Metal cutting and welding have been an essential part of many industries. Laser-cutting machines are widely used in almost all industries for metal fabrication. These high-tech machines can cut thick metal tubes, pipes, and sheets with much more ease and finesse than traditional means.

These modern machines have reduced production costs and enabled industries to meet the growing demand for supplies with their unmatchable speed.

This article will discuss how laser-cutting machines have enhanced speed, productivity, and efficiency in various industries. We will also understand a laser cutting machine, how it works, and other factors that may affect its performance.

What Is a Laser Cutting Machine?

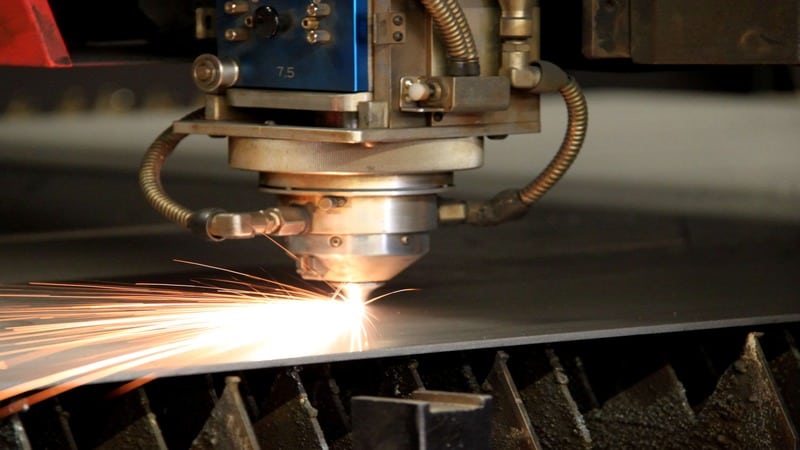

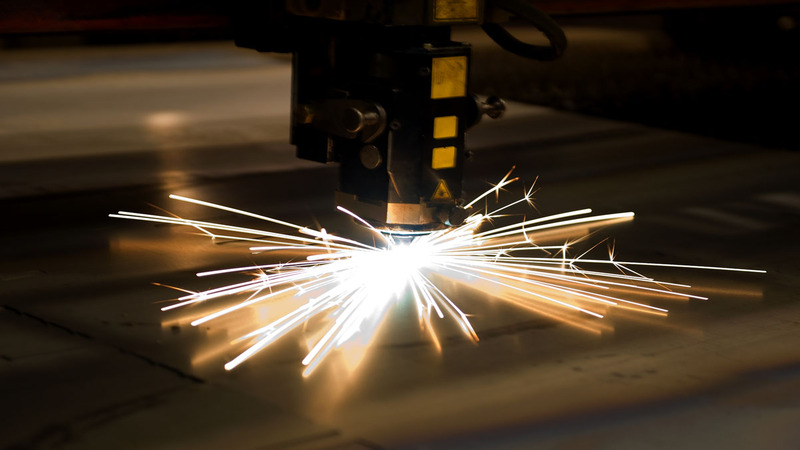

A laser cutting machine is a machine that uses laser technology to cut materials. The machine generates a high-powered beam that can cut through the toughest material within seconds.

A computer numerical program controls the movement of the beam so that it cuts only according to the required design. There is less material waste and accurate cutting results in a better end product.

Another great thing about laser-cutting machines is that they can be fully automated. You can streamline the production process without manual intervention, from loading and unloading to holding the material in the right position. This not only cuts the overall cost but increases productivity as well.

Types of Laser Cutting Machines

Here are several types of laser-cutting machines:

CO2 Laser Cutters

CO2 laser cutting machines use carbon dioxide and other gasses to generate high-powered laser beams. The gas mixture is charged by the electric power, producing a laser beam. These cost-effective laser machines are versatile enough to cut glass, ceramic, leather, wood, metal, fabric, and acrylic.

Fiber Laser Machines

Fiber laser machines are advanced laser cutters that are high-powered. The laser beam is amplified by a series of mirrors and transmitted by fiber optic cables. They are powerful enough to cut high-density materials like steel, carbon, aluminum, and brass. They can be expensive but are more efficient and can easily cut even reflective and tough materials.

Click the button to learn more about the fiber laser cutting machine.

Yag Laser Cutting Machines

These laser machines use a crystal medium to generate the laser beam. They are expensive as compared to CO2 and fiber laser cutters. They are especially used to cut very thin metal precisely.

By the way, if you are interested in the differences between YAG and fiber laser, click the button below/

ND: Yag Laser Cutting Machines

They are similar to Yag laser cutters but are more powerful. They are special machines used to cut metals with high precision on an industrial scale.

How Does a Laser Cutting Machine Work?

Now that we know the different types of laser-cutting machines, let’s take a deeper look at how laser-cutting machines work.

Before the cutting process, the workpiece is prepared. Material is held in place using clamps or vacuum tables. The loading system of the laser cutter machine can be fully or semi-automatic.

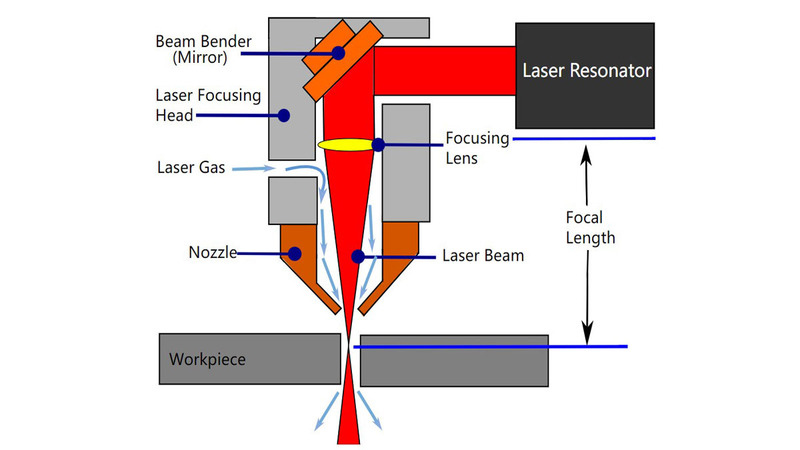

The process of cutting starts with beam generation. Both Co2 and fiber laser machines contain laser resonators where the laser beam is generated.

The laser beam is directed at the workpiece through lenses or mirrors. These lenses also amplify the laser beam in a fiber laser machine, and a beam travels through a fiber optic cable. Before the cutting process starts, the operator needs to adjust the cutting parameters, which are the shape or size of the beam, power, and speed.

The laser machine ensures the machine is aligned on the right path toward the workpiece. A CNC laser cutting machine system is used to adjust the cutting parameters such as the shape of the beam, size, power, speed, and focus.

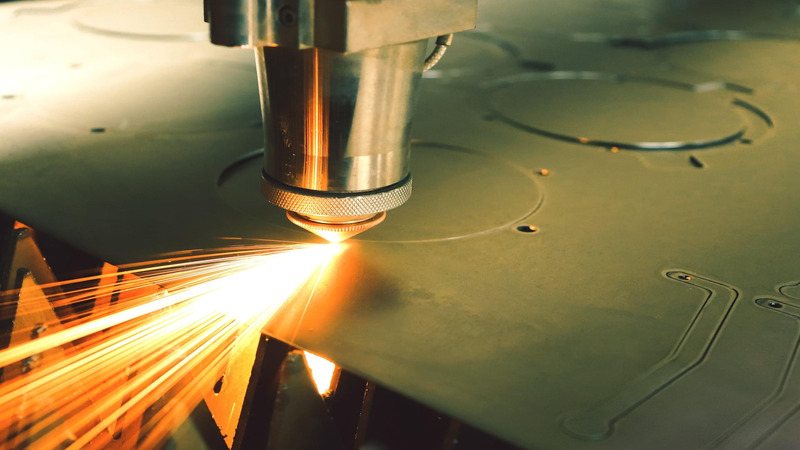

The laser head directs the laser beam on the workpiece. The high-energy laser beam heats the material and vaporizes it.

In some cases, assist gas is also used for laser cutting. These glasses are used to prevent the oxidation process and remove the molten material from the workpiece. These glasses improve the cutting quality.

The cutting head moves along the programmed path. The CNC system controls the movement of the beam, and as it travels on the workpiece, it cuts the material by vaporizing along the path.

What Are the Factors Affecting the Quality of Laser Cutting?

Here are a few factors that affect the quality of laser cutting:

Power

The power of the laser should depend on the material thickness and quality. Laser machines offer different power options for cutting. The control panel allows adjusting parameters, including the power setting. Just like too high power for a thin material can distort the material less for a thick material may also not give precise results.

Material Quality

Material quality and thickness, and properties are also important. The laser machine operator needs to know the exact nature of the material, its chemical properties, and how it can behave while cutting through a laser beam. The type of material also suggests which assist gas should be used to avoid distortion or oxidation.

Focus

The proper focus of a laser cutting head should also be adjusted. A laser beam moves through a CNC system, but the focal point should be adjusted for proper cutting.

Wavelength

The cutting parameters also include the option of wavelength. Selecting the right wavelength Laser machines offer the wavelength from ultraviolet to infrared. Shorter wavelengths have higher frequencies than larger ones.

Speed

Cutting speed is another important parameter. It should be selected according to the metal type and thickness for optimal results.

Loading System and Position

If you use a manual, semi-automatic, or automatic loading system, properly positioning the workpiece is essential for accurate and precise laser cutting. Make sure to check the position whether it is at a right angle. It not only ensures precise cutting but also wastes less material.

Spot Size

Spot size is the total diameter of the laser beam released from the focal point. It determines the contact zone of the laser beam. A narrow spot size concentrates more energy in a smaller area. The spot size is crucial for the quality and finesse of the final product.

Tips to Improve Laser Cutting Accuracy

Here are a few tips to improve laser cutting accuracy:

- Check the machine setting each time you start the machine. Every material has different properties, densities, and compositions. So one setting may only be suitable for cutting some types of material.

- For high accuracy, use a smaller spot size. A narrow beam has a limited contact zone and thus has higher accuracy. It’s like the tip of a paintbrush. A narrow beam can follow an intricate pattern and fine details.

- The working table is a crucial part of the laser-cutting process. Ensure it is aligned in the right position and the material clamped.

- Environmental conditions like humidity and temperature can also affect the working condition and laser machine cut. Maintain a controlled environment and set the temperature and operating parameters for consistent results.

- Make sure the people operating the laser cutting machine are professionally trained for their job. He should know the metal material, laser machine, required parameters, and machine’s capabilities. Proper machine techniques can significantly improve cut quality and machine accuracy.

Can Laser-cutting Machines Be Customized?

Laser-cutting machines can be customized to suit the manufacturer’s special needs.

Laser Power

Laser-cutting machines are available in different power options. You can choose the machine according to your application and product customization needs. The manufacturers can also accommodate any special needs.

Laser Machine Size

You can also customize your machines according to the work area.

Additional Features

Additional features or attachments can enhance the efficiency of your laser-cutting machine. These special features can be the addition of rotary devices, engraving, autofocus system, loading or unloading system, or various special features to improve alignments.

Software and Designing

The software or control system can be customized. Any specific application may need some special design features and compatible software.

Material Handling

Material handling needs can be different in every application. It can be tubes, pipes, plates, sheets, thin wires, or other components, so buyers can add a special conveyor, storage system, loading/unloading system, or other options to integrate the machine into their existing system for streamlined production.

At Baison, we offer full support to customers. Our staff is always available to discuss your manufacturing needs, and we try to accommodate these needs to the best of our ability. Bison also offers complete customization with our laser-cutting machines.

How Much Does a Laser Cutting Machine Cost?

There were times when laser cutting machines were too expensive, but their prices dropped as technology progressed. They are still expensive compared to traditional cutting machines, but laser cutting machines justify their price with their high precision, speed, and accuracy.

The price of laser machine depend on their

- Laser Type

- Power

- Features

- Size of machine

The laser machine can start from a few thousand dollars. The price increases with the power and special feature—an entry-level CO2 of $2000 to $10,000. The type of laser machine also determines the price. Co2 laser machines are more cost-effective than fiber laser machines. Fiber laser cutting machines are expensive and may go up to $50,000 depending on the size of the machine and power. Industrial-grade laser cutting machines can be expensive but have high power, speed, and features.

What Should You Consider While Choosing a Suitable Laser Cutting Machine?

Here are a few things you should consider while selecting a laser-cutting machine

Power: Choose the laser machine with enough power for all your manufacturing needs. You may need the machine for more than one material and versatile needs. To be safe, choose the maximum power you can buy, as you can adjust the power through the control panel and may use less power for thin materials.

Speed: Choose the machine that offers maximum speed for your production requirements. You may ignore speed if you don’t need to run the machine day and night and have limited production volume.

Application Requirement: The choice of the machine should depend on your application requirement. Industries with high precision, accuracy, and speed are required and may need a high-power laser system built for industrial-grade application. A smaller business or workshop may only need a little money on machines.

Special Features: Look for the brand that offers maximum features with the machine. Your special production need may require a special loading-unloading system, suction table, or other features. You don’t want to contact another dealer to buy the parts that can integrate with your existing system. So ensure you check whether the brand offers all the special features you require.

Cooling System: The cooling systems of laser cutting machines are important for the accuracy of cuts and the safety and longevity of your machine and its different parts. So check whether the machine has an appropriate cooling system for a better life cycle.

Brand Reputation: Laser machines are expensive, so always look for a brand with an immaculate reputation for customer support and complaints. This will be a long relationship as a machine may require maintenance, spare parts, or special features later, and you want a brand that offers full customer support.

Price: Lastly, price is detrimental when choosing a laser-cutting machine. These machines are expensive, but you should always consider the amount of money a business will save by reducing production costs and material wastage.

Conclusion

If you are looking for high-quality laser-cutting machines, Baison offers all you need. Our laser-cutting machines are the best in the market, and we offer full support to our customers. Our laser machines are user-friendly and perfectly safe for the environment. They require less maintenance and can be customized to suit your special needs.

Don’t hesitate to click the button to contact us today!