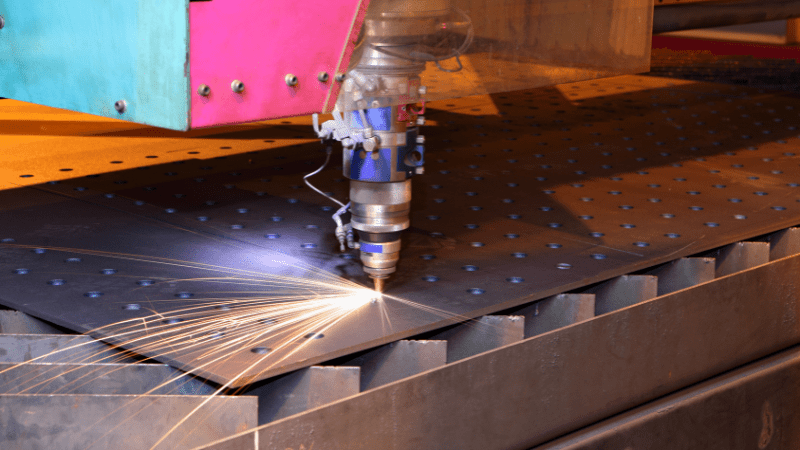

Laser Cutting Quality Standards

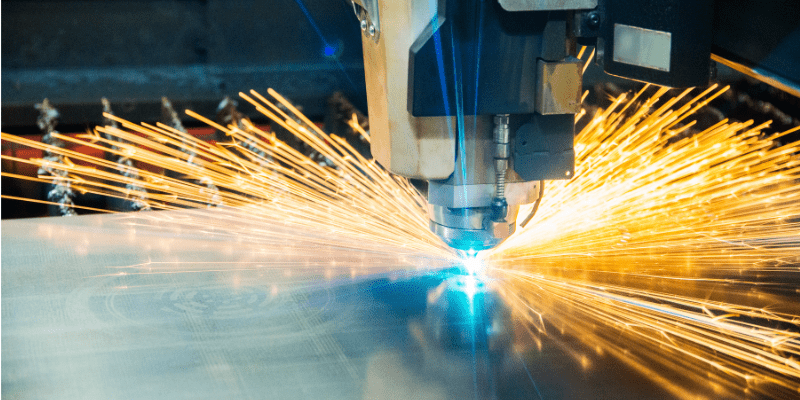

There is a good chance that the quality of your laser-cutting equipment is affected by many circumstances. Therefore, if you want to produce cutting of high quality, you need to be aware of all the quality requirements that need to be maintained.

The procedure of laser cutting or engraving is no exception to the rule that quality control is an absolute prerequisite in all processes. The following are a few different quality standards that you may adhere to keep cutting at an acceptable level.

Cutting Lines

This factor is dependent on how fast the material is cut. When you are cutting through dense materials at a rapid pace, you will become aware of such a problem. However, if you look at the incision section directly below the laser beam, you won’t see any molten metal.

The molten material is sprayed out of the back side, which results in the formation of curved lines on the cutting edge. If you want consistently excellent quality from your laser cutting edge, you must monitor this parameter at all times visually. When concluding the cut, all that is required of you is to slow down the feed. This will solve all your cutting-edge laser quality and cutting-line problems!

Roughness

Roughness is a significant issue that concerns the cutting industry. It has an effect on appearances as well as on various frictional properties. Analyzing the cutting surface to determine the depth of the generated vertical lines is a straightforward technique for evaluating the roughness of a material.

When it comes to figuring out just how rough the cut would be, the level of detail in the texture plays a significant role. When the incision is more profound, the surface has a smoother appearance. Similarly, if the surface is rough, you might notice uneven roughness and grains. Therefore, it would be best if you made every effort to smooth the roughness as much as possible. This would help the laser cuts to be of much higher quality.

Verticality

There is a good chance that many of you will ignore the idea that verticality occurs. Nevertheless, this is of utmost significance. If the material you are working with has a thickness of more than 10 millimeters, you must adhere to certain verticality factors.

When you go farther away from the laser beam, it often starts to deviate and gradually broaden toward the bottom or top. This results in the cut edge being moved a few millimeters more out from the vertical lines than it would have been otherwise. Always remember that the quality of the cut depends on how vertical the edge is, and the more vertical the edge, the better the cut.

Material Deposits

You could be surprised to learn that laser cutting machines make their initial contact with a distinct greasy coating before beginning to perform and melt the substance. Consumers or industries do not use gasification and other processes like it throughout this procedure. Instead, they make use of the wind to blow away the incision. However, this procedure will also create a material deposit on the surface, eventually lowering the cut quality.

Deformation

Always remember that the material will begin to deform if it gets overheated due to laser-cutting. In addition, you will face various difficulties if you do not have enough control over the power and speed the laser cutting equipment applies to your material.

The process of creating outlines and the assembly of small parts, this aspect requires an enhanced level of attention and precision. However, the process will result in deformation if one cannot control the laser power and uses short laser pulses. Therefore, you need either make sure that you are aware of how to regulate the power or acquire the assistance of an expert who can assist you with the procedure.

What Are the Factors That Affect the Quality of Cutting?

Although numerous elements affect the quality of the laser, this should not prevent you from regularly inspecting your laser equipment for impartiality. You can implement an exemplary initial implementation to avoid any potential issues. Some aspects are known to significantly impact the cutting process’s overall quality.

Laser Power

It is a common understanding that the power of the laser used in the cutting process impacts the outcome product. The laser power affects the material’s thickness which can be cut positively. If the power is sufficient, you can cut through materials of greater thicknesses. Additionally, it affects the workpiece’s ability to maintain accurate dimensions.

However, please remember that laser power is quite sensitive; not utilizing it correctly could bring you several issues. Different kinds of materials have different tolerance limits. If you apply excessive force to materials that are not very thick. In that case, you risk causing difficulties such as deformation, heat-affected zone, and other issues.

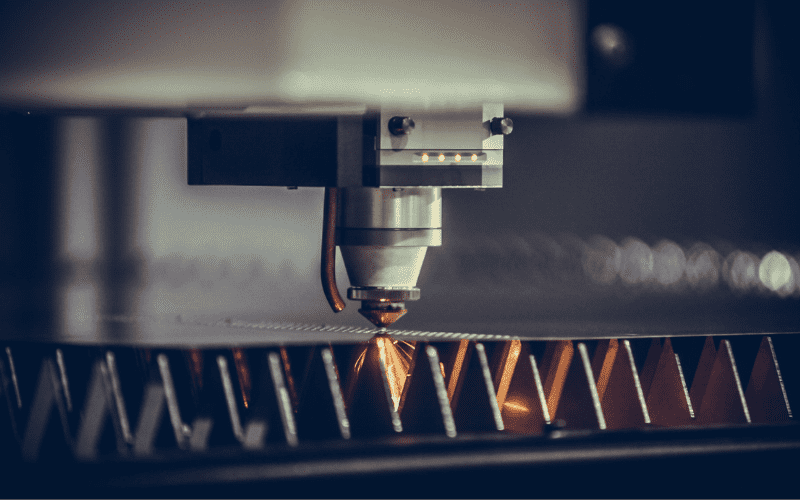

Nozzle

Although the nozzle might seem a tiny part of the massive laser machine, this seemingly insignificant piece of machinery significantly ensures that the metal laser cutting machine produces cuts of the greatest possible quality. Nozzles can be found in various forms, dimensions, and heights.

When using multiple nozzles, you may get a variety of outcomes and levels of quality. Moreover, if you do not adequately clean your nozzle or replace it regularly, it may lose its parallel form, which means it will not offer a smooth, high-quality cut.

You may want to know about the choice of the best nozzle.

Positioning

Laser cutting is essential to have the material in the right place at the right time. The positioning of the moving laser beam has an immediate and significant impact on the width, cutting section, slope, slag, and roughness.

Even something seemingly innocuous as the placement of the nozzle might give rise to a significant number of issues. For example, the process’s speed gets slowed if the nozzle is positioned far from the substance being worked on. As a result, correct positioning is of utmost significance since it plays a significant role in determining the level of quality achieved by a laser machine cut.

Get information on how to find the ideal focus position.

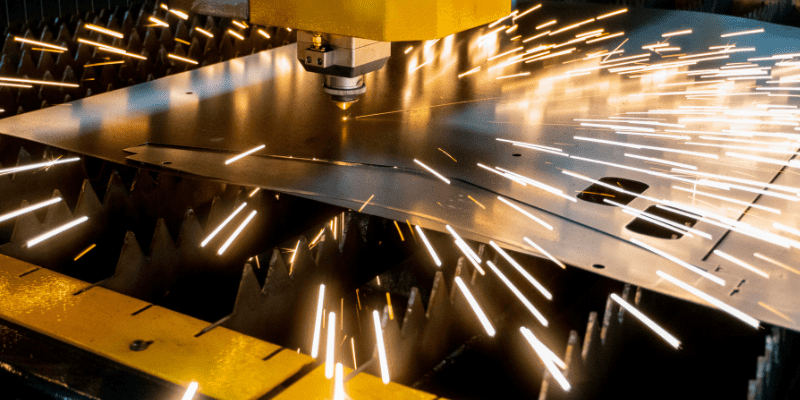

Laser Speed

The speed of the laser has always been one of the most critical factors determining the cut’s quality. The rate of the cutting operation has a significant bearing on the final quality of the material getting cut. When the appropriate speed gets combined with the proper material, the result will be cutting surfaces that are smooth and free of drag.

Finding the optimal cutting speed for the material you’re working with will achieve the cleanest cut. Remember that using laser machines at an excessively high or plodding speed has inherent drawbacks.

Material Types

Although this may not be a significant factor, it is nonetheless essential. Ensuring that the appropriate materials are used in the proper laser equipment is vital. Each material exhibits a one-of-a-kind rea when exposed to the laser.

The interaction of the materials with the laser’s strength and wavelength will determine whether or not they are compatible. Therefore, the cut quality can improve substantially by ensuring that the appropriate materials are combined with the appropriate laser equipment.

Common Laser Cutting Issues and How to Fix Them

1. Dross Formation

Dross is a common problem in laser cutting, usually identified by the presence of molten material on the underside of a cut piece. This is often due to incorrect settings for power, speed, and assist gas or from a worn-out nozzle. To resolve this:

- Check and adjust your laser power and cutting speed settings.

- Increase the assist gas pressure.

- Inspect the nozzle and replace it if necessary.

Learn more about How to Prevent Dross in Laser Cutting.

2. Striations

If you notice striations or lines on the edge of your cut, it could be due to an excessive cutting speed or low assist gas pressure. Here’s how to address it:

- Decrease the cutting speed.

- Increase the assist gas pressure.

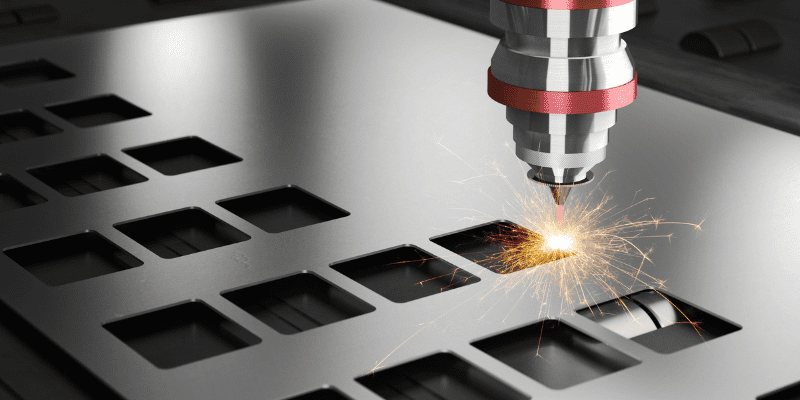

3. Inconsistent Cut Width

The kerf width should remain consistent throughout the operation. If it changes, this might be due to an out-of-focus laser beam.

- Check and adjust the focus spot size.

- Ensure the material is flat and level on the cutting table.

4. Burr Formation

Burr formation often indicates an insufficient assist gas flow or a low laser power setting. Burrs are more common in thicker materials. Reduce burrs in the cutting process:

- Increase the assist gas pressure.

- Increase the laser power.

5. Incomplete Cuts

You may need to adjust your settings if your laser isn’t cutting through the material entirely.

- Increase the laser power.

- Decrease the cutting speed.

Regular Maintenance for Optimal Laser Cut Quality

Regular maintenance of your laser cutter is vital to maintaining its performance. Here are a few practices to consider:

- Regularly clean and inspect the laser-cutting nozzle. Debris build-up or damage can affect the cutting quality.

- Ensure the lens is clean and dirt-free, as any obstruction can affect the laser focus.

- Regularly check and adjust the alignment of the laser beam.

- Lubricate moving parts as necessary to ensure smooth operation.

- Schedule periodic, professional servicing to ensure the machine is functioning optimistically.

Conclusion

There are many different kinds of laser-cutting machines on the market, and you need to have a comprehensive knowledge of the numerous quality standards and factors that affect the quality of laser cutting. This will provide you with insight into how to enhance efficiency.

Always remember that elements such as cut speed, power, gas pressure, and many others are essential to quality. By understanding common challenges and their solutions, you can ensure optimal cut quality in every project.

Elevate Your Laser Cutting with Baison!

Encountering issues with your laser cut quality? Don’t fret. At Baison Laser, we are committed to providing you with top-notch equipment and expert guidance. Dive deeper into achieving impeccable laser cuts. If you still have difficulty understanding the procedure, please contact us for clarification.