Common Mistakes to Avoid When Buying a Tube Laser Cutter

Looking to invest in a tube laser cutter that truly fits your production needs? Choosing the appropriate tube laser cutter can make or break your manufacturing process. We’ve seen how the correct equipment benefits businesses. While the wrong option causes delays and hidden costs. Using real-world examples, this comprehensive guide will highlight common mistakes and how to avoid them.

Mistake 1 – Not Defining Your Specific Cutting Requirements

One of the most common mistakes when buying a tube laser cutter is underestimating its actual cutting requirements. Every laser tube cutting machine has restrictions; knowing yours is important. Begin by considering the materials you’ll be working with.

Will the material be carbon steel, stainless steel, aluminum alloy, or something else? Different laser machines treat these materials differently.

Next, consider the tube shapes: round, rectangular, oval, L-profile, or square tubes. Check that the machine can handle the complex shapes and intricate designs with the required wall thickness and cutting length.

Finally, consider whether you will be cutting individual pieces or performing batch manufacturing. To avoid future bottlenecks, choose the proper machine for your production goals.

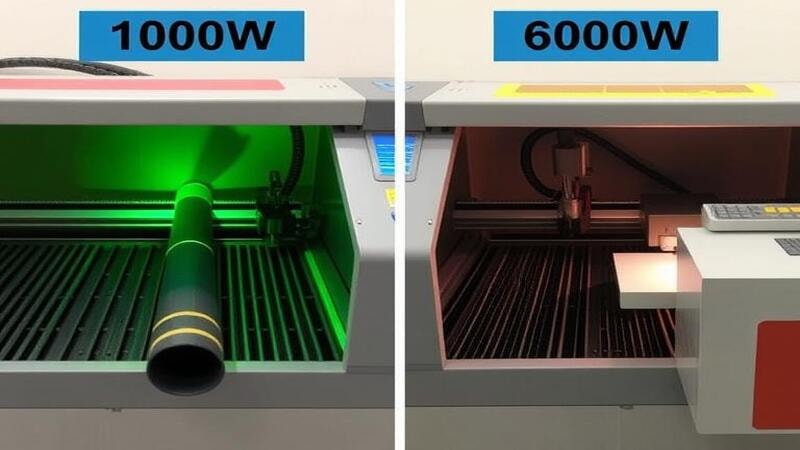

Mistake 2 – Choosing the Wrong Laser Power and Cutting Capacity

Buying in haste without complete understanding leads to purchasing a machine with the wrong laser power. It is the most costly mistake you can make. The machine’s wattage directly impacts the material you can cut. It also impacts the speed of the cutting process.

For example, a 1000W laser can handle thin-walled tubes. But it will struggle with thicker materials. Whereas, a 3000W or 6000W laser can easily cut thicker tubes at higher speeds.

Power efficiency is another important factor to be considered while purchasing. Some sturdy materials like aluminum and copper require higher power lasers to achieve clean cuts. Hence, it is important to choose a machine that balances power with energy use to get the most out of your investment.

Mistake 3 – Ignoring Automation and Smart Features

Cutting power is not the only thing that matters in tube laser cutting machines. While purchasing, you have to focus on automation as well. The smart features are the ones that reduce manual handling and often offer greater precision.

Modern tube laser cutters offer auto-feeders and automatic loading/unloading systems. These systems save time and reduce manual work. CNC laser cutting controls combined with smart task management help streamline the process.

Moreover, don’t forget the nesting software for optimized material use. It helps reduce material wastage, thus improving cost efficiency. With the help of these advanced features, you can meet your production requirements ahead of time.

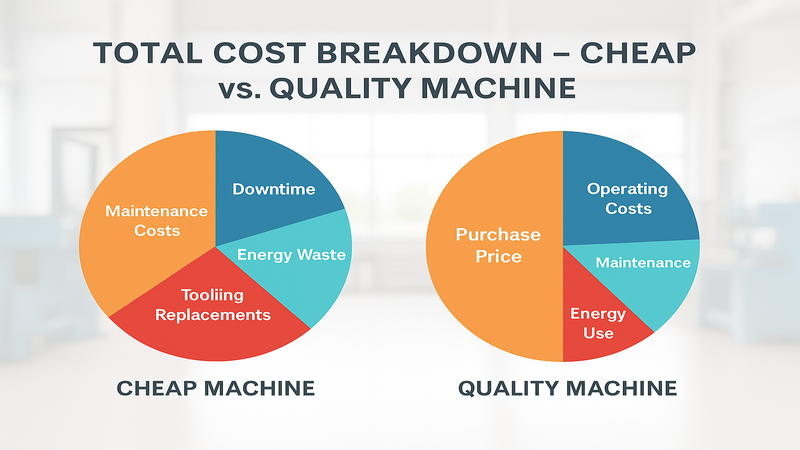

Mistake 4 – Focusing Only on Price, Not Total Cost of Ownership

It’s tempting to choose the cheapest machine, but that can backfire fast. A low upfront price often means higher costs down the road. Learn about the general cost of tube lasers before you make any decision.

Think about regular maintenance needs, spare parts availability, energy consumption, and operator labor. A cheaper machine may require frequent repairs or cause more material waste, raising your operating costs.

For example, spending $20,000 more on a quality machine could save thousands each year in downtime and scrap. Hence, it pays for itself within a few years. Always look at the total cost of ownership, not just the sticker price.

Mistake 5 – Overlooking Machine Stability and Build Quality

The machine build is one of the key factors that impact cutting results. A machine with high intensity laser beam and a suitable laser cutter might seem fit for all functions. But a solid frame and vibration resistance are key considerations for precise cuts.

Some machine manufacturers skimp on the build material or conveyor systems. It is your job to stay vigilant. Always look for machines with thick steel plates, a sturdy gantry, and reliable guide rail brands.

Investing in a suitable machine with high quality components means lower maintenance costs and no need for replacement parts.

Mistake 6 – Not Considering Material Handling and Fixturing Requirements

Most businesses fail to consider how they will manage materials, which might cause major complications. The tube dimensions determine the type of loading mechanism you’ll use.

Automatic chucking systems and bundle loaders can help you process longer or heavier tubes more safely and quickly. Rollers and conveyor systems also aid in supporting pipes during cutting. Thus, preventing them from bending or sagging, which can result in incorrect cuts.

Neglecting handling and fixturing creates unsafe situations, poor precision, and slows production flow.

Mistake 7 – Underestimating After-Sales Support and Technical Service

A powerful machine means little without solid after sales service. Often, companies forget to ask about installation, operator training, and warranty coverage. These services are crucial to getting the most out of your investment.

Make sure the vendor has easy access to spare parts and a dependable local service network. Rapid response times avoid costly downtime. The correct support allows you to keep production operating smoothly.

Mistake 8 – Not Evaluating Software Compatibility and Ease of Use

Laser technology is not new to the market. But it is possible that the laser tube cutter you end up buying is not compatible with your software. Overlooking this feature can lead to frustration and loss of productivity.

Ensure the control system (TubePro or CypCut) has an intuitive interface. So that your team can learn to control the laser beam easily. Furthermore, ensure that the supports common file systems like DF and STEP.

Also, consider how easily operators can scale from basic tasks to advanced jobs. The right software saves time and reduces errors at every stage.

Mistake 9 – Ignoring Factory Space, Power, and Setup Requirements

It is easy to overlook the readiness of your facility to house a new laser tube cutting machine. Before you make the purchase, compare the available floor space to the machine footprint. Also, remember to leave some extra space for machine loading, unloading, and maintenance.

It is extremely important to verify your power supply. The high cutting speed of the tube laser cutting machine might increase your power needs. Your space should also be prepped with safety features such as air compressors and exhaust systems. These are especially required in heat affected zones.

Proper pre-installation planning avoids costly delays and ensures a smooth start-up.

Mistake 10 – Not Planning for Future Scalability

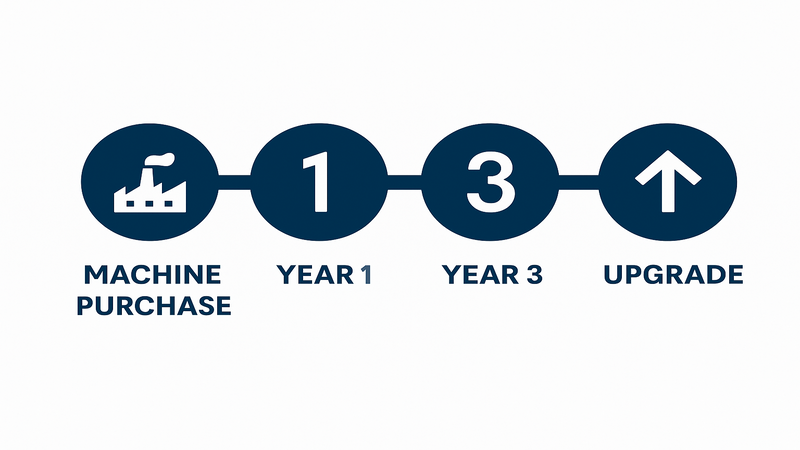

It’s easy to buy for today’s needs and forget about tomorrow’s growth. When choosing a tube laser cutter, check if the machine allows upgrades. The upgrades can include multiple laser head options or automation add-ons.

Consider whether the system can handle non-metallic materials as your product line evolves. It also helps to ask the vendor about their technology roadmap and the machine’s expected lifecycle. So your investment stays relevant as your business scales.

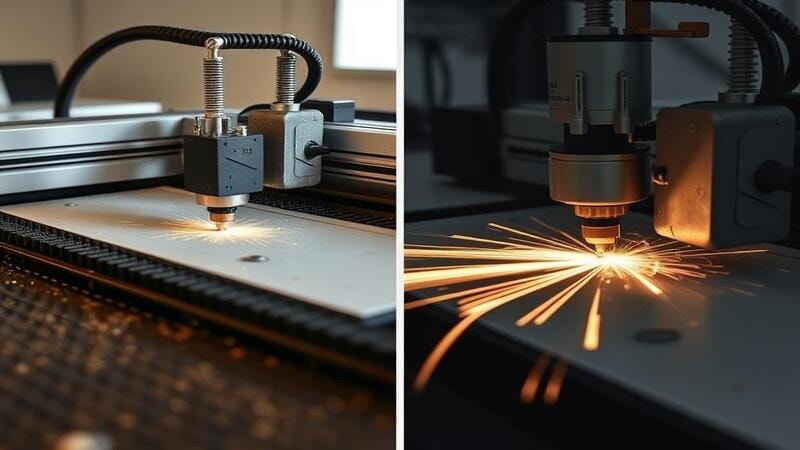

Mistake 11 – Buying Without a Demo or Industry Case Study

Laser tube cutting machines have applications in various industries. However, it is important to check which option (fiber laser or CO2 laser) offers high precision cuts for your products.

You can ask for a live demo or a recorded cutting session. It is ideal if the demo is created using both thick and thin materials. However, you can ask for a demo with your specific materials and profiles to ensure unparalleled precision.

Ask the vendor for reference customers in your industry. Review their results carefully: focus on edge quality, tolerances, and cutting speed. Remember, you can always start with one machine and scale up if you need more.

How to Choose the Right Tube Laser Cutter – Quick Decision Checklist

Before you decide, ask yourself and your seller the following crucial questions:

- What materials, shapes, and thicknesses will I cut most frequently?

- Does the machine’s laser power meet my cutting requirements?

- What automation and smart features are available?

- What is the true cost of ownership, beyond the sticker tag?

- How sturdy is the machine’s frame and build quality?

- Can it handle my materials’ lengths and weights safely?

- What after-sales support and service network is available?

- Is the software user-friendly and compatible with the file formats I use?

- Does my industrial space and power supply meet the installation requirements?

- Can the machine grow alongside my business in the future?

- Is there a live demonstration available or referenced industry case studies?

Final Thoughts – Avoiding Mistakes for Long-Term Success

Choosing the best tube laser cutter is a long-term investment in your productivity and growth. A suitable machine allows you to cut more efficiently, eliminate waste, and remain competitive for years to come.

Our team is here to help you navigate the process. We’ll help you assess your requirements, offer the finest alternatives, and avoid the costly pitfalls discussed in this guide.

Achieve Precision and Efficiency with Baison Laser

At Baison Laser, we specialize in providing manufacturers like yourself with reliable, high-quality laser cutting solutions that match your exact needs. Whether you are a first-time buyer or an experienced operations scaling up, we’re ready to support your success. With customer satisfaction at our core, we will ensure we answer all your queries.

Explore what’s possible, visit our website, or contact us to schedule a consultation or request a quote.