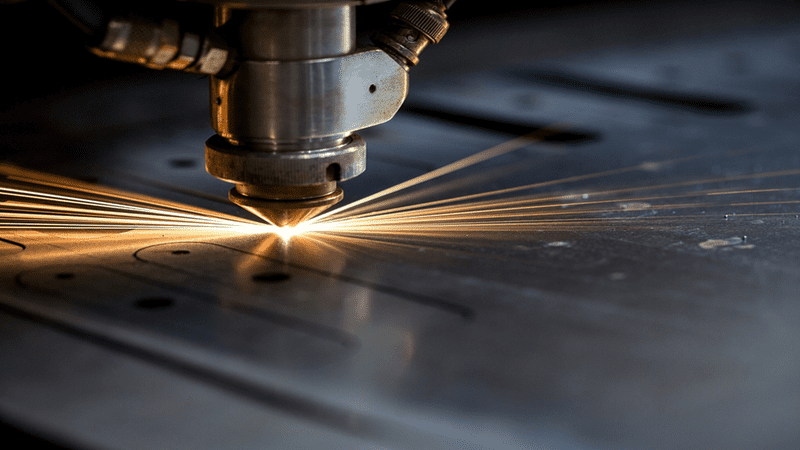

Laser cutting means using a laser to cut various materials, whether for industrial or other artistic applications, to give a perfect cut edge. The problem of contention is that there are some materials that you should not laser cut because they can’t withstand the process.

Here, you will find out why you shouldn’t cut these materials with a laser, the various procedures and types of laser cutting, and some of the alternatives you can find.

How Laser Cutting Works

You’ll find many pros to using laser cutters, making it the most sought option. They include accuracy, versatility, speed, and so on. This begs the question, how does laser cutting work? It functions in the form of a thermal separation procedure.

The laser beam—infrared radiation penetrates through the preferred surface. The heat from the process helps to melt or vaporize.

Also, it is possible to control the outcome depending on the application. To learn how a laser cutter works, mentioning important stuff like the process and types to expect is essential.

Laser Cutting Processes

Different laser-cutting processes that get the same result through similar but different means are available. Below are some of them.

Fusion Cutting

This type of laser-cutting method uses nitrogen to get the job done. The function of inert gas is to keep melted materials out of the way while cutting out your desired shape. However, nitrogen gas neither releases heat while cutting the material nor adds to the energy input.

Flame Cutting

Unlike fusion cutting, this cutting type uses oxygen for cutting materials. This process entails exerting mechanical force on the melted material. In return, this process causes heat to release during its formation and is responsible for boosting the energy input to the entire melt process.

Remote Cutting

This cutting differs from the first two. Opting for remote cutting results in having a partially evaporated material. It happens because the materials are cut with a high-intensity laser beam without any form of support from gas.

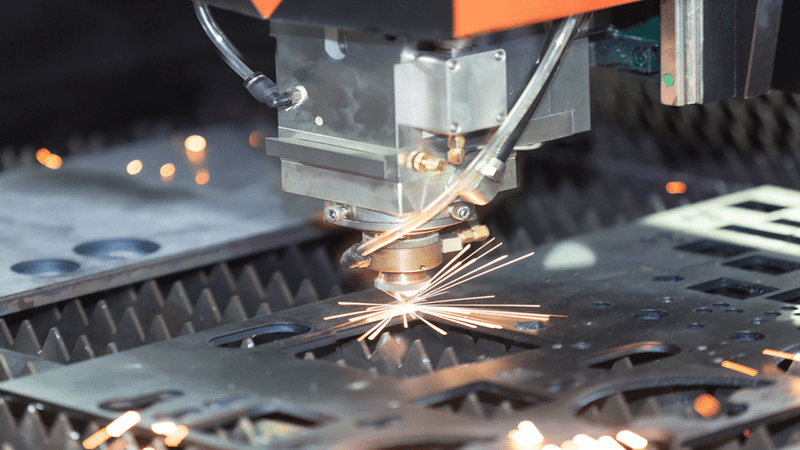

Types of Laser Cutting

Laser cutters are designed alike, but one significant difference that separates one from the other is the specific power range bestowed on it by the manufacturer. Here are some of them.

CO2 Lasers

The CO2 laser uses a combo of gasses that are usually induced electrically. As the name connotes, these gas mixtures are mostly carbon dioxide. CO2 laser cutting machine is one of the most common types because they are cost-effective, efficient, and can cut through different materials.

Foams, acrylic, wood, glass, paper-based products, and leather are lists of the materials this cutter can penetrate successfully.

Fiber Lasers

Fiber laser is a kind of laser with high power output and high precision using fiber as a gain medium. It can cut metal materials like aluminum, copper, stainless steel, etc. The cutting capability depends on the power and wavelength of the laser, as well as the material’s properties.

Neodymium Lasers

As the name implies, this laser is made from neodymium-doped crystals. They have a higher intensity level, making them able to cut through thick and strong materials.

The only con to this laser type is that they are high powered, which makes the machine wear and prone to a replacement from time to time. Neodymium Lasers can cut materials like ceramics and metals.

Differences between Laser Cutting and Traditional Cutting Methods

Before the invention of fiber laser cutting, people used conventional cutting methods to achieve the desired cuts from different materials. These conventional methods include mechanical cutting, waterjet cutting, plasma cutting, etc. The table below shows some distinctions between laser cutting and alternative cutting methods.

What Should You Not Cut with a Laser?

This is the safety part of the article that you have been waiting for. Here, there are highlights of some of the materials you should not try cutting with a laser. This way, you won’t encounter accidents or unintentionally destroy your laser cutter.

Plastics Containing Chlorine or Fluorine

It would help if you never tried to cut plastics containing chlorine or fluorine with a laser. The reason is that it emits many toxic fumes of pure chlorine gas during the procedure. Also, it can destroy the light beam, which is the core source of the sharpness of a laser.

As a result, the machine’s metal and motion control system can destroy and weaken, respectively.

Polycarbonate and Some Other Plastics

The danger of laser cutting on polycarbonate is that it cuts quite poorly, can catch fire, and even discolor. One important part of a laser cutter is the window, which helps to avoid spoilage to its optics caused by the specks from the cutting process.

Therefore, laser cutters’ windows are made with acrylic instead of polycarbonate because the latter does not support infrared radiation. Hence, it becomes incapable of cutting through the polycarbonate.

Wood with High Resin Content

Wood is part of the materials that a laser cutter can easily penetrate. However, you should ensure that the wood isn’t oily or resinous. This is because they are susceptible to catching fire during the cutting process. Other exceptions are glass and epoxy resin.

ABS

This abs plastic tends to release hydrogen cyanide in gas, and toxic fumes, which is harmful to humans when using a laser cutter. Also, abs plastic melts leave gooey resin deposits on the cutting grid and have a higher chance of catching fire.

Alternatives to Laser Cutting

There are other cutting methods that you can use to achieve the desired cut or marks you desire. Here are some of them.

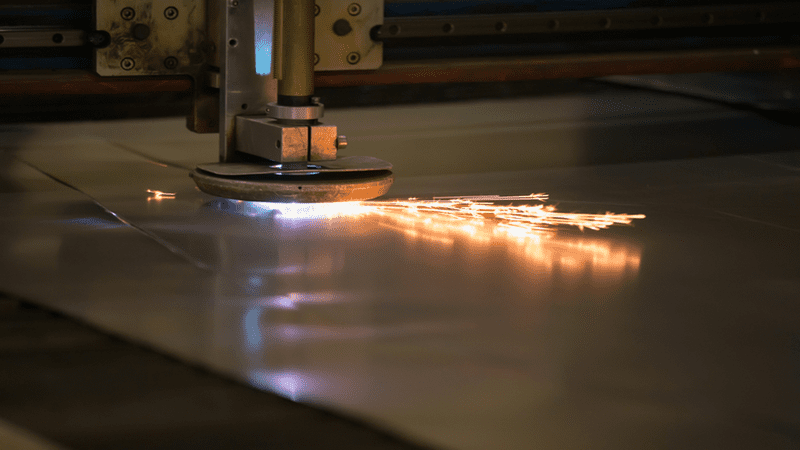

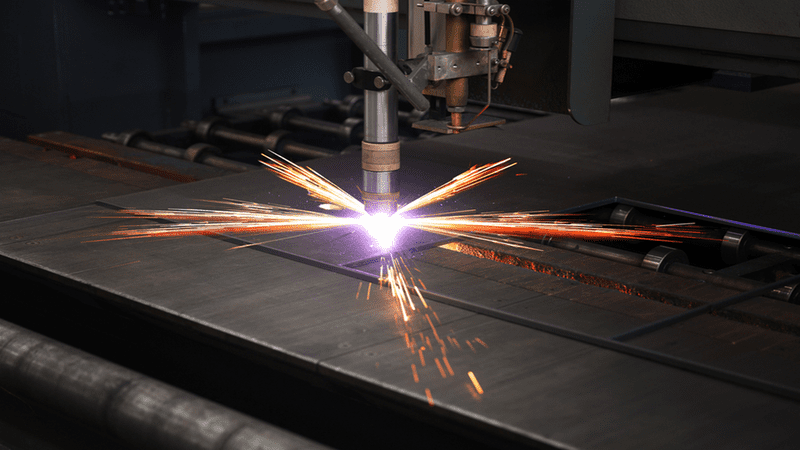

Plasma Cutting

The plasma-cutting process utilizes heat to slash materials. The best part of this method is that it can penetrate through thicker materials like copper, aluminum, metals, steel, and brass. This cutting process works via an electric channel of ionized gas—plasma. It is the first on the list of alternative cutters to laser and is faster than the other alternatives.

Learning about the difference between Plasma and Laser Cutting in detail will help you decide which one to choose.

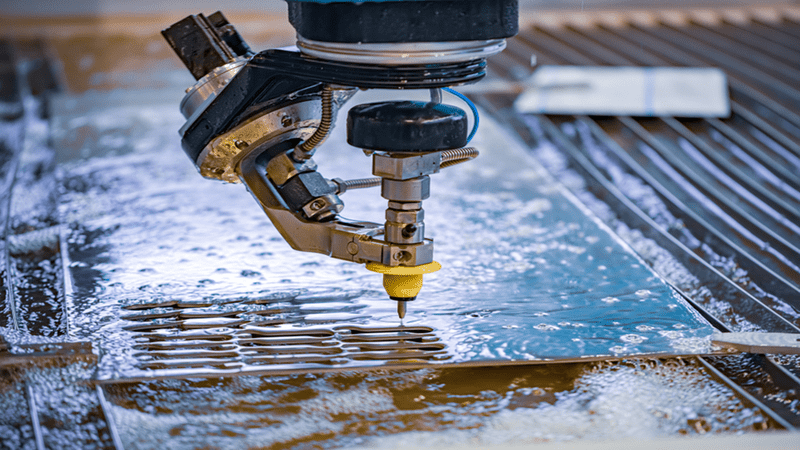

Waterjet Cutting

It can be likened to how erosion works. Waterjet cutting is a quick procedure that utilizes garnet or other coarse particles and high-pressure water to slice through materials. The cutting process is swift and can effectively replace a laser cutter. If you want to learn about the difference between Water Jet and Laser Cutting in detail, click here.

Flame or Oxy-fuel Gas Cutting

This reliable and cost-effective thermal cutting process utilizes a combination of fuel gasses like oxygen, acetylene, and propane. Flame or Oxy-fuel Gas Cutting can cut through mild steel with the heat produced by the oxy-fuel cutting torch.

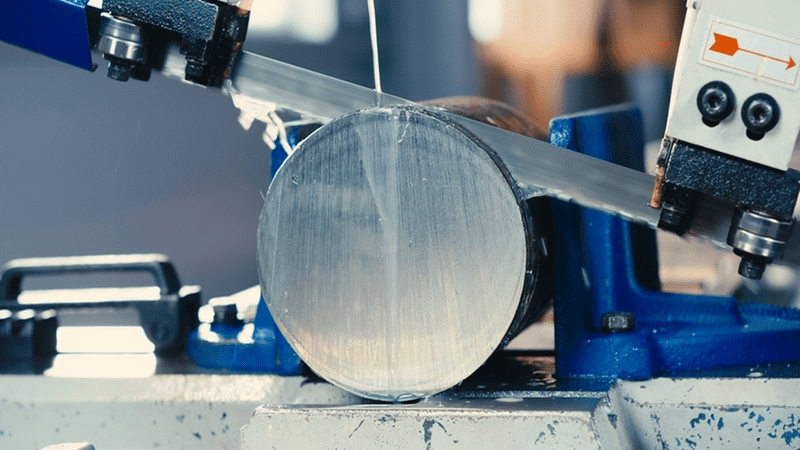

Mechanical Cutting

This cutting uses abrasive force to cut through materials. The materials from a workpiece are removed through slicing and shearing rather than vaporizing and melting. It involves the application of force into direct contact with the material of choice like composites, cut paper, wood, artificial leather, metals, artificial leather, etc.

Traditional Cutting

The conventional cutting method equals an unsophisticated one. Rather than machines, it employs hand tools like shears, knives, saws, scissors, etc. Depending on the tool, they can cut metals and wood.

What Could You Cut with a Laser?

Here are some materials you can cut using the laser cutter without fearing toxic fumes or the destruction of your machine. They are as follows.

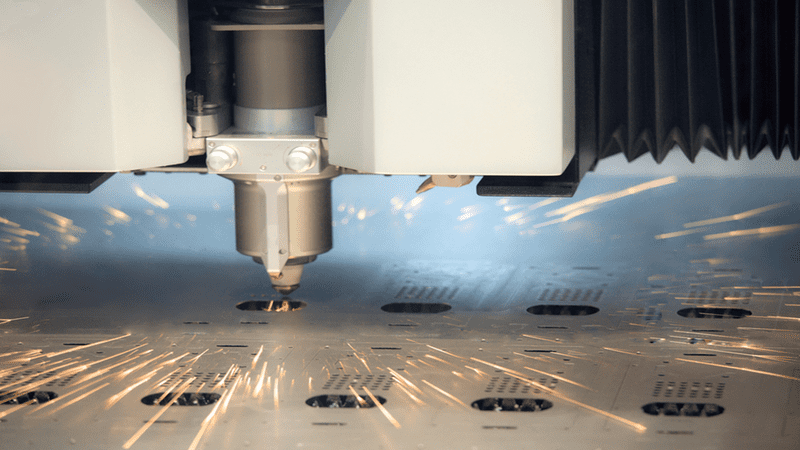

A Variety of Metals

You can easily slice through any metal, whether stainless or non-ferrous, with a laser cutter. However, the maximum thickness of metal that any laser can cut through depends on the power and your experience.

Wood

A laser can cut through different types of wood. This includes MDF (Medium-density fibreboard), composite woods, and plywood.

Paper & Cardboard

Whatever paper-based or cardboard material is available, you can easily cut it with a laser. The fun part is that the cuts are usually nimble and on point. However, it would be best to be careful because it is susceptible to catching fire.

Plastics

A laser cutter is your best bet to get a great finish when cutting. It is so because you get the perfect edges and cuts that seem polished after melting during the cutting process without worrying about the melted gooey deposits.

Some see-through plastics you can cut with a laser cutter include Lucite, Acrylic, and PMMA(polymethyl methacrylate), a lighter and shatter-resistant plastic alternative to glass.

POM

Polyacetal, aka acetal or polyoxymethylene (POM), is another type of plastic that you can cut neatly with a laser. This type of plastic differs from the rest because it is commonly used in engineering. Hence, they are used to make medical instruments, gears, food packaging, and sliding elements.

N.B: It is vital to note that our company’s laser cutting machines are perfect for just metal materials. Other materials like wood, glass, acrylic, etc., do not apply when using them.

How to Choose the Appropriate Cutting Method for a Specific Project?

When selecting the best cutting method to use for a particular project, there are some factors that you need to consider. These factors determine whether you get the expected result and help you achieve what you want. They are

● The machine power.

● The machine dynamics.

● The fixture stability.

● The depth of the slash.

● The material type.

It is important to note that choosing the appropriate cutting tool is paramount to the machine and the material. So, the next time you need to use any cutting method, ensure that the laser machine or cutting method you opt for can produce the desired outcome. In addition, you can get your cutting machines from Baison that can do the job for you.

Conclusion

While the above laser cutter cut is a good cutting method choice, it does not apply to every material. Don’t laser cut PVC (polyvinyl chloride), polypropylene foam, polystyrene foam, polytetrafluoroethylene (PTFE /Teflon), etc., to prevent releasing hydrogen cyanide and other toxic fumes that can endanger you.

A laser cutter can make complex cuts if not on the blacklist. Also, you can look up some Baison machines on our website to help you get the job done.

If you’ve been looking for where to get the best laser cutters, you can check out our website. In addition to good sales options, Baison can help guide you through purchasing the appropriate cutting machines to help get the job done. For more information, you can contact us.