Whether you want to upgrade your welding business or set up an entirely new operation, this guide will help you choose the right fiber laser welding machine. Here, we have gathered the essential factors you should consider based on scientific research and market trends. Let’s get started.

What is Fiber Laser Welding?

Fiber laser welding machine uses optical fibers doped with rare earth metals like ytterbium and neodymium to generate (and transmit) the laser beam. The laser beam can reach temperatures up to 3000 ℃ (5432 ℉). This high temperature melts the base metal and fuses the two pieces. Fiber laser is a modern technology and an upgrade to older CO2, Doped, and Nd: YAG laser machines.

These contemporary machines give a lot of flexibility in terms of welding. A button can adjust the settings to suit various materials and welding joints. Fiber lasers also make challenging welding positions easier to weld. Furthermore, these machines are faster, better, and more powerful than other welding machines. Laser radiation is harmful to human eyes, so proper protection is required.

How Does Fiber Laser Welding Work?

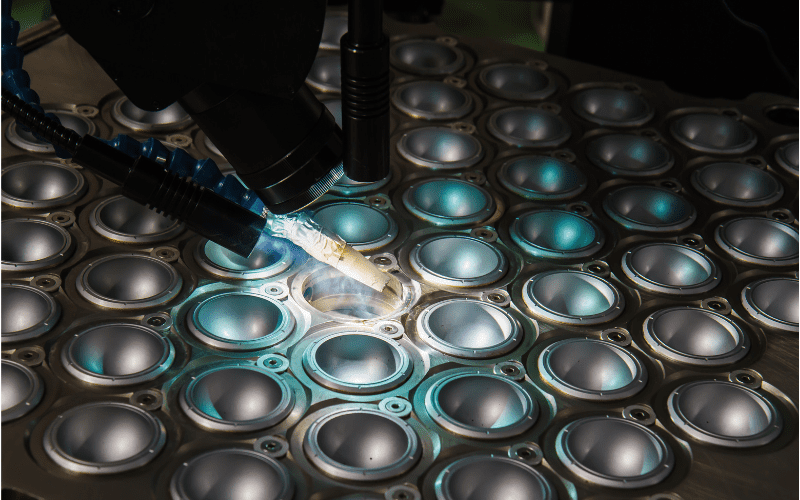

Fiber laser welding machines have different working components. Let’s take an automatic 2 kW fiber laser machine as an example. The main parts of the welding machine are the control panel, laser beam source, work bed, gantry system, and laser head. Additional laser welding equipment includes gas cylinders for shielding gas.

Like traditional methods, fiber lasers use the heat energy of a laser beam to fuse two base metals. Then, if needed, the filler wire is used to make solid weld joints.

Heat input in the case of laser welding depends on three crucial factors: the absorption rate, power output, and welding speed. Absorption rate means how much laser energy is absorbed by the material. It depends on the wavelength of the laser and material properties. These are inherent characteristics and can’t be changed. However, you can adjust laser power and welding speed for better weld quality.

Fiber lasers have three distinctive modes. These are conduction, transition and keyhole welding. In conduction welding, a lower power density laser beam heats the surface of the base metal, and fusion occurs. The weld penetration is not deep. In this case, the power output is 105 W/cm^2.

For stronger welds, keyhole welding mode is used. Here high power density beam melts and vaporizes the surface, creating a cavity (keyhole) at the starting point. Then, as the laser moves (or workpiece), molten metal fills the cavity behind the laser creating a perfect weld seam. In this way, deep penetration welding is ensured.

Benefits Of Fiber Laser Welding Over Traditional Methods?

The market share of laser technology is increasing every day as more industries adopt this modern-day technology. According to an economic report, lasers now contribute 11 billion dollars to manufacturing. And it’s continuously increasing. This is no fluke.

Here are some benefits of laser welding that can take your business to new heights.

Complex Welds

Laser welding allows you to perform welding on complex joints. Also, this type of welding works fine for any welding position. It’s also suitable for complex prototypes. Traditional welding can’t quickly adapt to unconventional designs. Lasers, on the other hand, can quickly adapt with minimal adjustments.

Material Versatility

A vast range of material compatibility is one of the biggest strengths of laser technology. With these machines, you can weld metals, non-metals, composites, organic materials, and thermoplastics. Furthermore, dissimilar materials can also be welded. This is something unprecedented. Traditional methods are only good for a specific group of materials.

Accuracy and Precision

Lasers’ ability to focus at a micro level makes them phenomenal. Laser welding can target a spot as small as 0.2 mm. Moreover, laser welding has the least tolerances compared to older technologies.

Material thickness is also not an issue, as laser welding can easily create deep keyhole penetration for clean welding seams. Moreover, fiber lasers can achieve a welding speed of 16 mm/s (and higher) with ease which was difficult in the past.

Low Footprint

According to a study conducted by the Technical University of Lisbon, Fiber lasers are also compact compared to traditional laser machines. A 4 kW fiber laser machine has only a 0.5 m^2 footprint compared to Nd: YAG, which has 11 m^2 with the same power. Fiber laser machines also have low maintenance requirements.

Vast Application

Laser welding has vast applications in the manufacturing industry. As laser technology is getting better, there is hardly any industry that is not touched by its magnificent performance. Major sectors include automotive, aerospace, oil and gas, construction, and appliance manufacturing.

Laser welding is suitable for both spot and continuous welding. Also, it doesn’t need access to two sides of the material for spot welding as the traditional method does.

Lower Distortions

Lasers produce minor heat-affected zones. That’s because lasers can precisely pinpoint where the heat needs to be applied without wasting energy.

The base metal melts and fuses, but the surrounding areas remain unaffected. Shielding gas also helps cool down the welds. This significantly reduces the distortion in the base plate. As a result, reducing the overall cost of rectification.

Easy to Master

Traditional methods like Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding needed years to perfect the craft. However, that’s not the case with modern laser welding. With a few training sessions, the laser welder can master this welding technique.

Factors to Consider When Purchasing a Fiber Laser Welding Machine

Setting up a laser welding system can be a daunting process initially. Therefore, you must consider these important factors before purchasing your first laser welding machine.

1. Types of Laser Welding Machine

Before investing in your first project, you must start by understanding various types of laser welding technologies. Each type of laser machine has a specific characteristic and is categorized by the laser source. Don’t worry. I’ll try to keep things simple as possible.

Gas Laser Welding

In this type of welding, the laser is produced when an electric charge is passed into a chamber full of carbon dioxide gas. The current excites the atoms, which as a result, releases energy in the form of light and heat.

The use of specialized lenses and mirrors then amplifies it. Finally, the resulting laser is used for welding.

Solid-state Welding

When a laser is produced using a crystal (solid state medium), in most cases, “neodymium-doped yttrium aluminum garnet; Nd: Y3Al5O12,” it’s said to be a solid-state laser. It’s then amplified and transmitted using special lenses and crystalline rods. Hence, it’s most commonly known as Nd: YAG laser technology.

Fiber Laser Welding

Fiber laser welding is a relatively newer technology. It uses optical fibers dope with ytterbium Yb3+ (mostly) for laser generation and transmission. In addition, these machines are more compact as optical fibers are pretty flexible.

The Superiority of Fiber Laser Welding

A study on laser welding machines found that a higher-power CO2 machine produced lesser weld penetration than a slightly lower-power Nd: YAG machine at the same welding speed.

Also, the wavelength of fiber lasers is shorter than CO2 lasers. This means fiber lasers have enhanced laser absorption that can lead to deeper weld penetration, especially in reflective materials like aluminum and mild steel.

Moreover, fiber lasers have better beam quality than YAG lasers. Fiber laser welding combines the benefits of CO2 and YAG lasers and gives better performance. For a comparison of these three lasers, you can refer to this article.

Pulsed and Continuous Laser Welding

Pulsed and continuous laser welding technology are other ways the machines are sorted.

When the laser beam is divided into packets of energy, it’s known as laser pulses. Nd: YAG laser welding machines primarily use pulsated beams. Such rays can produce higher peak intensity energies, perfect for spot welding.

When a laser beam flows in a continuous stream, it’s called continuous wave (CW) technology. Fiber laser welding can be pulsed or continuous. However, CW Fiber lasers are versatile and can perform faster welding.

2. Material Compatibility

Secondly, make a list of materials you want to work with. Laser welding is versatile and can weld metals, composites, and thermoplastics. Another factor that comes into play is the reflectiveness of metal. Shiny surfaces reflect the laser and result in loss of energy. Thankfully, laser welding is evolving, and different welding machines cover a vast spectrum of materials.

|

Compatibility |

Material |

Fiber Laser |

CO2 Laser |

Nd:YAG Laser |

|---|---|---|---|---|

|

Metals |

Aluminum |

Best |

Moderate |

Best |

|

Brass |

Best |

Low |

Moderate |

|

|

Copper |

Best |

Low |

Moderate |

|

|

Mild Steel |

Best |

Best |

Best |

|

|

Gold |

Best |

Moderate |

Moderate |

|

|

Silver |

Best |

Moderate |

Moderate |

|

|

Stainless Steel |

Best |

Best |

Best |

|

|

Non-Metals |

Acrylic |

Moderate |

Best |

Low |

|

Fabric |

Low |

Low |

Low |

|

|

Ceramics |

Moderate |

Best |

Moderate |

|

|

Leather |

Moderate |

Best |

Moderate |

|

|

Rubber |

Moderate |

Best |

Low |

|

|

Wood |

Moderate |

Best |

Low |

|

|

Thermoplastics |

Plastics |

Moderate |

Best |

Low |

|

Composites |

Moderate |

Best |

Moderate |

The right shielding gas makes the welding process all the more efficient. Furthermore, argon is the best choice, then comes nitrogen and helium.

3. Welding Compatibility

Different welding machines perform different functions. Nd: YAG is best for some applications, while fiber lasers perform better for others. Let’s discuss the application of each type of welding machine separately.

Fiber Laser

These welding machines are best for thin and thick sheet metal processing. Moreover, fiber lasers offer wall plug efficiency (WPE) of 30%, which is the best among all other laser technologies. This leads to deeper keyhole penetration and increased welding speeds.

CO2 Laser

These welding machines are suitable if you want to weld thick metal parts. However, some non-metals respond best to the wavelength of CO2 lasers. Their overall efficiency (WPE) is 5-10%.

Nd: YAG Laser

These welding machines are best for structural steel welding. It’s also used to weld stiffened panels in the shipbuilding industry. It offers higher welding speeds of 16mm/s at power output greater than 2KW. However, the efficiency of these machines is slightly lower than CO2 laser.

4. Industry Application

Whether planning to set up a small or large manufacturing industry, you must choose between these types.

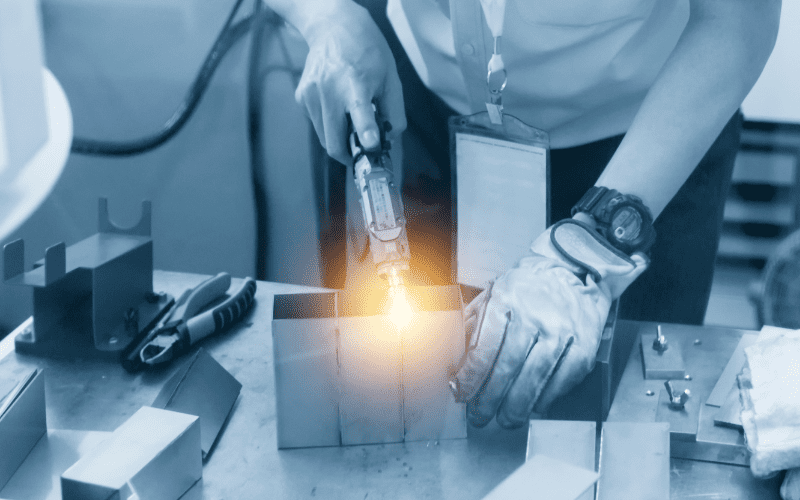

Handheld Laser Welding Machine

Typically, suited for small to medium-scale industries. Handheld welding machines are compact, semi-automatic, manual machines. It is easier to master laser welding compared to TIG and MIG welding. It’s suitable for repair work and medium size production. You can either use it for spot welding or continuous welding seams.

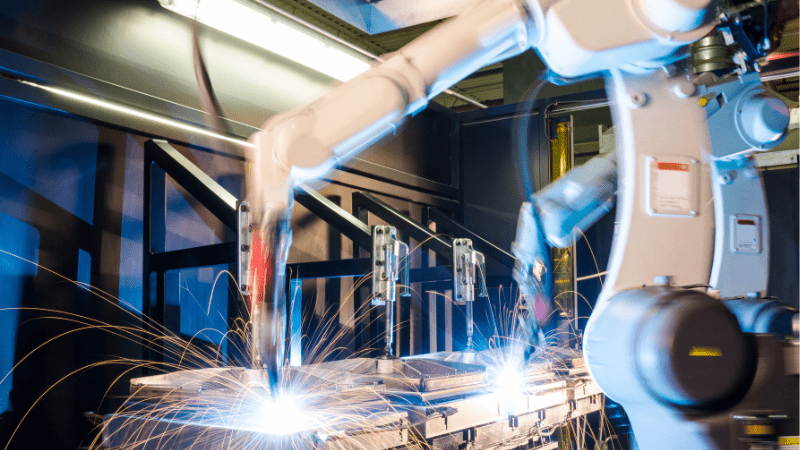

Robot Welding

Robot Laser welding machines use computer-controlled robotic arms to move in three-dimensional space. Therefore, they are only suited for large-scale industries with high budgets and workloads.

Another type is CNC-style laser welding machines that take in large plates of material and perform work on it. These machines use a gantry system, and welding is done in two-dimensional space

5. Laser Power, Speed, and Frequency

Remember the major parameters, what they mean, and how they affect the welding process before you choose the laser welding machine.

First is laser power. For continuous welding, you should look for a minimum of 1 KW to 2 KW machine. For small-scale work, a welding machine with a power output of 1000 W (or lower) is sufficient.

Secondly, moderate laser frequency (pulse per second-Hertz) and higher output are preferred for efficient welding. Fiber laser and Nd: YAG laser gives the best welding speed. Pulse width is another crucial factor determining material melting and keyhole penetration.

6. Filler Material in Laser Welding

Typically, laser welding uses heat to fuse two base materials. But just like traditional processes, laser welding can also use filler material. Most laser welding machines come with both options. Filler materials are usually used when the space between workpieces is too large.

7. Configuration

The laser machine should complement your workload, material processing, and job geometry. Configuration refers to either manual or semi-automatic and automatic laser welding machines.

Manual machines work best in small-scale production. In contrast, semi-automatics and automatic machines will yield greater profits in large production. Automated machines are larger and capable of large-scale production. It requires less intervention by the operator.

How Much Does a Fiber Laser Welding Machine Cost?

The cost of laser welding machines varies from country to country. Power output, configuration, and customization are significant factors affecting cost.

Typically, handheld laser welding machines cost $1k – $10k. The bigger automated machines can cost between $15k and $35k. Tax on imports can also escalate the price of the product.

The initial cost of laser welding is higher than traditional systems. However, the long-term benefits of low maintenance and higher quality make up for the investment.

Where to Find The Best Deals On Fiber Laser Welding Machines?

First, you must look for a laser welding machine manufacturer specializing in laser technology. Professional manufacturers make high-quality and durable machines. Durability is the main aspect, as any abrupt machine stoppage can directly affect your business. So, spending extra money on higher quality can save your business prospects.

This also brings us to the next step, which is after-sales services. Laser machines are more complex than traditional ones, so a company that offers such a service is a plus.

Thirdly, the brand should have a quality research facility and experienced staff. That way, you can ask them for specific customization in the machine that can help you increase production.

Last but not least, the company should give competitive market prices. The initial investment is already very large, so you don’t want to spend extra cash.

Conclusion

Hopefully, this in-depth manual about laser welding machines will serve as a guiding light for your project. Be sure to focus on the factors mentioned above that are crucial to consider before purchasing a new welding machine.

Amazingly laser welding has many types that can work on various materials. It can easily replace traditional methods and enhance the welding process.

Baison Laser Provides the Best Laser Welding Solutions

You are here for a reason, and we won’t leave you empty-handed. Our company manufactures premium quality laser welding machines for the emerging industry. Baison Laser welding machines are high-quality, durable, and equipped with the latest technology.

We produce a variety of welding machines that cater to different industry sectors. In addition, our catalog includes fiber laser welding machines with numerous power outputs and configurations suitable for different projects like the best handheld laser welder.

Moreover, you’ll get the option to customize your order, and our expert will guide you through every step of the process.

If you are unsure, sign up for a FREE evaluation. We offer competitive prices on all our products. So, what are you waiting for? Click the button below to get the machine now!