In the ever-evolving world of manufacturing and metalworking, tube laser cutting has emerged as a revolutionary technology, offering unparalleled precision and efficiency. Whether you’re a seasoned professional or a newcomer, understanding the intricacies of tube laser cutting is essential for optimizing production processes and growing your business.

In this guide, we’ll explore the fundamentals of laser cutting, its benefits, and its contribution to modern manufacturing industries.

What is Laser Tube Cutting?

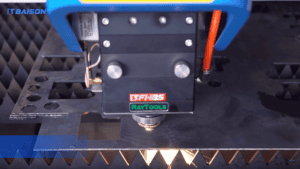

Laser tube cutting is a tube and pipe processing technique that uses a high-power laser beam to cut materials accurately. A computer numerically controlled (CNC) system precisely moves the laser head across the material surface.

Although tube laser cutting is primarily used for metal tube processing, it can also be deployed for plastic cutting applications.

How Does Tube Laser Cutting Work?

Tube laser cutting machines follow the same basic operating procedures as other CNC laser cutters.

The tube is positioned perpendicular to the laser head, with the cutting end clamped down in a rotating chuck.

A chuck is a rotating clamp that holds the tube end in place and rotates it as needed. Rotating the tube is much easier than having the laser head move in a circular path around the tube.

Next, the laser contacts the tube surface, cutting the material along a set path.

The chuck rotates the tube, and a motor at the back pushes it forward as needed. Most tube laser cutters will have three axes of motion. The laser stays mostly stationary, only moving up and down, while the tube can rotate and move back and forth.

Benefits of Laser Tube Cutting

The advantages of laser-cutting machines cannot be understated. Here are a few of the biggest benefits tube laser cutting brings to your business.

1. Precision & Accuracy

Tube laser cutting is more precise and accurate due to the CNC systems that manage the position of the laser head.

Accuracy is cutting parts as close to the desired dimensions as possible. Tube laser cutting involves a high-power laser concentrated at a small point (measured as spot diameter) on the material surface. The smaller spot diameter and the stability of CNC systems allow tube laser cutters to hold tight tolerances.

Precision is the ability to replicate the same accuracy for all cuts. CNC systems can repeat the same motion with extreme precision, making them a vital part of laser cutting.

2. Versatility & Flexibility

Traditional tube cutting is restrictive and often lacks fine control, which is necessary for complex designs. Laser tube cutting can make small, accurate cuts in the material, making it much more versatile than competing solutions.

Lasers also excel at cutting through wall thicknesses of 1 inch (25.4mm) or greater without warping or deforming the material. Through holes is one of the biggest challenges for any cutting technology, as the edges of the hole can easily melt and deform. Lasers can easily cut through holes in thick metals without excess heat radiating to the edges.

3. Faster Cutting Speed

Traditional or manual tube-cutting techniques are inherently slow because of human involvement. A person requires concentration to keep the cuts accurate and resting time after handling heavy cutting machinery.

Human operators have to prioritize one attribute: accuracy or speed. By comparison, lasers can maintain speed and accuracy for hours without a break. A laser-cutting machine can operate indefinitely if its cooling requirements are maintained.

4. Zero Material Waste

Accidents or small mistakes during cutting can ruin the entire tube design, resulting in material waste. Laser tube cutting reduces material waste as mistakes are rarely made during the cutting process.

Minimal material waste and high cutting speed can help businesses achieve maximum productivity.

5. Zero Tool Wear

Mechanical tube-cutting technology, such as grinders, electric saws, and hydraulic blades, will wear after repeatedly rubbing against metal workpieces. Laser tube cutting is a no-contact process where tool wear is a non-issue.

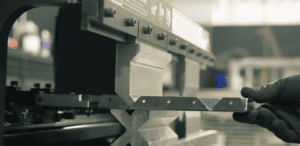

6. Smoother Finish

The smoothness of a cut depends on the sharpness of the tool and the heat generated during processing. Excess heat causes the edges to melt and deform, resulting in a poorer finish.

The smaller spot diameter of the laser beam ensures minimum heat is input into the material. Additionally, lasers don’t experience tool wear, so sharpness is not a factor.

Laser Beams for Tube Cutting

Tube laser tube cutting services are primarily divided into two categories.

Fiber Lasers

Fiber laser technology uses compact diodes to pump light into optic fibers for light amplification. As a result, fiber lasers are several times smaller than their CO2 counterparts. Fiber laser systems also have high energy efficiency, converting most electricity from the wall into laser heat output.

Fiber laser cutters have a smaller spot (beam) diameter, allowing for greater precision and depth penetration while maintaining good accuracy.

CO2 Laser Beams

CO2 lasers are generated using a large gas-filled glass chamber with a high electric current. The simpler design of gas laser systems allows them to produce high-power laser beams by consuming lots of electricity.

Gas lasers have a lower initial cost, making them an attractive option for most small businesses. However, the glass chamber has a shorter lifespan, thus increasing replacement and maintenance costs.

| Situation | Fiber Laser | CO2 Laser |

|---|---|---|

| Cutting Sheet Metal | Higher Compatibility | Lower Compatibility |

| Engraving Metals | Higher Compatibility | Lower Compatibility |

| Cutting Non-Metals | Good Compatibility | Good Compatibility |

| Cutting Rough Surfaces | Incompatible | Higher Compatibility |

| Cutting Speed | Faster for Thinner (<8mm) Materials | Faster for Thicker Materials |

| Energy Consumption | Lower | Higher |

| Energy Efficiency | >40% | 10-15% |

| Operation Cost | Lower | Higher |

| Initial Purchase Cost | Higher | Lower |

| Maintenance Cost | Lower | Higher |

| Space Efficiency | Higher | Lower |

| Gain Medium Life Span | Optic FibersOver 100,000 hours | Gas Chamber 2,000 to 10,000 hours |

Materials Suitable for Laser Tube Cutting

Laser-cutting machines can manage a wide range of materials. Everything from tough tungsten to soft acrylic melts under a laser’s power.

Laser tube cutting has an extensive range of materials available for processing. Tubes made of metals, plastics, wood, and even paper can be precisely cut and shaped using laser technology.

Metals and Alloy Compatibility

Aluminum

Brass

Copper

Stainless Steel

Titanium

Nickel & Chrome Plated Metals

Alloys of Al, Cu, Fe, Ti, etc.

Non-Metal Compatibility

Plastic materials are widely used in pipe manufacturing and the plumbing industry.

Wood tubes are a less common item, mostly used in furniture work.

Cardboard tubes are low-cost support structures for toilet paper and kitchen towels.

Thickness and Size Limitations

Laser tube cutting capabilities are primarily determined by machine size and laser configuration. The following are the technology’s general thickness and size limits.

Maximum Cutting Length – 60 inches (18m)

Maximum Tube Diameter – 24 inches (610mm)

Maximum Wall Thickness – 1 inch (25.4mm)

Most commercially available tube laser cutting machines only possess half of the above-mentioned capabilities.

Tube Laser Applications and Industries

Laser tube cutting services have become standard across many industries. The precision and accuracy of laser-cut parts are highly valued in high-performance applications.

1. Aerospace Industry

The aerospace industry requires precision-cut tubes for fuel and oxygen delivery systems.

2. Furniture Construction

Wood tubes are commonly used but not limited to furniture edging, and metal tubes are often used for furniture legs.

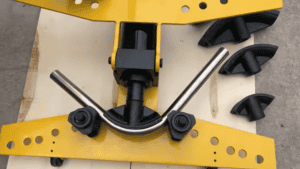

3. Sports Equipment

All sports equipment uses metal tubes and pipes for structural support. Laser tube cutting services are used to manufacture bike frames, golf equipment, hockey sticks, and more.

4. Construction Industry

Tube laser cutting machines are mostly used for processing round and square metal tubes. However, the construction industry also uses these machines to cut structural shapes such as I-beams, angle bars, and U-channels.

5. Electronic Devices

Tube laser cutting technology processes copper and aluminum cooling solutions for electronics. Heat sinks used in computer systems require precision-cut tubes with holes for efficient heat transfer.

6. Medical Equipment

The medical industry requires precision-cut metal tubes and pipes for various instruments such as ventilators, dialysis machines, and oxygen delivery lines.

| Industry | Application | Desired Attribute |

|---|---|---|

| Aerospace | Fuel, oxygen, and other delivery systems. | Tight Tolerances |

| Furniture | Edging and table legs. | Fast Production |

| Sports | Sports-specific frames. | Cost Savings |

| Construction | Cutting pipes and structural shapes. | Cost Savings |

| Electronics | Tubes for heat sinks and cooling systems. | Precision & Accuracy |

| Medical | Sensitive medical instruments, including ventilators and dialysis machines. | Precision & Accuracy |

5 Steps to Choosing the Right Laser Tube Cutting Machine for Your Needs

Choosing the right tube laser cutters is about knowing your needs and getting a matching machine. Always keep these five steps in mind when buying laser tube-cutting machines.

Material Choice – Your required material choice will determine your laser type (Fiber/CO2).

Tube Dimensions – Machine work bed and chuck size determine the maximum supported tube length and diameter.

Laser Power – Laser power determines the cutting speed and depth penetration.

Machine Tolerance – Tolerance or cutting accuracy determines the difference in size between the laser cut part and input dimensions.

Degree of Freedom (DOF) – Machine DOF (number of axes of motion) determines the motion and versatility of a laser cutter. Higher axis machines cost significantly more.

3 Valuable Tips for Getting Started with Laser Tube Cutting

Here are a few important lessons for beginners jumping into the complex world of tube laser cutting.

Focus on Producing Finished Parts

Businesses moving from traditional mechanical tools to laser cutters should focus on producing finished parts directly on the machine. Traditional cutting tools necessitated post-processing techniques like deburring, polishing, and sanding.

However, laser tube cutting can produce a finished part that requires little to no cleanup. You should account for the increased production rate when moving to laser cutting.

Add Capacity to Your Shop with In-House Tube Lasers

Investment in a tube laser cutting system is less about cost efficiency and more about production capacity. Automated laser tube cutting is ideal for large-volume productions.

Laser cutters offer more versatility in production, allowing you to make more complex cuts with unmatched speed and precision.

Expect a Slightly Longer Return on Investment Period

Return on investment (ROI) occurs when a business recovers its initial investment in new equipment. Generally, ROI should be around 1-2 years. In certain conditions, it may be much longer.

The following factors affect your ROI.

Number of laser cutters bought.

Hidden costs like installation and shipping costs.

The worker training period is not included in ROI calculations.

Industrial competition from other businesses.

Conclusion

Laser tube cutting is a highly precise process with extensive benefits in high-performance industrial applications. Advancements in laser technology have significantly increased the productivity of tube laser cutters and decreased the entry price. Businesses today have a lot to gain by shifting to laser-based tube cutting. Benefits like increased production speed and smoother finish are highly valuable in high-volume productions. A laser tube cutting machine is a piece and an investment into the future growth of your shop or facility.

Cut Through the Competition with Baison Laser Cutters!

At Baison, we are dedicated to providing high-quality, durable laser tube cutters that enhance precision and efficiency in your production process. Discover the unparalleled advantages of tube laser cutting with our top-of-the-line machines.

Our decades of experience, research, and dedication have paved our ascent to the top of the fiber laser manufacturing mountain. To maximize your investment, benefit from our comprehensive Free Application Evaluation and Free Customer Training Programs.

Stay ahead of the competition and elevate your operations today. Contact us Now!