Laser cutting is an efficient and cost-effective method of cutting materials, especially when compared to traditional processing methods such as mechanical sawing or water jetting.

Laser cutting has been used in various industries, including food processing, since the early 1990s.

In addition to its versatility, laser cutting offers advantages such as minimal waste generation and improved productivity through faster material removal rates.

In this blog post, we’ll take a closer look at Baison’s tube laser cutting in the food industry: advantages and applications.

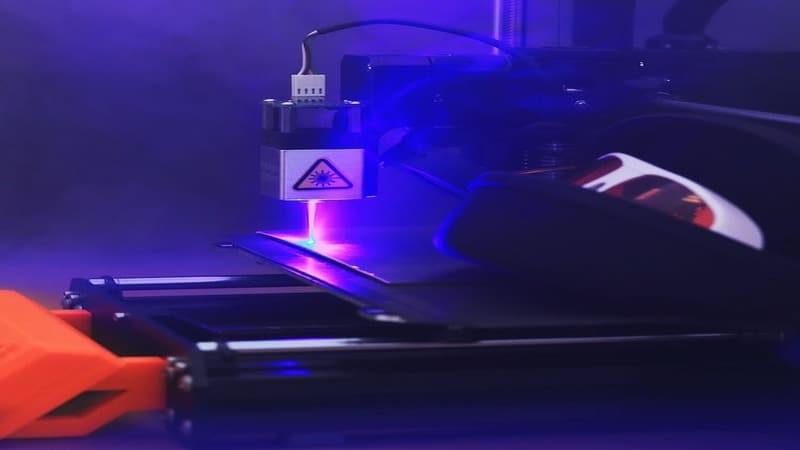

What Is Laser Cutting?

Laser cutting is the process of using a laser beam from fiber lasers to cut or engrave a material precisely and accurately. The laser beam cuts through the material by removing small portions of precise parts of it, leaving behind a clean edge. Besides, Understanding laser cutting parameters is important.

Tube laser cutting machines are used to cut tubes made of different materials, such as aluminum, carbon steel, and stainless steel. The tube-cutting machine can be used for both straight-line cuts and circular cuts.

Advantages of Tube Laser Cutting in the Food Industry

Tube laser cutting is a relatively new technology that has been gaining popularity in the food industry. It is an innovative way to cut tubes and pipes, and it features many benefits that make it ideal for use in this field.

Here are some of its advantages:

1. Precision and Accuracy

The first advantage of tube laser cutting technology is high precision and high-cutting accuracy. The machine uses a high-powered laser beam to cut through the material. This means that it can make very precise cuts with little effort or waste materials.

This makes it ideal for making intricate products like tubes or pipes. As well as for creating accurate labels for containers that need to fit perfectly onto them without leaving any extra room.

2. Versatility

Tube laser cutting machines are available in different sizes and configurations. This makes them suitable for various applications in various industries like aerospace, automotive, furniture, and many more. The versatility of these machines makes them very popular in many manufacturing process industries, including food processing and packaging.

Besides, you can use a tube cutting machine on any sort of material you want. It doesn’t matter if your product is made from metal tubes or plastic—the machine will work fine on both types of materials as long as they meet certain specifications.

3. Increased Efficiency and Speed

The tube laser can achieve high speeds by using high-power CO2 tube lasers with a large focal length lens. This allows for long working distances between machine components (laser head) and workpieces (stock material).

This increases productivity levels within production facilities, reducing overall costs per unit produced. Thereby making this type of machine highly cost-effective to purchase or lease on a long-term basis.

4. Cost-effectiveness

In the food industry, laser tube-cutting machines are cost-effective due to their ability to cut through a wide range of raw materials easily. They can also be used to cut out complex shapes and designs on different types of materials. It means that they can be used for a variety of commercial applications.

This makes them the perfect option for companies producing food product packaging. They can be used on various types of packaging that might need to be cut for production efficiency.

5. Safety

Tubular laser cutting machines are safe to use because they use lasers instead of blades or saws to cut through the material being worked on.

This means that there is no need for sharp edges or blades on the machine itself. Therefore, there is less risk of cutting head injury when using this kind of machine to make your products.

6. Low Waste Production

The amount of waste produced by tubular laser cutting machines is much lower, making it an ideal solution. This is when compared with other types of pipe-cutting machinery used for similar purposes because it only needs one side cut at once.

So if you have a product that needs both sides cut, you can flip it over before making another pass through the machine again (so long as it’s not too heavy). This means there will be much less waste produced overall than other methods available today

Applications of Laser Cutting in the Food Industry

In the food industry, laser technology is used for everything from packaging to production, logistics, and quality control.

With laser cutting services, manufacturers can create intricate designs that use less material than traditional methods. This is achieved while also ensuring that their products meet FDA guidelines.

Lasers are also useful in logistics because they make it possible for companies to pack items into boxes or bags quickly. This is without wasting time on paper jams or tape that might break during shipping.

In addition, a laser machine can be used in quality control by analyzing product defects before they’re shipped out, meaning fewer recalls.

In food processing plants and industrial applications, laser cutting can be used for many purposes such as:

- Cutting plastic and metal pipes or containers for packaging products

- Removing labels from bottles or cans

- Removing the excess material from cans before filling them with food products such as fruits or vegetables

- Cutting holes with great precision in bags for pouring liquid contents into bottles or cans that are being filled with fluid at high speed (e.g., milk)

What Is Chuck’s Self-Cleaning Function of the Laser Tube Cutting Machine?

Chuck’s self-cleaning function is one of the most important features of our Baison’s laser tube cutting machine, as it helps to keep the equipment in good shape and working well for a long time.

The Chuck uses compressed air to blow away any debris or dust that has accumulated on the Chuck. The compressed air has a temperature of 180 degrees Celsius (356°F) and is at a pressure of 80 bar (1170 psi). So it can remove stubborn dirt without causing damage to our machine.

This feature makes our machine ideal for use with beverage equipment, such as milk production lines, where there could be lots of dust floating around due to the nature of agricultural machinery and the product being produced.

Common Challenges in Tube Laser Cutting and How to Overcome Them

The tube laser cutting machine has been used in the food industry for a long time. It provides a number of advantages that make it well-suited for this type of work.

Let’s take a look at some other technologies with these advantages and applications in detail.

1. Contamination

Contamination is one of the most common issues in tube laser cutting in many industries. It occurs when a foreign material gets into the laser beam path and interferes with its operation. This might cause a reduction in the quality of your work or even a complete failure of the machine.

2. Heat Generation

Heat generation is another common problem with tube laser cutting machines. The amount of heat generated during the cutting process can be quite high. This can lead to problems like damage to materials like metal profiles, equipment failure, or even fire hazards if not handled properly.

3. Warping

Warping is another issue that you might face while using a tube laser cutting machine in food production industries. Warping occurs when too much heat is generated during this process and causes distortion of your material’s shape. This can lead to a loss of quality in your product or even make it unfit for consumption at all due to its irregular shape.

4. Deformation

Deformation also occurs during tube laser cutting processes as it can lead to damage or even complete failure of both equipment and material used for making your products.

Future Developments and Trends in Tube Laser Cutting in the Food Industry

The food industry has many future developments and trends in tube laser processing and cutting. One of these developments is that tube laser-cutting machines will continue to be used at an increasing rate for food packaging purposes. In fact, it is predicted that by 2024, these machines will be used for more than 50% of all food packaging.

Another trend is that many companies will invest in these machines and use them to improve their productivity. This will increase demand for tube laser-cutting machines. This increase in demand will be met by an increase in supply as well, which means that the price of such machines will fall further over time.

Finally, we can expect to see an increase in innovation when it comes to tube laser-cutting machines. This could include new features or new technologies being incorporated into existing models. It can also be improvements being made to existing models and entirely new models being created that provide even better value for money than before.

Conclusion

As predicted, there is a significant rise in the use of tube laser cutting machines in the food industry owing to their high demand. These machines can cut, etch and emboss many materials into all kinds of shapes that human hands cannot.

They are a great asset to food processing companies and other modern industries. The innovative technology cutters have an extremely high production rate, precision, and high accuracy throughout, making them perfect for labeling jobs.

Considering their high number of applications and usefulness, it is no wonder that businesses are using them for processing accuracy. Engage Baison‘s experts today and save money by requesting an instant quote ideal for your business.