In this article, you’ll learn how to identify and calculate the energy that your laser-powered cutter will consume. You’ll get different examples and comparisons so you can determine the power wattage that’ll be added to your electric bill.

Factors Affect the Electrical Consumption of Laser Machine

There are many factors affecting the way laser-powered cutting machines consume energy. Understanding these factors will help you determine how much it’ll cost you in your monthly electricity bill. Not only that, if you want to be more energy-efficient, you can use these factors to understand how you can minimize your carbon footprint.

Let’s go through the 3 factors that influence the laser cutting equipment’s consumption of power.

1. Type of Laser Cutting Machine

Research has shown the need to create more than one type of laser-powered cutter to make manufacturers more energy-efficient and sustainable. Getting to know these machines will give you an idea of how they differ in terms of the maximum laser power that they provide.

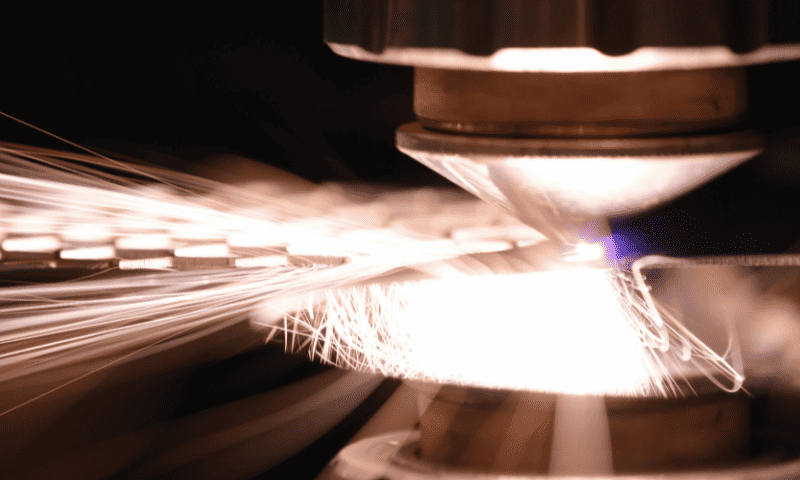

- A CO2 laser uses a mix of CO2 (carbon dioxide), N2 (nitrogen), and He (Helium) to produce a strong laser beam that can cut through materials.

- A fiber laser uses optical fibers along the laser tubes to induce laser energy towards a specific point to cut materials.

- A diode laser uses a semiconductor junction (usually made of GaAs or gallium arsenide) to generate powerful laser light for cutting.

- An infrared laser has two varieties. One uses Nd: YAG lasers equipped with yttrium aluminum garnet crystals. Another uses Nd: YVO lasers equipped with yttrium vanadate crystals. Both crystals have neodymium ions added to them.

Just like dealing with various motor types, these machines produce laser beams differently so the way they consume energy will also differ. For example, fiber laser cutting machines are said to be more energy-efficient so they consume less power compared to a CO2 laser machine.

The peripheral equipment associated with the machine should also be considered. Most laser-powered cutters require a cooling unit or exhaust system. This is another system that’ll add to the consumption of energy. Later on, you’ll learn more about what these add-on equipment are and how they affect the consumption of energy of laser-powered machines.

2. Working Time

The operation time also affects how much power the laser cutting equipment consumes. This is why when you’re calculating it, you have to consider the watt per hour of use.

Here’s an example. Diode lasers have a lower optical power compared to other laser-cutting equipment. While that would mean it consumes less energy, it also means you need more passes to complete a cut. That requires a longer working time. This could result in a higher electrical consumption compared to a fiber laser that has a higher optical power.

We have a more comprehensive comparison of fiber lasers and diode lasers for you, click here to see it.

You should also consider that the standby mode of laser cutting equipment consumes energy as well. Even if you’re not using the machine, as long as it’s still on, it consumes electricity. Fortunately, some machines are equipped with energy-saving features that use minimal power when left on standby.

3. Type of Usage

The engraving or cutting process will consume different amounts of energy. The power of the laser beam will be different. Generally, the cutting will take more energy compared to just engraving.

When you engrave a design, you don’t need maximum power to cut through the material. You just need enough to put a dent in the surface to make the design recognizable.

Of course, the material will also be a factor to consider. The type and thickness of the material will also come into play. This will be discussed in detail later on in the article.

Energy Consumption of Different Machine Components

Earlier, peripheral equipment was mentioned. The power requirement of each piece of equipment contributes to the consumption of energy in the overall cutting process. Laser cutters require specific add-ons such as cooling systems, air compressors, fume extractors, etc.

When each of the power consuming accessories is also recognized, it’ll give you a better idea of how much the laser system will affect your electrical bill.

- Servo motors: The stepper or servo motors are used to control the movement of the laser as it follows the design that’s required. While their energy use is notable, it’s generally efficient, especially in modern machines.

- Reducers: These play a vital role in stabilizing high-powered servo monitors. It also amplifies the torque to result in a more precise cutting or engraving. Their energy consumption is typically low and is embedded in the overall consumption of the motion control system.

- CNC system: This is the controller box that guides the operating system of the laser equipment as it does the work. It controls the output and makes sure there’s accuracy in the delivery of the design.

- Air compressors: Although these are required in laser-powered cutters, the sizes and consumption of energy will vary. Air compressors may be bigger or smaller depending on the machine pressure requirement.

- Chiller: This is the cooling unit of the system. It’s responsible for cooling the source of the laser so it doesn’t overheat and compromise the rest of the machine. High-power lasers can be large energy consumers.

- Fume extractor: This acts as the exhaust of the machine. It involves airflow and filtration – making sure the operational sustainability isn’t compromised.

How Much Power Do Laser Cutting Machines Consume?

Understanding the cost associated with the use of laser-powered cutters is vital for efficient budgeting and flow of operations. You have to consider the fact that a fiber laser-powered machine would consume energy differently compared to CO2 laser-powered ones. It’s best to consult the manual of the machine to get actual data for when you make your calculations.

While the variations should be considered, the general formula that you can use is as follows:

Daily Cost = Power in kW × Operating Hours × Cost per kWh

If you want to know the power consumption per hour, let’s take a look at the consumption in kilowatt hours based on the following examples.

Imagine a 20kW laser-powered cutting machine. If it operates for 8 hours a day and the electricity costs $0.12 for every kWh, you’d think that the computation would be to multiply all 3 values. That would make the daily cost computation look like the following:

Daily Cost = 20kW × 8 × $0.12

But before you proceed with the calculator, you need to guarantee that the consumption of power is only 20kW. Even if the cutting machine label says that it’s 20kW, that’s not the only thing that consumes power. Remember, other components use energy while you’re cutting materials using the laser-powered machine.

So let’s assume that the servo motors, CNC system, and reducers consume 5kW. The chiller consumes 7kW. The fume extractor consumes 3kW. The total power usage would be 35kW.

The daily cost calculation would be as follows:

Daily Cost = 35kW × 8 × $0.12

Daily Cost = $33.6

But that’s just an estimate. You also have to consider the standby mode of the machine. After all, when the cutter operates for 8 hours, that doesn’t mean it’s running on full power the whole it. Standby mode stays on standby mode. This consumes less energy compared to when it’s cutting materials.

How Do Materials Affect Laser Cutter Electrical Consumption?

The electrical consumption of lasers varies with the material being cut. After all, the material affects the cutting time and speed and therefore the power consumed. That’s why when you calculate the power consumed by these cutters, you have to consider several factors.

1. Type of Material

Different materials have varying levels of laser absorption. Some materials are harder to cut compared to others.

Steel is considered to be one of the hardest metals to cut. Compared to copper or aluminum, it’ll take a longer time to cut and will naturally consume more power. You might even have to turn the power up to full capacity to get the job done.

2. Size And Thickness

Apart from the type of material, you should also consider the size and thickness that’s being cut. A 3-inch sheet of steel will take longer to cut compared to a 1-inch thick sheet. You might also have to turn up the capacity to get the cutting depth that you need.

3. Reflectivity

Highly reflective materials, like some metals, can reflect a portion of the laser energy away, reducing cutting efficiency. The laser may need to operate at higher power or for longer durations to achieve the desired cut, thereby increasing energy consumption.

4. Thermal Conductivity

Materials with high thermal conductivity (such as copper) dissipate heat quickly. This trait requires the laser to use more energy to maintain the necessary temperature at the cutting point, leading to higher electrical consumption compared to materials with lower thermal conductivity.

Comparing the Power Consumption in Different Cutting Machines

It’s not enough to want to know how much power a cutting machine consumes. You’ll also need to compare it with other cutting machines so you can determine if it’s valuable or not.

Some people doubt that a laser is often expensive compared to other machines. In some aspects, this is true. When you buy a laser-powered cutter, it’s more expensive compared to plasma or oxy-fuel cutters. But if you take into consideration the cutting quality and the speed by which it cuts into materials, you’ll see that laser powered cutters bring the best value for your money.

Of course, the cost to acquire the machine is different from the operational cost.

How Much Electricity Does Each Laser Cutting Machine Consume?

To determine how much electricity a laser machine consumes, take a look at the table below to compare it with others.

| Cutting Machine | Energy Source | Power Consumption | Speed | Cutting Quality | Operation Cost |

| Laser Cutter | Laser beam | High | Fast | Excellent | High |

| Plasma Cutter | High-velocity Ionized gas | Low | Fast | Average | Low |

| Waterjet Cutter | High-pressure water | High | Very slow | Excellent | High |

| Oxy-fuel Gas Cutter | Flame torch | Low | Slow | Poor | High |

| Mechanical Cutter | Mechanical force | Low | Slow | Poor | Low |

Given this table, you can see that although the operation cost of lasers is higher, the quality makes it worth it. You’ll save time in cutting several materials because the speed of cutting is also quite fast. Overall, it makes lasers more energy-efficient and effective in providing high-quality cuts.

FAQs

Understanding laser-powered cutters and how they consume energy will give you better ideas as you optimize your operations to produce high-quality products. Here are the common questions asked about these cutters.

1. Why Do Laser Cutters Consume Energy Differently?

The consumption of power is different because of several factors. One is the laser source. One type of laser cutting machine may consume more than another depending on how the laser beam is produced.

You also need to check the details like the machine configuration, cutting parameters, and the materials that it’ll be used for. These will give you an idea of the electrical consumption of the specific cutter you want to use.

2. What Energy-Efficient Features Can Reduce the Electrical Consumption of Laser Cutting Machines?

There are modern laser-powered machines that have been incorporated with energy-efficient features to minimize their consumption of energy. This includes energy recovery systems, smart power management, pulse lasers, etc.

Get to know the new ways to optimize the power of lasers before you choose the machine that you’ll use in your operations.

3. What Practices Optimize the Performance And Power Consumption of a Laser Machine?

For one, you can conduct regular maintenance of the machine to ensure all the parts are working properly. Second, proper training is also a must for machine operators so they’ll know how to calibrate it well. Finally, talk to the manufacturer so you can implement the right practices that will increase the life span of the machine.

Conclusion

Learning how to calculate the consumption of energy of a laser-powered cutting machine will allow you to be sustainable, stick to your operational budget, and keep your overhead costs manageable. It’ll also help you maximize the use of the machine to create premium cuts for your projects.

Understanding the electrical consumption takes more than just knowing the power supply or wattage used by the machine. It’s also about knowing the power requirement of the whole project so you can consider all aspects of computing the total running costs.

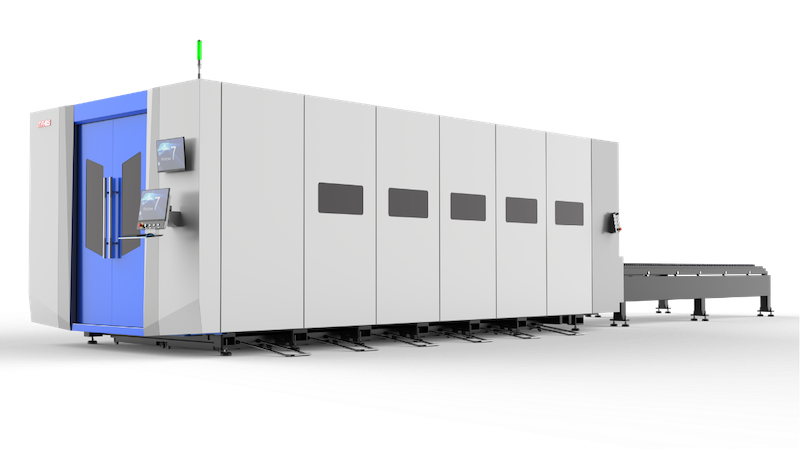

Choose Energy Efficient Laser Cutting Machines From Baison!

If you need expert advice before purchasing a laser machine, get in touch with Baison Laser. Our main products are laser-powered cutters that can cut through brass, aluminum, stainless steel, and carbon steel – among others. We can provide you with comprehensive information about each of them. We’ll help you make informed decisions so you can meet your specific cutting requirements.

Contact us so we can talk more about your requirements. We can give you a free application evaluation.