Marking Machine

Here’s a general breakdown of machine price ranges. We can take laser marking machines and break them down into three price points.

Please note the prices are in $USD and are subject to change after the publishing of this article.

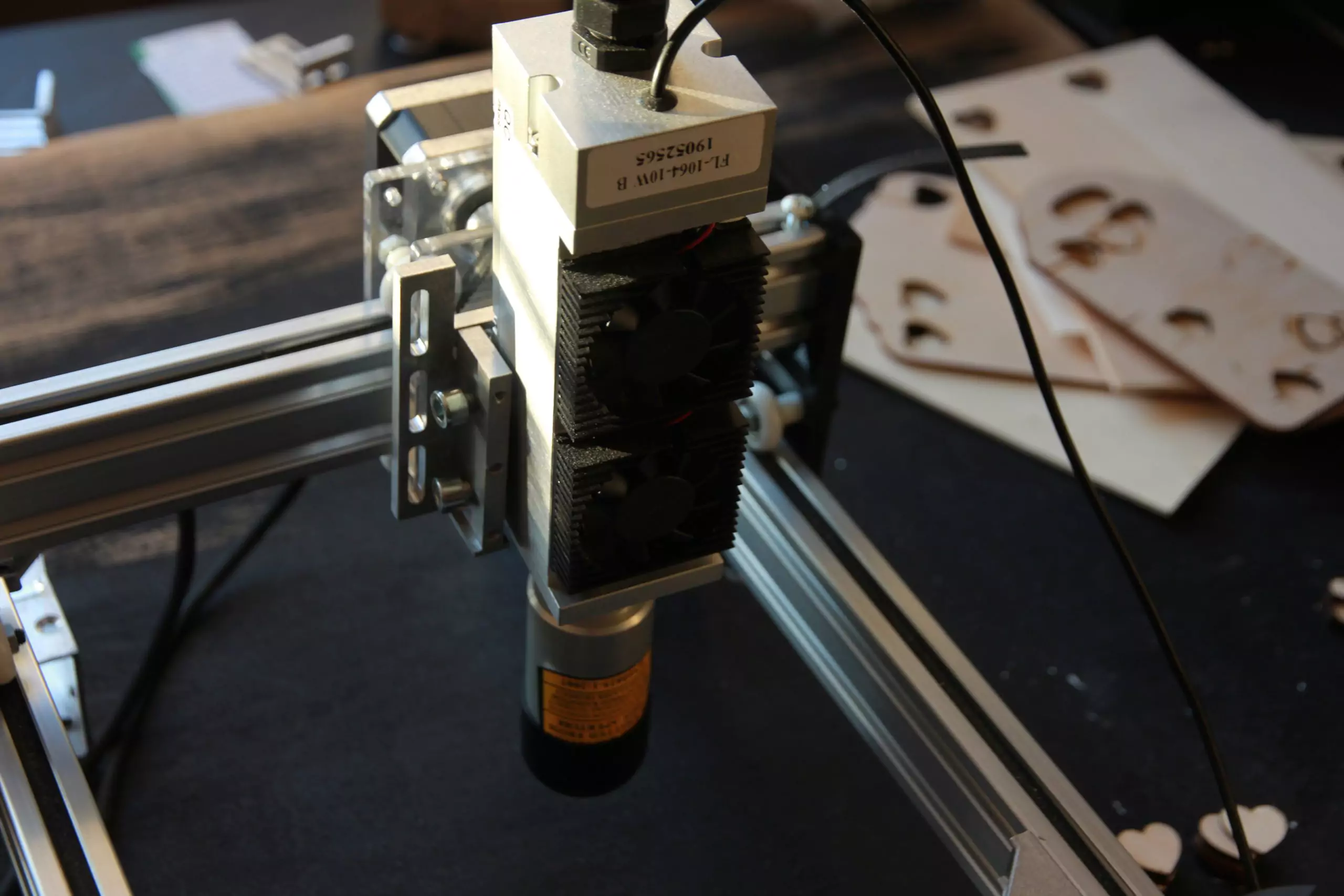

I. Entry-level Models (20W – 30W)

Entry-level laser marking machines, ranging from 20W to 30W power, are often designed for smaller-scale applications, making them a suitable choice for businesses or individuals exploring laser marking for the first time. These laser marker machines typically offer basic functionalities and a smaller marking area compared to other laser cutters or laser engravers for laser engraving.

Prices for entry-level models generally start around $2,000 to $5,000. While laser markers and laser cutters may have limitations in terms of power and features, they can provide a cost-effective solution for simpler marking tasks. Laser engraving machines and laser engravers are also capable of achieving similar results.

II. Mid-Range Machines (30W – 50W)

Mid-range laser marking machines, with power ranging from 30W to 50W, strike a balance between affordability and enhanced capabilities.

They are suitable for businesses with moderate marking needs and require more advanced features than entry-level models. With a price range of approximately $5,000 to $15,000, mid-range machines offer greater power, and marking area options, and often come with additional software and automation features. These machines cater to a wider range of applications, making them versatile for various industries.

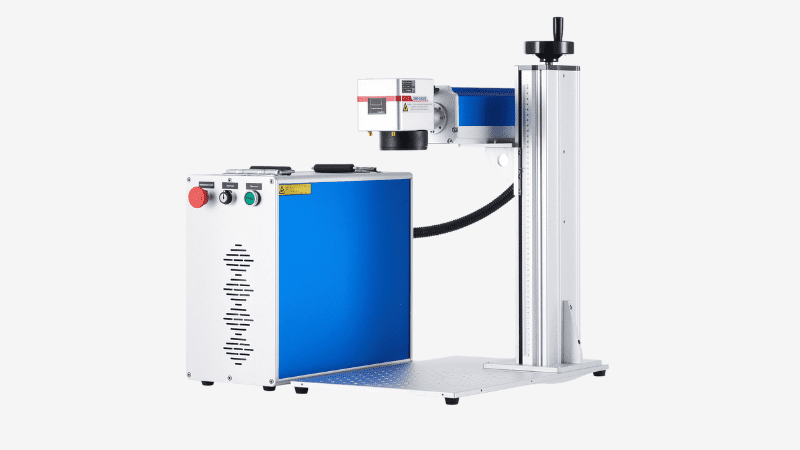

III. High-End Industrial-Grade Laser Markers (50W – 100W+)

For businesses with demanding marking requirements and high-volume production, high-end industrial-grade laser markers, with higher laser power ranging from 50W to 100W or more, are the go-to choice.

These robust machines offer top-tier performance, precision, and durability. With the laser engraving machine price ranging from $15,000 to $100,000 or more, these machines boast advanced features, larger marking areas, and the ability to handle a variety of materials and applications. They are the optimal choice for industries where reliability, marking speed, and exceptional quality are paramount.

Remember that the cost of a laser marking machine is influenced by factors like laser type, power, marking area size, and automation capabilities. Choosing the right machine depends on your specific marking needs, production volume, and budget considerations.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Key Considerations for Laser Marking Machine Selection

When choosing industrial machines, there are several key considerations to keep in mind. These factors will help you determine the right machine for your specific needs and ensure efficient production.

- Speed and Accuracy Requirements: Assess the speed and accuracy requirements of your marking process. Consider the volume of workpieces that need to be marked and the desired turnaround time when choosing a laser marker, such as a fiber laser marking machine or a fiber laser engraving machine. A CO2 laser marking machine may offer higher speed capabilities compared to other types.

- Compatibility with Materials: Determine the materials you plan to mark, such as metal, plastic, or glass. Ensure that the laser marking system is compatible with these materials. Different machines may have varying capabilities in terms of processing different materials.

- Ease of Use and Software Compatibility: Look for a laser marking machine that is user-friendly and easy to operate. Check if it comes with intuitive software that allows you to create and customize markings efficiently. Compatibility with your existing software systems is also important for seamless integration into your workflow.

- Workpiece Size and Processing Area: Consider the size of your workpieces and ensure that the laser marking machine can accommodate them comfortably within its working area or processing area. This will prevent any limitations or restrictions during the marking process.

- Power Output and Focal Length: Evaluate the power output requirements based on the quality and depth of markings needed for your application. Consider the focal length options available as they affect the precision of laser beam focus.

- Rotary Attachment Capability: If you anticipate marking cylindrical objects or curved surfaces, check if the laser marking machine offers a rotary attachment feature. This enables consistent markings on rounded workpieces without compromising quality.

By considering these key factors when selecting a laser marking machine, you can make an informed decision that meets your specific requirements for speed, compatibility, ease of use, workpiece size, power output, focal length options, and additional features like rotary attachment capability.

Common Applications and Industries for Laser Marking Machines

Laser marking systems have become essential tools in various industries due to their versatility and efficiency. Let’s explore some common applications and industries where these machines are widely used:

1. Automotive Industry

- Part identification: Laser marking is utilized to engrave unique codes, serial numbers, or logos on automotive components, ensuring easy traceability during assembly or maintenance processes.

- Traceability: By permanently marking parts with laser technology, manufacturers can track the origin of each component and ensure quality control throughout the supply chain.

2. Medical Device Industry

- Permanent markings: Laser marking is crucial for medical devices as it provides permanent identification on instruments, implants, or equipment. This ensures accurate tracking during sterilization processes and enhances patient safety.

- Compliance with regulations: The medical device industry must adhere to strict regulations regarding product labeling. Laser marking machines enable manufacturers to meet these requirements efficiently.

3. Jewelry Industry

- Intricate designs on precious metals: Laser marking machines offer precise control over the laser engraving process, allowing jewelers to create intricate designs on gold, silver, platinum, and other common metals.

- Personalization: With laser technology, jewelry manufacturers can easily customize pieces by fiber laser engraving names, initials, or special messages onto various metal surfaces.

These are just a few examples of how laser marking machines are employed across different sectors. From part identification in the automotive industry to permanent markings in the medical device field and intricate designs in the jewelry business – industrial laser marking machines have revolutionized product branding and traceability.

Manufacturers continue to innovate software and hardware solutions that cater specifically to the needs of each industry. As a result, businesses can enhance productivity while maintaining high-quality standards within their respective sectors.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. How long does a laser marking machine last?

Laser marking machines are built to be durable and reliable. With proper maintenance and care, they can last for many years. The lifespan of a laser marking machine depends on various factors such as usage frequency, operating conditions, quality of components used in manufacturing, and regular servicing.

2. Can I use a laser marking machine on all materials?

Laser marking machines are versatile tools suitable for various materials such as metals (including stainless steel, aluminum), plastics (including ABS, PVC), ceramics, glass, wood, leather, fabrics (including denim), paper products (including cardboard). However, certain materials may require specific settings or additional precautions due to their composition or heat sensitivity.

3. Can I integrate a laser marking machine into my existing production line?

Yes! Laser marking machines can be integrated into existing production lines, making them an excellent choice for industrial applications. They can be seamlessly incorporated into automated systems or used as standalone units depending on your specific requirements. Consult with the manufacturer or supplier to ensure compatibility and discuss integration options.

Conclusion

Now that you have a solid understanding of laser marking machines and the factors that influence their cost, it’s time to make an informed decision. Remember, investing in a laser marking machine is not just about the upfront cost but also about the efficiency, precision, and durability it can offer to your business. To ensure you make the right choice, do thorough research on reputable suppliers and manufacturers.

Unlock Precision and Power: Explore Laser Marking with Baison Laser

Baison Laser is a leading machine manufacturer of laser systems. Whether you’re seeking entry-level affordability or high-end industrial power, Baison Laser has you covered with our laser marking machines. Explore our production catalog now and make an informed investment in precision and efficiency. Reach out to us to explore the perfect laser marking solution for your needs!