Advantages of Fiber Laser Welding

- Home

- Laser Welding

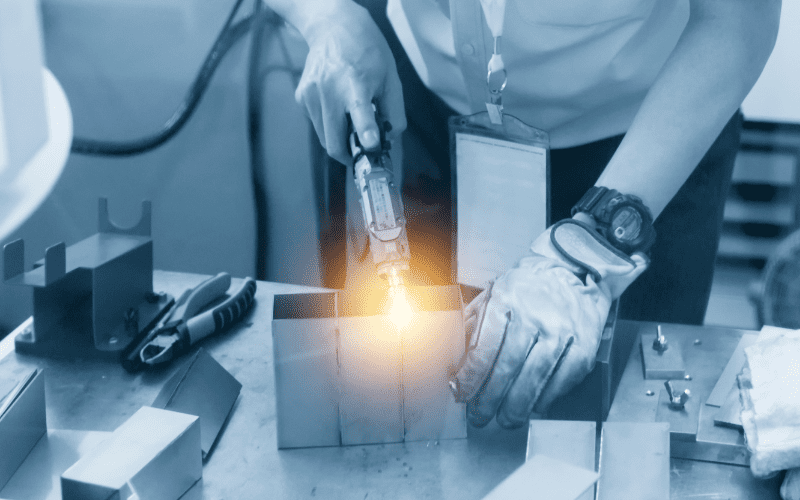

What is Laser Welding?

Laser welding is a modern-day technology that uses high-powered lasers to fuse metal, thermoplastics, and composite workpieces. Starting in the 1990’s it has continuously evolved, thus making industrial manufacturing better. It’s much faster, more precise, cost-effective, eco-friendly, and user-friendly than traditional welding. Most importantly, it’s compatible with modern automation and the ever-growing need for higher quality and intricate products. Laser Welding is also easier to master.

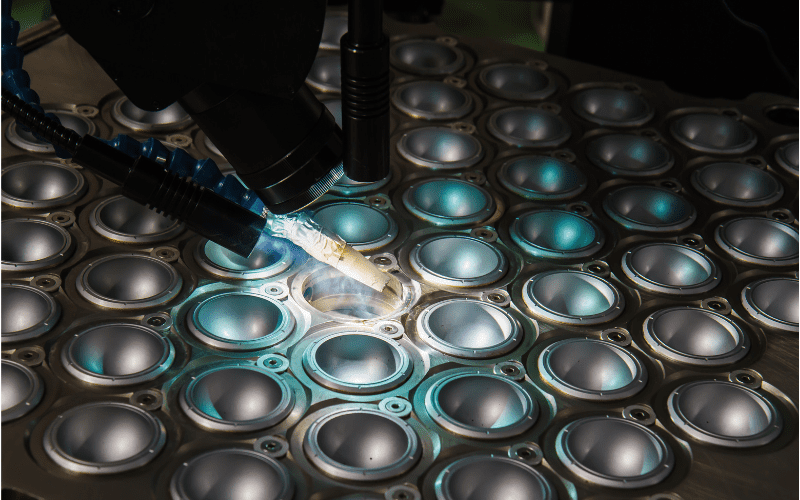

Applications of Fiber Laser Welding

Fiber Laser welding has quickly taken up the modern manufacturing process. Let’s discuss its applications briefly.

- Precision welding for complex geometry.

- Higher production due to a faster welding process.

- Reduced cost due to superior quality welding seam.

- Eco friendly as it produces less heat and toxic smoke.

- Suitable for industries looking for automation.

- Sensitive enough for materials prone to weld distortion.

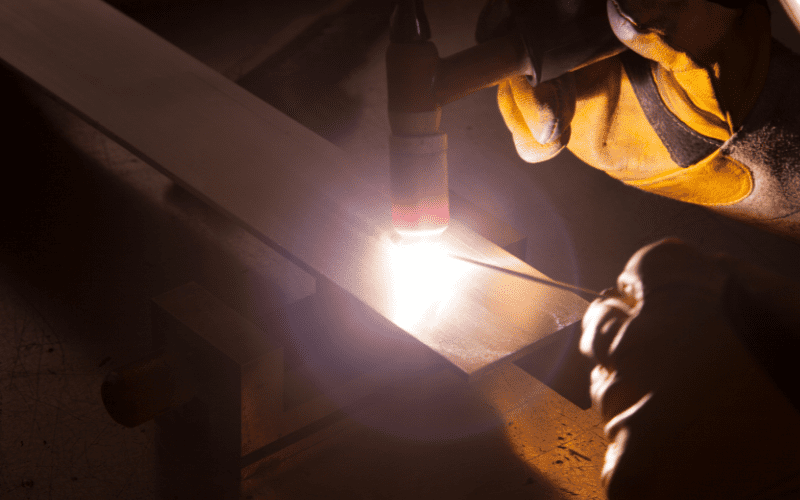

Fiber Lasers vs. Traditional Welding

Fiber Laser brings unique advantages to the table that can increase the efficiency of any industrial production. Here we have listed the key differences between laser welding and traditional welding.

Gas Metal Arc Welding (GMAW) vs Fiber Laser Welding

Gas Tungsten Arc Welding (GTAW) vs Fiber Laser Welding

Plasma Arc Welding (PAW) vs Fiber Laser Welding

Resistance Spot Welding (RSW) vs Fiber Laser Welding

Electron Beam Welding (EB) vs Fiber Laser Welding

Looking for Fiber Laser Welding Machine for Your Business?

Feel free to contact our expert team for a consultation. Get customized quotes and much more.

Advantages of Baison Fiber Laser Cutting Technology

Premium Quality

Our expert technicians and engineers use contemporary technology to produce high-quality fiber laser welding machines.

Customization

We believe every project is unique, so we customize our products to each client’s project specifications.

Reduced Welding Distortion

Our machines cause fewer thermal distortions. This significantly lowers the cost of post-weld treatments, which yields higher profits.

Mass Production

Our efficient laser welding technology makes mass production feasible for any industry.

Eco friendly

We manufacture eco-friendly machines which dissipate less heat and toxic smoke to the environment.

Low Maintenance Cost

Fiber laser technology doesn’t need regular maintenance and any consumable filler material, thus saving operational costs.

Ready to Speak to one of Our Experts?

Our team of experts are always available to answer your questions and help you find the best solution for your needs. Whether you’re looking for information on products, pricing, or just general advice, we’re here to help. So don’t hesitate to reach out – we’re always ready to chat.