This article explains how laser-cutting machines can be used in the fitness industry and how they are better than traditional machines at creating perfect products. So whether you are a fitness freak or want to manufacture high-end products for the fitness industry, this article will provide you with information on how using laser-cutting machines can help you can revolutionize the fitness equipment industry.

What are Laser Cutting Machines and How they Work

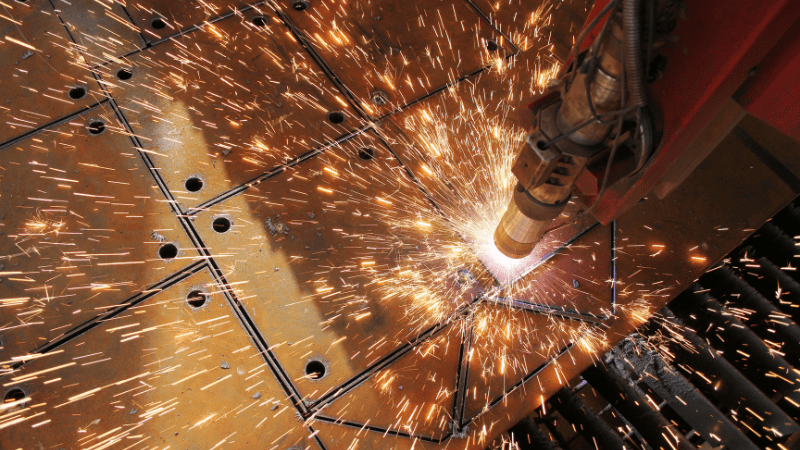

A laser cutting machine has relatively advanced cutting technology for cutting workout gear. Laser machines use a high-powered laser beam to cut through various materials. The laser beam is focused through a lens, which directs the energy to a specific spot, causing the material to melt, vaporize, or burn away.

Here are a few different types of laser-cutting machines for high production efficiency:

CO2 Laser Cutting Machines: This type of laser cutter uses a gas mixture of carbon dioxide, nitrogen, and helium to produce a high-powered beam of light. CO2 lasers are primarily used for cutting non-metallic materials such as wood, acrylic, and plastic.

Fiber Laser Cutting Machines: Fiber laser machines enable precise cutting and engraving on various materials, including metals, plastics, and composites. They are known for their high cutting speed and precision.

YAG Laser Cutting Machines: yttrium aluminum garnet (YAG) laser to cut materials such as ceramics and metals. They are often used in the aerospace and medical industries. YAG lasers can also be used for etching and engraving on a variety of materials, including metals, ceramics, and plastics. They are primarily used for cutting metals and other hard materials.

CO Laser Cutting Machines: CO lasers use carbon monoxide gas as the lasing medium. They are primarily used for cutting non-metallic materials such as plastics, textiles, and rubber.

Laser Cutting Machines VS Traditional Cutting Machines

Professional laser-cutting machines have revolutionized the tube and sheet metal processing industry in several ways:

Precision: Laser cutters cut precise cuts with very tight tolerances. The laser beam can cut through thick or thin materials with the same level of precision, and it can create intricate shapes and patterns that are difficult to achieve with traditional cutting tools.

Versatility: Professional Laser cutting machine can cut through any material: metals, plastics, wood, fabrics, and ceramics. They can also be used to engrave or mark surfaces, which makes them useful for creating custom designs or adding branding to products.

Speed: Laser cutting machines are typically faster than traditional cutting machines. They can cut through materials quickly and efficiently, which makes them ideal for high-volume production runs.

Minimal Waste: Laser-cutting machines produce very little waste, as the laser beam cuts precisely and minimizes the amount of material that is burned away or melted. This is beneficial for both environmental and cost-saving reasons.

Safety: Laser-cutting machines are generally safer than traditional processing methods. They require fewer moving parts and produce less debris. However, it is important to follow proper safety precautions when operating a laser cutting machine, as the laser beam can be dangerous if not used properly.

How can Fitness Equipment Companies Use Laser Technology?

A laser cutting machine can be useful for fitness equipment manufacturers in creating custom-fit workout equipment, accessories, and promotional items. Here are some steps to consider when using a laser-cutting machine in the fitness industry:

- Safety: Always follow the manufacturer’s safety guidelines when using the laser cutting machine. Make sure you wear appropriate personal protective equipment, such as safety glasses and gloves.

- Material: Choose the appropriate material for your project and make sure it is suitable for laser cutting. Materials such as acrylic, wood, and metal are commonly used for laser cutting, but the specific type and thickness can vary.

- Design: Create a design for your project and prepare it for laser cutting using software such as Adobe Illustrator or CorelDRAW. You can engrave names or messages, or logos with these machines. Make sure your design is compatible with the laser cutting machine’s software.

- Power and speed settings: Adjust the power and speed settings of the laser cutting machine to ensure the best results for your specific material and design. It is important to test the settings on a scrap piece of material before cutting your actual project.

- Ventilation: Laser-cutting machines produce smoke and fumes that can be harmful to your health. Make sure the machine is properly ventilated and use a ventilation system or exhaust fan to remove the smoke and fumes.

- Maintenance: Regularly clean and maintain the laser cutting machine to ensure it is functioning properly. Check the lenses and mirrors for any damage or debris and replace them if necessary. Examples of Laser Cutting Machines in the Fitness Equipment Industry?

How to Use Laser Cutting Machines in the Fitness Field?

Laser-cutting machines can be used in the fitness industry to produce:

Gym Equipment

Laser-cutting machines can be used to produce high-quality gym equipment such as weightlifting racks, benches, and dumbbell racks. These machines can cut and shape metal sheets, pipes, or tubes with precision, ensuring that the equipment is strong, durable, and safe to use.

Personalized Fitness Trackers

Fitness trackers have become increasingly popular in recent years, and laser-cutting machines can be used to produce custom fitness trackers. The machines can cut out designs and shapes from different materials, such as wood or acrylic, which can be used to create unique and stylish fitness trackers.

Resistance bands

Resistance bands are a popular strength training and rehabilitation tool, and laser-cutting machines can create custom bands with different resistance levels. The machines can cut the bands to specific lengths and widths, ensuring that they are the perfect size for the user.

Customized equipment

One of the primary ways laser cutting machines are used in the fitness industry is by producing customized equipment. For example, a gym may use a laser cutting machine to create customized dumbbells or weight plates for their members. Using a laser cutting machine, gyms can create equipment perfectly suited to their members’ needs, and they can do so quickly and accurately. Additionally, the precision of the cuts means that the equipment will be of high quality and last for a long time.

Gym decor

Another way that laser cutting machines are used in the fitness industry is for producing gym decor. This can include signs, wall art, mirrors, or even large-scale murals. Using a laser cutting machine, gyms can create unique and visually appealing pieces that reflect their brand and create a more inspiring atmosphere for their members. Additionally, the precision of the cuts means that the pieces will be of high quality and last for a long time.

Prototyping new equipment

Laser-cutting machines can also be used for prototyping new equipment. For example, a fitness equipment manufacturer may use a laser cutting machine to create a prototype of a new piece of equipment before investing in expensive molds or other manufacturing tools.

Baison offers all laser cutting machines, including our fiber laser cutting machines for small, medium, and big industries. We offer Fiber Laser Tube Cutting Machines and Multi-Functional Machines that can cut both sheets, tubes, and pipes. Using a laser cutting machine, the manufacturer can quickly and accurately create a prototype that can be tested and refined before moving on to the next production stage.

Final words

Many fitness equipment companies are using laser cutting technology. These machines enable manufacturers to create customized, high-quality equipment and decor pieces suited to different needs. Additionally, laser-cutting machines can help manufacturers save time and money by allowing them to quickly prototype new equipment before investing in expensive production tools. As this technology continues to evolve, we can expect even more innovation in the fitness industry and beyond.

Transform Your Fitness Equipment Production with Laser Cutting Machines

Looking to take your fitness business to the next level of technological innovation? Basion offers state-of-the-art laser machines that can help you create customized fitness equipment and accessories that will set your business apart.

With Basion’s laser cutting machines, you can achieve the precision and quality you need to make your fitness products stand out. Contact our team of experts for a free application evaluation or sample proofing. So why wait? Contact us now to learn more about our laser-cutting machines and how they can help you take your fitness business to the next level.