So why wait? Let’s dive into the realm of lasers and discover how these remarkable tools are shaping industries worldwide.

What is a Laser Welding Machine?

A laser welding machine is a type of welding equipment that utilizes a laser beam to join materials together. It is a highly precise and efficient welding method that offers numerous advantages over traditional welding techniques.

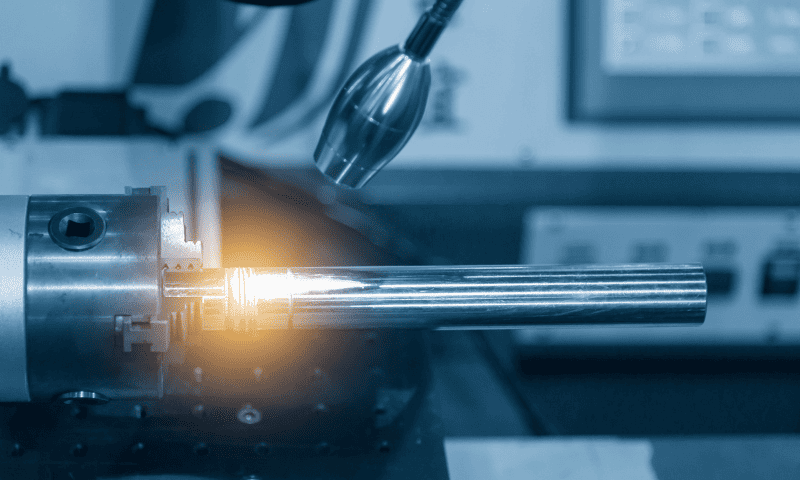

In a laser welding machine, a laser beam is generated by a laser source, such as a solid-state laser, fiber laser, or CO2 laser. The laser energy is focused and directed onto the materials to be welded. The intense heat generated by the laser power melts the materials, allowing them to fuse together. The laser energy can be controlled and adjusted for various welding parameters, such as power, duration, and focus, to achieve the desired welding results.

How Does Laser Welding Work?

Laser welding is a highly efficient and precise welding process that utilizes laser radiation to join materials together. In the welding process, by focusing a concentrated beam of light onto the materials to be welded, laser welding creates a fusion between them through the intense heat generated by the laser beam.

Here’s how it works:

- Focusing the Laser Beam: A laser welding machine directs a powerful laser beam onto the desired area of the materials to be joined. This focused beam ensures accurate and controlled welds.

- Melting the Material: The intense heat from the high intensity laser beam rapidly raises the temperature of the materials, causing them to melt. This melting process forms a molten pool at the welding joint or weld seam.

- Creating Fusion: As the material melts, it fuses together, creating a strong bond between them. The high energy density of laser radiation enables deep penetration into the material, resulting in robust welds with minimal distortion.

What are the types of Laser Welding Machines?

Laser welding machines come in commonly used types of laser welding machines: fiber laser welding machine, pulsed laser welder, and continuous wave (CW) laser welder.

Fiber Laser Welding Machines

These machines use a fiber laser as the energy source. They offer high beam quality, allowing fiber lasers for precise and efficient welding of various materials.

Fiber laser welding machine uses optical fibers doped with rare earth metals like ytterbium and neodymium to generate (and transmit) the laser beam. These contemporary machines give a lot of flexibility in terms of selecting laser welding equipment. Furthermore, these machines are faster, better, and more powerful than other welding machines. Laser radiation is harmful to human eyes, so proper protection is required.

Pulsed Laser Welders

Pulsed laser welding machines are designed to deliver short bursts of energy. These machines excel at precision welding on small parts, making them ideal for intricate projects that require utmost accuracy. With their ability to focus intense heat in a controlled manner, pulsed laser welders ensure precise and efficient results.

Continuous Wave (CW) Laser Welder

CW laser welding equipment provides a continuous stream of energy. This steady supply of power makes them suitable for larger-scale production and enables deeper penetration when welding thicker materials. CW laser welders are commonly used in industries that require high-volume manufacturing processes.

By understanding the differences among these types of laser welding machines, you can choose the one that best suits your specific needs. Whether you require delicate precision or robust productivity, there is laser welding machine equipment available to meet your requirements.

This guide will help you choose the laser welding machine that best suits your requirements. Each type of laser has unique attributes that affect the welding process, such as beam quality, wavelength, and power output. Fiber optic handheld laser welders currently offer greater advantages over other welding methods, so consider which type of laser is best for your application. With the right choice, you can achieve exceptional results and enhance your welding capabilities.

Benefits of Laser Welding Technology

Laser welding technology, a key component in the welding industry, offers numerous applications across various sectors. This advanced laser processing technique has found its place in industries such as automotive, electronics, jewelry making, and more. Let’s explore the benefits and versatility of various laser welding equipment here.

High Precise Control

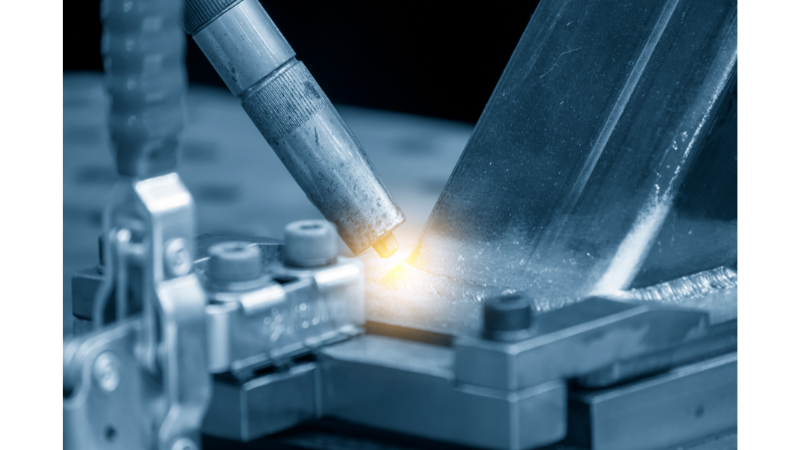

The focused laser allows for pinpoint accuracy in weld placement and for welding depth control. With its focused beam, it enables accurate and intricate welds that are not easily achievable with traditional welding techniques. Laser welding creates a minimal heat-affected zone (HAZ), reducing the risk of distortion or damage to surrounding materials.

Clean Welds

Another benefit lies in the reduced post-weld processing required. Laser welding produces clean and aesthetically pleasing welds with minimal spatter or debrisLaser welds typically require minimal cleaning or finishing work due to their precise nature. This saves time and resources for manufacturers, allowing for faster production cycles.

Versatility

Different types of lasers can be used with various materials like metals, plastics, or even optical fibers. Laser welding equipment excels at joining dissimilar materials with different melting points effectively. It enables the seamless fusion of metals that would otherwise be challenging to weld together using conventional methods. This capability opens up new possibilities for flexible manufacturing using laser technology across various industries.

The automotive industry particularly benefits from laser welding due to its high power density and accuracy. It is traditional welding process equipment that allows for the precise joining of components in vehicle manufacturing while maintaining structural integrity and durability. Moreover, laser welding finds application in powder metallurgy materials used extensively in automotive production.

Applications of Laser Welding Technology

The versatility, precision, and efficiency of laser welding make it suitable for a wide range of industries and welding requirements. Some common applications include.

Automotive Industry: Laser welding is widely used in the automotive industry for joining components such as body panels, chassis parts, exhaust systems, and engine components. It provides high-strength and precise welds, improving the structural integrity and durability of vehicles in laser welding products.

Aerospace Industry: Laser welding is utilized in the aerospace industry for joining critical components like turbine blades, engine casings, fuel tanks, and structural elements. It offers lightweight and high-quality welds, ensuring the safety and reliability of aircraft.

Electronics Industry: Laser welding is used in the electronics industry for joining components on circuit boards, such as connectors, sensors, and microelectronic devices. It enables precise and clean welds without damaging sensitive electronic components.

Energy Industry: Laser welding is employed in the energy industry for joining components in power generation systems and laser equipment such as turbines, solar panels, and batteries. It provides efficient and high-quality welds, enhancing the performance and reliability of energy systems.

Do Small Businesses Need a Laser Welding Machine?

Small businesses can benefit from having their own laser welding machine as it increases efficiency and reduces outsourcing costs. With in-house laser welding capabilities, small businesses gain quick prototyping and customization options. However, assessing the specific needs and volume of work is crucial before investing in a laser welding machine.

- Increased Efficiency: Having a laser welding machine on-site allows small businesses to streamline their operations by eliminating the need for outsourcing. This means faster turnaround times and reduced dependence on external suppliers.

- Cost Savings: By owning a laser welding machine, small businesses can save money in the long run. They no longer need to pay additional fees for outsourcing their welding needs, resulting in significant cost reductions over time.

- Quick Prototyping: Small businesses often require rapid prototyping to test new product designs or make modifications. With an in-house laser welding machine, they can quickly create prototypes without relying on external vendors, enabling them to iterate and refine their products more efficiently.

- Customization Options: Laser welding machine equipment provides small businesses with greater flexibility. The precise nature of laser welding allows for intricate designs and fine detailing that may not be achievable through traditional welding methods.

- Assessing Needs: Before investing in a laser welding machine, small businesses must evaluate their specific requirements. Factors such as the volume of work, types of materials used, and complexity of projects should be considered to determine whether owning a machine is economically viable.

Things You Need To Know Before Buying A Laser Welding Machine

Before purchasing a laser welding machine, it is necessary to investigate the machine configuration and company service of the welding machine, because the laser welding parameters will have an impact on the results. Details can be found here.

- Power output: Evaluate the power output of the machine as it determines the speed and strength of the welds. Higher power output allows for faster and stronger welds, while lower power may be suitable for delicate materials.

- Pulse frequency: Consider the pulse frequency options available on the laser welding machine. Different frequencies are suitable for various materials and welding applications.

- Spot size range: Assess the spot size range that the machine offers. This determines the precision and accuracy of your welds. Ensure that it aligns with your project requirements.

- Cooling system requirements: Check the cooling system requirements of the laser welding machine. Efficient cooling is essential to prevent overheating during prolonged use.

- Materials compatibility: Determine if the laser welding machine equipment is compatible with the materials you work with. Different machines may have different capabilities.

- Desired weld quality: Consider whether the machine can achieve your desired weld quality standards. Some machines offer higher precision and control over others, allowing for better-quality welds.

- Training and technical support: Ensure that proper training is available for operating and maintaining the laser welding machine effectively. Technical support should also be accessible in case any issues arise during usage. Considering the brand and service At present, many laser welding equipment manufacturers are growing rapidly. Well-known equipment generally uses better original parts and after-sales service.

By considering these factors before making a purchase, you can select a laser welding machine that meets your specific requirements and ensures optimal performance in your welding projects.

At present, many laser welding machine manufacturers will provide free proofing services. Before purchasing, customers must let the other party prove the effect to determine whether the use of automatic laser welding machines or equipment can meet their requirements

Best Laser Welding Machines for Small Business Owners Recommended

The recommended laser welding machines for small business owners are from Baison. The brand offers a combination of power, precision, reliability, and user-friendly features suitable keyboard laser welding equipment for small businesses.

Some popular models from this brand include:

Handheld Laser Welding Machines

Baison’s handheld fiber laser welding machines are a perfect solution for the accurate and high-speed welding of everything from stainless steel and iron to galvanized and aluminum sheeting. You can click here to learn its power. They are better than manual welding machines. Requiring minimal tooling, our handheld systems are a universal welding solution that is particularly well-suited to prototyping and product development.

Compared to other manual welding machines, this device has the following excellent features.

- Easy to operate

- Consistent welding results

- Low noise and power consumption

- Comprehensive safety feat

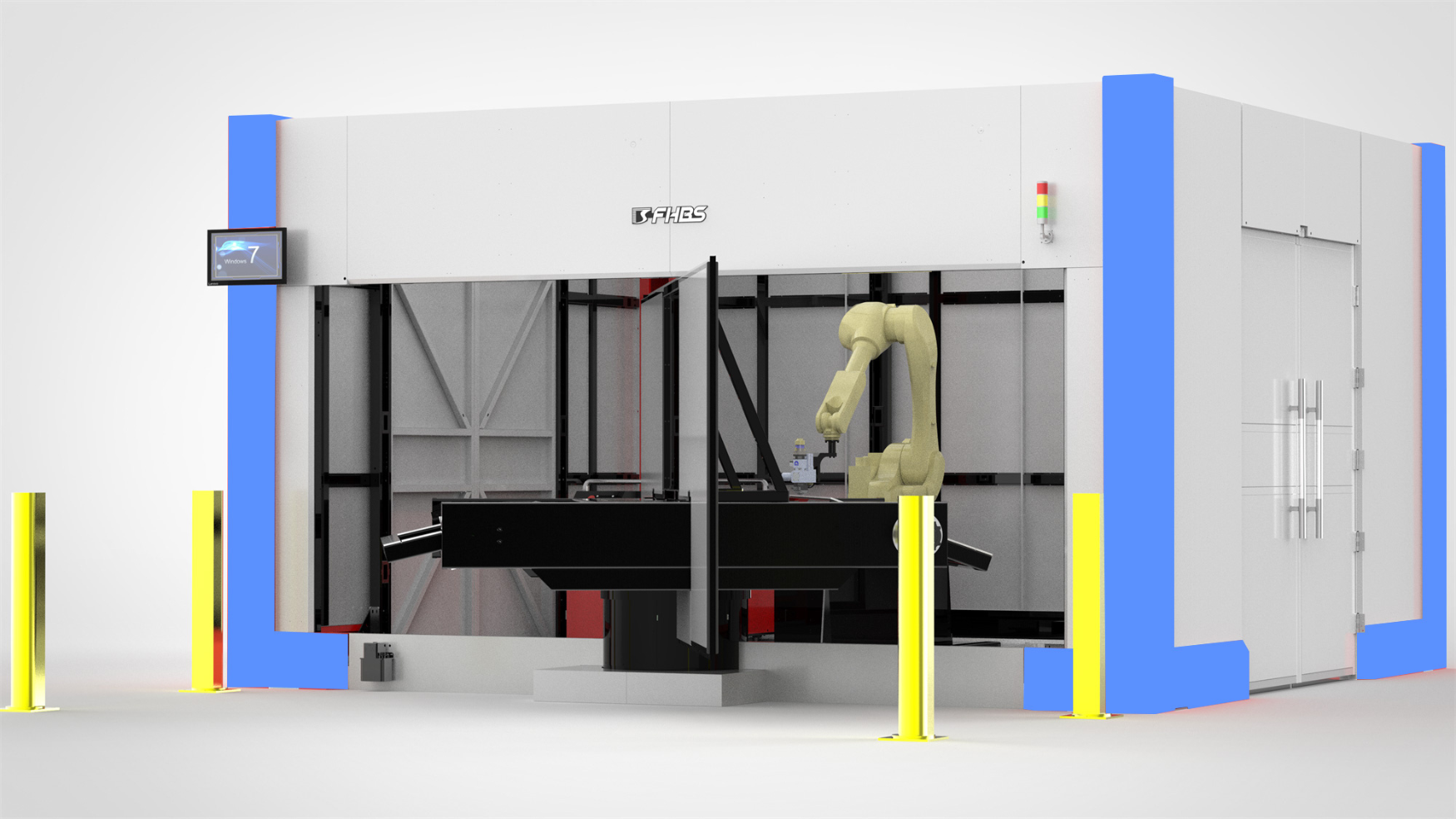

Laser Welding Robot

Baison’s fully-articulated robots ensure repeatable precision and continuous welding, on any scale required. Offering manufacturers the flexibility to perform even the most delicate welds reliably and consistently, our robots can perform pinpoint welds in the most hard-to-access areas. Baison’s automated system optimizes production line productivity while offering unmatched precision, versatility, and performance durability.

Some excellent features of this welder are described below.

- Low heat affected zone reduces distortion.

- Streamlined arm designed for maximum access

- Substantial deposition rate

- Maximizes manufacturing capabilities

Handheld laser welding machines and laser welding robots have gained popularity due to their exceptional performance in the field of laser welding. They are designed to meet the specific needs of business owners who require efficient and reliable welding solutions.

The laser welding robot is known for its high power output and advanced control systems. It provides excellent weld quality and can handle a wide range of materials with precision. The handheld laser welding Machine offers versatility and ease of use. It is equipped with intelligent features that simplify the manual laser welding process while ensuring consistent results.

They stand out with their compact design and user-friendly interface and allow small business owners to achieve accurate welds effortlessly. Investing in one of these laser welding machines can significantly enhance the productivity and efficiency of small businesses. With their advanced capabilities, they enable precise welding operations across various industries.

Frequently Asked Questions (FAQs)

1. Can I use a laser welding machine for both metal and non-metal materials?

Yes! A laser welding machine can be used for both metal and non-metal materials. However, it’s important to ensure that the specific machine you choose is compatible with the material you intend to weld. Different lasers may be required depending on the material properties.

2. Can laser welding equipment be used for precision welding?

Yes, laser welding machines are highly suitable for precision welding due to their ability to provide focused heat and precise control over the weld area. This makes them ideal for applications where accuracy is crucial, such as jewelry making or medical device manufacturing.

3. Is laser welding equipment cost-effective for small businesses?

While the initial investment in the right laser welding machine may seem significant, it can prove to be cost-effective in the long run. Laser welding offers high precision and efficiency, reducing material waste and minimizing the need for additional finishing processes. This can result in time and cost savings for small businesses.

Conclusion

Throughout this guide, we discussed how laser welding works and the different types of machines available. We have also explored this very early laser welding experiments the process’s various applications and advantages, highlighting why it is a valuable tool for small businesses and how to choose a laser welding system.

Before purchasing appropriate laser welding machine and equipment, it’s important to consider certain factors such as power requirements, budget constraints, and specific needs. We have provided essential information to help you make an informed decision when investing in the right laser welding machine.

Discover Excellence With Baison’s Customized Laser Welding Solutions

Baison is your go-to source for the Art of Laser Welding with Expert Guidance. Our laser welding machines are designed to provide you with precise and efficient welding solutions for a wide range of applications. With our expert guidance, you can confidently navigate the world of laser welding and harness its numerous benefits.

At Baison, we prioritize customer satisfaction by offering reliable products backed by our expertise in laser welding technology. We understand that every business has unique needs, and our team is here to provide personalized guidance and customer training throughout your journey. So why wait? Contact us now to take advantage of the Art of Laser Welding with Expert Guidance from Baison today!