There are surgical tools like Scalpel or forceps. There are prosthetic limbs that require intricate designs. Devices like pacemakers and heart valves require components that are accurate in size and design, biocompatible, and yet lightweight enough to mimic human limbs.

This article will discuss the importance of laser-cutting machines in medical device manufacturing. We will discuss how medical device laser cutting is essential. It can reduce burr and time and provides the precision that medical tools require.

Different Materials Used in Manufacturing of Medical Devices and Tools

There is a wide variety of tools that manufacturing industries make for diagnosing, treating, and monitoring patients. A variety of materials are used. Some common tools are:

Stainless steel

Stainless steel is a common material used in medical tools. It’s a great choice to make all sorts of surgical instruments and dental tools. It’s non-toxic and corrosion-resistant. Various stainless steel is used for different cutting and piercing instruments.

Most medical implants and body piercing tools are made of 316 and 316L, the common type of stainless steel used in medical tools. These are highly corrosion-resistant.

440 stainless steel is used for surgical cutting tools. They need special treatment and a sharp cutting edge. There are tweezers, forceps, hemostats, and other equipment. Then orthopedics use replacement joints, screws, and implants to stabilize broken bones and joints.

Nitinol

Nitinol is a highly temperature-sensitive material that makes several medical devices like insulin pens, stents, guide wires, filters, and orthopedic implants. It’s a shape memory alloy of nickel and titanium, and due to its unique properties like hardness, elasticity, and high melting point, cutting it without a laser cutter is difficult.

Titanium

Titanium is another material that can be substituted with stainless steel to make skeleton support. It is used to make customized parts from patients’ Xray and scans.

Cobalt Chrome

Another material is frequently used in the medical industry. Cobalt chrome alloys are used to make hip and shoulder socket replacements.

Aluminum

Aluminum is not used in parts used in the body. It makes tools and equipment like wheelchairs, walking sticks, IV stands, or orthopedic supports.

Platinum

Platinum is also corrosion-resistant, biocompatible, and highly stable inert material. Very fine platinum wires are used in internal electronic implants like pacemakers.

Iridium

The primary use of Iridium is to coat wiring used for electro-stimulating devices.

Tantalum

Tantalum is used in cranial bone replacements and dental devices like screws or crowns.

Besides these metal objects, several materials are used in making different casings and tools, like

- Glass-ceramic

- Plastic

How Laser Cutting Helps in Designing and Manufacturing Tools and Medical Devices

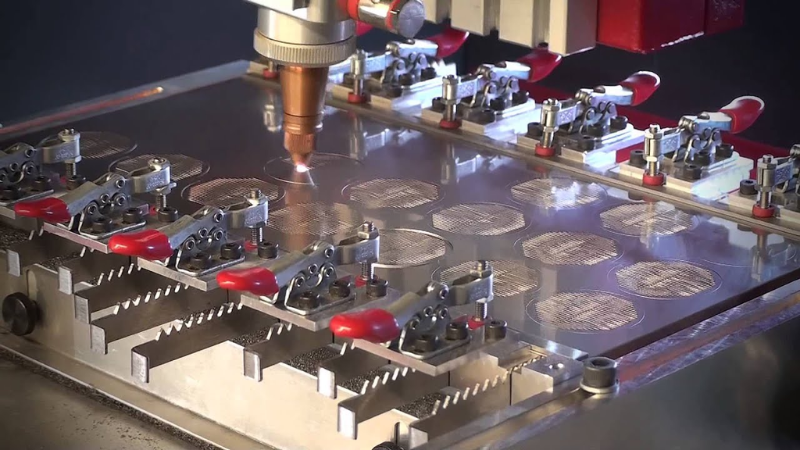

Laser cutting helps in cutting, marking, and welding delicate thin and thick metals, glass, or other materials and is also essential in making design tools to prepare medical devices and tools.

Laser-cutting machines can create prototypes, refine designs, and produce the final product. For example, a laser cutting machine can cut and shape metal components for surgical instruments, medical implants, and diagnostic equipment.

Additionally, new molds and templates are made to manufacture tools and devices. By using laser cutting technology to produce these molds and templates, manufacturers can create highly precise and accurate tooling that helps to ensure consistency and quality in the final product.

How Laser Processing Can Help in the Medical Industry

Laser cutting uses a high-powered laser beam to cut, etch, or engrave materials. The laser beam is focused through a lens and directed onto the material, typically held in place by a CNC (computer numerical control) machine.

As the laser beam heats the material, it vaporizes or melts it, creating a precise cut or etch. Even laser cutter machines come in different types: fiber lasers, CO2 lasers, and Nd: YAG lasers. All of these can be used for cutting in the medical industry.

Laser welding, laser marking, and laser drilling machines are used to process various purposes, including surgical procedures, diagnostic testing, and medical device manufacturing. They offer a contamination-free process required for the cutting process of medical components.

Benefits of Using Laser Cutting Machines in Medical

Precise and Accurate

Laser systems provide the high precision required for medical device manufacturing. When it comes to medical tools and devices, the size and design of the tool are critical. Precision is of the utmost importance in the medical field, and even small discrepancies in size can have significant consequences.

Complex Design and Marking

Surgical tools and other medical devices have complex designs that are difficult to cut without a laser cutter. The designs are fed into a laser machine, which the machine replicates with the accuracy that medical manufacturing demands.

Hard and Tricky Materials

Different medical device components and tools use a range of materials. A laser cutting machine is versatile enough to handle all types of metals. Whether cutting the maximum thickness or thin pins and plates, the cut quality remains the same.

Each material requires different handling and laser machine-cut edges with superior motion control and high precision. It can drill minute holes in tools and engrave or mark lines or patterns on catheters and needles. All types of micromachining with small pulse duration and less laser power.

No Thermal Damage

While handling all types of materials, there is a risk of thermal damage. The laser machine provides high dimensional accuracy with full control, where you can adjust the power of the laser. As it works with laser beams, the risk of heat damaging the material is zero.

No Risk of Flatening

When working with tricky mantels, the braiding and coiling can be tricky. Flattening is risky, but with laser machines, finished tools are accurate to the design without any misshaping.

Fast Turnaround Time

Laser machines work very fast and can hand production on a large scale. They are also fully automated machines that can work much faster than the traditional ways of cutting.

Cost Effective

Besides several other benefits of laser machines to cut, weld, and engrave medical tools and components, their design precision, intricate cut, accuracy, fast turnaround time, and versatility. The most important reason for using laser machines is cost-effective production.

How Process Control of Laser Machines Affect the Quality of Medical Tools?

Process control in laser cutting monitors and adjusts several parameters, including laser power, beam quality, cutting speed, gas assist, and beam focus. All of these adjustments can affect the quality of the cut, including the edge quality, dimensional accuracy, and surface finish. That is essential for cutting medical tools and devices.

With process control, manufacturers can ensure that each cut is consistent and meets the required specifications. This helps to reduce the risk of defects, such as burrs or rough edges, that can compromise the quality and safety of the medical tools.

Applications of Laser Cutting Machines Used in the Medical Device Industry

Here are some applications of laser-cutting machines in the medical industry.

Surgical Instruments

Surgical instruments are the tools that are used in surgeries. They are made of high-quality materials and require extreme precision and accuracy. They have intricate designs for specific purposes, including forceps, scissors, scalpels, retractors, or clamps.

Dental Implants

Laser-cutting machines can be used to fabricate some types of dental implants. They require cutting materials like ceramics and metal to specific shapes. They are also used to make custom-filled dental restorations.

Prosthetics

Prosthetics are designed to replace missing or damaged body parts. They can be made from various materials, including metal or carbon-filled. They require precise shapes and sizes. Laser machines also cut sockets that attach them to the human body and specific covers to make them appear natural. Besides cutting and shaping, these tools require specific marking and engraving to help the users.

Medical Device Components

Besides tools, medical device components are also made with the help of laser-cutting machines. They require specific parts made from different materials. These components are first designed using computer-aided design software.

Arthroscopic tools

Arthroscopic tools are also surgical instruments for minimally invasive knee, joint, shoulder, or hip procedures. These tools must be cut in specific shapes and cut with extreme precision. These tools are usually made from high-quality stainless steel. Hypotubes, catheters, or endoscopes.These tools require designing, cutting, and welding very thin materials.

Final Words

Devices and tools used in the medical sector come in a broad range. Different materials are used in their making. Laser-cutting machines offer the accuracy and precision to work on hard and thin materials and produce intricate designs.

Not only this laser machining can work on high-resolution materials, but the fast turnaround time ensures the safety standards as required by FDA.

Baison offers a range of laser machines for both small to big industries. We offer CO2 and fiber laser cutting machines, laser welding machines, and engraving machines that can produce high-quality medical tools and components of devices.

Revolutionize Your Medical Device Manufacturing With Our Laser Cutting Machines

Baison provides state-of-the-art laser cutting machines that can take medical device manufacturing to the next level; contact us today to learn more about our laser machines. Upgrade to our laser-cutting machines and revolutionize how you create medical tools and devices. If you are unsure which one suits your needs, we provide a free evaluation application to our customers.