In the world of laser-cutting machines, a reliable controller that offers precision, accuracy, and optimization while enhancing creativity is all you need to unlock your business’s full potential. And FSCUT takes center stage by allowing you to take your laser cutting experience to new heights.

Not only does it offer high precision and accuracy, but its advanced control capabilities and integration settings harmonize your workflow while allowing you to navigate your cutting process easier.

So, whether you’re an industry expert or an artisan seeking optimization and perfection, we are here to take you through the many reasons why the FSCUT laser-cutting machine controller should be your go-to control system for your production process.

What Is a Laser Cutting Control System?

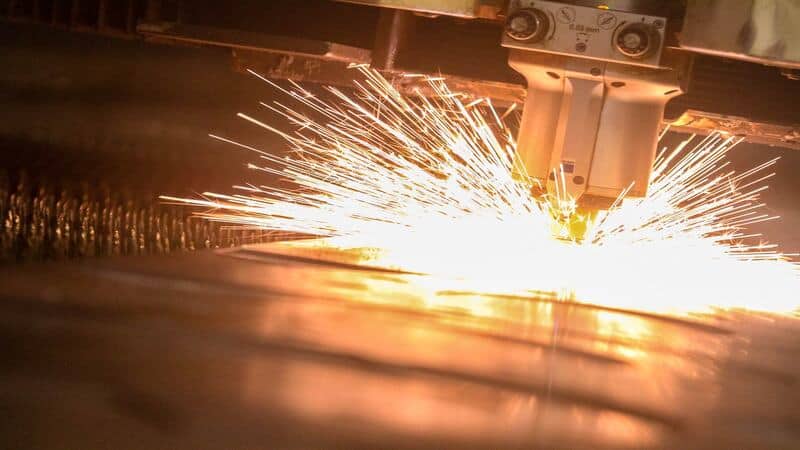

A laser-cutting control system is a computerized program that automates and controls the operations of a laser-cutting machine. These control systems can be hardware or software but efficiently control and coordinate the laser cutting process.

The systems play an essential role in ensuring precise cutting operations by effectively controlling the cutter’s power, trajectory, and movements.

This control system usually consists of a motion control unit that coordinates the movement of the laser along different axes, X, Y, and Z. There is also a power control mechanism that adjusts the intensity of the laser beam to suit different cutting needs.

And a user interface software that allows you to set different cutting parameters, simulate and optimize the cutting paths, and design import. This user-friendly interface essentially allows you to interact with the machine and communicate your cutting requirements.

Why Is a Laser Cutting Controller Important?

A laser cutting controller plays a vital role in the machine’s ability to achieve precision, speed and provide safety. However, they are also beneficial for several other reasons below:

Automation

The essence of these laser-cutting controllers is to coordinate and control the machines with minimal human intervention. Hence, automating the cutting process increases productivity and reduces human labor. They can also seamlessly integrate into other machinery, allowing for a more automated production system.

Ease of Use

Laser cutting controllers are equipped with user-friendly interfaces in the form of software, allowing manufacturers to set parameters and simulate the cutting process. This interface also makes it easy to use the machine, reducing the learning curve and increasing productivity.

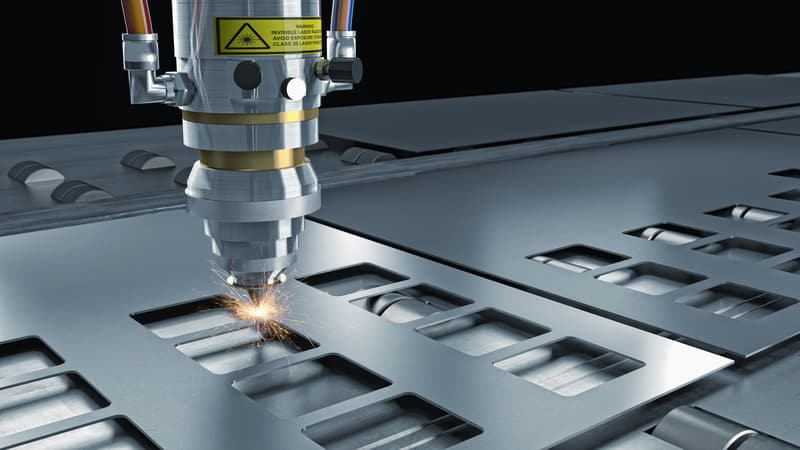

Accuracy

A laser cutting control system allows for precise laser beam positioning along the work path, ensuring accurate cuts. By coordinating the movement of the laser-cutting machine, the controller reduces production time and increases output while enhancing quality.

Safety

These laser-cutting controllers have safety features in place to prevent accidents such as accidental contact or exposure to the laser beam. The mechanisms used by laser-cutting controllers to control laser power also monitor the operations such that they can stop operations or shut down immediately if there are safety concerns.

Versatility and Customization

Laser-cutting controllers provide flexibility by allowing users to set different control parameters, such as power and speed. This allows manufacturers easily customize or adjust the cutting settings based on the type of material they are working with, thickness, and other production needs.

What Is FSCUT Laser Cutting Controller?

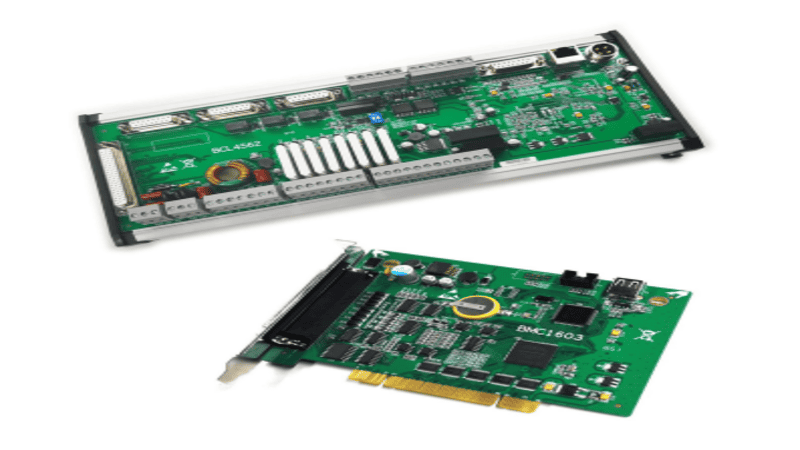

FSCUT is a laser cutting control system brand developed by Shanghai Friendess Electronics Technology Co., Ltd. This China-based company focuses on researching, developing, and producing laser motion control systems and other laser-processing technology.

Asides from FSCUT, they have also launched the CypCut laser cutting system, HypCut high-power laser cutting control software, and CypTube square tubes laser cutting control software.

FSCUT controllers are explicitly designed for laser-cutting machines, providing precise control and a wide range of advanced functions.

They also offer a wide range of features that are crucial for laser-cutting processes, such as motion control, ensuring accurate positioning and smooth movement, laser power control, allowing for adjustments of the laser based on cutting requirements, and a material database that provides recommended cutting parameters for various materials.

Additionally, these laser controllers have user-friendly interfaces, simulation, and preview functionality that allow you to preview and verify the design and cutting path before the process begins and an integration function to connect external devices such as automation equipment and computers.

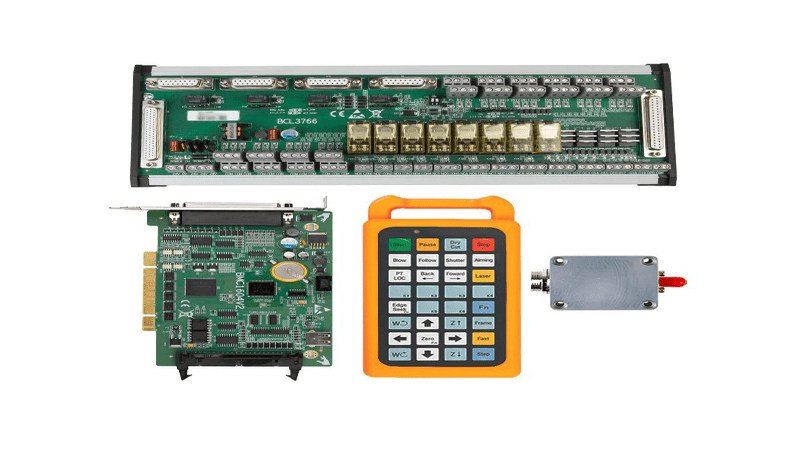

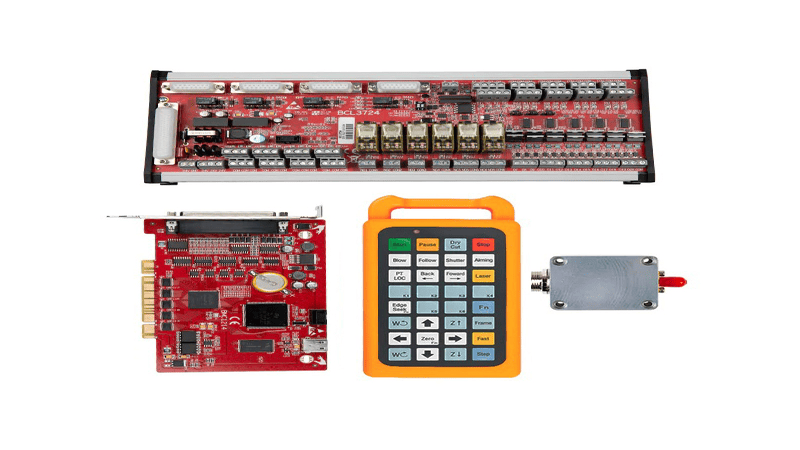

Types of FSCUT Laser Cutting Controller

FSCUT1000

FSCUT1000 is a simple, cost-effective, and low-power fiber laser cutting machine for small power applications, usually within 3000W, that integrates a motion and height control unit in one system. This controller is applied widely in metal and non-metal laser cutting and is used for thin metal sheet production.

The controller uses CypOne Laser Cutting Control Software with a maximum cutting and travel speed of 100m/min.

The trajectory of this fiber laser-cutting machine controller is accurate to about 0.05mm with a position accuracy of 0.01mm. And it supports a maximum acceleration of up to 1G. The FSCUT1000 also supports laser sources such as Max, Raycus, and Mars and the 2-stage piercing technique.

However, it doesn’t support advanced functions such as bend relief, ring-path for pointed workpieces, find workpiece edge, cooling point, and auto-nest. The work environment should also have a temperature range from 0-55℃ with humidity levels between 5%-95%.

FSCUT2000E

The FSCUT2000E is an open-loop, medium-power laser control system many high-quality manufacturers use. This laser control system is suitable for 1000W-4000W power laser cutting processes and can be used for metal and non-metal laser cutting, including thin metal sheets.

This laser control system is widely used in the metal fabrication industry because it can be conveniently installed, is easy to use, has an impressive performance, and comes with fully integrated solutions.

FSCUT2000E is operated using CypCutE software with a path positioning accuracy of up to 0.01 mm, positioning accuracy of up to 0.001 mm, and an unlimited cutting and travel speed. With a maximum acceleration of 2G, the work environment must be conducive to temperatures between 0-60℃ and humidity levels between 10%-20% relative humidity.

FSCUT3000

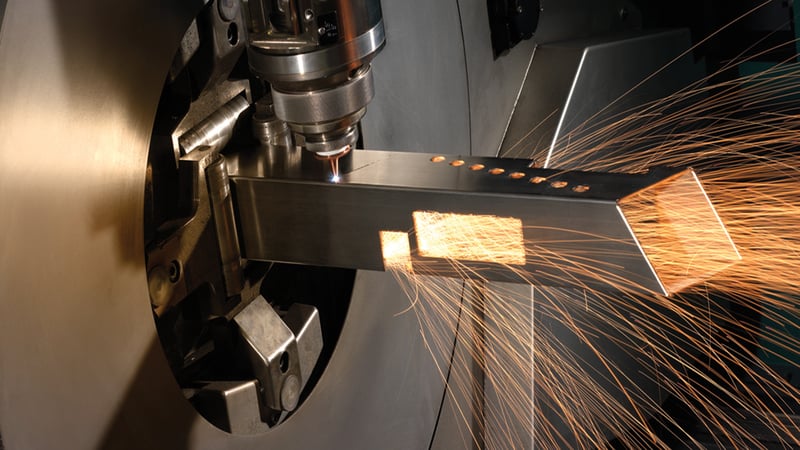

FSCUT3000 is a high-performance, open-loop laser control system designed for laser tube cutting productions, including standard tube, free form, stee channel cutting, tube cutting control, and standard channels.

And it is commonly used in industries such as sports equipment, display shelf, furniture, and architecture. It supports the functions of the FSCUT2000 system and uses TubePro tube cutting software/ CypCut controller.

The FSCUT3000 has a trajectory accuracy of 0.02 mm and a positioning accuracy of 0.001 mm. The system also supports automatic tube feeding, separate techniques for corner cutting, auto loading/unloading process, offset tube center error and cycle production. The workplace’s temperature range should be between 0-55 ℃ with humidity levels between 5%-95%.

FSCUT4000E

The FSCUT4000E is a closed-loop, high-performance laser-cutting machine controller for high-speed power cutting between 1.5-5.8KW. This laser-cutting machine controller is run on CypCutE software and uses EtherCAT motion control signal, which is more scalable and provides laser and gas control.

This high-precision control system provides advanced functions and is widely used in the electronic and 3C industries.

With a maximum acceleration of 2G, the FSCUT4000E can achieve unlimited cutting and travel speeds. It has a trajectory accuracy of 0.01 mm and a position accuracy of 0.001 mm. Temperatures in the work environment should remain between 0-60 ℃ while relative humidity should be between 10%-90%.

Benefits of Choosing the FSCUT Laser Cutting Controller

The benefits of using the FSCUT laser-cutting controller cannot be exhausted. Apart from being China’s number one supplier of operating systems for fiber laser cutting machines, with almost 80% of the market, the system requires no special knowledge from users and almost no thresholds. Here are a few other reasons why you should choose FSCUT:

Precision and Accuracy

FSCUT can transform any design into reality with unmatched accuracy and intricacy. The system used an advanced control system to direct the laser beam based on the cutting parameters, resulting in clean edges and consistent, high-quality cuts.

Easy Installation and Use

FSCUT laser cutting machine controller has a user-friendly interface that simplifies the control of the machine and the cutting operation. Hence, users can easily install the software, set sitting parameters and designs, and monitor the cutting process without needing any specialized skill or expertise.

Maximum Material Utilization

FSCUT optimizes the cutting process for precision, cost-effectiveness, and efficiency. Therefore, ensuring complete usage of cutting materials and minimizing waste. This also improves its sustainability and reduces material costs.

Compatibility and Integration

If you have a network of systems, networks, or external devices you want to integrate, FSCUT allows you to synchronize them for data exchange and collaboration. This enhances productivity, creativity, and harmonization of your production processes.

Durability

The FSCUT controller is made with the highest quality materials, like stainless steel, to ensure durability and long service life. This means you don’t have to worry about regular downtimes due to changing or fixing parts. Neither would you have to worry about regular maintenance.

Conclusion

Join the league of those who demand perfection and excellence by exploring the limitless possibilities of laser-cutting technology with FSCUT. FSCUT controllers boost productivity, minimize material waste, are reliable, enhance precision, and ensure your laser-cutting process is nothing short of excellent.

And this is why we at Basion trust the FSCUT operating system to control our laser machines. So, don’t hesitate to try out FSCUT when you require a controller for your laser-cutting machine.

Discover the Perfect Solution for Your Business with Baison

Take an adventure with precision and efficiency with innovative laser technology from Baison Laser. Let us become your trusted partners in ensuring maximum productivity and cost-effectiveness for your business. Request a quote or reach out to our customer service center to get started.

Click the button below to get more information about Baison!