The furniture industry mainly relies on cutting metal, wood, and other materials. Laser-cutting machines have taken the place of traditional cutting techniques in the furniture industry as well. They are not only used for cutting and designing but engraving as well. These machines have helped designers achieve complex and modular designs.

This article will discuss how laser-cutting machines impact the furniture industry and how they are a better choice for the furniture industry than conventional cutting machines.

We will discuss how it can play a vital role in increasing production and how to achieve innovation in the furniture industry while using laser-cutting machines. It can be used for cutting, decoration, engraving, and creating detailed patterns.

What Is Laser Cutting?

Laser-cutting technology uses laser-cutting machines to cut or engrave material. Laser machines use a high-powered laser beam to cut material. Computer software controls the laser beam movement, allowing you to cut complex designs and patterns precisely.

Laser cutting gives better speed and performance and increases the production volume while decreasing the production cost. These are fully automated machines that can be streamlined with other production processes, resulting in a reduced need for labor.

What Is the Process of Laser Cutting?

Let’s take a look at how does a laser-cutting machine work?

Laser Generation

The laser machine consists of a laser-generating source. The source generates a highly concentrated laser beam directed at the material.

Light Beam Delivery System

The laser beam is directed at the cutting materials through a series of lenses that guide the beam and amplify it. These optical lenses ensure the beam’s spot size and how it is delivered to the workpiece for precise cutting.

Cutting Parameters

Another important phase of the cutting process is setting the cutting parameters. The cutting parameters include speed, laser power, beam quality, spot size, and other parameters. These parameters are essential for the optimal cutting process.

Material Preparation and Loading

Before cutting, the workpiece is cleaned and placed on the work table securely. It should be clamped on the surface in the optimal position.

Laser Cutting Process

The laser source generates the focused beam directed at the material through a series of lenses. The beam moves on the material, and a computer control system controls its movements. The high-powered laser beam heats the material from the contact zone and melts it immediately, resulting in a cut.

Assist Gas

In many cases, an assist gas is used to blow away the melted material and cool down the melted material. It clears the area and prevents the material from overheating.

What Types of Materials Can Be Used in Laser Cutting for Furniture Design?

Gone are the days when furniture was only made from wood. The furniture industry has become very versatile, and many materials are used. Both thin and hard materials are used in furniture making. Here are a few materials that can be used in the furniture industry:

Wood

Wood is still the primary material that is used in the furniture industry. Different types of wood, such as veneer, maple, oak, mahogany, cherry, maple, and other trees, are used for making furniture. The wood of these each type of tree has different properties and may be thin, thick, or too hard to cut.

Hardwood is considered ideal for the basic structure of furniture. The use of metal with furniture enhances furniture’s durability and helps designers create different shelves and cabinets or hidden storage areas in furniture by mixing different materials.

Metal

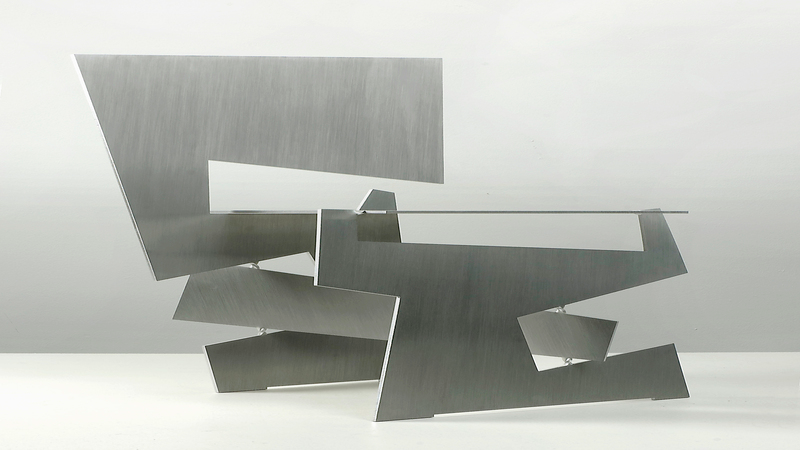

Besides wood, metal furniture is gaining popularity day by day. Wooden material has a limited scope, but metal has been widely used for innovative designs and structures. Metal is also more durable and long-lasting than wood.

Many contemporary designs for desks, chairs, sofas, and beds use, if not complete, metal structures than its parts for decoration and structural support. Even in metal, there is a wide variety of materials, including iron, brass, copper, aluminum, stainless steel, and aluminum.

The great thing about metal is that it can be moved and welded into different designs and can be used to increase strength, durability, and decorative furniture elements.

Leather

Leather is a luxurious material that has several applications in the furniture industry. It is used not only in covers and upholstery. Leather designs are timeless and admired for their durability, high finish, and luxurious look.

Upholstery

Upholstery is an essential part of the furniture for covering sofas, armchairs, ottomans, and other furniture. Materials like natural fibers, nylon, polyester, or foams are used for upholstery.

Glass

Glass is another fancy material that is difficult to cut and shape but is widely used in the furniture industry as a decorative element. Gass is used for making shelves, table tops, cabinet doors, and other decorative elements. Even glass has different types and adds a modern touch to the furniture.

Plastic and Acrylic

Besides these hard materials like wood and metal, even plastic and acrylic materials are widely used in the furniture industry. They are widely used for lightweight and affordable prices. These materials can be used in furniture, chairs, tables, or other decorative elements.

Other Material

Besides these basic materials, other materials like stone, bamboo, ceramic, and other composite materials are used in the furniture industry.

What Are the Advantages of Making Furniture with the Laser Cutter?

Here are the different advantages of using laser machines in making furniture:

Precision and Accuracy

As mentioned, modern furniture designs have complex shapes and innovative designs. Most modern designs require almost impossible assembling without accurate and precise cutting. Hidden storages, the utility of space, and customization all of these features rely on accuracy and precision.

The modern trend of using less space and incorporating more elements in furniture requires cutting complex designs to utilize the material and space. Laser-cutting machines are capable of cutting all types of material with high precision.

They use laser beams that make the contact zone very limited. Also, beam movements are controlled by a computer software system that gives them high precision and accuracy in cutting and welding.

High Speed and Time Saving

A great advantage of using laser cutting machines over traditional ones is their high speed. They can achieve the same cutting excellence within a fraction of the time compared to the other cutting methods. Manufacturers can speed up production. These machines can work day and night without any manual intervention.

Customization

Customization is an essential part of the furniture industry. People need to make furniture based on the space available. Laser-cutting machines allow full customization. All you have to do is change the designing soft water; the same machines can cut different shapes, sizes, and materials with the same precision.

Versatility

As we have mentioned, the furniture industry uses too many different types of material, including wood, stone, ceramics, metal, and glass. These materials require different cutting techniques. However, a laser cutting machine can cut all these materials with equal precision.

Minimal Material Waste

Laser machines allow narrow kerfs and cut material according to a fixed pattern or software design. That means very minimum material waste. These machines ensure maximum use of raw material and keep the production control in check by optimal use of material.

Reduce Production and Labor Costs

Laser machines are fast; they can work day and night without requiring an army of manual staff. So they can produce more volume of products in less time. This not only boosts the production of manufacturers but the reduction of labor cost and also help them to save more. It also helps them keep the final product’s prices in check.

Design Freedom and Complex Designs

A lot of modern designs require the use of dissimilar materials and complex shapes. A laser-cutting machine allows you to design as many complex pieces as you like.

All you have to do is to use a computer software system to achieve these complex shapes. You can work on complex patterns, geometrical shapes and make furniture more visually appealing, space-saving, and artistic.

Safe

Laser machines are safer than other cutting techniques. They can be fully automated; even loading and unloading does not require manual power. It is safer for the staff, and the chances of accidents, mismanagement, or hazards are lower than other cutting methods.

What Are the Limitations of Making Furniture with the Laser Cutter?

Here are a few limitations of making Furniture with Laser Cutters

Limitations of Material

Laser-cutting machines are versatile and work best for many types of materials, but they can still be some materials that are not suitable for laser machines. They can work best on material that can vaporize the material by heating it. Certain reflective materials or materials with high heat resistance.

Thicker Materials

Laser machines may also pose a limitation in cutting very thick pipes or wooden pipes. They are better for thin sheets, but heavy wooden logs and hardwoods may require several passes for a perfect cut.

Cost

Laser machines are expensive. You can go for a less expensive machine, but it may need more power to cut all hard materials. In some workshops, the production volume could be higher to justify the cost of the laser machine.

Design Limitations

Laser-cutting machines provide design freedom, but they still pose several limitations. They may be unable to cut sharp internal corners or require additional support for cutting some designs.

Difficult Assembly

The modern design and easy shipment have created a new trend of making furniture that requires assembly. A laser cutting machine may be accurate for cutting different parts, but this furniture is difficult to assemble for customers. These designs can be complex and have interlocking systems that are difficult to join.

Size Limitations

Laser machines have limitations regarding the size of pipe or tube they can handle. They may need help to go above that size, and large or oversized pieces are difficult to handle with a laser-cutting machine.

How Does Laser Cutting Allow for Customization in Furniture Design?

Laser machines control the beam movement through a computer-aided program. Even the intricate designs can be cut with the same precision. Here is how you can customize furniture with laser-cutting machines:

Personalized Designs

You can create personalized designs for furniture with the help of laser-cutting machines. A laser cutting machine can produce parts of furniture that are cut according to the space available. Furniture pieces can be customized according to available space, and designers can create intricate designs with laser machines.

Modular kitchen designs and furniture pieces that suit customers’ space and preferences are not difficult with fiber lasers.

Laser Engraving

Another great feature of laser-cutting machines is engraving. It can create designs and engrave personal messages, names, logos, or decorative patterns on furniture.

Material Variety

Laser cutting machines can handle different types of material like metal, wood, plastic, or glass. Manufacturers can use different materials according to the personal choice of customers or can mix and match dissimilar materials.

Batch Customization

Manufacturers can customize the whole batch very conveniently. Laser machines can be integrated with other production lines, creating a whole line or series of furniture with the same design.

Time and Cost Saving

Customizing or personalizing furniture items can always be costly with other machines, but laser-cutting machines incur no extra expense. The laser machines can cut any design or engrave easily, and all designers have to create are amazing designs.

Challenges of Laser Cutting in Furniture Design

Here are a few challenges that manufacturers face with laser-cutting machines:

Material Selection

Several furniture manufacturers face challenges with material selection and combination. Although laser cutting machines can work on several materials but stills, some materials can be toxic or emit fumes or may generate excessive smoke while cutting some material.

This can be solved by conducting thorough research before material selection. Choose materials that are suitable for the overall look of the furniture, the environment, and the machine.

Burn Marks

Another challenge that the furniture industry face is to avoid burn marks. Laser machines can sometimes leave burn marks, especially on wood. It can affect the aesthetic appearance of the piece.

However, operators can avoid these marks by adjusting the power and other parameters while cutting specific materials. They can also utilize techniques such as assist gases or material masking to prevent the surrounding material from being affected by heat.

The Complexity of Design and Material Handling

Although laser machines can replicate any design, no matter how intricate, sometimes designs can be challenging due to incorrect material selection. It can be avoided by carefully selecting parameters and the right choice of materials.

Incomplete design information

Another problem in laser cutting can be due to the incomplete file preparation of laser designing. Incomplete file information or incorrect file format can cause several challenges while cutting. Designers can combat this issue by preparing files in the correct format and using only designing software compatible with laser cutting machines.

Product Cost

Laser machines reduce the production cost, but they are themselves very expensive. They are costly for small to medium-scale businesses and may face challenges.

So businesses should conduct a trough analysis of costs and benefits to ensure they invest only what they need. Otherwise, they have to compensate by increasing the price per item. They should assess the overall return on investment and their production needs thoroughly.

Future of Laser Cutting in Furniture Design

Laser cutting and welding machines are the new future of furniture design. They give the designers the liberty to design modern and artistic furniture pieces that are not only space-saving but also artistic and convenient.

Laser machines have enabled manufacturers to create furniture pieces that are economically affordable, space-saving, and full of features. Modern designs require assembling, making shipping furniture pieces worldwide convenient. Here are a few things we expect from the furniture industry in the future.

Increased Customization

With these machines making customization so easy, we expect even more customization in the future. Customers can demand furniture pieces of their choice in size, material, shape, and color.

Automation and Robots

Welding robots have replaced traditional techniques, and even laser machines can be fully automated to save a lot of labor power. The human staff has its work limitations, but machines can work nonstop and are far more precise and fast than the traditional methods. So we expect more and more automation and robots to be used in the industry.

Advanced material Compatibility

We expect each type of laser to become more efficient and advanced as technology progresses. We expect a lot of experimenting in the furniture industry as well, which may allow using unconventional materials and unique and stunning designs in the furniture industry.

With artificial intelligence rampant, even the designing of furniture pieces is expected to become innovative.

Integration with Additive Manufacturing

Laser machines can be integrated with designing software and technologies like 3D printing. It gives a new potential to furniture manufacturers to create complex hybrid structures in furniture making. By combining these methods, manufacturers can create innovative designs and structures of furniture.

Conclusion

Furniture making is a booming industry that can utilize laser machines for several benefits. Modern designs, innovative structures, and unique customization replace outdated, bulky looks and designs.

Laser machines can help manufacturers create smart space-saving designs that can be assembled conveniently and are easy to move and ship. These machines are more efficient and speedy than other cutting technologies.

Invest in Baison’s Laser Cutting Machines for Innovation in Furniture Industry

Baison offers high-powered laser technology for versatile use. These machines help manufacturers to bring innovation into the furniture industry. Laser machines can speed up the production process and help manufacturers control the price per article with reduced labor costs.

They also give a competitive edge to businesses by offering unique, personalized furniture pieces to suit their different needs. So embrace laser power for cutting, welding, and engraving with Baison.