Plasma Cleaning VS. Laser Cleaning: Which One Is Better?

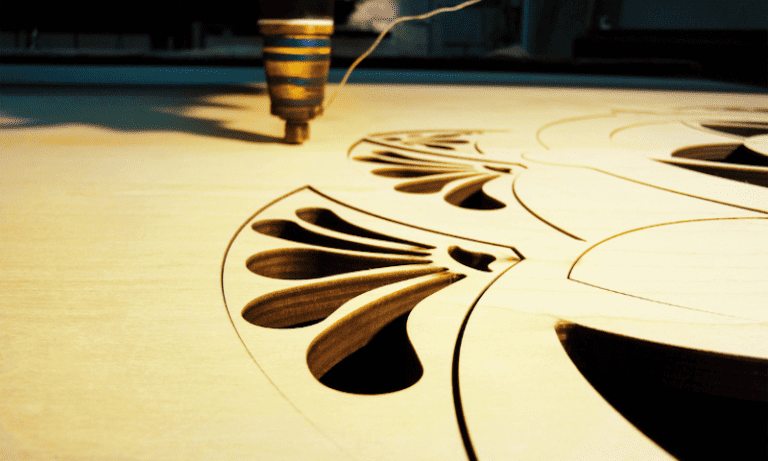

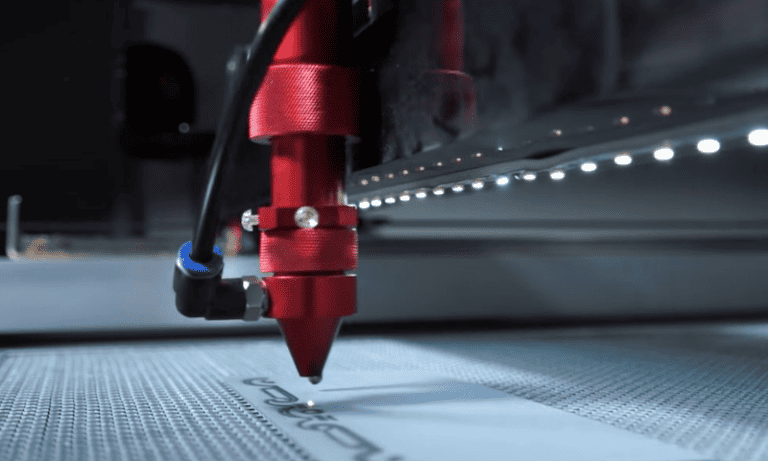

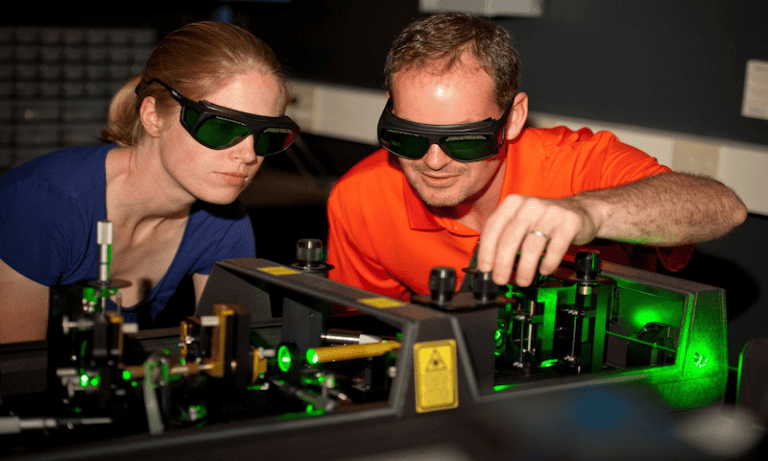

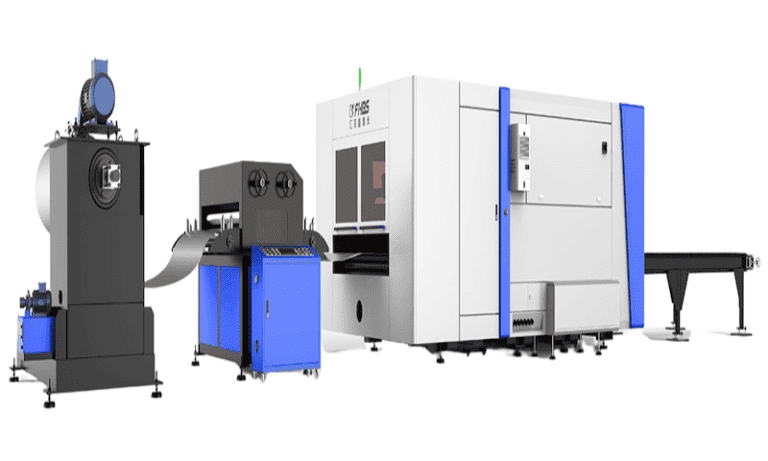

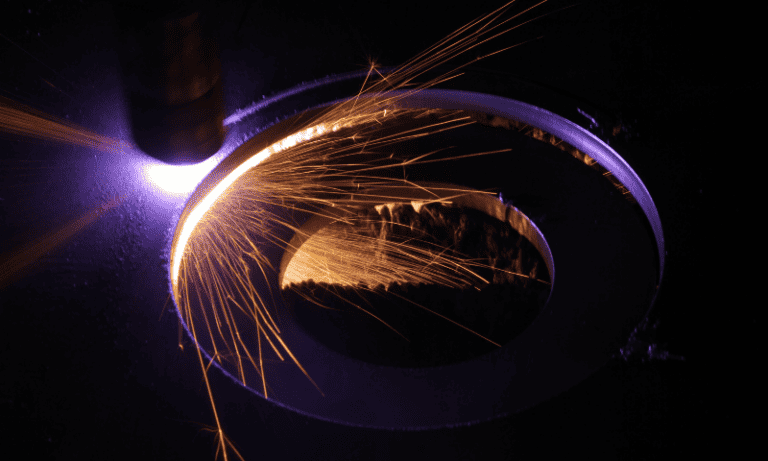

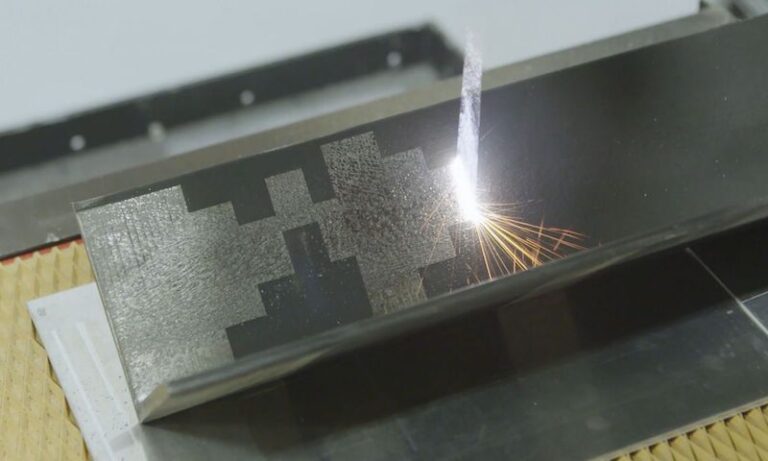

Laser cleaning and plasma cleaning are two types of surface cleaning methods. The main purpose of these two is to prepare surfaces for subsequent manufacturing processes, such as welding metal surfaces and the application of any coating.