There are factors to consider when choosing a CO2 laser cutter, and we enumerate some of the most important ones in the article. Once you make a purchase, the article will also provide maintenance tips to keep your machine running for a long time.

If you do encounter problems, we list down some of the most common issues you might encounter and how to fix them. But first, let’s understand what a CO2 laser-cutting machine is.

What Is a CO2 Laser Cutting Machine?

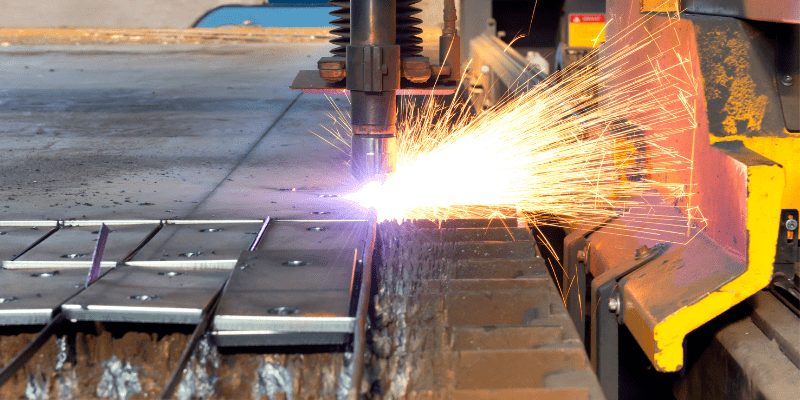

CO2 laser-cutting machines use CO2 laser technology to cut through different metal and non-metal materials using a focused laser beam.

CO2 laser-cutting machines use gas lasers which are electrically driven to cut any material. A focusing lens is used to direct the CO2 laser beam on the material to cut, engrave, or even mark it. Compressed gas also blows away any molten material on the material’s surface.

This is made possible by using either nitrogen or oxygen in the whole process. But there is a stark difference between the two – oxygen burns the material while nitrogen melts through it.

Oxygen is best for cutting thicker materials but be careful because it tends to create oxide layers on the surface. On the other hand, Nitrogen leaves the material’s surface a little dull and rough around the edges.

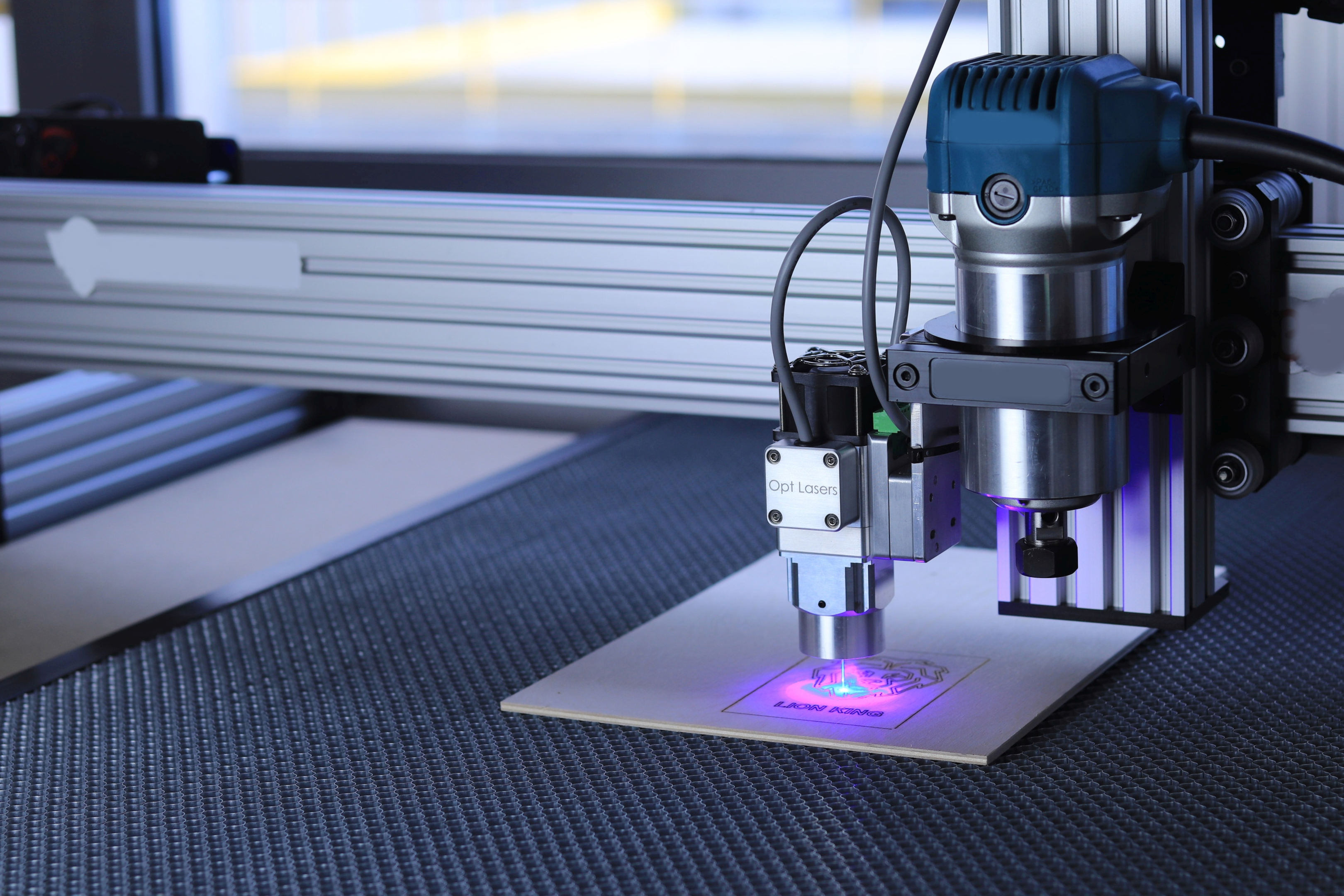

However, a laser-cutting machine remains one of the most flexible cutting tools you could ever own. You can use it not only for industrial-cutting requirements but even for a small business and some personal hobby needs.

How Does a CO2 Laser Cutting Machine Work?

A laser-cutting machine houses the CO2 laser heads to cut metal and non-metal materials. The laser cutters produce laser beams from gas-filled tubes. The electricity running through the laser head reflects through a mirror on one end of the tube and passes through another mirror on the opposite end. This is how the laser beam is guided directly on the cutting surface.

The gas mixtures inside the tubes normally consist of 4 different types of gas. Apart from carbon dioxide or CO2, the mixture can also have hydrogen, helium, and even nitrogen. You must understand that although lasers are light created by the gas mixture, this is an extremely powerful beam that can cut through metal. One reason is that the mirrors inside the tube reflect the light, allowing the beam to increase in intensity.

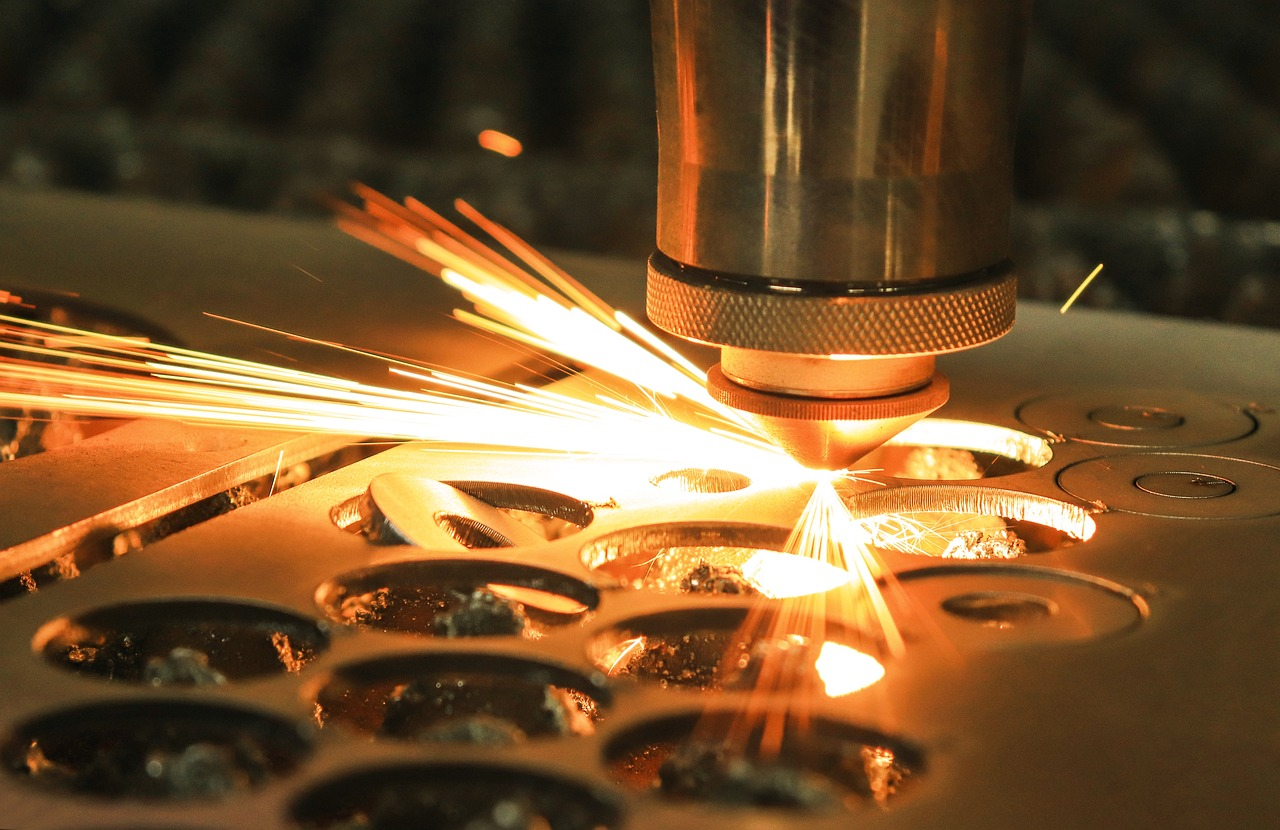

The path of the light starts from the laser head and is directed towards which becomes like resonators building up the energy of the light beam. It passes through a focusing lens as it exits, further concentrating the laser. As it goes out the nozzle of the cutting head, the laser is guided toward the surface, it has to cut, etch, or engrave.

Types of Laser Sources

The two most common types of CO2 laser sources for laser-cutting machines are glass and metal tubes. The water-cooled glass type is normally found in low to mid-type laser-cutting machines. They are usually used for machines with about 25 to 150 watts and have a shorter life span.

The Metal laser tube is commonly found in a high-end laser cutting machine with higher wattage. Although they cost as much as 20 times more than glass laser tubes, they last longer. They can sometimes work for as long as 8 years.

What Are the Benefits of Using a CO2 Laser Cutter?

A CO2 laser machine is effective in cutting materials, both metal and non-metal. Their affordability, flexibility, and use cover industrial and business needs and can also be used by hobbyists. This laser cutter is used in various industries that use leather, clothing, electronic appliances, handicrafts, and even paper products.

Here are other benefits of using a CO2 laser cutter we can look at:

1. Flexibility

You can use the same set-up of your tools for separate cutting jobs. You do not have to stop after each cut and change a lot of elements in your CO2 laser cutter. Do remember that this usually works for materials with the same thickness. It might be different when you are working with thick and thin metals.

2. Precision

CO2 laser cutting machining allows you to make precise cuts every time. This is important because it lowers the chance of doing the job several times over in trying to achieve the right cut. This saves you time and effort and retains the material’s integrity.

3. Repetition

One of the biggest advantages of CO2 laser cutters is that they allow you to repeatedly make repetitive cuts while achieving the same quality in your cuts. This helps you process batch orders for the same cut. You get peace of mind in knowing that your output will always be the same as the first cut you made.

4. Fast Cutting

CO2 lasers not only give you the same results every time, but they can accomplish cutting jobs with incredible speed. Combined with precision, you get quality cuts on all your jobs.

5. Automated Operation

Technology has made CO2 laser cutters ideal for automated operation. With minimal human supervision, you focus your manpower on other important parts of the job. But remember that machine operators still need to input data to the CO2 laser cutter computer. This guides the cutter with the correct pattern and ensures the laser stays within the bed.

6. No Friction

Every time you use a CO2 laser cutting machine, no part of the optical head contacts the material except for the laser beam itself. This means there is no mechanical friction between the cut material and the machine. As a result, your machine’s wear and tear are minimal, and you can make the most out of your CO2 laser cutter for an extended period.

7. Quality Work

You get quality workmanship when you can automate a repetitive process that yields the same results every time. One benefit of a CO2 laser cutting machine is that it makes it a constant in most industries.

8. Small Kerf

CO2 laser cutters make precise cuts that the kerf is almost negligible. This versatile tool means that you get to use a lot more of the material, all while getting precise cuts every time

If you are wondering what types of materials a CO2 laser-cutting machine can process, here are some of them worth looking into:

- Metal

- Aluminum

- Alloys

- Titanium

- Mild steel

- Wood

- Paper

- Acrylic

- Plastic

- Epoxy resin

- Stone

- Leather

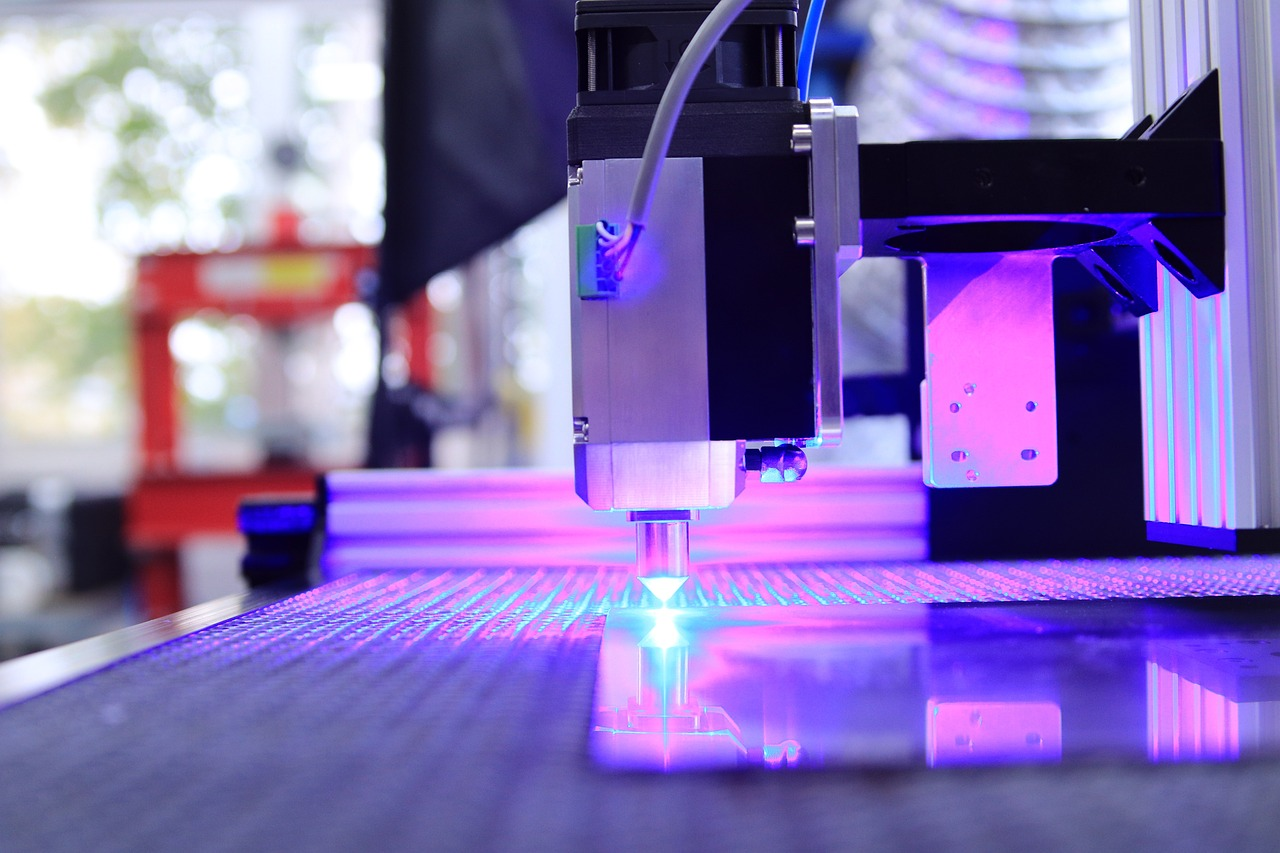

CO2 Laser Cutting VS. Fiber Laser Cutting

The two most significant differences between CO2 and fiber laser cutting are the material used to produce the laser beam to cut and the price point between the two machines. As the name suggests, CO2 uses a gas mixture and mirrors to create and focus the laser beam on the surface of the material it is cutting. Fiber laser cutters use diodes and fiber cables to create and focus the laser for cutting.

Let’s look at these points and other striking differences between a CO2 laser and a fiber laser cutter.

I. Laser Beam

As mentioned above, CO2 lasers use a mixture of gas components like carbon dioxide or CO2, hydrogen, helium, and even nitrogen. Focusing lenses or mirrors are then utilized to reflect and eventually focus the laser beam for cutting. A fiber laser cutter has diode pumps to create the laser. It focuses the beam on the laser cutting head through a fiber optic cable.

II. Material Compatibility

CO2 laser cutters can cut through metal and non-metal materials quickly and precisely. However, fiber laser cutters are more advanced technology. Its laser beams are much more powerful, making it ideal for thicker metals.

In conclusion, both can cut through, engrave, and etch metal and non-metal materials. Fiber laser cutters have an edge in better quality and cut through many types of metals.

III. Energy Savings

CO2 lasers require more energy to produce laser beams to cut through materials. On the other hand, fiber laser cutters require less energy to produce their laser beams. On top of this, fiber lasers can still produce excellent cutting power.

IV. Cost

CO2 and fiber laser cutters have an inversely proportional relationship regarding cost. For the upfront cost, CO2 laser-cutting machines are less expensive when compared to fiber laser-cutting machines.

However, when it comes to maintenance costs, the roles are reversed. CO2 laser cutter maintenance tends to be higher because of all the consumables and vulnerable parts. Fiber laser cutters have minimal maintenance costs because of fewer vulnerable parts and a higher tolerance for a harsh working environment.

V. Cutting Speed

CO2 laser cutters are fast, but since fiber laser cutters have more power, they can cut with much more efficiency and speed. Fiber lasers have the upper hand, especially with thicker metal materials.

How to Choose the Right CO2 Laser Cutter for Your Business?

You need to ask yourself two basic questions to help you choose the most appropriate CO2 laser cutting machine for your business – What materials will you mostly work with, and what is your budget for the machine?

1. Materials to Cut

This is one of the primary considerations when choosing what CO2 laser cutter is best for your business needs. The basic rule of thumb is that the thicker the metals you will cut, the higher the laser power rating you need for your machine. This will not only help you cut faster, but your cuts become more efficient as well.

2. Budget

One of the most important considerations for any business costs; is the same for CO2 laser-cutting machines. The more powerful machines would tend to cost more than entry-level models.

However, the most affordable machines might not be able to help you make quality cuts when working with thicker metals. In this case, you might need the more powerful and expensive types. Remember that Oxygen might be needed when working with high-powered CO2 laser cutters, which also increases your operational costs.

3. Laser Machines Safety

More than the type of material you will cut and your budget, you need to look at the machine’s safety rating. It is important to remember that the laser beam of a CO2 laser-cutting machine is invisible in the color spectrum. As a result, accidents could happen if the beam is not properly handled. It can burn or blind the machine operator if you are not careful. Be sure to check safety measures in the machine closely.

It can be like an automatic shut-off when the job is done or access prevention to the laser nozzle when there is an ongoing cutting job. Remember that Class III or IV machines normally require you to use Personal Protection Equipment (PPE) during operation.

4. Ease of Use

No matter how effective the CO2 laser cutter is, it will be useless if you have difficulty operating it. More than the mechanical aspects, the software to use the machine must be straightforward. This is one important factor when choosing the right CO2 laser-cutting machine for your business needs.

5 Tips for Maintaining Your CO2 Laser Cutter

Maintenance for your CO2 laser machines includes checking the mechanical parts and even the laser nozzle head. Once you decide and purchase a machine, these are just some of the factors you need to keep on top of your mind to help your CO2 laser cutter run smoothly. Let’s take a closer look at these maintenance factors.

1. Glass Laser Tubes

This is the part that houses the gas mixtures for the laser and one that would need regular maintenance or replacement. On average, some more known brands can last up to 8,000 hours of operation. Of course, you need to look at other factors like wattage and temperature to identify the lifespan of the CO2 laser glass tubes.

2. Laser Mirrors and Lenses

These are the ones that intensify and direct the laser beam out of the nozzle to cut the materials. As a result, they need to have regular cleaning. But over time, it will have some damage and even stains. You must ensure you replace your mirrors when you get to that point. Otherwise, you run the risk of declining quality in your laser cuts.

3. Fume Extraction Units

This is an important component of CO2 laser machines. It helps extract particulates and fumes inside the laser chamber and returns clean air. When you have this, make sure that you regularly check, clean, and replace the filter.

4. Water Chiller

Glass laser tubes need a chiller or water cooler to manage high temperatures. This is one component you need to maintain regularly.

5. Air Assist

A parallel blast of air comes out with the laser to help ensure that the material’s surface remains particulate-free. It also helps keep the lens clear and work for longer. This is free of any blockage to ensure it works properly.

Common Problems with CO2 Lasers and How to Solve Them

Some common problems with a CO2 laser machine are that it does not emit light or stops working. When this happens, you must check the ammeter reading to know if the machine is working properly. Replacing or resting the breaker sometimes helps if the machine suddenly stops working.

Here are some other common problems and the appropriate steps you can take to solve them:

I. The Machine Is not Working After Being Turned on

When this happens, you can check the power supply to ensure there is power in the machine. The electrical components or motherboard might be affected in more severe cases. You need to call professionals to help you fix this issue.

II. Engraving Depth Is Different From the Design

The most common culprit when this happens with a laser cutter is loose screws in the machine. When you find one, tighten them down. The laser beam’s alignment could also be a factor and might need some alignment. The focusing lens could also be dirty and easily remedied with a clean cloth.

III. Software Glitches

There might be times when the software component might encounter some issues. The first thing to check is if the software settings are appropriate for the material you are working on. If that does not work, turning the machine off and then on again usually restarts the software. Re-installing the CO2 laser cutting machine operating system could be explored for more serious incidents.

IV. Broken Mirrors or Lenses

Replacement is the only solution when this happens. It is a good idea always to have spare mirrors or lenses in your shop, so you only have minimal downtime in production.

Conclusion

CO2 laser cutting machines are widely used in various industries to enable them to cut through different types of materials. Although this is used mostly for cutting metal components, this laser machine can also be used for laser engraving and even etching different types of materials. This flexibility is one of the reasons why a CO2 laser-cutting machine is in demand.

The Only Thing You Need to Do Now!

Now that you know the great value of having a CO2 laser cutting machine for your business, the next logical step is to talk to experts and get tech support. We at Baison Laser can help you choose the best CO2 laser cutting machine for your business. Get in contact with us now!