Welding is an essential process in manufacturing industries. Fiber laser welding machines are fast replacing traditional methods due to their speed, efficiency, and precision. These laser machines use a narrow beam and high laser power to melt and join different metals.

The laser machine control helps the manufacturers to use these machines in a versatile way. They can efficiently work on thick and thin materials with the right speed, power, and beam.

These machines are fast, and their weld quality is way better than other welding techniques. Fiber laser welding machines have made welding a breeze without needing consumables and pressure.

In this article, we will discuss plane fiber laser welding machines. We will understand how it works, its different parts, and how it can reduce production costs. We will also guide you in selecting the right laser welding machine for your manufacturing needs.

What Is Fiber Laser Welding Machine?

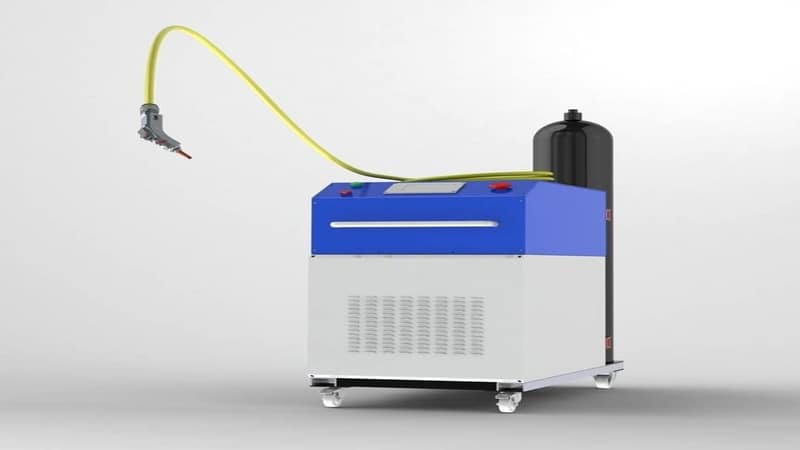

A fiber laser welding machine uses fiber laser energy to combine two or more metal plates or pieces. The machine produces a high-energy laser beam. A laser source generates the laser beam, and a fiber optic cable delivers the laser beam to the workpiece through a series of lenses.

The laser beam heats and vaporizes the material, forming a welding pool that solidifies on cooling and joins the material.

A fiber laser machine produces a highly narrow beam that is more powerful than manual welding. It heats only the spot where it is directed. A CNC system controls the beam movement; thus, room or error is zero, as in the traditional welding method.

Click the button below to get a professional fiber laser welding machine!

What Are the Basic Components of a Plane Fiber Laser Welding Machine?

Let’s understand some basic components of a fiber laser welding machine:

Laser Source

The laser Source is the part of the machine where a laser beam is generated. The fiber source generates a beam characterized by wavelength, power, and beam quality.

Beam Delivery System

Once the laser source produces the fiber laser beam, it is delivered through a beam delivery system. A fiber optic cable delivers the laser beam to the head. As the beam is passed through a fiber optic cable, it is guided and amplified by the doped core of the fiber optic cable.

Laser Head

The laser head delivers the beam on the material. It consists of a lens or a series of lenses that reflect the beam and focus it on the right spot. Some laser heads also have a vision system or camera to monitor the position of the welding joint. The laser head also controls the parameters like speed, power, size, or beam for the welding process.

Control System

The control panel of a laser welding machine is like the brain of this overall operation. It controls the laser power density, the quality of the beam and its shape and size, power, speed, and motion system and software. It may have a screen interface that allows the monitoring of the welding process.

Workload System

The workload system is the process of loading, unloading, and securing the welding material. It can be a manual, semi-automatic, or fully automatic system. Laser machines nowadays can have a fully automatic loading and unloading system that diminishes the need for manual intervention.

Motion System

A motion system consists of gears, motors, and mechanical components responsible for moving the workpiece for the welding process.

Protective Gas System

A protective gas system protects the weld pool from contamination and oxidation. Argon and helium gases are used that not only protect the molten pool but improve the speed and welding properties.

Cooling System

The cooling system of any fiber laser welding machine is the system that removes the excessive heat from the laser source and prevents overheating. Not only does it keep the temperature of laser parts in control, but a cooling system dissipates the heat of the workpiece and prevents it from overheating.

The cooling system of a fiber laser machine can be a water-cooling system or an air-cooling system.

How Does a Plane Fiber Laser Welding Machine Work?

We have already discussed the component. The manual staff prepares the welding joint by cleaning and preparing the surface for welding. Metal pieces are clamped in the correct position. They may also be preheated to reduce thermal stress.

The operator turns on the machine once the metal pieces are all set. Laser sources generate the beam that is delivered through a fiber optic cable. The laser beam is focused on the welding joint; the heat-affected zone is melted with heat that solidifies to form the joint.

The cooling rate of metal can be controlled by welding speed and power. Once the material is cool, the welding joint is inspected for postprocessing, which may include grinding, polishing, or cleaning the weld joint.

Benefits of Plane Fiber Laser Welding Machines

Here are a few benefits of fiber laser welding:

Versatility

Fiber lasers are powerful machines that are versatile enough to handle any material. They can work on the toughest and most difficult-to-weld materials, like copper, aluminum, and tough steel, that are difficult to weld by traditional means.

High-Speed

Fiber laser machines work much faster than other welding techniques. It increases the productivity rate and reduces the cycle time as well.

Precision and accuracy

A fiber laser machine uses a narrow beam to heat the material. Heat affected zone is very targeted and does not affect the surrounding material. That means no risk of cracks or material distortion with a laser weld. Computer software controls laser beam movements, making welding highly accurate and precise.

Welding Flexibility

A laser welding machine allows you to weld any welding like butt joint, overlap, or any other position conveniently.

Narrow Weld Seam

Besides all other advantages, the only reason that justifies the price of a fiber laser welding machine is its weld quality. It gives superior weld quality than any other welding technique.

The strength of the joint is also higher; the weld seam requires less postprocessing. It can work on even complex shapes and irregular pieces and join them with maximum strength.

Reduce Maintenance

Fiber laser welding machines have fewer moving parts and do not require as many consumables as traditional welding. These are easier to maintain and reduce the maintenance cost as well.

Safety

Fiber laser welding machines can be fully automated. They also emit fewer fumes and radiation than other welding techniques. Besides, these laser machines also come with safety sensors to ensure the safety of operators. If operators follow some safety guidelines, the welding process is safe for labor and the environment.

Reduce Production Cost

A fiber laser welding machine may cost you more but offers better speed, precision, and weld quality. It can help with high-volume production and the reduced labor cost help you reduce the production cost. It also eliminates the need for consumables or filler metal for welding.

What Are the Applicable Materials of Plane Fiber Laser Welding Machines?

A fiber laser welding machine is a versatile welding machine that welds multiple materials precisely.

Stainless Steel

Many kitchen appliances and kitchenware industries use stainless steel materials of different grades. The material is widely used in furniture, door or windows, cabinets, kitchenware, or the medical industry. Even appliances and equipment like gym equipment are made up of stainless steel of different categories.

Stainless steel has high thermal conductivity and may be prone to distortion and cracks if not handled carefully. A narrow laser welding beam heats only the spot it is directed at. Thus leaving out room for errors.

Carbon Steel

Unlike stainless steel, carbon steel has low thermal conductivity. The heat during the welding process can melt or distort the surrounding material. A fiber laser welding machine works with extreme precision. A large variety of equipment, automotive parts, pipes, and tubings is made of carbon steel.

Alloy steel

High alloy content makes alloy steel more challenging to weld than carbon steel. It requires more heat and can be prone to cracking during the welding process. Preheating and post-welding treatments are also required. A fiber laser welding machine gives a smooth weld, requiring the least postprocessing.

Silicon Steel

Silicon steel is widely used in electronic and electrical industries due to its magnetic properties. Silicon steel is also prone to cracks and can be challenging to weld due to its high silicon material. It requires extreme control of welding parameters like welding speed, power, and heat output that a laser welding machine can provide.

Spring steel

Spring steel is used in the making of springs and other components. It also has a high carbon content, making welding quite challenging. Fiber laser welding can be trusted for his kind of challenge.

Aluminum alloys

Aluminum and its alloys are lightweight but can be extremely reflective. Aluminum also forms an oxidative layer easily. This makes them difficult to weld. However, a fiber laser welding machine gives precise results with aluminum and its alloys.

Galvanized Steel

Galvanized steel has a zinc coating, making it more challenging to weld than stainless steel. It can also produce toxic fumes. A fiber laser machine can be fully automated. That makes it safer for these types of welding materials.

Factors Affecting the Quality of Fiber Laser Welders

Here are a few factors that can affect the quality of welding:

Laser Power and Beam Quality

These parameters must be adjusted before the welding process. Not one setting is suitable for all types of material. An expert operator should set the parameters to ensure the weld quality. Too high power for a soft material can be damaging to the material. In the same way, too low power for a very tough material may not produce the desired results.

Welding Speed

Like power and beam quality, welding speed should be set accordingly.

Material Properties

All metals and their alloys have different properties, like melting point, thermal conductivity, or composition. Knowledge of these properties and how to deal with them is essential for a laser operator.

Fixture, alignment, and Loading system

The workpiece should be firmly clamped in the right position during welding. If you use an automatic loading system, ensure it aligns the workpiece optimally. Irregular shapes may be difficult to be clamped at a right angle.

Operator skill

A fiber laser welding machine with the latest technology may be modern, but human intelligence can’t be replaced. The operator’s skill and knowledge of different materials and their properties are essential for superior weld quality. The welding results depend on the parameters like speed, power, and beam quality that only a trained staff can control.

What Should You Consider When Choosing a Handheld Fiber Laser Welding Machine?

Here are a few things you should consider while selecting the fiber laser welding machine

Material Thickness

Assess your manufacturing needs. If it requires welding tough material and thick sheets, then a high-powered laser machine can be selected.

Power Output

Laser welding machines are priced based on their power. A higher-power machine can work on tough materials with ease. Even a less powerful welding machine works way better than other welding techniques.

Volume of Production

Laser welding machines can justify their high price only by the precision of welding and the increased volume production. It speeds up the welding process and can almost double your production volume than traditional means.

Welding Applications

Specific welding applications can also determine the laser power and beam quality. These parameters can help you select the laser machine that fulfills these needs. Specific industries, like the medical or aerospace, and electronic industries, may not have high volumes, but they require the extreme precision and accuracy that laser welding machines can provide.

Ease of Use

Welding is something that only some can do; it requires expertise and technique that one can learn and practice with experience. Laser welding machines are easy to use; anyone can use them and have satisfying welding results.

Price

Budget can be the deciding factor when selecting the machine. The price of a laser machine depends on its power, capacity, speed, and other features. They may seem expensive, but overall ease of use, productivity, and accuracy justify their price and may reduce the production cost in the long run.

After-sales service

Brand reputation must be considered while selecting the machine. Not only their service staff but their after-sale services should be considered. These machines may require timely maintenance, and a brand that offers warranties and aftersale services is imperative.

Check their track record, market reputation, and whether they will provide spare parts for the machine.

Conclusion

Fiber laser beam welding has made welding more efficient foolproof, and more accessible. You don’t have to be an expert to use these machines. These are user-friendly machines that anyone can use with some basic safety precautions. The welding results are accurate and precise every time you use it.

Many industries like aerospace, electrical, medical, and automotive are successfully using fiber laser welding machines. They can speed up manufacturing and save time, labor, and cost. Their use in industries is increasing each year due to their numerous advantages.

Revolutionize Your Production Efficiency with Baison

Baison has been a leading brand in laser cutting or welding solutions. We offer high-technology machines that are built on modern designs. Not only these innovative machines are user-friendly and efficient, but they can be automated to reduce production costs and manual intervention.

We offer fiber laser welding machines and handheld laser welding machines, and welding robots and fiber laser cutters are also available that can revolutionize your welding needs.

Don’t hesitate to click the button below to contact us!