Laser-cutting technology is a widely used manufacturing process in which computer-controlled lasers are used to cut and shape materials.

The laser cutter’s laser beam passes through workpieces, and the heat it produces causes the material’s surface to melt or evaporate. This change creates an opening through which material can be removed from the part.

Laser cutting is extremely accurate because it consistently produces repeatable results with minimal waste. And it’s even noble when incorporated into the warehouse.

We’re going to learn more about how laser cutting systems and warehouse compatibility affect feeding productivity.

What Is a Laser Cutter?

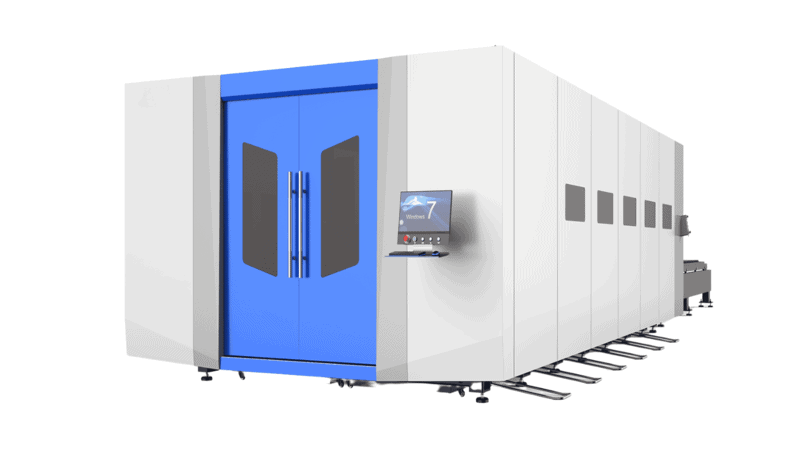

A fiber laser cutter is a machine that uses a laser beam to cut and engrave different materials. It can be used to cut metal, paper, plastic, and wood. The laser beam is controlled by computer software, and the speed of the laser is adjustable.

The fiber laser cutting machine works by directing the focused beam of light onto the material to be cut. The laser power light burns away the surface layer of the material, leaving behind an exact copy of what was drawn on the computer.

The laser cutting technology process is used widely in manufacturing and design industries. The coil-fed laser blanking creates prototypes and production parts quickly and accurately.

How Do Laser Cutters Work?

A fiber laser cutter is a machine that uses a laser beam to cut materials. The Baison laser cutter stands out over traditional cutting methods because of its ability to create intricate designs. It also produces cuts in details in materials such as wood, metal, plastic, and other materials.

The process starts with the design being loaded onto the computer. Next, it is sent through a CAM program (computer-aided manufacturing) which converts it into G-code (the language understood by CNC machines).

This code tells the system where to cut or engrave your material based on how you want it done!

What Is Feeding Productivity in the Laser Cutting Procedure?

Feeding productivity is the term used to describe the time a laser cutting machine takes to cut a particular piece of material.

This can be measured in terms of time, which is measured in seconds or minutes. Alternatively, it can be as a percentage of the total time taken by the machine to complete a job. The feed rate is an important factor that determines how fast your laser-cutting machine will work.

It takes approximately 4 seconds for laser-cutting machines to process one sheet of paper, while it takes around 2 seconds for them to cut through plastic materials such as ABS and acrylics.

However, if you are using your fiber laser cutter for thick materials like wood and metal, then it might take a bit longer than usual. This is due to their thickness which may hinder the speed at which they are able to move forward.

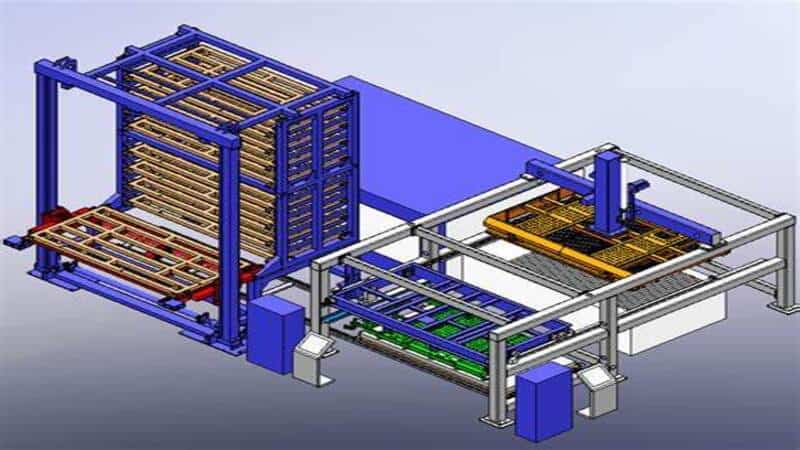

What Is the Relationship between the System and Warehouse Compatibility?

The relationship between the system and warehouse compatibility affects feeding performance.

The warehouse system is the most important part of the laser cutter system, so it should be compatible with your machine.

The warehouse management system controls all warehouse storage, retrieval, and transportation aspects, including product flow paths, palletization methods, and storage locations.

If you want fast loading speeds on your material handling equipment (MHE), then you need to select an appropriate MHE. This will work well with your laser cutter’s cutting speed capabilities.

It will help ensure that your operators don’t have to wait around while materials are being cut offsite before they can begin loading them into their trucks/trailers.

Benefits of Making the Warehouse System Compatible with the Laser Cutter System

There are many reasons to look for ways to make your warehouse system more compatible with the laser cutter system.

Here are some of the benefits:

Reduce the Time Spent on Processing Orders.

When you make your warehouse system compatible with your laser cutter system, you can reduce the time spent on processing orders. This is because you can use the same software for managing both of them.

In addition, there is no need to manually update or change any data since both systems are linked together. This means that you will be able to save time and money that would have been used for manually updating and maintaining records.

Increase the Efficiency of the Warehouse.

When you make your warehouse system compatible with your system, you can increase the efficiency of your warehouse. This is because all information about stock levels will be automatically updated each time an order is placed or processed by either system.

You will be able to see live updates about current stock levels and the availability of different products. This means that there will be no need for manual updates, which can take up valuable time and resources.

Improve the Quality of Products.

It improves quality control over products produced by ensuring everything goes smoothly. This is without any mistakes occurring during the production and streamlining processes, such as shipping samples out for testing purposes before mass producing them.

Improve the Efficiency of Your Warehouse System.

The efficiency of your warehouse system is also improved because it reduces waste. This is by cutting out only what is necessary from each piece of material being used to create an item or set of items.

It means that less material goes unused and wasted at each stage, along with less time spent sorting through this excess material trying to find what was cut out by mistake or not needed anymore after creating one item or set.

How to Increase Productivity with the Right Combination of Laser Cutter and Warehouse System?

When it comes to increasing productivity, the key is to find a combination of laser cutter and warehouse system that works for your business. The right combination can help you cut parts faster, which means more work gets done in less time.

If you’re looking for ways to improve feeding performance, here are some tips:

1. Get the Right Software Installed on Both Machines.

You can install the right software, including controller software (like VCarve Pro) and CAM programs (like Mastercam).

You can also have additional software tools for cutting jobs–such as CAD/CAM packages. You can also have any additional utilities needed when working with specific materials such as plastics or wood composites.

You’ll also want some material management system so that operators know what material is available at any moment.

2. Ensure There Are No Obstructions

Make sure there are no obstructions between where operators stand during production runs. Otherwise, product throughput will suffer greatly since it takes longer than usual before each operator becomes available again after completing their task(s).

Factors Affecting Feeding Performance in Laser Cutters and Warehouses

The way you choose to feed your products into a laser cutter can have a significant impact on your overall productivity.

Here’s what you need to know about factors affecting feeding performance in laser cutters and warehouses.

1. Feeder Type

A wide variety of different feeders are available on the market today.

The type of feeder you choose will depend on your particular application. Some common types include gravity feeders, vacuum feeders, and pneumatic feeders.

A gravity feeder is the most common type of feeder used in a fiber laser cutter. It usually comprises a hopper and a vibrating bowl that moves back and forth over the material to be fed into the laser cutter. The speed of this type of feeder determines how quickly the material will be fed into the laser-cutting machine.

2. Feeder Size and Speed

The size of the feeder determines how much material it can hold at one time. However, if you increase its capacity, it will take more time to fill up before starting again.

The speed at which your material moves through the laser cutter also affects your overall production rate. It will take longer for larger pieces to pass through if they have to move slowly through your machine.

So, try as much as possible to keep your pieces small enough so they can pass through quickly without causing any jams. Or other problems on either side of your machine.

3. Feeder Position, Orientation, and Location

The position of the feeder can affect the productivity of a laser cutter system.

The feeder must be placed in a location that allows it to deliver materials to the laser cutter without causing any problems.

In addition, the feeder orientation and location should be set up to ensure convenient access for operators who need to load or unload materials.

4. Load on the Feeder System

The load on the feeder system can affect feeding performance because it affects how much material is pushed through the laser head at once.

If there is too much material pushed through at once, it may cause damage to the machine’s components.

It can also result in the breakage of parts due to excessive pressure exerted by these items against each other during operation.

How to Optimize Feeding Performance in Laser Cutters and Warehouses?

The feeding process is one of the most important steps in laser cutting. The quality of your materials directly affects your production line’s productivity, stability, and safety.

In order to optimize feeding performance, you should consider both the compatibility between your warehouse management system and fiber lasers’ system as well as how they can work together efficiently to improve overall efficiency.

Conclusion

Combining laser cutters and warehouses is an important factor in feeding performance. The right combination will allow you to optimize the productivity of your business. So, it’s worth taking some time to think about what kind of system would work best for your needs.

At Baison Laser, we’ll ensure the laser technology you settle for is compatible with your warehouse. This way, you’ll have an easy time managing your business.

To get started, get a free application evaluation to transform your business into six figures.