Are you in search of top-tier laser cleaning systems for your business? Or are you a vendor seeking the finest laser cleaning equipment? Your search ends here! We’ll explore the strengths of the top 10 laser cleaning manufacturers worldwide, helping you make the right choice for your project.

Welcome to the future of eco-friendly cleaning. Let’s dive in.

Laser Cleaning Machines— An Overview

Laser technology is extremely versatile, and it has brought a revolution to the surface cleaning industry. Almost all manufacturing sectors, like shipbuilding, electronics, aerospace, sheet metal work, etc, require efficient cleaning processes. Rust, paint, and other detrimental layers inevitably end up on the material, causing harm to the material and delaying the manufacturing process, resulting in big losses to companies.

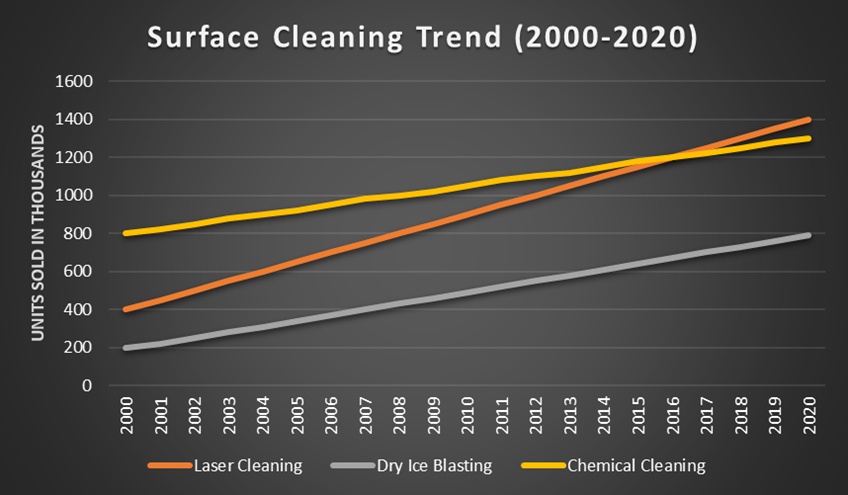

Though traditional cleaning processes like dry ice blasting and chemical cleaning are efficient, they are neither eco-friendly nor cheap. Conversely, laser cleaning is swift, eco-friendly, and cost-effective. (You may want to learn about traditional methods versus laser cleaning, such as dry ice blasting vs. laser cleaning, and chemical cleaning vs. fiber laser cleaning.)

The underlying principle entails high-intensity lasers burning and evaporating unwanted layers, leaving only pure matter. The laser beam’s non-damaging nature adds to its efficiency. Also, laser cleaning machines are compatible with a wide range of engineering materials.

There are two prevalent laser cleaning methods in the market: Continuous Wave (CW) lasers and Pulsed Lasers. A continuous laser cleaning machine is ideal for deep rust cleaning, while a pulsed laser is recommended for lighter tasks. Both CO2 and fiber lasers can serve as the laser source for these methods.

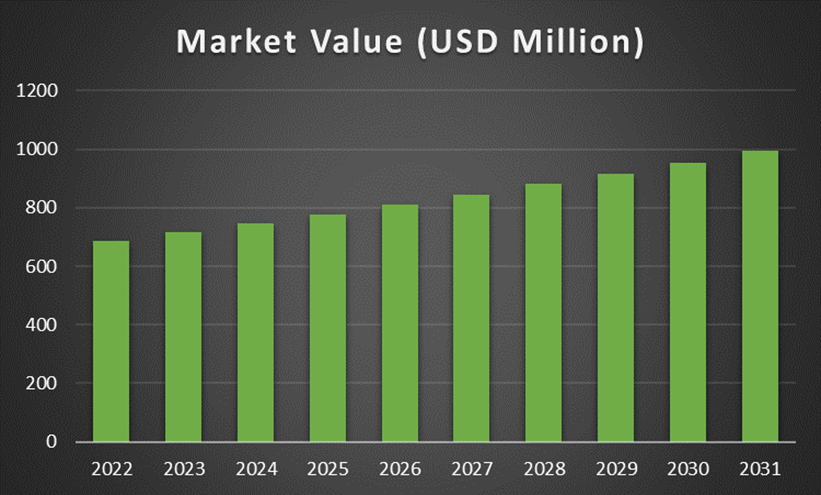

The future of laser cleaning machines appears promising, as shown in the graph above. Projections indicate that the laser cleaning industry will soar to an impressive USD 992.83 million by 2031.

Do You Have Any Questions?

Let Us Solve Your Problem

Top 10 Laser Cleaning Manufacturers and Suppliers in the World

This table compiles data on the leading global laser cleaning machine manufacturers, assessed by factors such as quality, market share, estimated revenue, and customer service.

| Rank | Brand Name | Year Established | Location | Employee Size |

| 1 | TRUMPF | 1923 | Germany | 14,500+ |

| 2 | Baison Laser | 2003 | China | 500+ |

| 3 | IPG Photonics | 1990 | United States | 2,000+ |

| 4 | Coherent | 1966 | United States | 5,000+ |

| 5 | Laserax | 2010 | Canada | 200+ |

| 6 | Laser Photonics | 1987 | United States | 100+ |

| 7 | CleanLASER | 1997 | Germany | 200+ |

| 8 | SCANLAB | 1990 | Germany | 500 |

| 9 | Anilox Roll Cleaning Systems | 1950 | USA | 100+ |

| 10 | TLM Laser | 2006 | UK | 200 |

Keep reading to gain a comprehensive insight into the global laser surface cleaning industry and its major players.

1. TRUMPF

Trumpf is a family-owned business that started as a chain of mechanical workshops in 1923 and, within 100 years, has become a global conglomerate based in Germany. Trumpf has subsidiaries in 70+ countries around the globe and is known for cutting-edge laser technologies.

Trumpf is a world-leading provider of high-end solutions in many areas of the manufacturing industry, such as VCSEL and photodiodes, 2D 3D laser machines, sensors, real-time localization, additive manufacturing, electronics, power tools, software, and services.

Moreover, Trumpf has specific machinery for laser cleaning, such as the TruMark series and TruMicro series. The TruMark machines use various wavelengths and high peak pulse laser power to clean the toughest layers of rust and dirt from any material. What’s amazing about these machines is that they can also work for “Laser Marking”, making them extremely versatile.

On the other hand, the TruMicro series uses shot and ultrashot pulse lasers for large-scale cleaning. Their huge catalog of machinery is a testimony to their brilliance and high quality.

Pros

- Experienced manufacturer

- Supply chain around the globe

- Vast product catalog

- Premium laser rust removal equipment

Cons

- Machines are expensive

2. Baison Laser

In the second spot, we’re proud to introduce Baison Laser, a leading laser machine manufacturer from China. We are an upcoming company excelling in the fields of solid-state laser, CO2 laser, and fiber laser technology.

Established in 2004, Baison Laser has quickly pierced the laser machining market with its cutting-edge technology, emphasis on R&D, and exceptional OEM and ODM services. As a Chinese manufacturer, we are committed to offering highly competitive rates without compromising quality.

Baison Laser excels in advanced laser cutting, welding, marking, and cleaning machines. The company offers 1000 W and 2000 W portable highly functional fiber laser cleaning machines in the cleaning category.

Featuring advanced pulsed and continuous wave laser technology, these machines clean rust, oil, and debris in seconds and are suitable for a wide range of industries, for small-scale to large-scale operations.

Baison Laser’s estimated revenue surpassed the 1 billion yuan mark last year, a testament to our remarkable success. Besides high-quality machinery, Baison Laser offers product customization, timely delivery, professional training, and 24/7 after-sales support by expert engineers.

Pros

- A youthful and innovative firm.

- Laser technology experts.

- Tailored laser rust removal machines.

- Competitive rates in the market.

Cons

- Limited Marketing and Outreach.

3. IPG Photonics

IPG Photonics is an American laser machine manufacturing company started in the early 90’s. They produce top-level machinery based on high-end optical fiber and diode pump technology. In addition, they also provide laser machining components like sensors, delivery systems, diodes, Mid IR crystals, etc. Apart from producing laser machines exclusive for machining, they also manufacture laser machines for the medical industry.

IPG Photonics has numerous fiber laser machines in the catalog for surface and structural cleaning, such as micro-material removal systems and ablative coating removal systems. They also offer great after-sales services, customization, and training for the machines.

IPG’s vertical integration strategy encompasses full control over designing, manufacturing, and overseeing key laser components to deliver solutions exceeding customer expectations.

Pros

- High-performance laser rust removal tool.

- A broad range of applications.

- Strong U.S. Presence.

Cons

- Expensive Prices

4. Coherent

Coherent is another American laser machine manufacturer; however, unlike others on the list, this company also focuses on the research of new laser technology and holds a strong connection with academia.

It was founded in 1966 in California and, since then, has developed a diverse portfolio of laser systems components, laser delivery components, and laser measurement instruments. In addition, Coherent also deals in engineering materials, electronics, and lithium-ion batteries.

You can find machinery targeting various industries such as aerospace, defense, medical and life sciences. Their product catalog has Powerline CO2 and fiber laser-based systems that can drill, cut, engrave, and clean metal, non-metal, and composite materials, making them extremely versatile.

What’s unique about coherent laser systems is that they are designed for new and emerging engineering materials, which are still developing, thanks to their state-of-the-art research facility. Like most on the list, Coherent provides training and after-sales services for their products.

Pros

- A diverse range of laser technologies.

- Strong presence in the United States.

- Reputation for quality.

Cons

- It may not be a dedicated laser cleaning manufacturer.

5. Laserax

Laerax is a Canadian laser system manufacturer established in 2010. By far, the company is one of the youngest on our list. However, their innovation, research, and development are still top-notch. It’s a relatively small company with 200+ employees and initially provided inline laser machines to smelting plants. Eventually, the business expanded, and now they manage laser solutions for casting and the automotive industry as well.

Laserax’s main laser solutions involve marking, cleaning, texturing, and hardening surfaces. The company’s product catalog is much smaller than others on the list, but on the positive side, they are more focused on limited applications making their products efficient.

Despite being a small company, they have a presence in America, Europe, and some parts of Asia. Other than selling products under their own brand, they also provide OEM laser markers and laser cleaners. Companies can also lease Laserax machines on a monthly basis, which is also a unique feature.

Pros

- Focus on laser cleaning.

- OEM services

- Laser machines available at rent

- Canadian manufacturing.

Cons

- Limted product catalog

6. Laser Photonics

Next, we’ve another shining prospect from America: Laser Photonics. Founded in 1987, it has 200+ employees and is a relatively smaller setup than others on our list, but nonetheless, it excels in the manufacturing of laser cutting, welding, cleaning, and marking machines.

They primarily deal in fiber laser and semiconductor technology. In addition to machines, Laser Photonics also provided machine components like laser cutting heads, scanners, and controllers.

Laser Photonics has a specific brand, “CleanTech”, dedicated to surface cleaning. The product ranges from handheld laser cleaners to heavy-duty industry-grade laser cleaning machines. In addition, they also offer OEM services, making them extremely versatile.

Laser Photonics is continuing to expand its business and ventured into 3D metal printing as well, which is a milestone in itself. Laser Photonics laser machines are priced fairly compared to other America-based competitors.

Pros

- High-end technology

- Diverse applications.

- U.S.-based for local support.

Cons

- Limited presence outside the USA

7. CleanLASER

Clean Laser is a laser cleaning machine supplier from Deutschland that solely focuses on surface cleaning technology. The company has a solid presence in Aachen Technology Hub in West Germany and is the epitome of research and development.

Founded in 1997, it has grown organically into one of the leading manufacturers of laser surface cleaning technologies. Clean Laser has a vast catalog of handheld and industry-scale laser cleaning machines. The premium machines deliver precise cleaning of machine tools, which makes them really efficient.

The company has specialized machinery for different applications like paint removal, mold-cleaning, and pre-treatment, which is a good business looking for specific products.

Clean Laser also offers turn-key laser production plant solutions, robotic guided systems, handheld, gantry systems, and training services for their clients. Currently, they manage to provide their services in 30 countries around the globe.

Pros

- Compact and portable systems.

- Versatile laser rust removal machine.

- German engineering excellence.

Cons

- Expensive machinery

8. SCANLAB

ScanLab was established in 1990 with humble beginnings, initially manufacturing galvanometer scanners. They have since become world-leading experts in laser scanning technology, with their R&D and manufacturing site headquartered in Puchheim, Germany.

ScanLab has a global presence, spanning from the USA to China, which enables the delivery of high-end laser solutions worldwide. Their primary focus is laser scanning technology.

You won’t typically find standalone laser machines in their catalog; instead, they specialize in offering cutting-edge scanners for laser cleaning machines. They are an excellent choice if you want replacement or enhancement of laser scanner components in your cleaning machines.

The company has a variety of dynamic laser scanners for surface cleaning machines, which provide precise positioning of the project. Some popular choices include SCANcube III and varioSCAN for high-speed surface cleaning. Additionally, they also provide calibration products and software for laser machines.

Pros

- Precision scanning technology.

- Integration with laser cleaning technology.

- German engineering quality.

Cons

- Not a dedicated laser cleaning manufacturer.

9. Anilox Roll Cleaning Systems

Anilox Roll Cleaning Systems lives up to its name by specializing in the development of laser cleaning machines designed specifically for Anilox rolls, a critical cylindrical component in printing technology.

The company has a remarkable history of producing cleaning technology for Anilox rolls since 1948, and it was only natural to adopt laser technology in the future as it’s more eco-friendly, sustainable, and efficient. However, they still produce other cleaning, more traditional cleaning solutions.

Anilox’s flagship laser cleaning system is the Eclipse laser machine, which can effectively remove residual paint, gunk, and coating from printing Anilox rolls. For smaller-scale work, they also sell portable laser cleaners.

The American brand delivers its products globally. Additionally, they also offer on-site laser cleaning surfaces and training for their customers.

Pros

- Specialized in anilox roll cleaning.

- Tailored laser equipment.

- Application-specific expertise.

Cons

- Limited focus on other industrial applications.

10. TLM Laser

Last on our list is a relatively young English laser cleaning machine manufacturer founded in 2006, which has rapidly climbed the ranks in the laser industry thanks to its high-quality products. Their Jetlaser series includes both industrial-scale and handheld cleaning systems for various applications. Furthermore, they offer software for Laser and CNC machines.

Pros

- Diverse Laser Cleaning Process

- High-quality products

Cons

- Relatively younger presence in the market

Do You Have Any Questions?

Let Us Solve Your Problem

Final Thoughts

As we wrap up this detailed list, you probably have gained new insights into the world of leading laser cleaning manufacturers. Each company offers unique services to its clients. So, to make the best decision, compare the products, services, and logistics of the company and brainstorm which one aligns best with your business needs.

Why Choose Baison Laser Cleaning Machines for Your Projects?

At Baison Laser, we stand out among laser cleaning machine manufacturers by not only meeting but exceeding customer demands. Our intense R&D program ensures we deliver durable laser systems that meet international quality standards without compromising affordability. Powered by high-tech fiber laser technology, our machines efficiently and precisely clean a variety of materials, from metals to plastics.

What sets us apart is our commitment to customizing and tailoring machines to your project’s specific needs for enhanced success and profits. Also, our dedicated fiber laser specialists are available 24/7 for project evaluation and FREE sample proofing.

Contact us NOW! Experience the Baison Laser advantage.