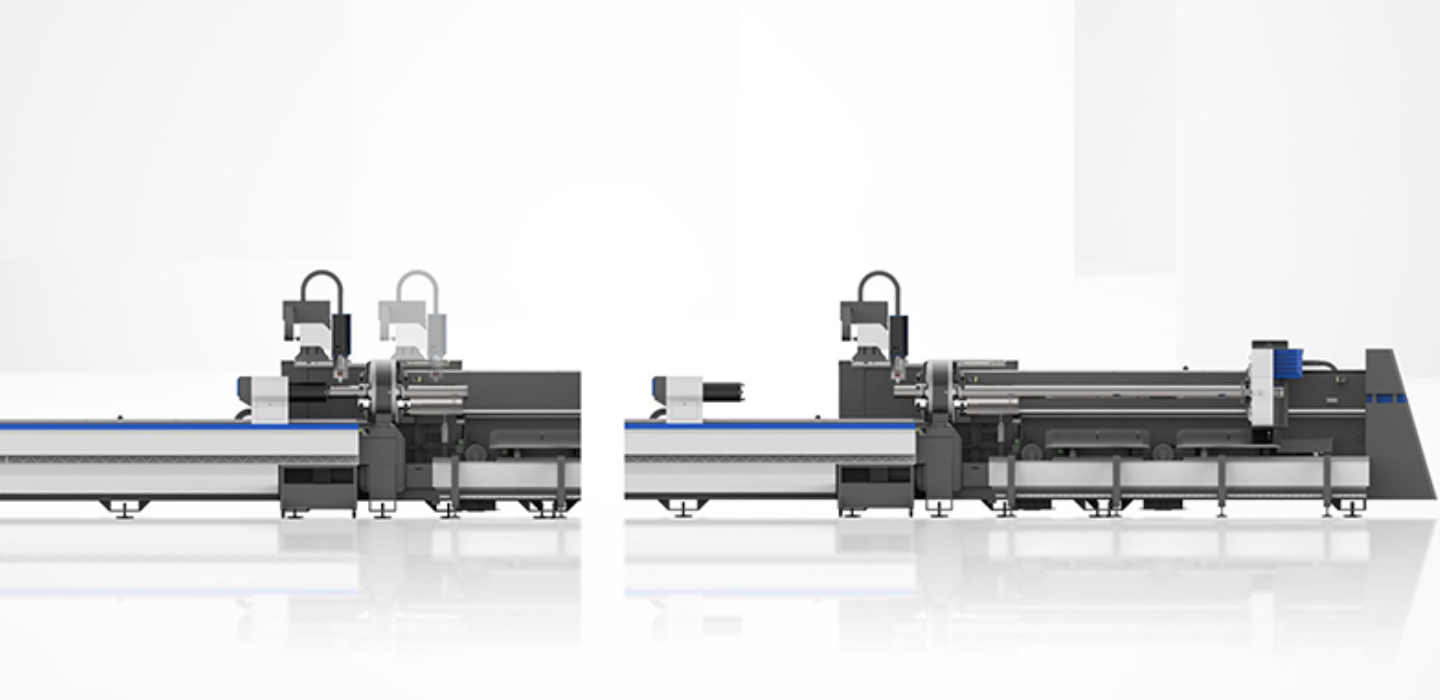

Specifically, should you invest in a three-chuck laser pipe cutter or its four-chuck counterpart? In this blog post, we’ll dive deep into the merits and demerits of both these machines, empowering you to make an informed choice that suits your business best.

What Is Three Chuck Laser Pipe Cutter?

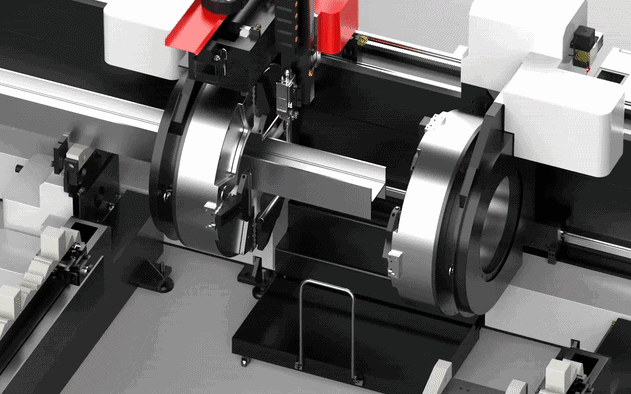

A three-chuck laser pipe cutter is a high-tech piece of machinery, designed specifically for precision in laser tube cutting. This tool utilizes three chucks to secure tubes or pipes, ensuring accuracy and efficiency during the cutting process.

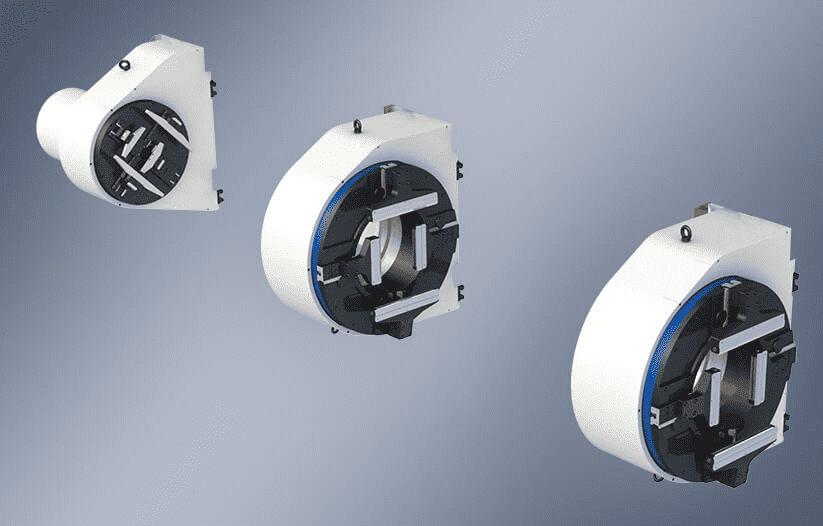

In the fast-paced environment of manufacturing, the three-chuck laser tube-cutting machine stands as an essential tool. Its role is significant in reducing material waste and increasing productivity. The machine can handle various tube shapes like round, square, and rectangular tubes, and it works efficiently with multiple materials such as carbon steel and copper. This versatile capability makes it a valuable asset in diverse product lines.

Do You Have Any Questions?

Let Us Solve Your Problem

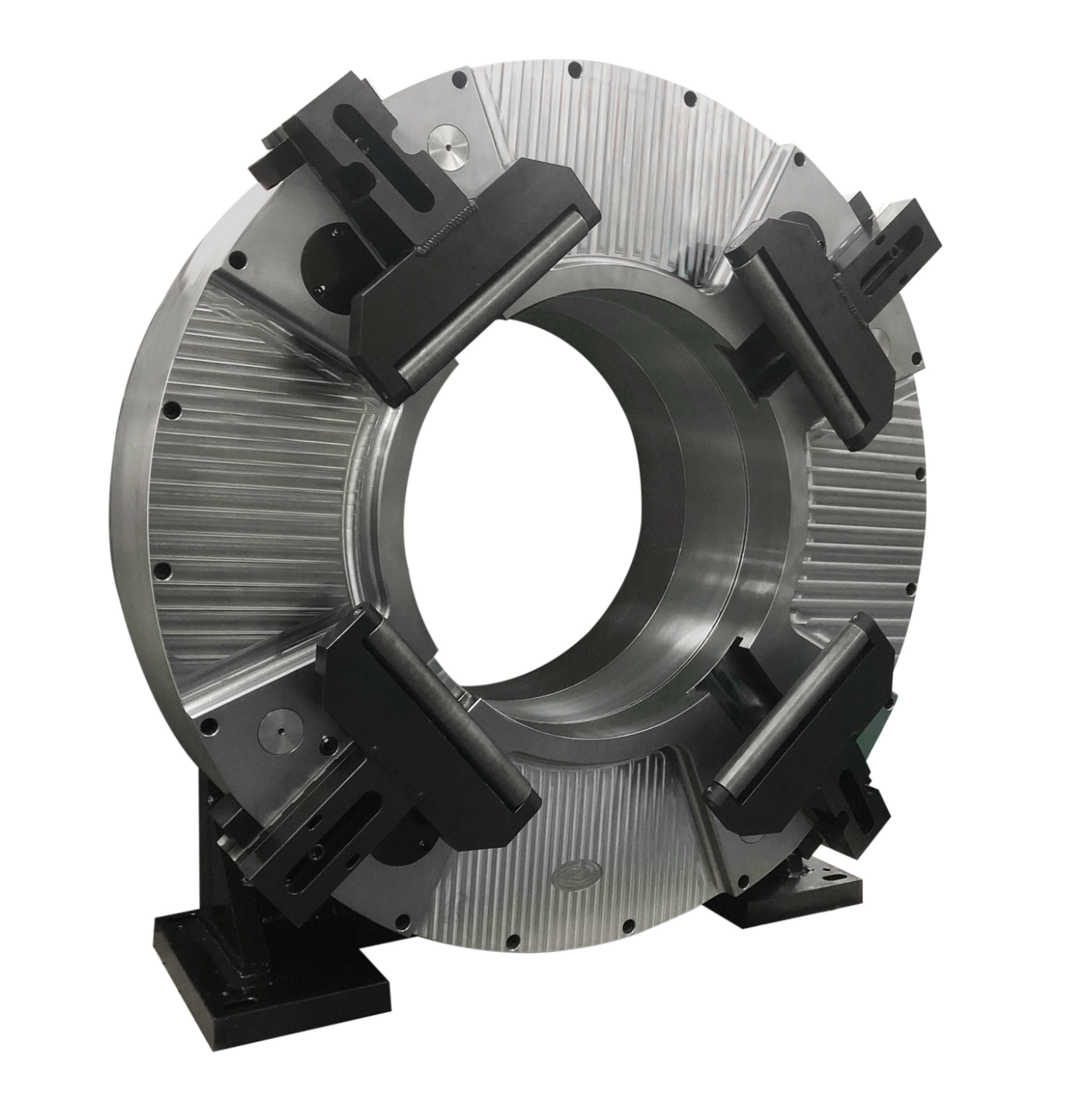

What Is Four Chuck Laser Pipe Cutter?

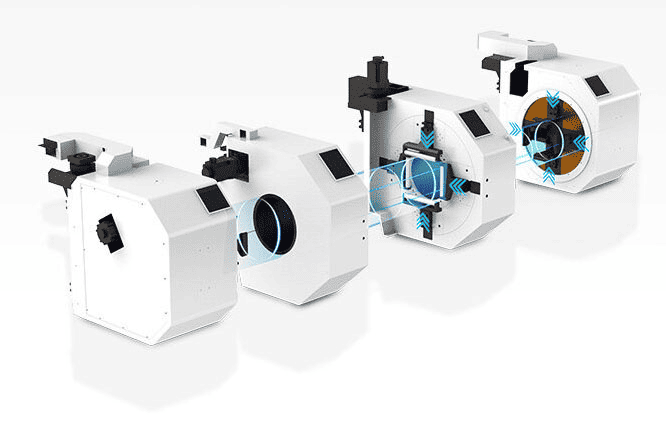

A Four Chuck Laser Pipe Cutter is a technologically advanced cutting solution specifically designed for high-precision cutting of tubes and pipes. The unique element of this tool, as the name suggests, is its four chucks, providing a firm grip, enhanced stability, and superior precision, accommodating diverse pipe shapes and sizes.

But why does it matter to a business owner? With the competitive market environment, businesses strive to optimize their manufacturing processes and achieve superior quality products. Four chuck laser pipe cutters are an answer to this call, offering high efficiency and precision in a tube and pipe-cutting processes, leading to higher production rates and cost-effectiveness.

The Pros and Cons of Three Chuck Laser Pipe Cutter

The Three Chuck Laser Pipe Cutter holds a unique position in the laser tube cutting industry, offering an intriguing blend of benefits and drawbacks that significantly influence its applicability. By closely examining these pros and cons, businesses can make a more informed decision about the suitability of this tool for their specific operations.

Pros of Three Chuck Laser Pipe Cutter:

- Precision Cutting: Thanks to the firm grip provided by the three chucks, this device offers high precision in the cutting process. This is particularly advantageous when tasks require intricate shapes and designs.

- Versatility: The three-chuck system is capable of accommodating a broad range of tube sizes, enhancing the machine’s versatility for diverse projects.

- Cost-Effective: Compared to more complex systems, such as the four-chuck cutter, three-chuck cutters are often more affordable, making them a budget-friendly choice for many businesses.

- Ease of Operation: In general, a three-chuck system is simpler to operate, potentially reducing the learning curve for new operators.

Cons of Three Chuck Laser Pipe Cutter:

- Limited Stability: Although three chucks provide a good grip, they may lack the stability offered by a four-chuck system. This can affect the cutting precision when handling larger or heavier tubes.

- Longer Loading and Unloading Times: With only three chucks, the loading and unloading process could take longer than with a four-chuck system, possibly affecting overall production efficiency.

- Less Optimal for Irregular Profiles: For tubes with irregular shapes or profiles, a three-chuck system may not offer the same level of adaptability and precision as a four-chuck system.

The Pros and Cons of Four Chuck Laser Pipe Cutter

The Four Chuck Laser tube cutting machine, a more advanced alternative to the Three Chuck model, brings its own set of advantages and challenges to the table in the realm of laser tube cutting. Understanding these strengths and weaknesses can guide businesses toward the optimal investment for their unique needs and operations.

Pros of Four Chuck Laser Pipe Cutter:

- Superior Stability: The four-chuck system offers enhanced stability during operation, which can lead to improved cutting precision, especially when dealing with larger or heavier tubes.

- Faster Loading and Unloading: A four-chuck cutter could potentially speed up the loading and unloading process, increasing the overall efficiency of your production line.

- Greater Versatility: This cutter excels in handling irregularly shaped tubes, due to the superior adaptability and precision of the four-chuck system.

Cons of Four Chuck Laser Pipe Cutter:

- Higher Costs: With additional complexity comes a higher price point. The four-chuck cutter tends to be more expensive than the three-chuck cutter, potentially making it a less viable option for businesses with tighter budgets.

- Increased Complexity: The operational complexity of a four-chuck system is higher, meaning there might be a steeper learning curve for operators unfamiliar with the machine.

- Maintenance Needs: With more moving parts, the four-chuck cutter may require more frequent maintenance and checks to ensure its optimal operation.

How to Choose: Three-Chuck Laser Pipe Cutter VS Four-Chunk Laser Pipe Cutter?

When choosing between a three-chuck laser pipe cutter and a four-chuck laser pipe cutter, several considerations will guide the decision-making process. The key aspects to evaluate include material support, cutting accuracy, and cost.

Material Support

- Three-Chuck Cutter: This cutter is adept at handling square, rectangular, and round tubes. It can also manage other shapes, although with less precision than the four-chuck model.

- Four-Chuck Cutter: The four-chuck model shines when dealing with irregularly shaped tubes, such as elliptical or custom profiles. Its design provides superior adaptability and handling.

Cutting Accuracy

- Three-Chuck Cutter: While the three-chuck cutter offers good precision, its performance may slightly vary when dealing with heavy tubes or pipes with large diameters.

- Four-Chuck Cutter: Thanks to its extra chuck, this cutter tends to provide more stability during operation, leading to improved cutting precision. This is especially useful for larger or heavier tubes.

Cost

- Three-Chuck Cutter: The three-chuck model is generally less expensive, making it a cost-effective choice for businesses with a tighter budget or lower production needs.

- Four-Chuck Cutter: The four-chuck model, while more expensive, may be worth the investment for businesses that handle a lot of custom or irregularly shaped tubes, or that have high production needs.

Q&A: Common Questions about Three Chuck Laser Pipe Cutter VS Four Chunk Laser Pipe Cutter

Q1: What is the primary difference between a three-chuck and a four-chuck laser pipe cutter?

A: The main difference lies in their design and functionality. A three-chuck laser cutter is well-suited for cutting square, rectangular, or even a round tubes. On the other hand, a four-chuck cutter offers better handling and cutting precision for irregularly shaped tubes due to its other chuck.

Q2: Which is more cost-effective: a three-chuck or four-chuck laser pipe cutter?

A: In general terms, a three-chuck laser pipe cutter is less expensive, making it a cost-effective choice for businesses on a tight budget or with lower production needs. However, a four-chuck cutter, though more costly, may be a worthwhile investment for businesses that regularly work with irregularly shaped tubes or have high production requirements.

Q3: Does the number of chucks affect the cutting accuracy?

A: Yes, the number of chucks can influence cutting accuracy. A four-chuck laser pipe cutter typically offers higher cutting accuracy, especially for larger or heavier tubes, due to its enhanced stability during operation.

Q4: Can both three-chuck and four-chuck laser pipe cutters handle all types of materials?

A: Both three-chuck and four-chuck laser pipe cutters are designed to work with a variety of materials such as carbon steel, stainless steel, aluminum, and copper. However, the specific handling capabilities may vary between different models and manufacturers.

Q5: Which one is easier to operate: a three-chuck or a four-chuck laser pipe cutter?

A: Both three-chuck and four-chuck laser pipe cutters are designed for ease of operation. However, a three-chuck model might be slightly simpler due to its fewer components. It’s important to note that adequate training and familiarity with the machine’s operation are crucial for efficient and safe usage, irrespective of the number of chucks.

Q6: Can I switch from a three-chuck to a four-chuck laser pipe cutter without altering my production process?

A: Changing from a three-chuck to a four-chuck model might require some modifications in your production process due to the additional chuck. It’s advisable to consult with the manufacturer or an experienced engineer to ensure a smooth transition.

Conclusion

In conclusion, choosing between a three-chuck laser pipe cutter and a four-chuck laser pipe cutter depends largely on your specific needs, budget, and the materials you frequently handle. Both offer a range of benefits, from cost-effectiveness to high precision, making it crucial to understand your production requirements. If you’re looking for more guidance or information, explore other resources on our website or get in touch with our expert team. Remember, the key to an efficient production line is not just the right tools but also informed decisions.

Ready to Boost Your Production Line Efficiency?

Request an Instant Quote today. At Baison Laser, we’re committed to delivering high-performance laser-cutting solutions tailored to your needs. To see our machinery in action, Get a Free Application Evaluation. Let’s forge a future of precision together.”