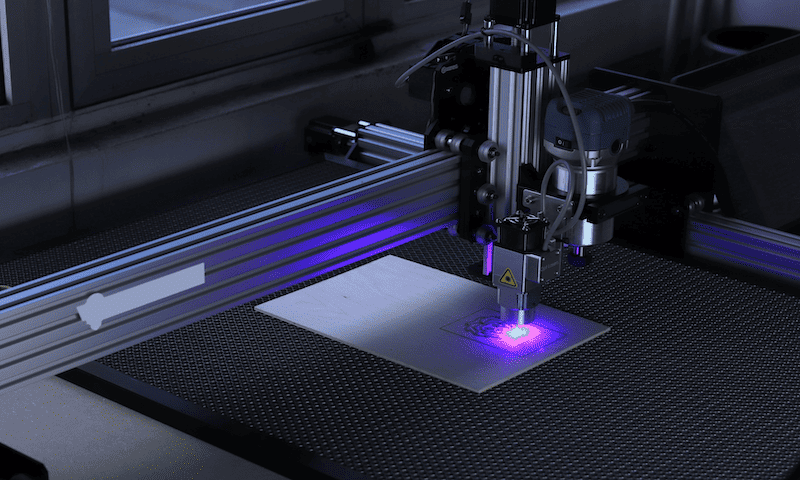

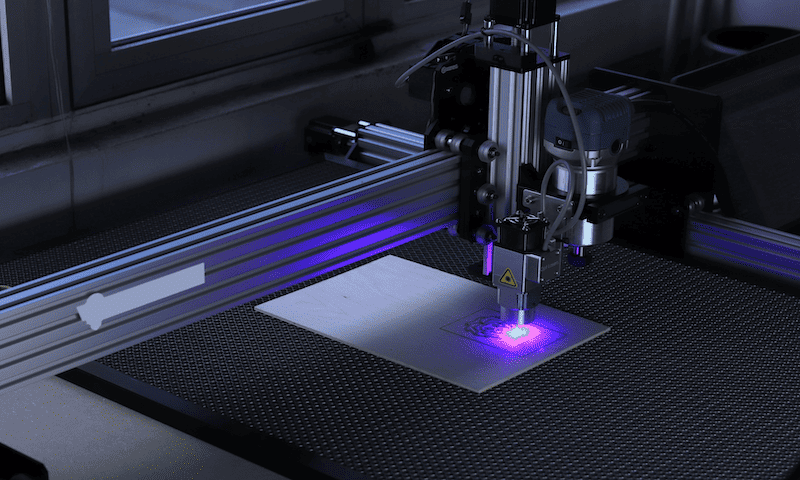

In this article, we are going to talk about the role vector files play in the processes of laser cutting, and the various benefits of using vector files in laser cutting. Vector file format can be used to bring forth unique and intricate designs with the help of laser-cutting machines. This article will help you understand the ways vector files can come in handy in your laser-cutting business.

Understanding Vector Files

Laser cutting can incorporate a lot of unique and complex designs. But if the curves, and shapes are not well-defined, it can be quite difficult to scale up in size.

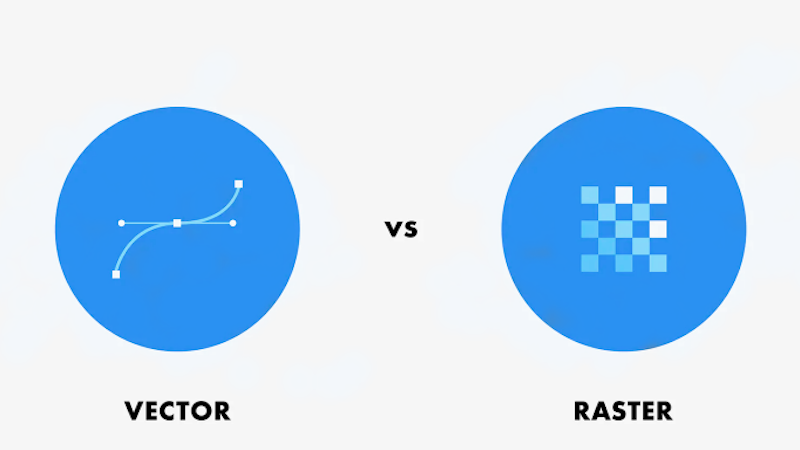

Vector files include designs that can be applied not by pixels, but by mathematical instructions. This is the essence of vector files. These digital blueprints are composed of points and paths, allowing for the creation of clean, infinitely scalable designs.

A raster image can become blurry when enlarged but that is not the issue with vector files. Vector files come in PDF as in Portable Document Format files and maintain their sharpness and precision regardless of size. (For more details about vector file and raster file comparison, refer to this article.)

Do You Have Any Questions?

Let Us Solve Your Problem

The Role of Vector Files in Laser Cutting

Without a good design that can be easily implemented, the benefits of laser cutting become null and void. Vector designs are of high resolution and do not get pixelated. They act as this roadmap, guiding the laser beam along specific lines and curves to create the desired cuts.

These instructions ensure accuracy and consistency, even when dealing with intricate details and complex designs. Vector laser engraving is of a much higher quality than raster engraving.

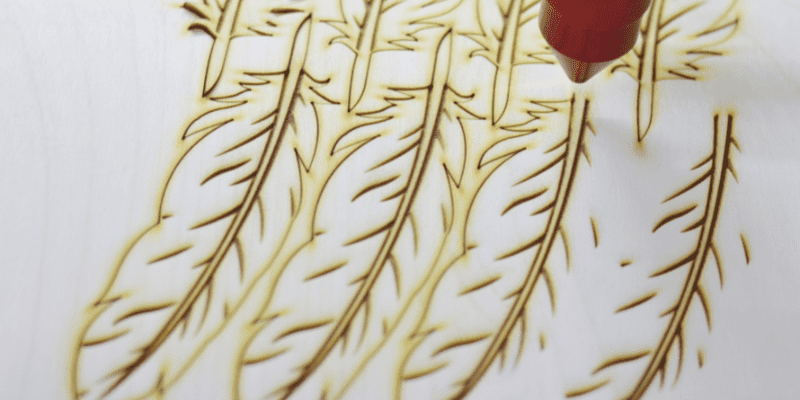

- Intricate Cuts: Vector files enable the creation of complex and detailed designs with laser precision. Even if the design needs to be enlarged, there is no issue with the quality of the design.

- Precise Patterns: Even intricate patterns and designs can be accurately replicated with the help of vector files.

- Customized Designs: Vector files offer the flexibility to personalize and customize projects according to specific requirements.

Benefits of Using Vector Files in Laser Cutting

Laser cutting has a lot of amazing uses and these uses can be best implemented when the design is good. The main advantage of a laser cutting machine is the precision cutting process. This is where the benefits of vector graphics come in.

- Unmatched Precision: Vector files guarantee clean, sharp cuts with minimal waste, eliminating the risk of jagged edges and imperfections.

- Scalability for All: According to Stanford University, whether you’re working with a miniature piece or a large-scale project, vector designs can be resized without losing quality.

- Versatility and Adaptability: Most laser cutters and software are compatible with popular vector formats, offering flexibility and ease of use.

- Easy Changes and Modifications: Vector files can be easily manipulated and adjusted, allowing for fine-tuning your design before cutting.

Do You Have Any Questions?

Let Us Solve Your Problem

7 Types and Formats of Vector Files

As a design element, vector files come in various formats. Different formats can be used in different industries. Several vector formats are used in laser cutting, each with its own strengths and weaknesses. Here are some of the most common:

1. EPS (Encapsulated PostScript)

- High Quality: EPS files support various color models and can handle complex graphics with high fidelity.

- Wide Compatibility: Compatible with most design and laser cutting software, making it a universal choice.

- Flexibility: Supports both raster and vector data, allowing for mixed content projects.

2. SVG (Scalable Vector Graphics)

- Scalability: SVG files retain their quality regardless of size, making them ideal for large-scale projects.

- Lightweight Nature: Compared to EPS, SVG files are smaller and faster to load, perfect for web graphics.

- Open Source: SVG is an open standard, ensuring free access and wide software support.

- Potential Compatibility Issues: Not all laser cutting software might support all SVG features, potentially affecting some aspects of your design.

3. DXF (Drawing Exchange Format)

- Industry Standard: Widely used in CAD software, making it ideal for technical drawings and engineering projects.

- Precise Data: DXF files store precise data about lines, points, and dimensions, ensuring accurate cutting results.

- Compatibility with Laser Cutting Software: Most laser cutting software supports the DXF format, making it a reliable choice for cutting projects.

4. AI (Adobe Illustrator)

- Industry Standard for Design: AI is a go-to format for graphic design, widely used by professionals.

- Highly Versatile: Supports intricate designs with multiple layers and color models.

- Adobe Ecosystem Compatibility: Seamlessly integrates with other Adobe software but may have compatibility issues with non-Adobe products.

- Proprietary Format: Requires Adobe software for full feature utilization, potentially limiting accessibility.

5. PDF (Portable Document Format)

- Universal Accessibility: Widely used across various platforms and devices.

- Versatility in Content: Can contain both vector and raster graphics, text, and images.

- Reliable for Print and Digital: Maintains quality across digital and print mediums.

- Variable Editability: While editable with certain software, not primarily used for detailed graphic editing.

6. CDR (CorelDRAW)

- Dedicated Graphic Design Format: Primarily used for vector graphic illustrations.

- Specialized Features: Offers unique tools and effects specific to CorelDRAW.

- Compatibility: Best suited for CorelDRAW users; may require conversion for use with other software.

- Less Universal: Not as widely recognized as AI or SVG, which may limit sharing and collaboration.

7. WMF (Windows Metafile) / EMF (Enhanced Metafile)

- Microsoft Integration: Developed for seamless use within the Microsoft ecosystem.

- Good for Simple Graphics: Ideal for basic illustrations and designs.

- Limited Complexity Handling: WMF and EMF may not be suitable for highly detailed or complex designs.

- Compatibility Outside Windows: Potentially limited compatibility with non-Windows platforms and advanced graphic design software.

Do You Have Any Questions?

Let Us Solve Your Problem

Creating and Optimizing Vector Files

Creating a vector file is also something that requires skills and knowledge. If you want to create a great product, the source material needs to be great as well. Not all vector files are created equal. Successful businesses need to avoid using raster files because of the liability they pose. To ensure optimal laser-cutting results, you must consider these tips:

- Use dedicated software: Design software like Adobe Illustrator, Inkscape, and CorelDRAW offer tools specifically tailored for vector creation.

- Simplify your design: Focus on clean lines and avoid unnecessary details for smoother laser cutting.

- Check for overlaps: Overlaps in design can actually ruin the whole thing. Make sure to eliminate overlapping paths to prevent unwanted burns or miscuts.

- Choose appropriate strokes and fills: Designs need to be precise to get the desired precision on the output. Gradients cannot be input into the system. Avoid gradients and fills that can affect laser-cutting behavior.

Vector File Software for Laser Cutting

Laser cutting requires the use of some good software that enhances the job output. Vector files are also used in laser cutting through various software. Several software options can help you prepare and manage your vector files for laser cutting:

- LightBurn: This is one of the most popular and most widely used software. It is an affordable and user-friendly software with specific features for laser cutting.

- LaserCut: This one is a free and open-source software offering powerful tools for advanced projects.

- SendCutSend: SendCutSend is another one of the well-performing software. It is a cloud-based platform that allows you to upload your files and get them laser-cut directly.

How to Convert a File to a Vector?

Converting a file to a vector depends heavily on the type of file you’re starting with. The quality of the conversion will depend on the complexity of the original file. Simple images with clean lines will convert better than images with lots of detail or gradients.

When the need strikes, you need to convert other files into vector images for better results in your laser-cutting business. Raser images include file types like JPG, PNG, etc. Raster images can be converted into vector images by following these methods:

- Image Trace Software: Programs like Adobe Illustrator, CorelDRAW, Inkscape, and online tools like Vectorizer.com offer image trace features that automatically convert raster images to vector paths. These tools vary in complexity and control, but they can be a good starting point.

- Manual Tracing: For more control and detailed results, you can trace the image manually using pen tools in vector design software. This is a time-consuming process but allows for greater precision and customization.

Do You Have Any Questions?

Let Us Solve Your Problem

FAQs

1. How can I ensure my vector file is optimized for laser cutting?

You can ensure that the vector file is properly optimized for your laser cutting machine by using dedicated software like Adobe Illustrator. You can simplify the design and avoid unnecessary details. Also, it is good to check for overlaps in the design lines. But most importantly, make sure that the file is in a compatible format with the laser cutting software.

2. What is the future of vector files and laser-cutting technology?

Laser-cutting technology is constantly evolving, offering greater precision, speed, and versatility. Vector files will continue to play a crucial role in this advancement, enabling the creation of increasingly complex and intricate designs. It can be a good addition to your laser-cutting business.

3. What are some common problems encountered when preparing vector files for laser cutting?

Some common issues with vector files include problems like overlapping paths in the design which can cause unwanted burn marks. If the shading and design fills are not clearly depicted, it can create design issues. The machine cannot decipher the design and might cut unwanted areas in the design.

Conclusion

For anyone seeking precision and accuracy in their laser cutting projects, vector files are an essential tool. By understanding their advantages you can elevate the skills and performance of your business.

At the same time, choosing the right format is very important. Optimizing your designs, you can unlock the full potential of laser cutting and bring your creative visions to life with remarkable detail and flawless execution with the help of vector files in your laser cutting.

Add More Precision and Uniqueness to Your Laser Cut Designs!

In this competitive industry, having the upper hand is a must. In your laser cutting business, the use of vector files can bring extra crispness to the projects. Contact Baison Laser today and take the first step to bring your projects to life in the best way possible with the best in laser technology.