As a result, this blog post will offer a comprehensive insight into the diverse industries these machines serve and illustrate their undeniable value. By exploring this, we aim to provide businesses like yours with an understanding of how adopting such advanced technology can optimally streamline your production processes.

What Are Pipe Laser-Cutting Machines?

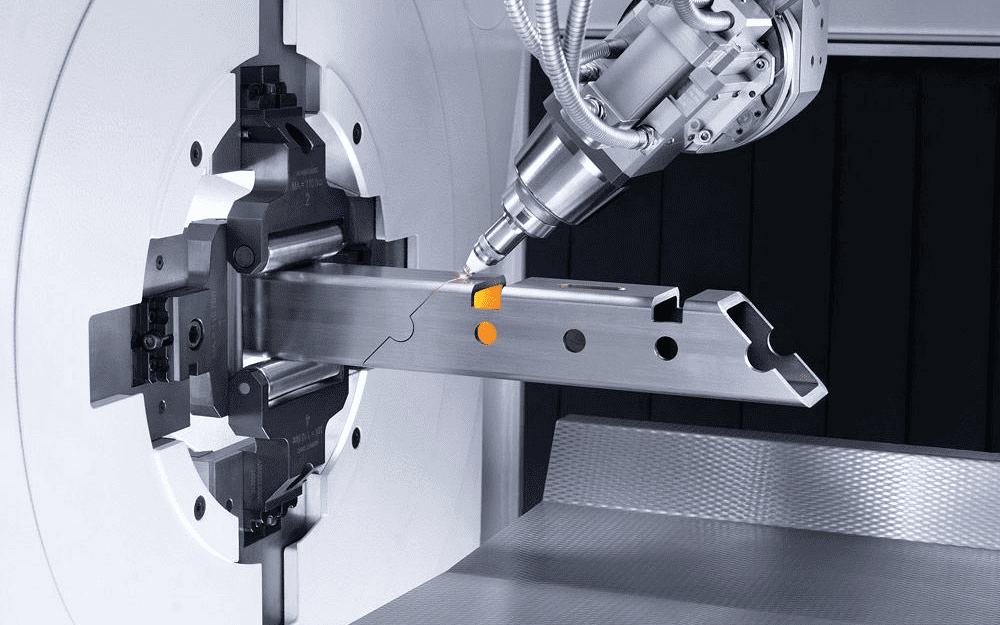

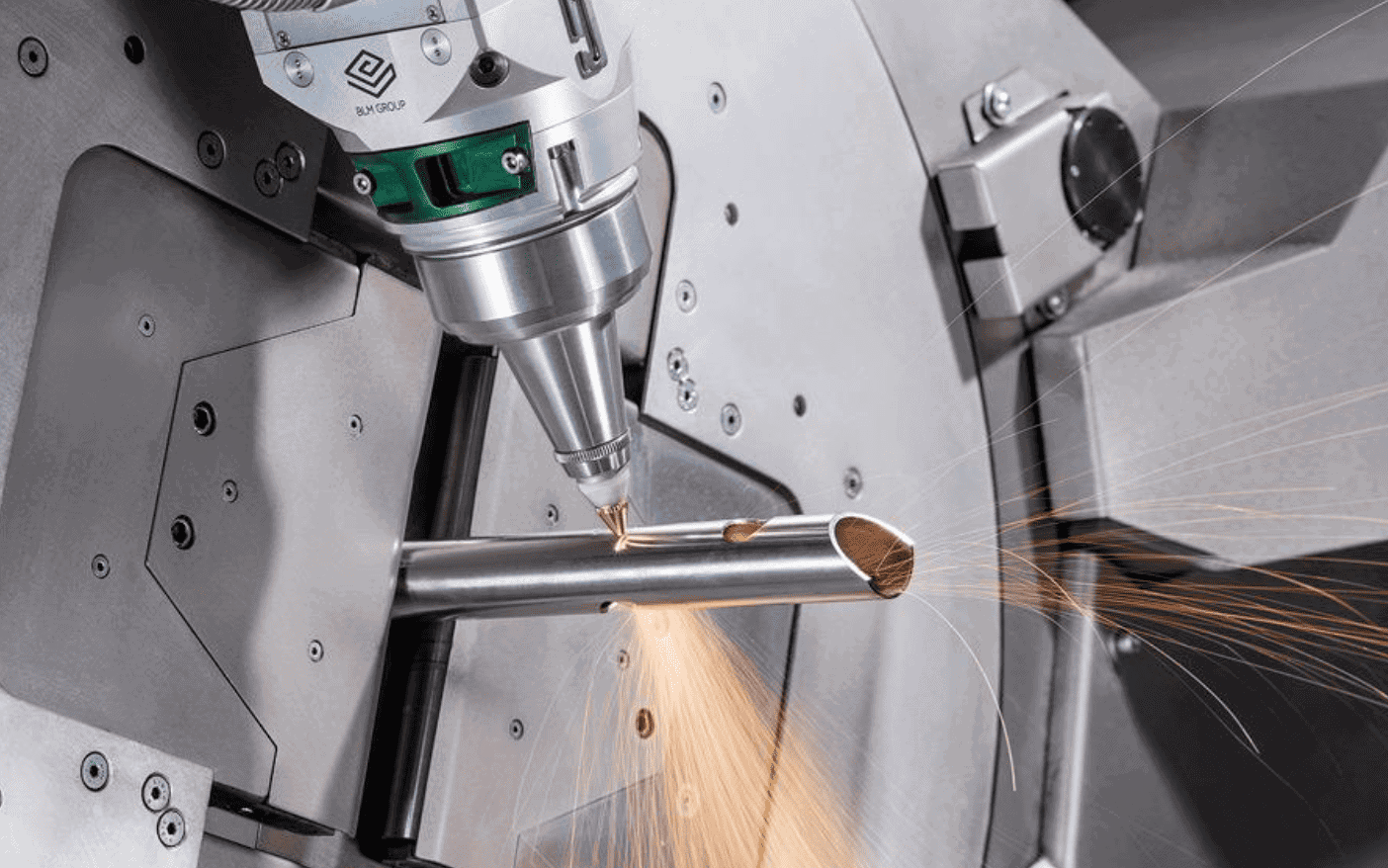

Pipe laser-cutter machines utilize fiber lasers to cut metal pipes with precision. They create clean, accurate cuts in stainless steel, carbon steel, and aluminum. Moreover, the machines feature specialized fiber laser heads that navigate around pipe contours, ensuring precise cutting and minimal heat-affected zones.

Additionally, small pipe laser-cutting machines are invaluable in the manufacturing, automotive, aerospace, and furniture manufacturing industries. They replace traditional methods like mechanical drilling, offering faster production speeds and improved accuracy. With the ability to cut various pipe shapes, these machines find applications in metal furniture, fitness equipment, medical devices, and more. On top of it, efficiency and optimization save time and bring down costs in the long run.

The Types of Pipe Laser-Cutting Machines

When it comes to pipe laser-cutting machines, businesses have a range of options to choose from. Each fiber laser cutting machine is tailored to specific needs and requirements. Hence, it is vital to understand the different types available. Let’s see what each of the prominent types has to offer and how they differ from each other:

Table-Top Pipe Laser-Cutter Machines

Table-top pipe laser-cutting machines are compact and versatile, designed for smaller-scale operations. They offer high precision and are suitable for cutting thin metal tubes and pipes. Additionally, these machines are ideal for applications in industries such as medical equipment manufacturing, where cutting small-diameter stainless steel pipes is crucial. Their compact size and portability make them convenient for space-constrained environments and mobile operations.

Small Pipe Laser-Cutting Machines

These tube laser-cutting machines are specifically designed for the precision cutting of pipes with varying diameters. They excel at handling a wide range of pipe shapes, including round tubes, rectangular tubes, special-shaped pipes, and small-diameter pipes. You will find these machines in industries like metal furniture manufacturing, fitness equipment production, and sports equipment fabrication.

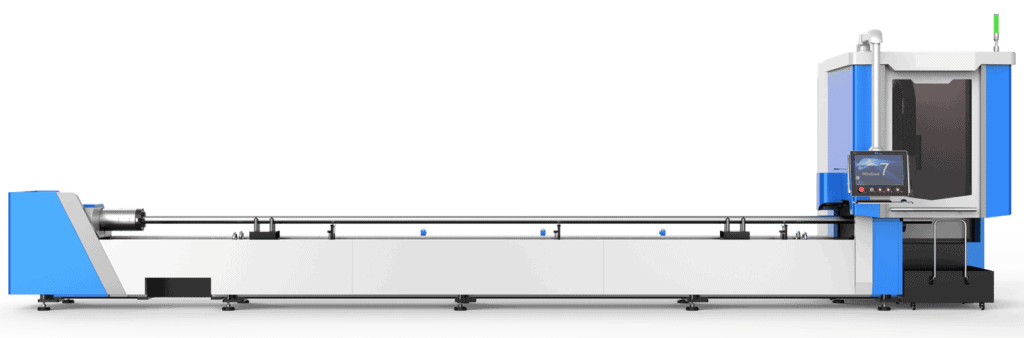

Large Pipe Laser-Cutting Machines

These machines are engineered to handle pipe cutting with larger diameters and thicker walls. Hence, they are commonly used in manufacturing, automotive, and aerospace industries, where processing larger metal pipes is essential. Moreover, they offer excellent cutting power and efficiency, enabling the production of structural components for vehicles, aircraft parts, and other large-scale applications.

The Advantages of Small Pipe Laser-Cutting Machines

Small pipe laser-cutting machines bring a multitude of advantages to the table, transforming metal fabrication processes across industries. With their precise cutting capabilities and efficiency, these machines offer substantial benefits. Let’s have a look at the top five benefits:

Advantages:

- High precision: Small tube laser-cutting machines deliver exceptional accuracy, ensuring clean and precise cuts with tight tolerances. This results in superior quality and eliminates the need for extensive post-cutting finishing processes.

- Enhanced efficiency: These machines operate at high speeds, significantly reducing production time and increasing overall efficiency. The ability to swiftly cut through metal pipes allows for streamlined workflows and improved productivity.

- Versatile applications: They can also handle a wide range of pipe shapes and sizes, making them suitable for diverse applications across various industries. From round tubes to rectangular tubes and special-shaped pipes, these machines offer versatility in fabrication.

- Clean and smooth cuts: Laser cutting technology used in these machines produces clean and smooth edges, eliminating the need for additional deburring or surface refinement. This not only saves time but also ensures a high-quality finished product.

- Material compatibility: Small pipe laser-cutting machines are also compatible with a variety of metal materials, including stainless steel, carbon steel, aluminum, and brass. This versatility allows businesses to work with different materials based on their specific requirements.

What Industries Use Small Pipe Laser-Cutting Machines?

Are you wondering how to make the most of a small tube laser-cutting machine at your production unit? Due to the high versatility of these modern machines, they are suitable for use in a wide range of industries. Let’s have a look at how these industries utilize them to enhance their production processes:

Construction

Small pipe laser-cutting machines are indispensable in construction for the precise fabrication of plumbing and HVAC systems. They ensure the accurate cutting of pipes, reducing installation time and enhancing overall quality in projects like skyscrapers and stadiums.

Agriculture

In agriculture, small tube laser-cutting machines are essential for irrigation systems. They cut pipes of various sizes, optimizing water flow to crops. These fiber laser cutters machines also fabricate components for farm equipment, such as sprayers and fertilizer distribution systems, ensuring efficient agricultural practices.

Manufacturing

Small pipe laser-cutting machines revolutionize manufacturing by fabricating components for automotive exhaust systems, machinery frames, and more. They offer precision and versatility in creating robust pipe structures, enhancing performance and compliance with the automotive industry and standards.

Furniture

Small pipe laser-cutting machines are a game-changer in furniture manufacturing, enabling intricate cuts for metal furniture frames. They ensure precise joints, seamless assembly, and high-quality finishes, meeting the aesthetic demands of both residential and commercial furniture markets.

Electronics

Small pipe laser-cutting machines play a vital role in the production of electronic enclosures, racks, and brackets. They deliver precision laser cutting services used for the proper assembly and protection of electronic components, meeting the electronics industry’s high standards and quality requirements.

Medical Equipment

The medical equipment industry uses small pipe laser-cutting machines to fabricate tubing for surgical instruments, hospital beds, and medical carts. These machines provide accurate cutting for tight tolerances, ensuring reliable performance and compliance with medical standards.

Military

Small pipe laser-cutting machines are instrumental in manufacturing military vehicles, aircraft, and naval vessels. They cut and shape pipes for fuel systems, hydraulics, and structural components, contributing to the production of high-quality and reliable equipment for defense purposes.

Tips for Using a Small Pipeline Laser-Cutting Machine

Following proper guidelines and safety measures is crucial when using a small pipeline laser-cutting machine. These tips will help ensure a safe and efficient operation. From understanding the user manual to wearing protective gear, these guidelines promote a secure working environment and optimal laser machine performance.

- Read and understand the user manual: Familiarize yourself with the machine’s operation and safety guidelines to ensure proper usage.

- Wear protective gear: Always wear appropriate personal protective equipment (PPE) like safety glasses, gloves, and ear protection to safeguard yourself from potential hazards.

- Keep the cutting area clean: Maintain a clutter-free workspace to prevent debris from interfering with the machine’s operation and compromising cutting quality.

- Keep a fire extinguisher nearby: As a safety precaution, have a fire extinguisher readily accessible in case of emergencies or accidental fires.

- Be aware of your surroundings: Maintain awareness of people, objects, and potential hazards around the machine to avoid accidents and collisions.

- Never operate the machine without training: Proper training is essential to operate a small pipeline laser-cutting machine safely and effectively. Ensure you have received adequate training before using the machine.

- Ensure the machine is in good working condition: Regularly inspect and maintain the machine to ensure it is functioning optimally and promptly address any potential issues.

Q&A: Common Questions about Using Small Pipe Laser-Cutting Machines

Q: How does a small pipe laser-cutting machine work?

A: Small pipe laser-cutting machines work by utilizing a focused laser beam to cut through metal pipes with precision. The laser melts and vaporizes the material, creating clean and accurate cuts.

Q: What materials can be cut using a small pipe laser-cutting machine?

A: Small pipe laser-cutting machines can be laser cutters for a variety of metal materials, including stainless steel, carbon steel, aluminum, and brass.

Q: Is it necessary to have specialized training to operate a small pipe laser-cutter machine?

A: Yes, it is crucial to have the proper training to operate a small pipe laser-cutting machine safely and effectively. Training ensures an understanding of machine operation, safety protocols, and optimal laser tube-cutting machines and techniques.

Q: How accurately do small pipe laser-cutting machines make cuts?

A: Small pipe laser-cutting machines provide high precision and accuracy, with high cutting precision allowing for clean cuts with tight tolerances. They deliver exceptional cutting quality, reducing the need for additional finishing processes.

Q: Can small pipe laser-cutting machines be integrated into automated production lines?

A: Yes, small pipe laser-cutting machines are compatible with automation systems. Their integration into automated production lines enhances production efficiency and productivity and enables efficient material handling and processing.

Conclusion

In conclusion, small pipe laser-cutting machines offer high precision, enhanced efficiency, versatility, clean cuts, and material compatibility. These advantages revolutionize metal fabrication processes across various industries. Discover the power of precision cutting with small pipe laser-cutting machines, and explore our website for more insights and solutions.

Take the first step towards precision and efficiency.

Discover the perfect solution for your business with Baison Laser. Request an instant quote or get a free sample proofing to experience the Baison Laser difference. Contact us today, and let us be your trusted partner in metal fabrication. Visit our website for more information: Request Instant Quote and Get Free Sample Proofing.