With fiber laser marking machines, you can engrave anything from metals to plastics with precision and finesse. So whether you need to mark your tools for identification or add some pizzazz to your jewelry creations, a fiber laser marking machine is your go-to companion.

Stay tuned as we dive deeper into the wonders of fiber lasers and discover what materials can be marked with a fiber laser machine.

Overview of Fiber Laser Marking

Before we dive into the materials suitable for fiber laser marking, let’s first understand the laser marking technology itself.

I. Explanation of How Fiber Laser Machines Work

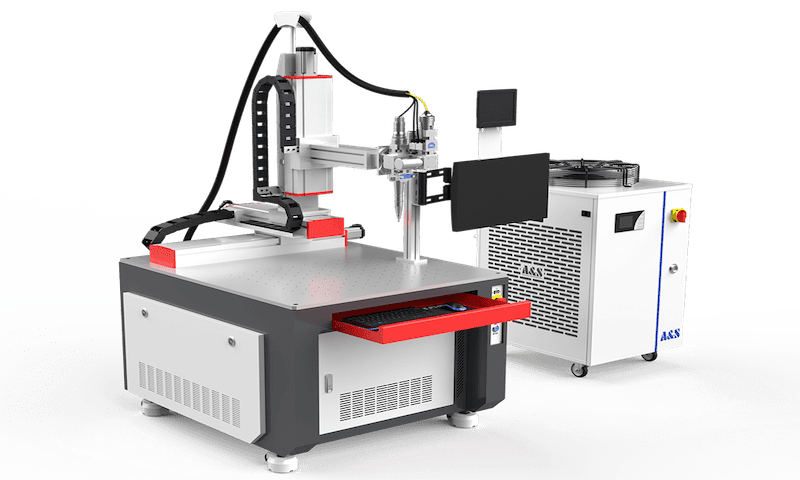

Fiber laser machines utilize a high-intensity laser beam generated from a fiber optic source. The laser beam is directed onto the surface of the material to be engraved, fulfilling the marking requirements with the marking machine. Inside the machine, a series of mirrors and lenses guide the laser beam to the desired location with precision.

The laser marking machine uses a laser beam to engrave and mark materials, meeting all laser engraving and marking requirements. The superior beam interacts with the material, causing a chemical or physical change on its surface, resulting in high-contrast permanent marks. The marking speed and accuracy of the laser beam can be controlled, allowing for intricate designs and precise markings.

II. Applications of Fiber Laser Marking

Fiber laser marking is a versatile and widely used technique for marking various industry materials. Let’s explore some of the key applications where marking machines and engraving are utilized to meet various marking requirements. Fiber laser markers are commonly used in these applications due to their efficient and precise usage.

- In automotive manufacturing and aerospace engineering, fiber lasers play a crucial role in ensuring traceability by marking serial numbers or barcodes on metal components. This enables easy identification, tracking, and quality control throughout the production process using a laser marking system. Fiber laser marking machines are commonly used in the industry for laser etching. This is an article about the application of laser marking in the aerospace industry.

- The medical industry relies on fiber laser marking to meet regulatory requirements and ensure product identification. By using a marking machine to laser engrave important data such as model numbers, manufacturing dates, and unique identifiers onto medical devices, fiber lasers contribute to patient safety and compliance.

- Consumer electronics companies in the industry utilize marking machines, specifically fiber lasers, to engrave logos or essential information on plastic casings. This branding technique is commonly used for advertisement purposes. This enables effective branding while maintaining durability and aesthetic appeal.

By harnessing the power of fiber laser technology in various industries, businesses can achieve reliable markings that enhance product identification, traceability, and compliance with regulations while maintaining brand integrity.

Common Materials Suitable for Fiber Laser Marking

Fiber laser machines offer the versatility to engrave and mark a wide range of materials, meeting various marking requirements in the industry. Now let’s take a look at the materials that often use laser marking technology.

1. Metals

Stainless steel stands out as a popular choice due to its durability and resistance to corrosion. Aluminum is another commonly marked metal that finds applications in various industries. The fiber laser marking technique is compatible with titanium and brass for engraving services. These techniques utilize a machine to process data.

- Stainless steel: Stainless steel is a popular material for fiber laser marking due to its durability and resistance to corrosion. The fiber laser marking machine is commonly used for marking serial numbers, logos, and product information on various metal products. It is a versatile tool in the laser series and is highly efficient.

- Aluminum: Aluminum is another commonly marked metal using fiber lasers. It is lightweight, versatile, and widely used in the automotive, aerospace, and electronics industries. Fiber laser marking on aluminum can be used for branding, part identification, and traceability. International Conference on Mechanical Engineering has published experimental articles on laser marking aluminum.

- Titanium: Titanium is a strong and lightweight metal often used in medical implants, aerospace components, and high-end consumer products. Fiber laser marking on titanium is ideal for product identification, branding, and ensuring traceability.

2. Plastics

In addition to metals, common plastics like ABS (Acrylonitrile Butadiene Styrene), PVC (Polyvinyl Chloride), polycarbonate, and polypropylene can be easily marked using fiber lasers.

These plastics are widely used in manufacturing consumer products such as electronics, automotive parts, household items, and various other applications where laser power is required. Using these plastics in such forms has increased the demand for laser power services.

- ABS (Acrylonitrile Butadiene Styrene), ABS is a common thermoplastic used in various industries, including automotive, electronics, and consumer goods. Fiber laser marking on ABS can be used for part identification, barcoding, and branding.

- PVC (Polyvinyl Chloride), PVC is a versatile plastic commonly used for electrical cables, pipes, and signage. Fiber laser marking on PVC is suitable for marking product information, safety labels, and identification purposes.

- Polyethylene, Polyethylene is a widely used plastic in packaging and labeling applications. Fiber laser marking on polyethylene can be used for barcoding, product identification, and branding.

3. Other Materials

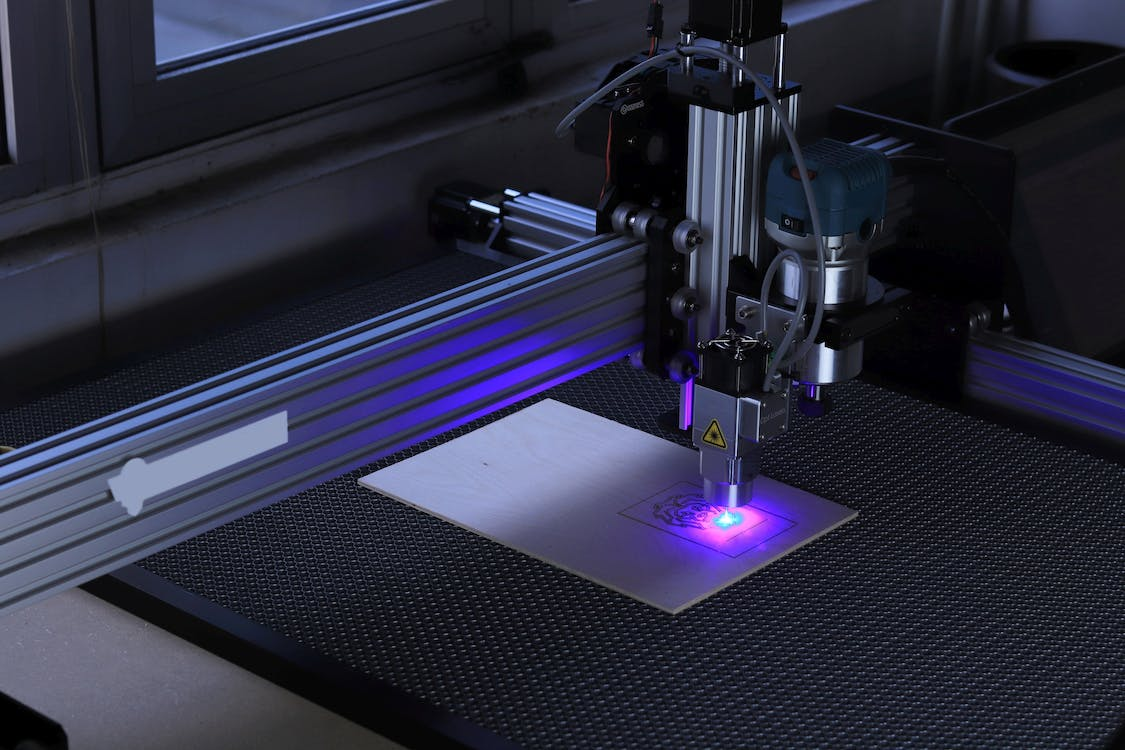

Furthermore, fiber lasers can mark other materials such as ceramics, glass, leather, carbon fiber, wood, and certain fabrics. This opens up opportunities for customization in sectors like decorative arts and fashion.

- Glass

Glass materials can be marked with fiber lasers, enabling precise and intricate designs on products such as glassware, mirrors, and decorative items. Fiber laser marking on glass is commonly used for branding, personalization, and product identification.

- Ceramics

Fiber lasers can create permanent marks on ceramics, making them suitable for branding, product identification, and customization. Fiber laser mark is widely used for ceramics in the pottery, tile, and home decor industries.

The usage of fiber laser marking services on ceramics is common for these industries as it allows for precise and detailed designs to be engraved onto the surfaces. This technique is often employed on various ceramic forms such as pottery, tiles, and other home decor items.

- Wood

Wooden surfaces can be beautifully engraved with fiber lasers, allowing for intricate designs on furniture, promotional items, and personalized gifts. Fiber laser marking on wood is commonly used for branding, customization, and decorative purposes.

These are just a few examples of common materials suitable for fiber laser marking. The versatility of fiber laser technology allows for marking on a wide range of materials, making it a popular choice for various industries.

Factors Affecting Fiber Laser Marking Results

Material composition significantly impacts the quality of marks produced by a fiber laser marker. Surface preparation and cleanliness also play a crucial role in determining the adhesion and contrast of the mark. Various laser parameters influence the outcome of fiber laser marking, including power level, scanning speed, pulse duration, and frequency.

To achieve optimal results when using a fiber laser machine for marking purposes, it is essential to consider these factors:

1. Material Composition: Different materials respond differently to fiber laser marking. For example:

- Metals like stainless steel, aluminum, brass, and titanium are commonly marked with excellent results.

- Plastics such as ABS, polypropylene (PP), polycarbonate (PC), and acrylic can also be effectively marked.

- Ceramics and glass may require specialized techniques or additives for successful marking.

2. Surface Preparation and Cleanliness: The condition of the material’s surface dramatically affects the quality of the mark, so ensure that surfaces are clean and free from dust, oils, or other contaminants before marking. Proper cleaning methods may include wiping with alcohol or using ultrasonic cleaners for intricate parts.

3. Laser Parameters: Adjusting specific laser parameters allow for customization based on material characteristics:

- Power Level: Higher power levels often result in deeper marks but can also cause thermal damage if excessive.

- Scanning Speed: Controlling how quickly the laser moves across the surface affects both mark depth and overall time required.

- Pulse Duration: Shorter pulses generally create finer marks while longer pulses may be necessary for certain materials.

- Frequency: Selecting an appropriate frequency ensures efficient energy absorption by different materials.

By considering these factors—material composition, surface preparation/cleanliness, and laser parameters—you can optimize your fiber laser marking process to achieve high-quality results on a wide range of materials.

Advantages of Fiber Laser Marking

Fiber laser marking is a highly efficient and reliable method for marking various materials. It offers several advantages over traditional marking techniques, making it an ideal choice for many industries.

- Precision and Accuracy: The laser beam used in fiber laser marking is delivered through a fiber optic cable. This allows for precise control and focused energy delivery. Fiber lasers offer excellent beam quality, allowing for precise and intricate markings. They can create sharp lines, small characters, and complex designs with high accuracy, ensuring the clarity and legibility of the marks.

- Versatility: Fiber laser marking technology is compatible with a wide range of materials, including metals, plastics, glass, ceramics, and wood. This versatility allows businesses from various industries to benefit from the technology and enhance their products with customized markings.

- Non-contact Process: Fiber laser marking is a non-contact process, meaning the laser beam does not physically touch the material. This eliminates the risk of damage or deformation, especially when marking delicate or sensitive materials.

- Cost-effective: Fiber laser marking technology offers a cost-effective solution for marking and engraving needs. The absence of consumables and the durability of the marks reduce maintenance and replacement costs over time.

- Speed: Fiber laser systems offer fast processing speeds for efficient production lines. High-speed scanning capabilities enable quick mark completion without compromising accuracy.

FAQs

1. Is it possible to mark curved surfaces with a fiber laser marking machine?

Absolutely! Fiber laser machines are highly flexible. With advanced scanning technology and adjustable focal lengths, they can effectively adapt to different shapes and contours.

2. Can I achieve color variations in my markings with a fiber laser marking machine?

While fiber lasers primarily produce black or grayscale markings on most materials, there are options available to achieve color variations on specific substrates such as plastics or anodized aluminum. Specialized additives or coatings may be required for this purpose.

3. How long does it take to mark an item with a fiber laser marker?

The marking time depends on various factors such as the complexity of the design, the size of the marking area, and the material being marked. However, fiber laser machines are known for their high-speed capabilities, allowing for quick and efficient marking processes.

4. Are fiber laser markings permanent?

Yes, fiber laser markings are highly durable and resistant to fading or wearing off. They can withstand harsh environmental conditions, making them suitable for applications that require long-lasting and indelible markings.

Conclusion

Now you have known the basics of laser marking technology and the materials that can be cut. By knowing this, you can make informed decisions about the right materials and design. The fiber laser provides superior fiber laser engraving and marking capabilities while ensuring optimal performance. Whether you’re an amateur or a professional designer or manufacturer, investing in this technology can open up new possibilities for your project.

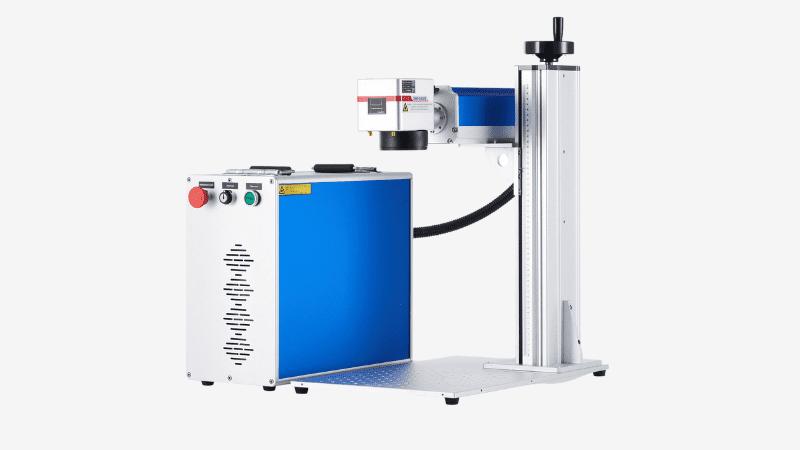

Why Choose Baison Laser Machines for Marking Applications?

Whether you need high-speed marking on delicate materials or deep engraving on hard surfaces, the custom fiber laser marking solutions of Baison can be optimized for your unique needs. By applying our laser marking machines or laser cutting machines, you can significantly increase your productivity in manufacturing. Why not contact us now to find out and get a free sample right now?