With laser marking, you can say goodbye to frequent replacements. The markings are long-lasting and durable, ensuring your products stand the test of time. Stick around as we dive deeper into the six ways laser marking can make a significant impact on your bottom line.

What is Laser Marking?

Laser marking technology is a non-contact method that utilizes laser technology to create permanent laser marks on various materials. By harnessing the power of high-energy laser beams, laser marking machines can be used as laser cutting machines and laser etching machines, effectively altering the surface properties of various materials without causing any damage.

This innovative production process allows for precise and intricate designs, making it ideal for creating QR codes, serial numbers, data matrix codes, and other markings. Different types of lasers are used depending on the specific application. For instance, fiber lasers are commonly employed for metal marking, while CO2 lasers are more suitable for organic materials.

Applications of Laser Marking

Automotive Industry: Laser marking systems have many advantages and are widely used in the automotive industry for engraving purposes on the surface. Dot peen systems are also utilized for various purposes in this industry. It is commonly employed for part identification, allowing easy tracking and identification of components.

Traceability codes and serial numbers are laser marked using surface marking techniques such as engraving and dot peen marking on engine parts to ensure accurate documentation, quality control, and enhanced traceability.

Electronics Industry: Laser marking is a vital process in the electronics industry for marking metal components with identification codes, logos, and other essential information. This technique enhances brand recognition and ensures product authenticity, making it a valuable branding tool.

Jewelry Industry: Laser marking is used in the jewelry industry to mark precious metals and gemstones with identification marks, logos, or personalized engravings. This adds value to the jewelry and helps in authentication.

Packaging Industry: Laser marking is used to mark the surface of metal packing materials with information like batch numbers, expiry dates, and barcodes. This helps in efficient inventory management and product traceability.

By adopting laser marking as part of your manufacturing or product identification processes, you’ll not only benefit from its precision but also experience significant cost savings in the long run.

Types of Laser Markers

There are several types of laser marking machines or systems available, each with its own capabilities and applications.

- Fiber Laser Markers: Fiber laser markers use a fiber laser source to generate the laser beam. They are known for their high beam quality, which allows for precise and detailed marking on a wide range of materials, including metals, plastics, ceramics, and more. Fiber laser marking is widely used in industries such as automotive, electronics, medical devices, and jewelry.

- CO2 Laser Markers: CO2 laser machines use a carbon dioxide gas laser source to generate the laser beam. They are particularly suitable for marking organic materials such as wood, paper, leather, glass, and certain plastics. CO2 laser markers are commonly used in industries such as packaging, signage, and engraving.

- UV Laser Markers: UV laser markers use an ultraviolet laser source to generate the laser beam. They are primarily used for marking or engraving materials that are highly sensitive to heat, such as plastics, glass, or certain metals. UV laser markers are often used in the electronics, medical, and semiconductor industries.

Laser Marking vs. Printing: Advantages and Cost Comparison

Laser marking offers several advantages over traditional printing methods, resulting in significant cost savings for businesses. Let’s explore the benefits of laser marking and how it compares to printing:

- No additional consumables: Unlike printing methods, laser marking does not require the use of ink or solvents. This eliminates the need to purchase and replenish the laser marking machine and laser engraving consumables regularly.

- Enhanced durability: Laser markings are highly resistant to wear, fading, and smudging when compared to printed labels or codes. This durability ensures that important information remains legible for extended periods, reducing the need for re-marking or re-labeling.

- Reduced inventory costs: With laser marking, there is no reliance on pre-printed labels or packaging materials. Instead, products can be marked directly using a laser marking machine during the manufacturing process. This laser process is also known as laser engraving. This eliminates the need for maintaining a large inventory of pre-printed items, resulting in cost savings.

- Improved efficiency: Laser marking offers remarkable speed and accuracy, making it more efficient than traditional printing methods. The precise nature of laser technology allows for high-quality markings at faster cycle times.

6 Ways Laser Marking Saves Costs

Laser marking is a versatile and efficient method for permanently marking or engraving various materials. Here are several ways in which laser marking can help save costs.

Elimination of Consumables

Laser marking eliminates the need for inks, dyes, or labels that are typically used in other marking methods. This means you don’t have to constantly purchase and replenish these consumables, resulting in significant cost savings over time. Additionally, the absence of consumables reduces waste generation and the associated disposal costs.

Increased Efficiency and Productivity

Laser marking is a fast and automated process that can mark multiple parts simultaneously. This speed and automation significantly improve efficiency and productivity compared to manual or slower marking methods. By reducing the time required for marking, laser marking saves labor costs and enables high-volume production with shorter cycle times.

Compliance and Traceability

Laser marking ensures compliance with regulations by providing permanent and easily traceable markings. Compliance with industry standards and regulations is crucial for many businesses, and non-compliance can result in penalties or recalls. The efficient traceability provided by laser marking reduces the time and costs associated with quality control, recall procedures, and potential legal consequences.

Maintenance and Downtime Reduction

Laser marking systems have minimal maintenance requirements compared to other marking methods. They are designed for long-term use with minimal downtime, reducing the need for frequent repairs or equipment replacements. This results in cost savings by minimizing maintenance expenses and reducing production downtime.

Long-lasting and Permanent Markings

Laser markings are highly durable and resistant to wear, chemicals, and environmental factors. Unlike other marking methods that may fade or degrade over time, laser markings remain intact and legible for the lifespan of the marked product. This eliminates the need for frequent remarking or re-labeling, saving costs associated with remarking materials and labor.

Versatility and Flexibility

Laser marking is suitable for marking various materials, eliminating the need for multiple marking methods. Instead of investing in different marking technologies for different materials, businesses can use a single laser marking system for all their marking needs. This versatility and flexibility result in cost savings by reducing the need for multiple equipment purchases and maintenance.

In conclusion, laser marking saves costs by eliminating the need for consumables, increasing efficiency and productivity, providing versatility and flexibility, enabling customization and serialization, ensuring compliance and traceability, and reducing maintenance and downtime. These cost-saving benefits make laser marking a valuable investment for businesses across various industries.

Factors to Consider When Choosing a Laser Marking System

- Material compatibility is crucial. Different types of lasers have varying levels of compatibility with different materials. Ensure that the laser source you choose is suitable for your specific material requirements.

- Power output options matter. Consider the power output of the laser marking system and ensure it aligns with the needs of your intended application. Opting for the right laser power level will prevent unnecessary costs or inefficiencies.

- Size and portability affect costs. The size and portability of the laser marking system can impact installation and operational expenses. Choose a system that fits well within your workspace and doesn’t require excessive resources for transportation or maintenance.

- Integration capabilities enhance efficiency. Evaluate how well a laser marking system can integrate with your existing production lines or automation systems. Seamless integration ensures smoother operations, saving time and reducing potential errors.

By considering these factors when selecting a laser marking system, you can optimize cost savings while meeting your specific requirements effectively.

FAQs

What types of materials can be marked with laser marking?

Laser marking is versatile and can be used on various materials such as metals (including steel, aluminum, and titanium), plastics (including ABS, PVC, and polycarbonate), ceramics, glass, wood, leather, and more.

Is laser marking permanent?

Yes! Laser markings are highly durable and resistant to fading or smudging. They provide long-lasting identification even under harsh environmental conditions.

Can laser marking be done on curved or uneven surfaces?

Absolutely! Laser markers are designed to adapt to different surface contours. With advanced focusing techniques and precise control over beam movement, they can effectively mark curved or uneven surfaces with exceptional accuracy.

How fast is the laser marking process?

The speed of laser marking depends on factors such as material type and desired depth of mark. However, modern laser systems are capable of high-speed operations that ensure efficient throughput without compromising quality.

Conclusion

In today’s competitive business landscape, finding ways to save costs while maintaining efficiency is crucial. Laser marking offers a cost-effective solution that can revolutionize your manufacturing process. By investing in customized laser markers, you can seamlessly integrate this technology into your production line, achieving remarkable results.

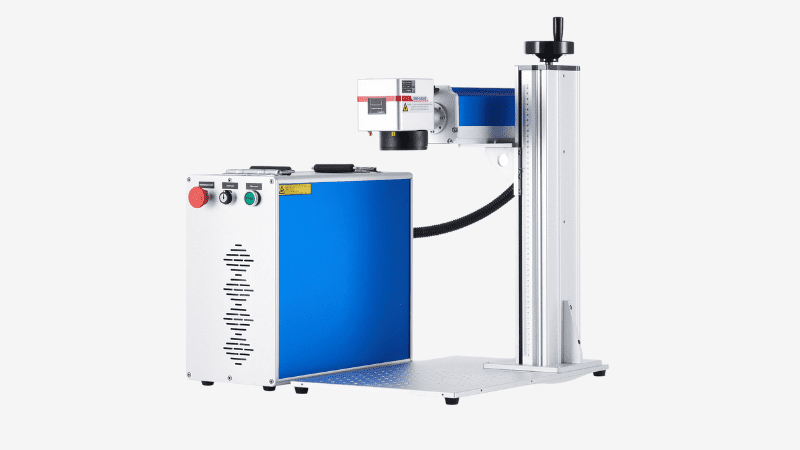

Baison Provides The Customized Laser Markers

The advantages of high precision marking, increased productivity, and reduced material waste make laser marking an invaluable asset for any industry. Whether you need high-speed marking on delicate materials or deep engraving on tough surfaces, a customized fiber laser marker of Baison can be optimized for your unique needs.

With the best laser solutions provided by Baison, you have the flexibility to tailor the system to meet your specific requirements. This ensures seamless integration into your existing workflow without disrupting productivity.