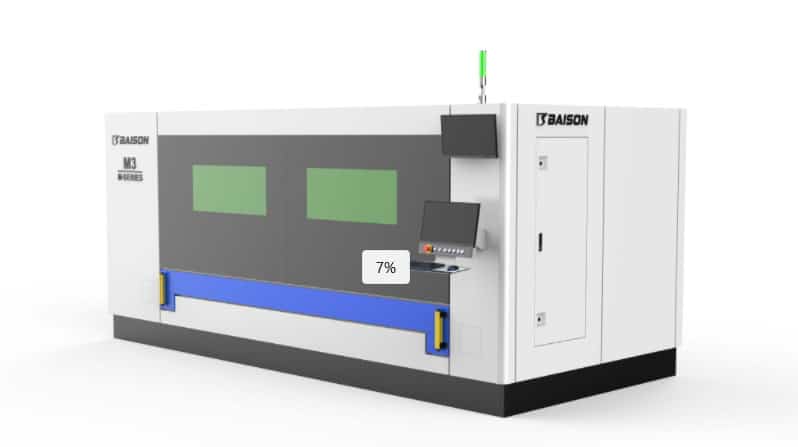

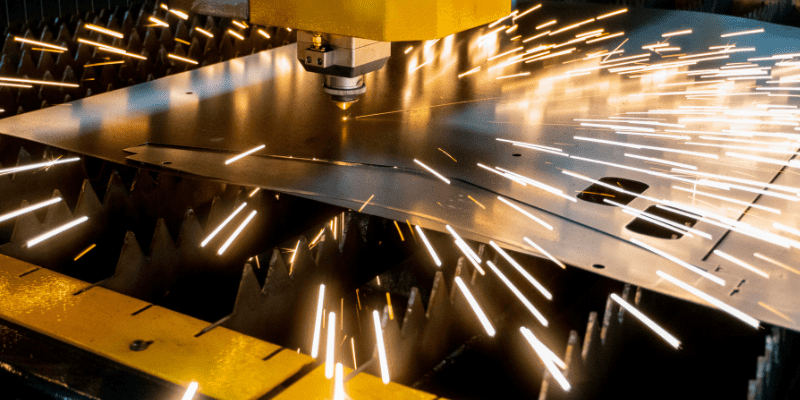

Small format laser cutting machine

Small-format laser cutting machines are easy to operate and can cut a variety of complex graphics. The machine occupies a small area and is easy to store and transport. It is very suitable for most factory workshops.

Sheet Metal Laser Cutting Machine

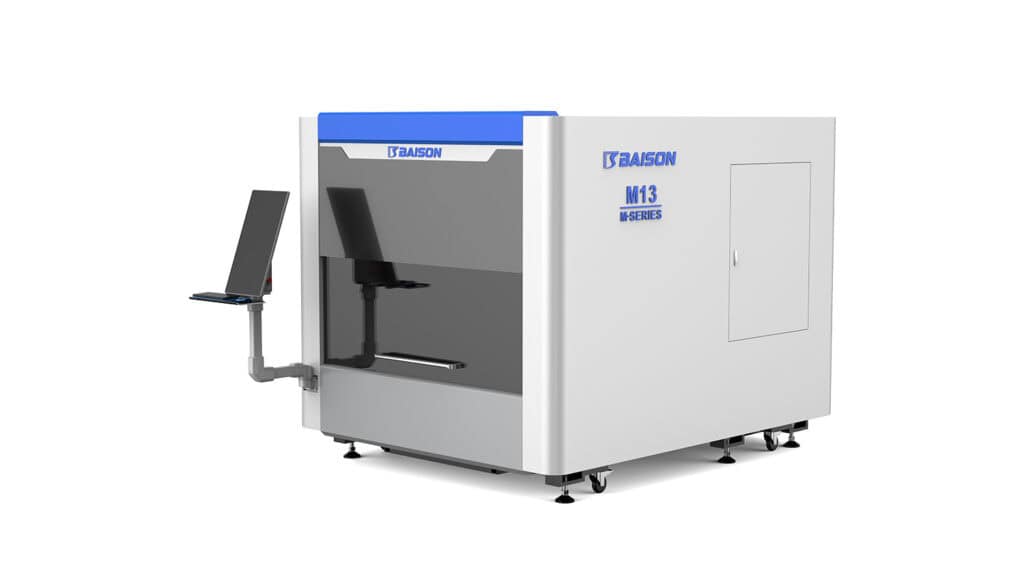

M Series

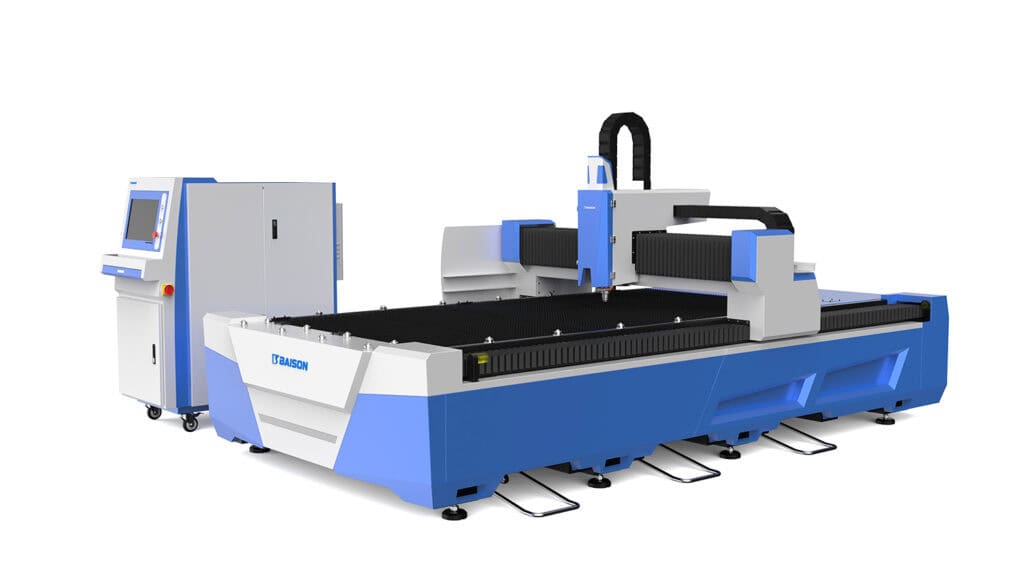

EC Series

E Series

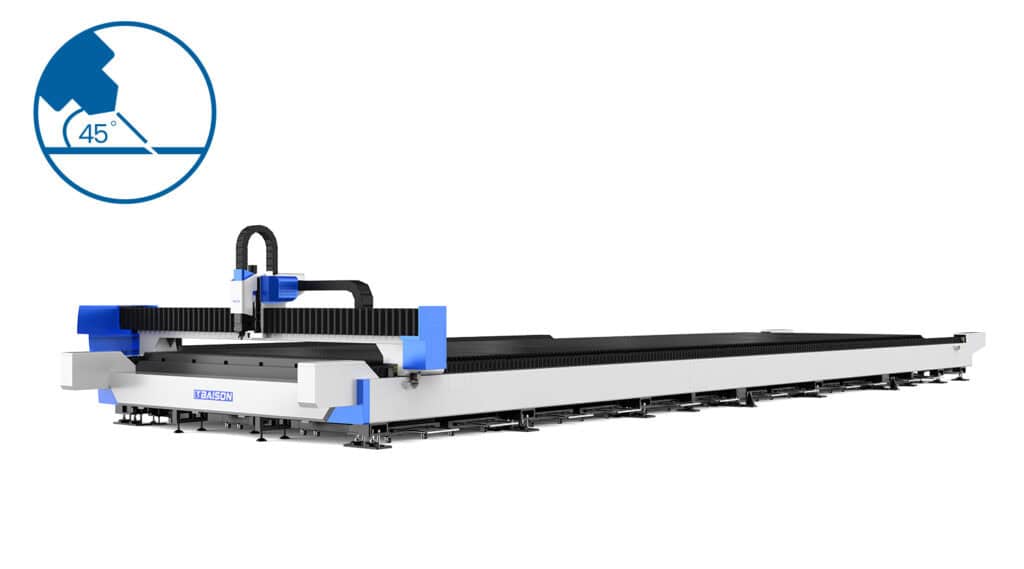

EL Series

Small format laser cutting machine

Small-format laser cutting machines are easy to operate and can cut a variety of complex graphics. The machine occupies a small area and is easy to store and transport. It is very suitable for most factory workshops.

Small equipment footprint

Small footprint of equipment can save more space and reduce costs

High cost performance of the machine

The M3 model machine is cheaper than other machines and can cut the same materials, so it is very cost-effective.

Suitable for small parts processing

The machine is small format and more suitable for processing small parts.

Convenient transportation

The equipment is small in size and easier to transport

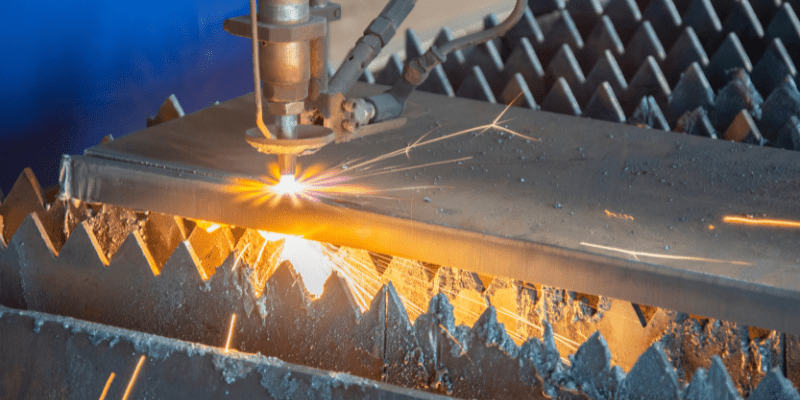

Can cut a variety of metal materials

Can cut a variety of metal materials (carbon steel, stainless steel, copper, brass, iron)

Easy-to-operate control system

The control system is simple and easy to learn, with a dedicated tutorial

Small format laser cutting machine is suitable for the industry

Small-format laser cutting machines are suitable for many industries and provide a good solution for small parts processing

Jewelry

Billboard

Home appliance industry

Functions of small format laser cutting machine

Below you can find the main specifications of our machines so that you can get an idea of what our machines can help you achieve. If required, you can download a detailed specification sheet.

| Model | ME | E3 |

|---|---|---|

| Laser Power | 1500W~6000W | 1500W~20000W |

| Cutting Area | 3000×1500mm | 3000mm×1500mm |

| Max Moving Speed | 120m/min | 120m/min |

| Positioning Accuracy | ±0.03mm/m | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm | ±0.03mm |

| Max. Acc. Speed | 1.2G | 1.2G |

Configuration of small format laser cutting machine

Our small-format laser cutting machines are designed for small and medium-sized businesses that need a reliable, cost-effective way to cut sheet metal.

Laser Source

Higher Electro-optic conversion efficiency Superior reliability & modularity Easy maintenance with low downtime Anti-high reflection capability

Laser Cutting Head

Auto focus Higher accuracy Longer service life Calibration and focus lenses, and nozzle, better protected

REDUCER

Stable operation Low noise High output torque High speed ratio

Servo Motor

High accuracy High-speed performance High adaptability & stability Timely motor response with short dynamic response time Comfortable operation with less heat and noise

FSCUT Control System

FSCUT2000E laser cutting control system is a high-performance open-loop laser control system independently developed by Shanghai Bochu Electronic Technology Co., Ltd. It is widely used in the field of metal and non-metal laser cutting.

Due to its outstanding performance in the field of medium-power fiber laser cutting, it has been favored by a large number of high-end users.

1. Easy to use

2. Various file editing functions

3. Real-time alarm and protection

4. Built-in simple nesting function to maximize the utilization of the board

5. Fly cutting/secondary perforation cutting, etc.

Laser Cutting Resources and Articles

We are not just a fiber laser manufacturer; our goal is to provide customers with a one-stop metal-cutting solution. The following article may help you improve your production efficiency and cutting quality.

20 Tips To Help You Improve the Laser Cutting Quality

Laser Cutting VS. Plasma Cutting: Which Procedure is Better for You?

What is the Laser Cutting Thickness Limit for Different Materials?

Frequently Asked Questions

Below are some common questions regarding our fiber laser cutting systems. Please do not hesitate to contact us if you have any other questions or need a quick quote from us.

What is the reason why the laser power decreases during use?

It may be that the mirror in the laser is affected by dust or contaminants. The solution is to clean the laser mirror and check and maintain it regularly.

What is the problem if the laser beam pattern is abnormal?

This may be caused by damage to the optical components in the laser or improper adjustment. Professional technicians are required to perform maintenance and adjustment.

What is the reason for uneven cross section during cutting?

It may be that the focus between the cutting head and the workpiece is not adjusted correctly or the cutting head nozzle is seriously worn. The solution is to readjust the focus or replace the cutting head nozzle.

What is the reason for the cutting gap to be too large?

It may be that the cutting speed is too fast or the power is insufficient. You can try to reduce the cutting speed or increase the cutting power to improve it.

Do You Want to Be More Productivity?

Contact Baison to get the right solution that quickly increases productivity and lowers the cost per part in your production today.