Understanding Custom Sheet Metal Cutting

Precision and accuracy are paramount in sheet metal cutting. It’s all about achieving those clean cuts and maintaining the desired bend radius. To gain a better understanding of this field, it’s essential to explore the different aspects involved in the process.

What Is Custom Sheet Metal Cutting?

Sheet metal refers to thin, flat pieces of metals commonly used in various industries such as automotive, aerospace, construction, and electronics. Custom sheet metal cutting is an essential part of the manufacturing industry and is the process of cutting and shaping these metals according to specific design requirements or customer specifications.

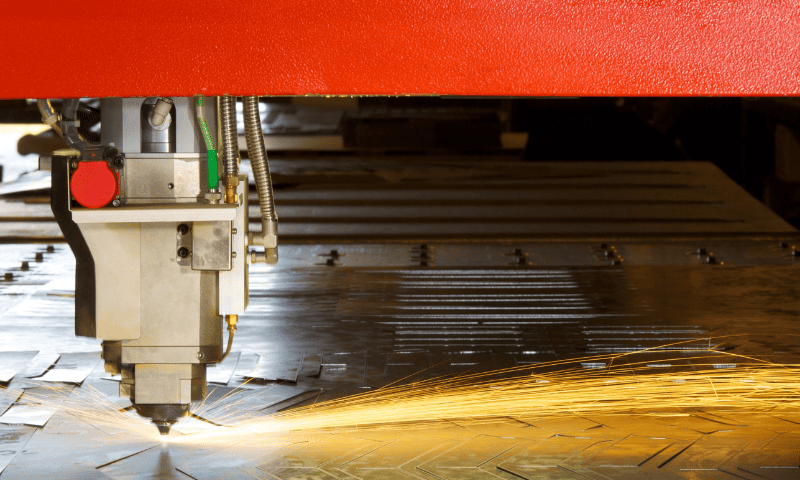

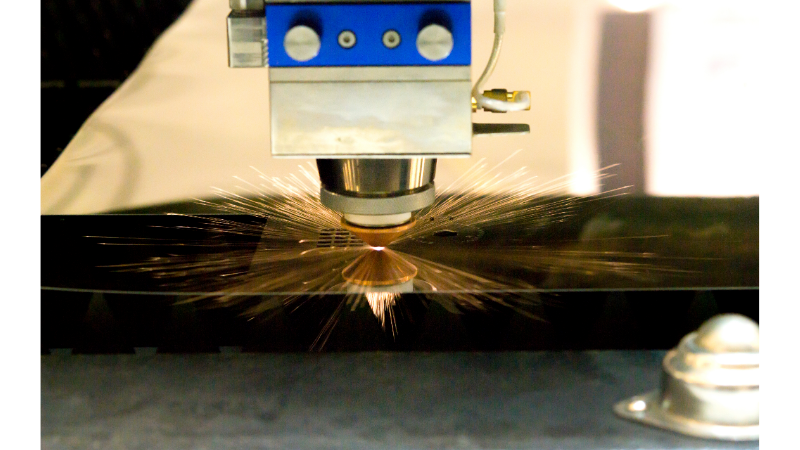

It involves using various cutting techniques like laser cutting, plasma cutting, or waterjet cutting to accurately shape the metal sheets. This manufacturing process is essential in welding, plating, and other metal-related applications.

The Process of Custom Sheet Metal Cutting

a. Selection of Cutting Technique: The first step is to determine the most suitable cutting technique based on factors like the type of metal being used, its thickness, and the required precision. Common cutting techniques include laser cutting, plasma cutting, and waterjet cutting.

b. Material Preparation: Once the fabrication process and manufacturing process cutting technique is chosen, the metal sheet is prepared for cutting. This may involve cleaning the surface, removing any contaminants or protective coatings, and ensuring the sheet is flat and free from any deformities.

c. Positioning and Securing: The metal sheet is then carefully positioned and secured on the cutting machine. Precision is crucial in this step to ensure accurate cutting and prevent any movement or vibrations during the process.

d. Programming and Design: The fabrication process begins with programming the cutting machine using computer-aided design (CAD) software. This allows for precise and intricate designs to be created before the manufacturing process, which includes welding and stamping, takes place on the metal sheet.

e. Cutting Process: The cutting machines follow the programmed design and access the selected cutting technique to cut through the metal sheet. Laser cutting utilizes a high-powered laser beam to heat, melt or vaporize the metal, plasma cutting uses a jet of ionized gas to cut through the metal, and waterjet cutting operation employs a high-pressure stream of water mixed with abrasive particles to erode the metal.

f. Finishing and Quality Control: Once the cutting process is complete, the cut metal pieces may undergo additional finishing processes such as deburring, sanding, or polishing to remove any rough edges or imperfections. Quality control checks are performed to ensure the accuracy and precision of the cut metal components.

Custom sheet metal cutting allows for the creation of customized metal parts or components that meet specific design requirements. It offers flexibility in terms of material choice, shape, and size, making it a widely used process in various industries.

Applications of Custom Sheet Metal Cutting

Custom sheet metal cutting is a production method and a widely used manufacturing process in various industries. It involves cutting metal sheets according to specific requirements. This fabrication process is essential for creating different products and components. Let’s explore some common uses and examples of this sheet metal cutting process.

Industries Using Custom Sheet Metal Cutting

Custom sheet metal cutting is a crucial process in the manufacturing industry, as it is used to cut and form various metals for different applications. Here are some industries using sheet metal cutting.

Automotive

Custom sheet metal cutting is used to create various automotive components such as body panels, chassis parts, brackets, and exhaust systems. It allows for precise shaping and cutting of metal sheets to meet the specific requirements of different vehicle models.

Aerospace

The aerospace industry relies on custom sheet metal cutting for manufacturing aircraft parts, including structural components, engine parts, and interior fittings. The high precision and accuracy of sheet metal cutting techniques ensure the production of lightweight yet strong parts for aircraft.

Electronics

Sheet metal cutting is crucial in the manufacturing and fabrication process of electronic enclosures, cabinets, and panels. These components require precise cutting of metals, such as steel, to accommodate circuit boards, connectors, and other electronic equipment. Custom sheet metal cutting allows for the creation of complex shapes and sizes to fit specific electronic devices.

Construction

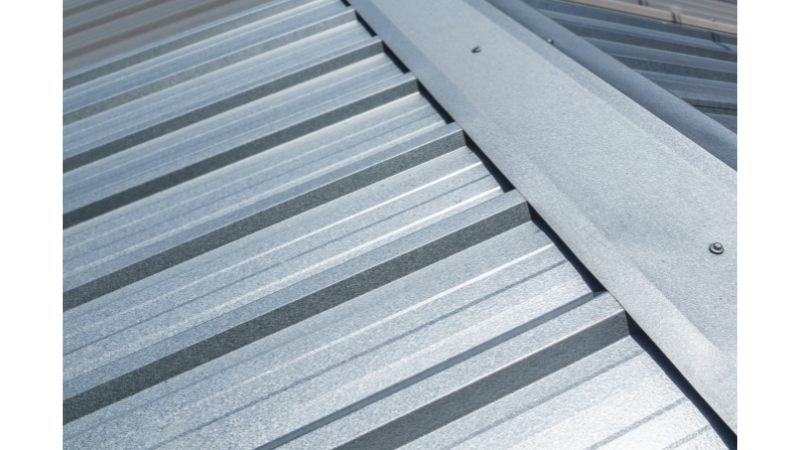

Custom sheet metal cutting is widely used in the construction industry for fabricating architectural elements, HVAC (Heating, Ventilation, and Air Conditioning) systems, ductwork, and metal roofing. It enables the creation of customized metal components that fit seamlessly into construction projects.

These are just a few examples showcasing how custom sheet metal cutting is applied across different industries. No matter what the industry, this versatile process proves invaluable in creating intricate designs and functional components.

Popular Products and Implementations

Industrial Equipment: Custom sheet metal cutting plays a crucial role in many forms of manufacturing of industrial equipment and machinery components. This includes the production of machine frames, brackets, and panels that are essential for the functioning of various industrial processes. Custom sheet metal cutting allows for the creation of precise and customized parts that fit seamlessly into the overall machinery design.

Customized Metal Parts: Durability sheet metal cutting is widely used to create custom metal parts for various applications. This includes components for appliances, lighting fixtures, medical equipment, agricultural machinery, and many other products. Custom sheet metal cutting enables manufacturers to produce sheet metal parts that meet specific design requirements, ensuring the functionality and performance of the final product.

Architectural Elements: Custom steel sheet metal cutting is utilized in the manufacturing of architectural elements for both residential and commercial buildings. This includes the production of decorative metal panels, railings, and façade elements. Custom sheet metal cutting allows architects and designers to create unique and visually appealing architectural features that enhance the overall aesthetics of the building.

Automotive Accessories: Custom sheet metal cutting is employed in the production of automotive accessories such as grilles, trim pieces, brackets, and decorative accents. It allows for precise shaping and cutting of metal sheets to meet the specific design requirements of different vehicle models. Custom sheet metal cutting enables the creation of customized automotive accessories that enhance the appearance and functionality of vehicles.

By leveraging custom sheet metal fabrication techniques, manufacturing businesses can achieve precise results tailored to their specific tasks in steel and other common materials. This ensures high-quality products that meet industry standards while allowing for creative customization of sheets.

Selecting a Custom Sheet Metal Cutting Service

When choosing a reliable custom sheet metal cutting service, there are several factors to consider. Turnaround time, customization, and design capabilities should also be taken into account.

Factors to Consider When Choosing a Service

Quality and Precision: Look for a service provider that has a reputation for delivering high-quality and precise sheet metal cutting. The accuracy and precision of the cutting process are crucial to ensure that the final product meets your design requirements.

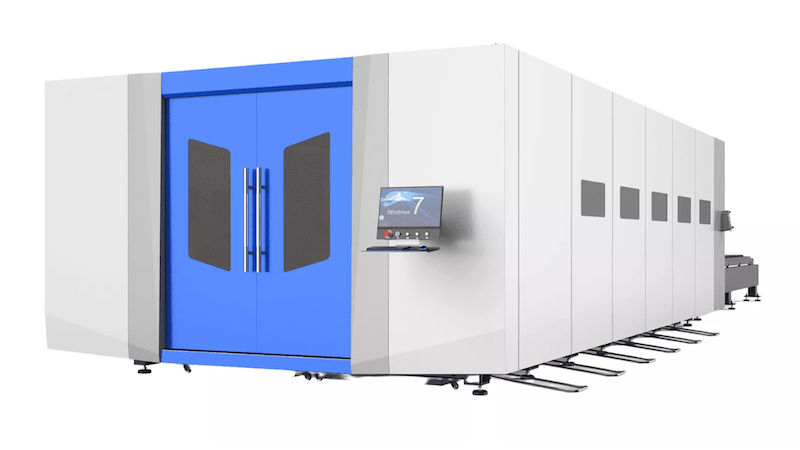

Technology and Equipment: Check if the service provider utilizes advanced technology and modern equipment for sheet metal cutting. This ensures efficient and precise cutting, resulting in accurate and consistent parts.

Material and Thickness Capability: When selecting a service provider for steel fabrication, it is crucial to consider their expertise in handling various categories of sheet metals and thicknesses. Make sure they have experience cutting the specific metal materials and thicknesses required for your project. ( You may want to know the Laser Cutting Thickness Limit for Different Materials)

Customization and Design Capabilities: Look for a service provider that offers customization options and has the ability to work with complex designs. This allows you to create unique and customized metal components that meet your specific requirements.

Turnaround Time: Evaluate the service provider’s turnaround time and their ability to meet your business project deadlines. A reliable and efficient service provider should be able to deliver the finished products within the agreed-upon timeframe.

The Benefits of Baison Laser’s Services

Baison Laser offers a range of custom metal fabrication services that cater to various industries and applications. With our expertise in custom parts manufacturing and powder coating, we provide customers with high-quality solutions tailored to our specific requirements.

- Advanced Technology: Baison Laser is a company that utilizes state-of-the-art laser cutting technology and tools for precise and efficient sheet metal cutting. This ensures high-quality results and faster turnaround times.

- Material Versatility: Baison Laser has expertise in cutting a wide range of metal materials, including stainless steel, aluminum, copper, and more. We can handle various thicknesses, allowing for versatility in project requirements.

- Customization and Design Capabilities: Baison Laser offers customization options and has the ability to work with complex designs. Our experienced team can assist in optimizing designs for efficient production and achieving desired outcomes.

- Quality Assurance: Baison Laser maintains strict quality control measures throughout the sheet metal manufacturing processes to ensure the highest level of precision and accuracy on metal surfaces. We are committed to delivering steel products that meet or exceed customer expectations, utilizing our expertise in cutting and shaping metal sheets.

- Competitive Pricing: Baison Laser offers the best prices and prompt service for custom sheet metal cutting services. We provide transparent and detailed quotes, enabling customers to make informed decisions based on their budgetary requirements.

- Timely Delivery: Baison Laser understands the importance of meeting project deadlines. We strive to deliver finished products within the agreed-upon time frame, ensuring customer satisfaction.

If you don’t have the space or equipment for sheet metal fabrication in-house, outsourcing may be the best option for your business. So why don’t you have a look at our product catalog and make an informed decision?

FAQs

How long does it typically take to complete a custom sheet metal cutting project?

The duration of a project depends on factors such as complexity, quantity, and the workload of the service provider. It is best to consult with the provider directly to get an accurate estimate.

Can I provide my own design files for custom sheet metal cutting?

Yes! Most service providers specialize in sheet metal prototyping, providing you with that personalized service and accepting design files in formats like DXF or DWG. Ensure that your files are compatible with their software before submitting them.

What materials can be used in custom sheet metal cutting?

Custom sheet metal fabrication and cutting is a process that can be performed on a wide range of materials, including stainless steel, aluminum, copper, brass, and various alloys. Consult with your service provider to determine the best material for your project.

Concluding Thoughts

This guide should equip you with a solid understanding of custom sheet metal cutting. What are your primary applications for custom cut sheet metal? Let us know in the comments. If you’re ready to take advantage of custom cutting services, explore Baison Laser’s top-tier offerings. Our team is ready to help you create the precise custom cuts your project requires.