The laser cutting and engraving processes have gained much popularity, especially in recent years. From small business owners to large enterprises, everyone uses laser machines for their production.

A strong and sturdy machine bed indicates a laser engraver’s or laser cutter’s durability. High-quality engraving can only be achieved using a laser machine with a solid foundation.

Therefore, having laser engravers and laser cutters with a powerful laser bed is important. This would enhance your production and increase profits.

What Is a Laser Cutter Machine Bed?

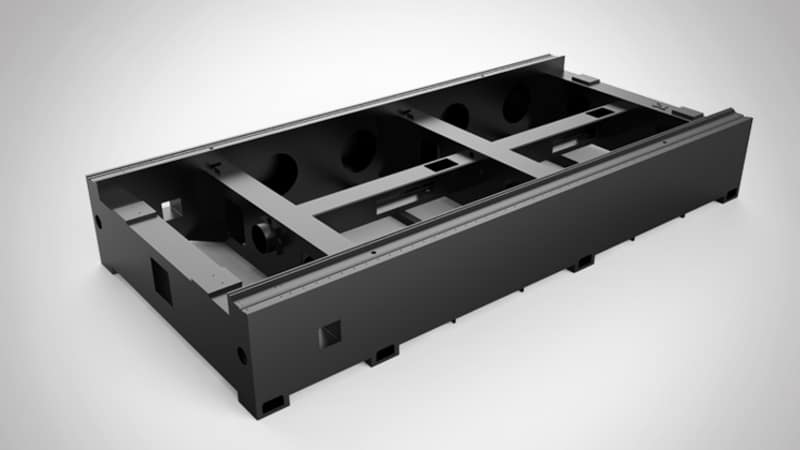

The machine bed is an integral component of laser machines. It is the foundation on which the entire engraving machine rests. Hence, it is the basic building block of a laser engraving or cutting unit.

The laser cutter requires different components for its overall functioning. The machine bed supports motors, rails, head assembly, mirrors, and laser beams. If these components are made up of high-grade materials but rest on a poor bed, the laser machine would be useless.

A low-quality machine bed is prone to deforming easily. It would also not last a long time. A deformed foundation would badly affect the cutting machine’s laser cutting speed, engraving speed, and engraving capability.

This is because the guide and gear would also get deformed. The laser beam is installed on the rack. The laser machines work by running the rack and pinion to and fro. The deformation would cause malfunctioning in the working of the laser cutter unit.

Repairing this fault would be very difficult. The entire laser engraving unit often becomes useless and would have to be discarded. Hence, a good-quality laser cutter machine bed is necessary for a long-lasting laser cutter or laser engraver.

Do You Have Any Questions?

Let Us Solve Your Problem

Importance of Machine Bed in Laser Cutting and Laser Engraving

As mentioned earlier, a laser-cutting machine cannot function without a proper bed. It allows you to cut through thick materials and produce precise cuts and intricate designs.

- The laser engraving process becomes more efficient due to the stability provided by the laser cutter bed. The laser power of the laser beam can also be adjusted precisely compared to other laser cutters. The laser head and laser nozzle can be stabilized in the correct position throughout the cutting process.

(You may also want to know about the selection of related parts such as laser heads and nozzles.)

- A proper foundation also gives laser engravers and laser cutters more power output. This is beneficial for cutting and engraving thicker materials as well as thin ones like acrylic sheets and cast acrylic sheets.

- The support bed also allows you to use a CNC router with ease. It can help you engrave or cut pieces of wood efficiently.

- Accurate angles of the high-energy beam of the laser head help produce perfectly round shapes as well. Sharp edges and cylindrical objects can also be processed easily using laser master and rotary attachments simultaneously.

- Certain materials that are tricky to work with can be cut effectively due to strong support from the bed. Other materials of various thicknesses and different material compatibility can be cut easily. (You can learn more about laser cutting in terms of different classes of material types and cutting thickness.)

- The bed enhances the overall efficiency of engraving or cutting materials. It also prevents the laser cutting unit from getting damaged by preventing any deformations.

Advantages of Using High-grade Machine Beds in Laser Cutters

Using a high-grade bed in laser cutters and engravers has numerous advantages. Some of them are explained below.

1. Fine Cutting Quality

Whether small or high-scale projects, customers expect perfection when they spend money.

It is important to change and adapt the working style of your laser cutter depending on the work at hand. The adaptations would be based on the type of projects at hand.

The machine bed would enable you to make the required changes for the laser settings. This would result in the production of fine-cutting quality materials. It would also ensure the complete preservation of the cut material.

2. Better Air Extraction

A strong foundation bed prevents the chances of having heat marks on the final products. This is due to the advanced air compressor present in the unit. The bed allows a stable air compressor which is useful in the air assist mechanism.

Suitable air pressure is created during the laser engraving or cutting process. This removes any unwanted vapors and other particles that may interrupt the final look of the finished products.

3. Accurate Positioning

The base support is adjusted depending on the type of laser cutter. It ensures stable and accurate material placement and positioning of the laser nozzle and laser head.

It also adjusts the focal length precisely. For example, it would adjust the beam to a shorter focal length to create a very small mark.

4. Efficient Exhaust Mechanism

Additionally, the bed also allows the material to be placed in a way to eliminate toxic fumes. These fumes are necessary to be removed during the process through an exhaust fan. This is crucial for the safety purposes of the cutting and engraving process. The exhaust is also considered important safety equipment for the process.

Do You Have Any Questions?

Let Us Solve Your Problem

Types of Machine Beds for Laser Cutters

Different types of support beds for laser cutters are available in the market. The kind you should choose depends on your work and the laser machine.

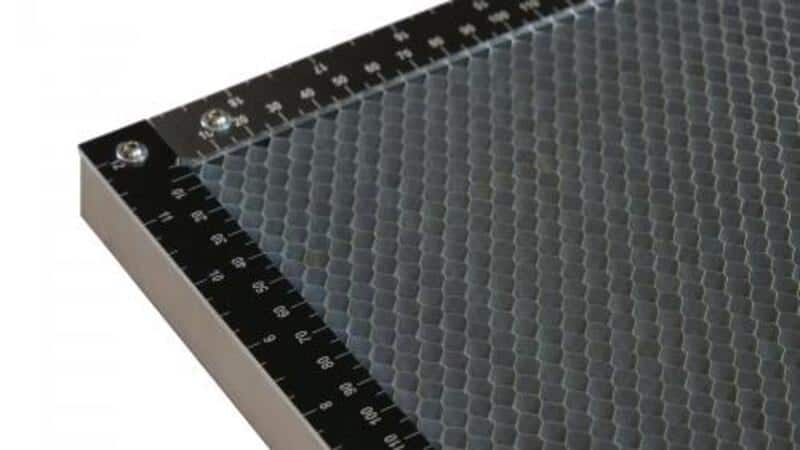

1 – Honeycomb Bed

A honeycomb bed has numerous points for support, keeping the material flat. Hence, it can provide greater stability during laser engraving and cutting.

Such a support bed is suitable for the processing of thin material and less rigid material ((for example paper or fabric). Honeycomb beds can also be used for engraving single or multiple products. This is due to the large surface area that easily covers the entire area to be engraved. The honeycomb structure also allows heat and waste material from the cutting process to escape.

Features

- Stainless steel body

- Long-lasting strength

- Increased durability

- Accurate positioning due to marked alignments

- Easily removable from the laser cutter

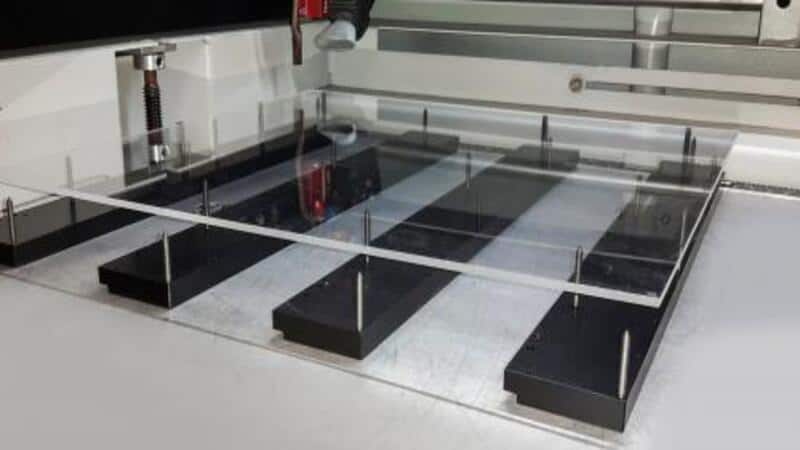

2 – Pin Table Bed

This type of support bed is used while engraving delicate objects such as wine glasses. The main reason is to reduce back flashes. This helps to avoid marks caused by reflection.

Features

- Decreased back-flash

- Easy to assemble

- Pins are removable

3 – Slats Bed

The laser-cutting slat bed is another type of support bed. It reduces the number of points of contact with the engraving materials.

Such a foundation is required for the processing of rigid and heavy materials. Any scraps that are cut during the engraving process are collected in a tray underneath. These can then be collected at the end of the procedure.

The slat bed is also anodized black. This is to avoid any discoloration on the body due to back-flash phenomena.

Features

- Easy to assemble and remove

- Adjustable

- Adequate ventilation

- Scrap-collecting trays

Machining Process of a Laser Cutting Machine Bed

The laser engraving and cutting bed undergoes several steps during the machining process. The steps are explained as follows.

1. Welding

The first step that the laser bed undergoes is the welding process.

All the metal parts required for manufacturing the bed are gathered. They are then heated up to a specific temperature and joined together by pressing and hammering.

This process releases very important stress. If this stress is not removed, the joined and welded parts will add extra pressure on the bed. This would eventually make it break down and deform.

Hence, welding is crucial to producing a durable laser engraving and cutting unit.

2. Vibrating Treatment

After the welding process, the bed undergoes the vibrating treatment. This lasts for about 20 to 30 minutes. It is done with the help of a vibration aging instrument.

This process is necessary since it applies added alternating stress to the laser cutter bed. When this is paired with the residual stress, the metal bed goes through micro or macro visco-elastic mechanical changes.

The workpiece is made to absorb energy. This helps it reach or exceed the threshold energy level for that material. This helps the residual stress inside the bed to reduce or homogenize. Hence, this makes it more stable and durable.

3. Annealing at High Temperature

The laser engraver bed’s next step is annealing at high temperatures. A CNC high-temperature furnace designed for annealing is used.

The bed is heated from room temperature until it reaches 650C. This temperature is maintained for 4 hours.

After this, the bed is cooled using the insulating cooling technique. Temperature is brought down from 650C to 250C slowly and gradually. The furnace door is slightly opened and the bed is allowed to further cool down naturally. Once the bed’s temperature and outside temperature reach and equilibrium, it is pulled out.

The entire annealing process lasts for about 24 hours.

4. Sandblasting

High-power compressed air at the fastest speeds is used for sandblasting. It is used to spray different materials like copper ore, quartz sand, diamond sand, sea sand, and iron sand.

This allows the shape of the bed to change. The surface of the workpiece also gets cleaned and becomes rough. This improves the overall mechanical properties of the bed and aids in its unique features.

5. Spray Primer

The primer is then sprayed onto the workpiece. This is important to prevent the laser engraver bed from corrosion. It also saves it from any kind of mechanical damage during storage, transportation, and use.

6. Rough Machining

This process is done to take off large pieces of materials from the bed workpiece. It also rough processes the bed into whatever shape you want.

This makes the overall shaping process more efficient.

7. Still Equipment

The bed is then placed outdoors in an open environment. This is also done to cause further temperature stress to the workpiece. The stress is induced due to the temperature difference between the day and night.

This added stress is useful to enhance the stability and durability of the bed.

8. Second Vibrating Treatment

The laser cutter bed undergoes a second vibrating treatment. This helps to get rid of some of the residual stresses from the workpiece.

9. Finish Machining

This step finishes the laser cutter bed’s surface. It removes marks from machining, scaling, and roughening. This is useful to enhance the surface appearance of the bed.

The bed is then ready for different coating processes like bonding, painting, plating, etc.

10. Surface Spray Painting

After finishing the bed, it is ready to be painted. The surface is spray painted using the pass or single-pass method.

Painting the bed makes the surface look more finished and increases its life.

11. Assemble

Finally, the support bed is ready to be assembled for your laser engraving or cutting unit.

Do You Have Any Questions?

Let Us Solve Your Problem

Final Thoughts

Great production is not only achieved by having a high-class laser cutter or laser engraver. A good-quality laser cutter bed is equally important for successfully working your laser machining unit.

The bed not only serves to be a strong foundation for the entire unit. It also ensures that the cutting and engraving processes are carried out smoothly.

A high-quality laser engraver bed is important to increase the overall lifeline of the laser unit. It also increases production exponentially. Hence, it helps you become more efficient in manufacturing better products. Thus, increasing the profit rate as well. These attributes are useful for both a big and a small business.

Discover the Perfect Solution for Your Business with Baison

Here at Baison, our customers are our top priority. Therefore, we believe in providing perfection.

Be it our laser cutting units or handheld welding ones, we guarantee the best products for your business. Our laser cutter and engraver beds are of premium quality that would upscale your production. They also ensure that your laser units last at least 15 years or more. Don’t hesitate to contact us!