In a world where technology always pushes the frontiers of what is possible, one breakthrough is blazing brighter than ever: laser cleaning technology. Consider this: a high-tech struggle against pollutants on a variety of surfaces, ranging from historic monuments to cutting-edge industrial equipment.

Buckle up for an exciting ride as we delve into the fascinating world of laser cleaning systems. We will reveal its unique functions, laser cleaning applications and methods, and supernatural capacity to eliminate impurities. Join us on this journey as we reveal the secrets, benefits, procedures, and dazzling array of laser cleaning kinds. Prepare to see a cleaner, greener future emerge.

What is Laser Cleaning?

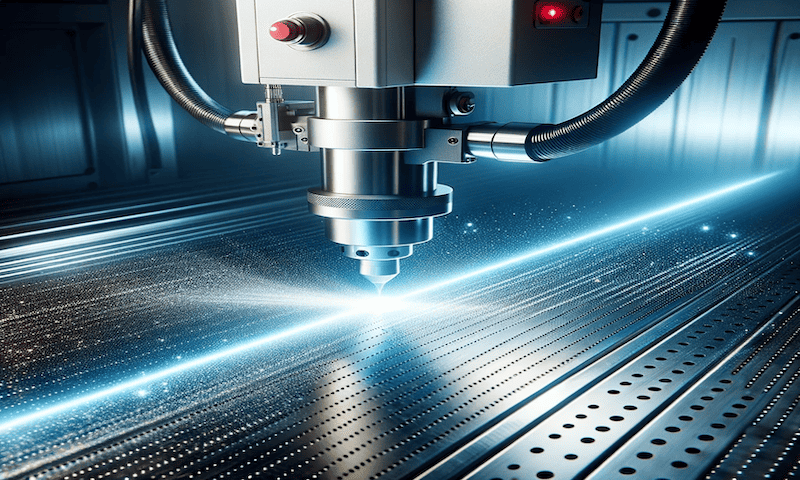

In simple words, it is the process of using a high power laser beam to clean metal and non-metal surfaces. The Fiber Laser Cleaning Machines delicately lift away rust, dust, paint, or even centuries-old coating on various surfaces.

Pulsed fiber laser handles the heavy lifting instead of harsh chemicals or labor-intensive cleaning in this process. They function by emitting powerful bursts of light energy that interact with pollutants, causing them to evaporate or degrade into harmless chemicals, resulting in a chemical-free process.

The exact accuracy and non-contact characteristics of laser cleaning make it perfect for protecting delicate historical artifacts, repairing metal surfaces, and revitalizing industrial equipment.

In a word, laser cleaning work is about more than simply cleanliness; it is also about conserving the past, assuring safety, and embracing a sustainable future, for detailed analysis you can check out Baison Laser.

Why Can Laser Cleaning Tech Battle Contaminant?

You may be wondering why laser cleaning is so good for removing unwanted material. It all boils down to the tremendous power of concentrated laser light.

Consider using a magnifying glass to focus sunlight on a single point and watch it become extremely hot. Laser cleaning works similarly but with far higher precision.

The laser beam is similar to a superhero’s laser vision, except it is used for cleaning. When it comes into contact with a pollutant, it absorbs it and rapidly heats it up.

This quick heating causes the surface material, e.g., dust or rust layer, to degrade and vanish, leaving the surface clean and bright.

What makes a laser cleaning system even more interesting is that, like a laser surgeon, it can target only the contamination while leaving the underlying base material alone.

So, whether it’s removing graffiti from a historic building or removing rust from a classic automobile, a laser cleaning solution swoops in and saves the day.

But wait, there’s more! Laser cleaning, unlike traditional methods, is also environmentally friendly. Because there are no toxic chemicals involved, it is environmentally friendly.

So, when it comes to fighting toxins, laser cleaning is a high-tech superhero on the scene and you can choose the best fiber laser machine, to make the planet cleaner and greener.

The Process to Battle Contaminant with Laser Cleaners Technology

Although laser cleaning appears to be a magical process, it is a precise and systematic procedure. Let us have a look at the stages involved in using this potent technology to tackle contaminants:

Step 1. Surface Evaluation

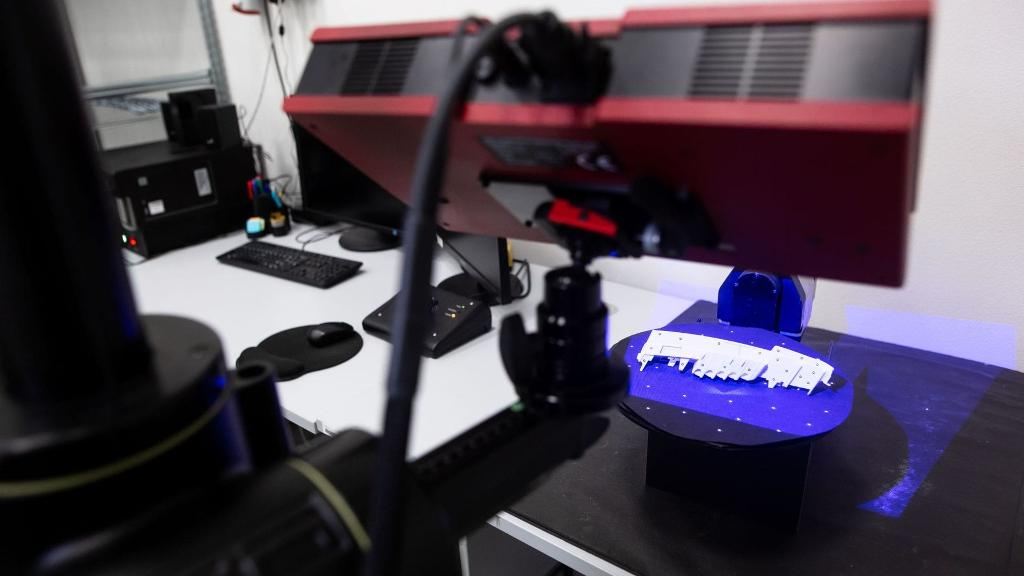

The trip begins with a thorough examination of the contaminated surface. This stage determines the kind and level of pollution, allowing professionals to select the types of lasers, appropriate laser settings, pre treatment, and a suitable power laser cleaning machine.

Step 2. Laser Calibration

The next step is to calibrate the laser. This involves changing the laser intensity, laser pulse energy, pulse duration, and focus point to provide the best cleaning results.

Step 3. Laser Beam Delivery

Laser cleaning systems use different ways to send the laser beam to the surface. Handheld system devices or robotic arms equipped with laser heads may be used in these ways to ensure accurate aiming.

Step 4. Contaminant Removal

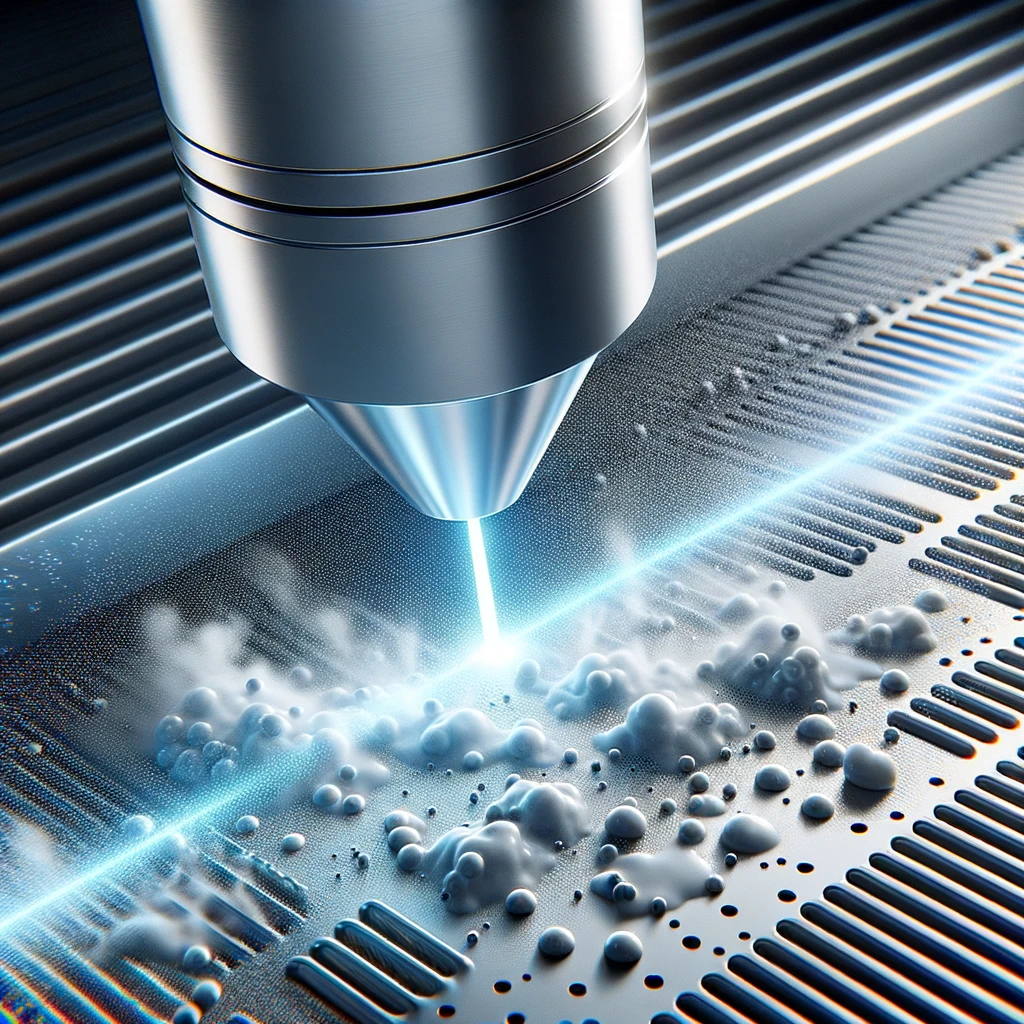

After firing the pulsed lasers, it interacts with the pollutants on the surface. This contact can entail ablation threshold, oxidation, or other chemicals, depending on the cleaning procedure used. The contaminants are dissolved or vaporized, resulting in a clean surface.

Step 5. Contaminant Catch

Specialized systems catch and filter the removed pollutants to avoid recontamination and assure the surrounding environment’s and other materials’ safety. This is especially important when working with dangerous materials.

Step 6. Surface Preservation

Because laser cleaners are non-contact, the underlying substance is not affected. This is especially important for sensitive surfaces.

Step 7. Final Examination

A final inspection verifies that the surface satisfies the necessary cleanliness criteria before completing the project. This stage is critical in situations where safety and quality are paramount.

A few other important things followed in this laser cleaning system are:

- Quality control methods are conducted following the cleaning process. Technicians evaluate the cleaned surface to ensure that all impurities have been appropriately removed without causing damage to the underlying substance.

- Proper cleaning process documentation, such as before-and-after photos, laser settings, and cleaning records, offers a clear record of the job completed.

- Laser cleaning machines must be serviced on a regular basis to ensure their continuing operation. This includes routine checkups, cleaning of optical components, and system calibration.

- Strict safety standards as stated in the ISO guide, e.g., personal protective equipment, are followed throughout cleaning to safeguard professionals from laser exposure and other risks.

Remarkable Advantages of Laser Cleaners

Consider a cleaning procedure that not only restores surfaces to their original state but also is ecologically friendly, cost-effective, and highly accurate. It has many advantages that are changing the way we deal with contamination issues:

1. Precision

Laser cleaning solution is like a skillful surgeon for surfaces. It has the ability to target certain pollutants with pinpoint accuracy while leaving the rest unaffected. Because of its accuracy, it is ideal for fragile things, metal cleaning, the automotive industry, and irreplaceable artifacts.

According to BBC, Laser lifts dirt of ages from artworks and is well established for stone and metal artifacts already. It has now been successfully applied to the wall paintings of the Sagrestia Vecchia and the Cappella del Manto in Santa Maria della Scala, Siena, Italy.

2. Environmentally Friendly

Unlike traditional cleaning procedures, which can include harsh chemicals and trash, laser systems are safe and environmentally friendly. It produces little waste and has no toxic chemicals, making it an environmentally friendly alternative.

3. No Surface Damage

Say goodbye to abrasion and damage caused by abrasive products or severe cleaning. This laser cleaner eliminates impurities softly and effectively without hurting the underlying substance and saves it from deterioration.

4. Rules of Versatility

This fiber laser technique can handle a wide range of surface cleaning chores, from rust and paint removal to graffiti cleansing and delicate restoration work. Its scalability makes it a popular choice in a variety of sectors.

5. Safety

Traditional cleaning procedures may expose you to hazards such as chemical exposure or dust inhalation. Because it eliminates the need for such harmful products and techniques, laser cleaners are a safer option.

6. Economical

While laser technology may appear to be high-tech, it might really save you money in the long run. Its accuracy decreases the need for rework or material replacement, which saves labor costs in the long run.

Laser cleaning equipment is built to last and requires little maintenance. It implies fewer difficulties and more cost advantages connected with maintaining the system.

7. Time-saving Ability

Because laser cleaning is rapid, you receive results faster. With less downtime for cleaning and maintaining production lines, your projects will be more productive.

In conclusion, the benefits of laser cleaning are game changers in the realm of surface cleaning. Its accuracy, environmental friendliness, and adaptability make it a superhero in the fight against pollutants, guaranteeing that surfaces are not only clean but also well-preserved.

Laser Cleaning Methods: Dazzling Array Of Cleaning Techniques

Laser cleaning is not a one-size-fits-all solution; rather, it is a dynamic field with a variety of procedures customized to specific cleaning jobs. Let’s have a look at the various laser cleaning techniques:

1. Laser Ablation

This process vaporizes surface pollutants by using high-intensity laser beams. It is a popular option for removing paint, corrosion, and coatings. Surfaces are cleaned and residue-free after laser ablation, which is similar to precision surgery.

Moreover, by using high-tech laser cleaning machines, you can control the ablation threshold to protect the material, such as metal underneath the contaminants.

2. Laser Coating Removal

Laser coating removal provides a clean and effective option for replacing or reworking coatings on diverse surfaces. It’s ideal for large-scale cleaning in sectors such as automotive, where accurate surface preparation is critical.

3. Laser Rust Removal

Laser rust removal defeats rust, the enemy of metal surfaces. This method works like a superhero, quickly and accurately eliminating rust without damaging the underlying metal. It is a potent ally in the process of bringing metal things back to their former luster.

For a better understanding and assessment of this laser rust removal process, you can get help from the Baison Laser rust removal process.

4. Laser Oxidation

The laser oxidation cleaning method removes impurities such as rust and oxides from metal surfaces. It saves the material from further deterioration by removing the oxidation layer and causes chemical processes that transform pollutants into harmless chemicals, leaving the surface clean and free of corrosion.

5. Laser Mold Cleaning

It can be difficult to remove mold and pollutants from delicate surfaces without causing damage. Moreover, using laser mold cleaning solves the problem of abrasive blasting.

This is an article about laser cleaning versus sandblasting.

There are many different laser cleaning processes, each with a certain charm and function. They perform their duties in cleaning and restoration with precision and dexterity, just like painters, doctors, and superheroes. Accept these strategies as your road map to a world that is cleaner and more attractive.

At Baison Laser, each of these laser cleaning systems has its own set of advantages, making it suited for a wide range of applications across many industries. The approach chosen for easy removal is determined by the individual cleaning operation and the material involved, highlighting the adaptability of laser beam cleaning.

Factors to Consider in Laser Cleaning Systems

You can guarantee that laser cleaning is not only efficient but also safe and appropriate for your unique cleaning needs by carefully evaluating these elements.

| Factors To Consider During Laser Cleaning Systems | |

| 1. Material Acceptance | Laser cleaning affects different materials in different ways. To avoid damage, consider the material of the surface to be cleaned and select the suitable laser settings. |

| 2. Pollutant kind | The kind of pollutant is critical. Although laser cleaning may efficiently remove rust, paint, grease, and other contaminants, the cleaning procedure may differ. |

| 3. Laser Strength and Intensity | To fit the cleaning work, adjust the laser power and intensity. For harder pollutants, higher force may be necessary, but be careful not to harm the surface. |

| 4. Wavelength of a laser | Different wavelengths are used by laser cleaning systems for different applications. For best results, make sure the wavelength matches the contaminant and substance. |

| 5. Security Measures | To protect operators and bystanders from laser exposure and possible risks, implement stringent safety standards, such as eye protection and sufficient ventilation. |

| 6. Surface Sensitivity | Consider the cleansed surface’s sensitivity. Delicate or ancient materials may necessitate less laser power and more accuracy. |

| 7. Environmental Damage | Although laser cleaning is environmentally safe, it is critical to appropriately capture and dispose of impurities to minimize any potential environmental damage. |

| 8. Cost Analysis | Although laser cleaning is environmentally safe, it is critical to appropriately capture and dispose of impurities to minimize any potential environmental damage. |

| 9. Cleaning Time | Although laser cleaning is often faster than traditional methods, cleaning speed may still be an important element in your particular application. |

| 10. Operator Training | Proper operator training is required to handle laser cleaning equipment safely and efficiently. |

Applications of Laser Cleaning Solutions

Although laser cleaning methods may sound like they belong in a science fiction film, they are actually quite practical and very powerful. Here are a few noteworthy examples:

1. Historic Restoration: Restoring Life to the Past

The restoration of historical structures is one impressive use of laser cleaning. Imagine structures, sculptures, and artifacts that date back hundreds of years coated in layers of sludge and filth.

Traditional cleaning techniques, such as chemical cleaning or thermal cleaning, may be harsh and harmful. Contrarily, laser cleaning softly eliminates impurities, revealing these historical gems’ genuine beauty. It brings the past back to life like a miraculous brush.

2. Industrial Equipment Maintenance: Supporting Smo of Operations

Machinery and equipment are often exposed to hazardous conditions and pollutants in the industrial sector. A non-intrusive method of maintaining and extending the life of this equipment is laser cleaning.

Laser cleaning is a cost-efficient and ecosystem-friendly option for cleaning sensitive components without disassembly or eliminating rust from metal surfaces.

3. The Automotive Sector: A Shiny Finish

In the case of autos, a spotless finish is crucial. Today, surfaces are cleaned with lasers to remove impurities and outdated paint without causing harm to the surface. The outcome? is a pristine, showroom-quality polish that automakers and fans like.

One such example of laser cleaners is reported by BBC where laser solutions are being tested and applied in cleaning railway tracks through laser trains.

4. Aerospace Precision: Providing Sky Safe

Precision and safety are crucial in the aircraft sector. Parts of aircraft are maintained using laser cleaning to keep them free of impurities that can impair performance. It’s an important phase in aviation maintenance that helps make flights safer.

5. Healthcare: Sterile Environment

Healthcare facilities must be completely sterile and clean. By eliminating impurities from surfaces, walls, and equipment, laser cleaning contributes to the maintenance of a sanitary workplace.

A key component of healthcare is infection management and laser cleaning is a key tool in reaching this goal.

These different applications illustrate laser cleaning technology’s adaptability and efficacy in combating pollutants while keeping the integrity of surfaces and materials in a variety of sectors.

Conclusion

Laser cleaning machines are a potent option in the fight against pollutants in the realm of industrial and technical breakthroughs. This guide has emphasized its accuracy, environmental friendliness, adaptability, and wide range of applications.

As technology advances, the laser cleaning process holds the possibility of expanded applications and increased efficiency. It is an essential instrument in creating a cleaner, greener, and more sustainable future. Accept this cutting-edge technology, knowing that it will contribute to a brighter future.

Harness The Power Of Laser Cleaning Systems with Baison!

We can assist you if you want to learn more about how laser cleaning technology may improve your cleaning procedures and contribute to a cleaner, more sustainable future. Whether you want a free sample proofreading, a free application evaluation, or to get in contact, we urge you to take the next step.

Take advantage of the chance to learn about the possibilities of laser cleaning systems in your company. Let us all work together and get in contact with Baison Laser to make the future cleaner and brighter.