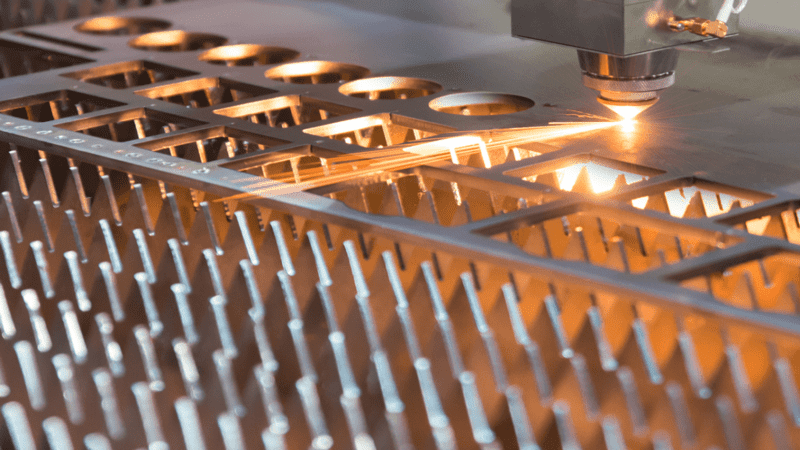

Businesses that want to stay ahead in technology and productivity continuously use automated laser-cutter technology in their facilities. These fiber laser-cutting machines offer versatile and precise results for small- and large-scale production.

However, with a massive variety out there, finding the most suitable cutting head for your laser cutting machine becomes a bit daunting. In this blog, we will overview the various types of laser cutting heads and their applications and discuss some vital factors to consider when choosing one for your business.

What Is Laser Cutting?

Laser cutting is the process whereby highly intense fiber lasers cuts through materials of different types. The process involves a laser-cutting machine with several components, such as a laser cutting head, nozzle, workpiece, etc. All of these work in sync to direct the laser beam at the material being cut, ensuring the material is burnt, vaporized, or melted away.

Businesses can cut a variety of materials using a laser machine. These include and are not limited to steel, metal, aluminum, brass, copper, plastic, and composites. On top of it, the highly precise laser cutting allows you to cut complex shapes accurately and with ease. The process is also fast, which enhances overall productivity.

Additionally, laser cutting can reduce waste and minimize the need for post-processing or finishing. This makes the laser cutter valuable for businesses requiring high-quality and consistent product cuts.

Laser-Cutting Metal Materials: The Variety

As we already know, businesses use laser-cutting machines to cut through various materials. This blog will focus on the most common metal materials you can cut using fiber laser cutters.

Stainless Steel

Stainless steel is known for its excellent corrosion resistance, high durability, and appearance. Hence, businesses use stainless steel components in many of their products, such as electrical appliances and automotive parts. The surgical instruments industry also readily uses laser-cutting machines to cut stainless steel parts.

Carbon Steel

Carbon steel resonates with toughness thanks to its industrial toughness and ability to withstand high temperatures. As for its uses, the aerospace, construction, and automotive industries readily use a laser-cutting machine to cut carbon steel components for their strength and versatility.

Brass

From what it appears, brass has a decorative function. However, this copper alloy also features excellent electrical and heat conductivity. As a result, manufacturers use brass parts and components for electrical appliances such as heat exchangers. On top of it, brass is highly malleable, making it a versatile material to work with.

Aluminum

This is one of those materials that offer more strength for less weight. Hence, credit to the strength-to-weight ratio, industries like the military and aerospace use laser-cut aluminum parts for applications that require durability and low weight.

Titanium

Just like aluminum, titanium also offers an incredible strength-to-weight ratio. On top of it, titanium shows good resistance to corrosion which means its highly reliable for sensitive applications in the medical and aerospace industries. Additionally, titanium is biocompatible, which means laser-cut titanium implants are ideal for medical surgeries.

Nickel Alloys

Nickle alloys aren’t just one material. In fact, it is a group of materials that boast several chemical and mechanical properties such as high strength, corrosion resistance, heat resistance, etc. These properties make them ideal for use in the automotive, aerospace, and even chemical processing industries.

Copper

Copper resists corrosion excellently. At the same time, it also lets the current pass through quickly. Hence, both electrical and plumbing industries use fiber laser cutters to cut copper parts to use in their applications.

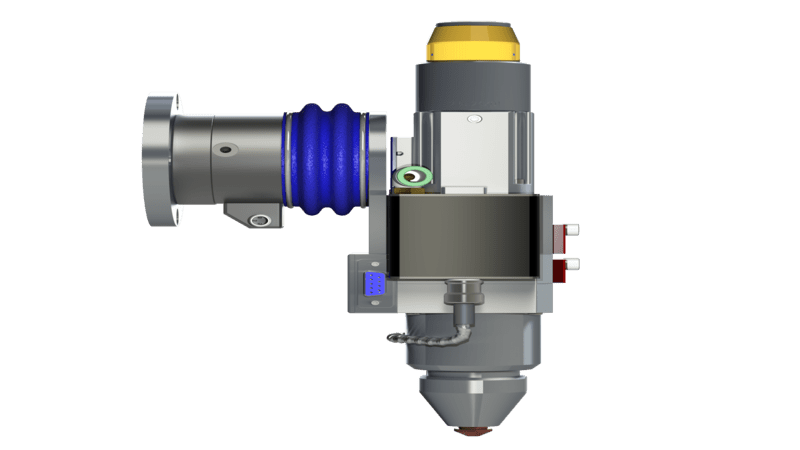

What Is a Laser Cutting Head?

Simply put, a laser cutting head is part of a laser cutting machine that directs the laser beam onto the cutting material using a lens. It has a vital role to play when it comes to cutting speeds, precision, quality, and efficiency. Hence, a laser cutting machine must have the correct cutting head to produce superior cuts, which increases productivity and reduce downtime.

Businesses find the right cutting head for their needs by consulting a laser-cutter expert. Now that is feasible, but there are other ways too. Like you are reading this blog, you will have enough knowledge to decide which cutting head is ideal for you by the end.

As for properly using the cutting head and making the most out of it, you will need technical support from the laser cutter manufacturer. So, make sure you work with someone who is reliable.

Types of Laser Cutting Heads

- Fixed Focal Length Cutting Heads: these cutting heads come equipped with predetermined focal lengths. This means it cannot change the distance between the lens and the material being cut.

- Auto-Focusing Cutting Heads: an auto-focus cutting head comes equipped with adjustment sensors. These sensors automatically adjust the distance between the lens and cut material to ensure consistent and clean results. Hence, they come in handy when the material being cut has an uneven or curved surface.

- Capacitive Sensor Cutting Heads: in order to ensure cut consistency and cleanliness, this cutting head uses a capacitive sensor to maintain a constant distance between the material being cut and the lens. Therefore, the distance between the two remains the same throughout the fiber laser-cutting process. This is also suitable for uneven surfaces.

- Non-Contact Cutting Heads: as the name suggests, these cutting heads do not come in contact with the material being cut. Instead, they use a high-pressure gas stream that removes all unwanted workpiece material. This eliminates the risk of uneven or non-smooth edge cuts. Moreover, the cutting head does not have to touch the material since the gas stream has enough laser power to cut through it.

Laser Cutting Heads: A Comparison

We have discussed four main types of cutting heads so far. Let’s compare them so you have enough knowledge to decide which is right for you.

Fixed Focal Length vs. Auto-Focusing Cutting Heads

- Cost: auto-focusing cutting heads are more expensive than the fixed focal length.

- Operation: it is easier to work around a fixed focal cutting head compared to the alternative.

- Cut Accuracy: auto-focusing cutting heads offer greater cutting accuracy thanks to the auto distance adjustments.

- Material Compatibility: auto-focusing cutting heads cut through thinner materials more efficiently compared to fixed focal length heads as they are more suited for thicker materials.

- Maintenance: it is far easier to maintain a fixed focal cutting head.

Capacitive Sensor vs. Non-Contact Cutting Heads:

- Cost: you will have to pay a higher cost for a capacitive sensor cutting head

- Operation: it is far easier to operate a non-contact cutting head compared to the technicalities of a capacitive sensor cutting head.

- Cut Accuracy: you can achieve better cut accuracy with a capacitive sensor cutting head.

- Material Compatibility: non-contact cutting heads can cut through thicker materials faster with higher laser power, whereas the alternate works faster with thinner materials.

- Maintenance: you will have to spend more time and cost maintaining a capacitive sensor cutting head.

Other Key Considerations: An All-Round Comparison

- If your business needs require you to work with reflective materials a lot, then a non-contact or capacitive sensor cutting head will suit your laser cutters more.

- Businesses that have to cut through materials of varying thicknesses frequently will benefit more from an auto-focusing cutting head on their laser cutting machine.

- Non-contact cutting heads create extremely high gas pressures. As a result, they are not suitable to work with materials prone to warping as they can cause distortion.

Four Mainstream Laser-Cutting Head Brands on the Market

The table below shows a brief comparison of the four-mainstream laser-cutting head brands available on the market by laser machine companies:

| Comparison Items | IPG | Raycus | MAX | nLIGHT |

| Electro-Optical Conversion Rate | 40%-45% | 40% | 30%-35% | 35%-40% |

| Maximum Power | 30kw | 30kw | 30kw | 30kw |

| BPP | 3.3-4 | 4-4.5 | 4.-4.5 | 5 |

| Output Power Range | 10%-100% | 10%-100% | 5%-100% | 5%-100% |

| Light Decay | 1% | 2% | 5% | 2% |

| Non-Ferrous Metal Processing Capacity | AA | AA | A | AAA |

| After-Sales Service Rating | AAA | AA | A | A |

What Should You Consider When Choosing a Laser Cutting Head?

We get your struggles when you are out there looking for a cutting head but don’t know where to start. Here are some key factors to help you move in the right direction:

- Cutting Thickness: different types of cutting heads offer varying levels of cutting thickness. Therefore, you need to be absolutely sure about the thickness of the materials you need to cut. This helps ensure you get the right specification for your laser cutter.

- Cutting Speed: just like cutting thickness, cutting heads also come with varying specifications for cutting speeds. Here again, you need to ensure you get the right cutting speed that your cutting material requires or can handle.

- Precision and Accuracy: some cutting heads, like the auto-focusing one discussed above, offer greater precision and accuracy than others. It is up to you; your cutting needs to determine your required precision level. Once you know that, you can invest in the right type of cutting head. This also can take a few trials before you get to the perfect cutting head for your laser cutter.

- Material Type: as cutting heads come in different types, they aren’t all suitable for every material out there. Hence, it would be best if you cross-check whether the cutting head you are getting is suitable to cut through the material you need to work on.

- Maintenance: it is an important factor because while some cutting heads, such as the fixed focal one, require minimal maintenance, a capacitive sensor cutting head requires high maintenance. Therefore, keep this in one because maintenance directly impacts the lifespan of the cutting head.

- Cost: obviously, any business decision is finally driven by the cost. You need to get a product that falls within your budget. Hence, go out and thoroughly research the prices and the features they offer. Don’t pay a higher price for features you don’t need. Stick to the requirements and also keep future expansion plans in mind.

How to Identify Your Business’s Specific Needs and Determine the Optimal Laser Cutting Head?

Follow the following steps to identify the specific needs of your business, which will help you find the optimal laser-cutting head for your laser cutter:

- Researching Options: Every major business decision must start with research. Explore all the available options on the market and thoroughly read through the features and specifications of laser heads available for laser cutting machines.

- Assessing Your Business Needs: this includes assessing the materials you plan to cut, their thickness, and the desired precision and accuracy of your customer’s demand. Moreover, consider the cutting volume and the level of automation required to meet the production demands.

- Expert Consultations: if you aren’t the best in this field, then we recommend talking to a laser-cutting expert. Discuss your business needs and applications with them. They can offer professional and practical insights directing you towards a suitable cutting head, considering the maintenance, compatibility with your machines, and other vital factors.

- Cost Evaluations: spending on a laser system head is an investment. Hence, as a business, you must invest in a cutting head that offers long life and minimal maintenance costs. All of this excludes the initial cost of the product, as you have to consider the long-term impact on your business’s profitability and laser machines operations.

Conclusion

Laser-cutting technology has modernized the manufacturing process with its high speeds and excellent precision. Businesses that still use traditional cutting machines always need to catch up to competitors who have adopted laser cutters in their facilities.

But to get optimal results from a laser cutter, you need to have certain aspects in the right order, and the cutting head is just one of them. Another critical component is the laser machine’s nozzle which you can learn about here.

Elevate Your Manufacturing with Our Advanced Laser Machines

Baison‘s commitment to excellence means we understand that every customer is unique and provide customizable laser-cutting machine solutions tailored to your business needs. Whether you need a standard cutting machine or a customized solution, we have the expertise and technology to deliver unparalleled results. Get Free Sample Proofing.