Understanding Titanium and its Applications

Titanium is a versatile metal widely used in various industries due to its unique properties. Its exceptional strength, low density, and high corrosion resistance make it an ideal choice for many applications. Let’s explore the properties of titanium and its common uses in the aerospace, medical, and automotive sectors.

Properties of Titanium

- High strength-to-weight ratio: Titanium is known for its impressive strength while being lightweight. This property makes it suitable for applications where weight reduction is crucial.

- Corrosion resistance: Titanium exhibits excellent resistance to corrosion from various elements, including saltwater and chemicals. This attribute makes it highly desirable for marine environments.

- Biocompatibility: Titanium is biocompatible, meaning it can be safely used in medical implants without causing adverse reactions within the human body.

- Heat resistance: Titanium can withstand extreme temperatures without significant degradation, making it useful in high-temperature applications such as aircraft engines.

Common Use of Titanium in Various Industries

- Aerospace industry: Titanium finds extensive use in aerospace due to its strength, lightness, and corrosion resistance. It is utilized in aircraft structures, engine components, landing gear systems, and fasteners.

- Automotive sector: Titanium’s durability and heat resistance make it suitable for automotive applications such as exhaust systems, valves, springs, connecting rods, and suspension components.

- Medical field: The biocompatibility of titanium makes it valuable for medical devices like orthopedic implants (e.g. joint replacements), dental implants, surgical instruments, and prosthetics.

The Basics of Laser Cutting Titanium

Laser cutting technology is a highly effective method for working with titanium material. Here’s what you need to know about laser cutting titanium.

The Process

The laser cutting process involves using a high-powered laser beam to melt, vaporize, or burn through the titanium material. Such beams create a precise and clean cut, allowing for intricate designs and shapes. Laser cutting is carried out on modern equipment using CNC machines. The process of laser cutting titanium typically involves the following steps.

- Material preparation: The titanium sheet or plate to be cut is prepared by cleaning it to remove any dirt, oil, or contaminants that may affect the cutting process.

- Laser setup: The laser cutter is set up with the appropriate laser power, focusing lens, and cutting parameters based on the thickness and type of titanium being cut.

- Alignment: The titanium sheet is accurately positioned and aligned on the cutting bed of the laser machine to ensure precise cutting.

- Laser cutting: The laser beam is directed onto the titanium surface, melting and vaporizing the material along the designated cutting path. The high-energy laser beam rapidly heats and removes the titanium, creating a narrow kerf or cut.

- Gas assist: In some cases, an assist gas such as nitrogen or argon is used to blow away the molten titanium and prevent oxidation during the cutting process. This helps to achieve cleaner and smoother cuts.

- Quality control: After the laser cutting is complete, the laser cut titanium pieces are inspected for accuracy, smoothness, and any potential defects.

Advantages

Laser cutting titanium offers several benefits that make it a popular choice for many applications.

- High precision: The focused laser beam oflaser cutting provides exceptional accuracy, allowing for intricate designs and precise cuts on titanium materials.

- Minimal material wastage: Laser cutting technology can be used on various thicknesses of titanium, making it suitable for a wide range of applications. The focused laser beam minimizes waste by cutting with high efficiency, reducing the amount of scrap generated during the process.

- Good edge quality: The laser cutting process involves minimal heat-affected zone, and produces minimal heat transfer to the surrounding material, reducing the risk of warping or distortion. Laser cutting produces clean and smooth edges on titanium, eliminating the need for additional finishing processes.

- High Efficiency: Laser cutting is a fast and efficient process, speeding up your manufacturing process and reducing turnaround time. It can quickly cut through titanium, making it ideal for large-scale production.

Challenges

However, there are also challenges to consider before choosing this method. Let’s take a closer look at the challenges of laser cutting titanium.

- High initial investment cost: Acquiring a laser cutter capable of handling titanium can be expensive initially due to its specialized requirements. The laser machines require higher price for small business and industrial use.

- Reflectivity: Titanium has high reflectivity, which can cause a portion of the laser energy to bounce off the material instead of being absorbed. This can reduce cutting efficiency and require adjustments to laser parameters for optimal results.

- Oxidation: Titanium readily reacts with oxygen, forming titanium oxide. During laser cutting, high temperatures can result in oxidation on the cut edges, leading to discoloration and potential surface quality issues. Gas assist or inert gas shielding is often used to minimize oxidation.

- Material Thickness: Laser cutting thick titanium can be challenging due to its high melting point and thermal conductivity. It may require higher laser power and slower cutting speeds to achieve clean and precise cuts.

Overall, laser cutting offers numerous advantages for cutting titanium, but it also presents challenges related to reflectivity, oxidation, material thickness, and safety. With proper equipment, techniques, and safety measures, these challenges can be effectively managed to achieve high-quality cuts in titanium.

Choosing the Right Laser Cutting Machine for Titanium

When choosing a laser cutter for titanium, there are several important factors to consider. These factors will help ensure that you select the best laser cutter for your needs and achieve optimal results. Here are some key points to keep in mind and some excellent laser cutting machine models.

Factors to Consider

- Power Output: Titanium is a tough and reflective material, so a laser cutter with sufficient power is essential. Higher laser power allows for faster and more efficient cutting through the titanium.

- Beam Quality: The beam quality of the laser is crucial for achieving precise and clean cuts in titanium. A laser cutting equipment with a high-quality beam will result in better edge quality and a minimal heat-affected zone.

- Compatibility with Thicknesses and Grades: Ensure that the laser cutter you choose is compatible with the specific thicknesses and grades of titanium you’ll be working with. Different alloys may require different settings or techniques for optimal results.

- Gas Assist: Gas assist, such as nitrogen or argon, is often used during the laser cutting of titanium to prevent oxidation and improve the cutting quality. Ensure that the laser cutting machine has a gas assist system or the capability to integrate one.

- Compatibility with CAD/CAM software systems: To seamlessly integrate the laser cutter into your existing workflows, ensure compatibility with CAD/CAM software systems. This allows for the efficient transfer of design files and enables the precise execution of complex designs without any compatibility issues.

By considering these factors, one can select the best laser cutter that meets the specific requirements for cutting titanium, ensuring efficient production and high-quality results. Now that we’ve covered what factors you should consider when choosing a titanium laser cutter, let’s explore some top laser cutting machine models.

Top Laser Cutting Machine Models

There are several different laser cutting machine models available on the market, using different types of laser, each with its own features and capabilities. Currently, the market is dominated by two laser cutting technologies: CO2 lasers and fiber lasers. Here are some popular laser cutting machine models.

CO2 Laser Cutting Machines: These machines use a carbon dioxide laser to cut a wide range of materials, including titanium. Such machines are commonly used for cutting or engraving medium to thick thickness materials and are known for their versatility and affordability.

Fiber Laser Cutting Machines: A fiber laser cutter is a more powerful machine than other machines. These machines use fiber lasers to cut through various materials, including titanium and non metal materials. They are known for their high cutting speed, excellent beam quality, and energy efficiency. Fiber laser cutters are often used for cutting thin to medium thickness materials. They can also be used as laser marking machines.

Nd: YAG Laser Cutting Machines: These machines use an Nd: YAG laser (neodymium-doped yttrium aluminum garnet laser) to cut materials. These solid-state lasers are well-suited for high-power applications and can effectively cut through thick plates, including titanium. Nd: YAG laser cutters are known for their high power and ability to cut reflective materials.

It’s important to note that different manufacturers offer various models within each laser cutting machine category, with varying power levels, cutting speeds, and additional features. When choosing a laser cutting machine model, it’s essential to consider the specific requirements of the titanium cutting application and select a machine that meets those requirements effectively.

Baison Laser’s Offerings for Laser Cutting Titanium

Titanium is notorious for its toughness, making it a challenging material to work with. That’s why finding a laser cutter that can handle this mighty metal is essential. From power requirements to beam quality and cooling systems, there are numerous factors to consider. Our machines are known for their reliability and high precision and can meet all your needs.

Overview of Baison Laser’s Machines

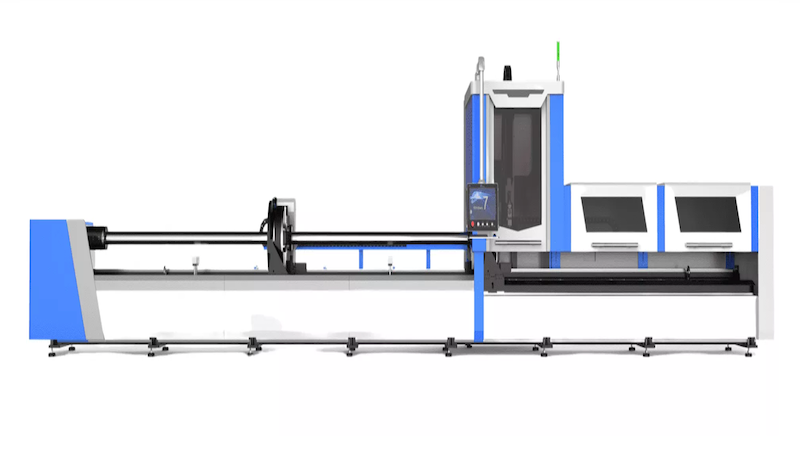

- Baison All-round Tube Laser Cutting Machine: This laser cutter has gained a reputation for its precision and speed when cutting titanium. It uses solid-state laser that allows for short processing times and high-volume production. The machine offers advanced features such as a tube auto-loading system and adjustable power settings, making it suitable for various titanium thicknesses and heavier titanium tubes.

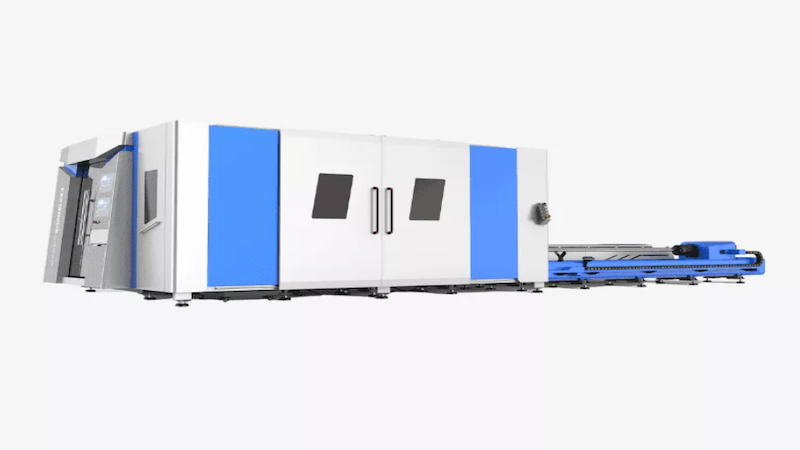

- Baison Dual Platforms Sheet Metal & Tube Laser Cutting Machine: It takes advantage of the strengths prevalent in both platforms: short processing times for large ranges or possible tubes, as well as cutting through thicker materials with an increased power level! Known for its versatility, Dual Platforms Sheet Metal & Tube Laser Cutting Machine is capable of handling intricate designs on titanium with ease. It boasts a user-friendly interface and offers a fully enclosed machine design, allowing you to achieve precise cuts on different grades of titanium.

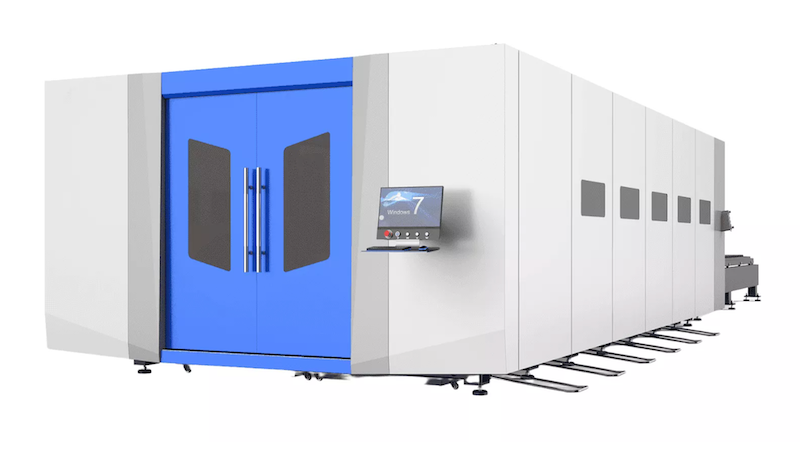

- Baison High Power Sheet Metal Laser Cutting Machine: With its high-powered laser beam, High Power Sheet Metal Laser Cutting Machine stands out in terms of efficiency and productivity. It can handle thick titanium sheets effortlessly while maintaining excellent cut quality. Make you a leader in your industry with our high-power sheet metal laser cutters fused with innovative, premium-grade technologies and fiber optic delivery.

Why Choose Baison Laser?

High-Quality Laser Cutters: Baison Laser is known for providing high-quality laser cutters that deliver precise and clean cuts in titanium, whether it’s a carbon dioxide laser cutter or a fiber laser machine. Our machines are equipped with advanced technology and superior beam quality, ensuring minimal heat-affected zone and excellent edge quality. This results in superior finished products and meets the high standards required for titanium cutting.

Exceptional Customer Service: Baison Laser values customer satisfaction and provides exceptional customer service. They have a team of knowledgeable and experienced professionals who are dedicated to assisting customers throughout the entire process, from pre-sales consultation to after-sales support. Their prompt response and reliable support ensure a smooth and hassle-free experience for customers.

Customized Solutions: Baison Laser understands that each titanium cutting application is unique and may have specific requirements. They offer customized solutions to meet the specific needs of customers. Whether it’s adjusting the machine parameters, integrating additional features, or providing tailored training, Baison Laser ensures that our laser cutters are optimized for the specific titanium cutting requirements.

In summary, Baison Laser provides excellent options for laser cutting titanium. By understanding your specific needs and carefully evaluating the available options based on the key considerations outlined above, you can choose a suitable laser cutter that meets your requirements.

So, whether you’re an industrial professional or a DIY enthusiast, join us as we explore the ins and outs of selecting the perfect laser cutter for your titanium cutting needs. Take the next step towards enhancing your titanium cutting capabilities by exploring Baison Laser’s offerings today!

FAQs

Q: Can I use any laser cutter for cutting titanium?

A: No, not all laser cutters are suitable for cutting titanium. Titanium is a challenging material due to its high melting point and reactivity with oxygen. It requires specialized lasers with sufficient power and cooling systems designed specifically for this purpose.

Q: How do I determine the power output required for laser cutting titanium?

A: The power output needed depends on the thickness and type of titanium you plan to cut. Thicker materials generally require higher power levels. Consulting with experts or conducting test cuts can help determine the appropriate power requirements.

Q: Can Baison Laser provide support and training for using their titanium laser cutters?

A: Yes, Baison Laser offers comprehensive support and training programs to ensure customers can effectively operate our titanium laser cutting machines. We have a team of experts who can assist with installation, routine maintenance, and troubleshooting.

Conclusion

We’ve delved into the world of laser cutting titanium, highlighting the process, advantages, challenges, and tips for choosing the right machine. How will this knowledge impact your future projects involving titanium? Let us know in the comments section. If you’re ready to elevate your titanium cutting process with high-quality laser machines, explore the options Baison Laser offers.