Welders have been using various welding techniques for a long time. Most traditional welding machines release toxic fumes and welding dust. However, handheld laser welding machines offer a much safer solution for innovative projects. It is a revolutionizing technique empowering various industries, including automotive, aerospace, and jewelry manufacturing.

In this blog post, you’ll learn about the thickness a handheld laser welding machine can weld. We’ll also familiarize you with the factors that influence the thickness of handheld laser welder welds. So, let’s dive into it.

Overview of Handheld Laser Welding Machine

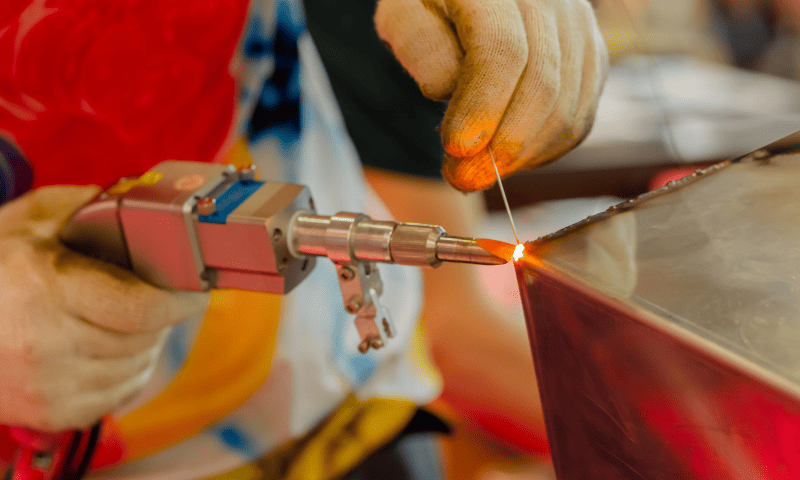

Handheld laser welding employs a laser source that generates a high-intensity laser beam. The laser beam melts the metal, providing the weld pool for joint formation. It eliminates the need to create weld beads and feed the wire as a filler. In addition, the right adjustment of the laser parameters gives you more control over the welding process. It minimizes the effects of head distortion.

Employing handheld laser technology for welding also enables organizations to upskill their employees. Most handheld laser machines come with presets for various material thicknesses. You can learn about the settings from the manufacturer’s instructions and set the laser for particular materials and thicknesses.

Factors Influencing Welding Thickness

Welding needs precision and careful consideration to achieve the desired results. Several factors influence the welding thickness. The following are some prominent factors that impact the welding thickness of a handheld laser welding machine:

1. Laser Power

Laser power is the energy emitted by a laser beam. According to LinkedIn, the requirement of laser power is accessed by the thickness of the material you want to weld. The laser power impacts the depth of the joint. High laser power offers better weld penetration depth. High-power laser welding machines are the best fit for thick materials.

However, you need to consider the power of the laser, as excessive energy from a high-power laser can lead to excessive melting. It enlarges the heat-affected zone, which can eventually lead to deformation and quality issues with the end product. To prevent this issue, you need to balance the speed and welding quality while picking up the laser power.

2. Beam Quality

Beam quality significantly impacts the thickness a laser beam can weld. The quality of the laser beam influences the energy distribution and focusing of the laser, which in turn affects the heat input and thermal behavior of the material being welded.

High-quality laser beam offers a uniform distribution of energy. The beam is also concentrated with a small focal point. It boosts the weld quality, resulting in a strong joint.

3. Beam Focus Position

The focus position of the laser beam is also a crucial factor that impacts the thickness of a laser welding machine weld. When the beam focus position is above the point of weld creation, you get a large heat-affected zone. It also offers you better welding depth.

However, locating the focal position above the weldment can distort the thinner materials. For thinner materials, a focus position below the point of weldment is the most suitable. It results in a smaller heat-affected zone with a smaller penetration depth.

4. Scanning Speed

Scanning speed defines the speed at which the laser beam is moved in the welding region. Low scanning speed increases the time for welding. It results in more heat transfer to the welding area, leading to deep weld. High scanning speed is often unsuitable, especially for thick materials that need deep joints. However, high speed is more suitable for dealing with thinner material.

5. Laser Beam Diameter

The diameter of a laser beam is another considerable factor while welding a material. A small beam diameter has a high energy density. It concentrates the heat energy over the welding area, leading to less depth. It makes small laser beam diameters suitable for thin materials.

You need to go with a broader laser beam diameter for thicker materials. It offers more in-depth heat energy penetration, resulting in deeper weld.

Material Considerations

The material’s properties also influence the thickness a handheld laser can weld. The following are some material considerations you should keep in mind:

1. Absorption Coefficient

The absorption coefficient of a material defines the extent to which a material absorbs energy when exposed to a laser beam. A material with a high absorption coefficient absorbs more laser energy. The heated material results in deeper penetration of the weld pool, leading to a thick weld.

However, a material with a low absorption coefficient results in less deep penetration of the weld for a particular wavelength of laser beam than a material with a high absorption coefficient.

2. Thermal Conductivity

The thermal conductivity of a material impacts the heat distribution during welding by laser, influencing the thickness of the weld. Materials with low thermal conductivity effectively retain heat due to minimal heat distribution. It allows the laser beam to penetrate deeply, creating a thick weld.

However, materials with high thermal conductivity tend to distribute the laser energy away from the welding region. The weld can’t penetrate deeply into such materials, leading to a shallow and weak weld.

3. Melting Point

The melting point of a material also affects the thickness of the weld a laser welding machine creates. The material absorbs the laser energy to reach its melting point and create a weld pool.

The low melting point of a material allows it to achieve melting temperature with less laser energy. The heat energy penetrates deeply and results in a thick weld. Materials with high melting points need more energy to melt, leading to shallow penetration and less thick weld.

Maximum Thickness of Laser Welding Machine with Different Power

The power of a handheld laser welding machine impacts the thickness it can weld. Here is an overview of the maximum thicknesses of various materials that handheld laser welding machines with different powers can weld:

| Handheld Laser Power | Maximum Welding Thickness |

|---|---|

| 300W | 0.3mm |

| 300W | 0.3mm |

| 600W | 1mm |

| 1000W | 2mm |

| 1000W | 2mm |

| 1500W | 5mm |

| 2000W | 8mm |

1. What Can a 300W Handheld Laser Weld?

A 300W handheld laser welding machine can weld stainless steel of about 0.3mm thick. You can also weld stainless steel thicker than 0.3mm by adjusting the parameters. However, it leads to thermal deformation, resulting in unwanted products. However, if you are welding carbon steel and titanium, you should vary the parameters.

2. What Can a 600W Handheld Laser Weld?

A 600W laser welding equipment welds a 1.5mm steel plate. However, the thickness of steel plates should not exceed 1mm. This laser can also weld thick stainless steel plates and home appliances. The maximum thickness of stainless steel and appliances you want to weld should not be more than 1mm.

3. What Can a 1000W Handheld Laser Weld?

A 1000W laser welding machine has excessive power and can weld thick materials. You can employ it to weld up to 2mm thick stainless steel plate. You can achieve the same results with a 500W laser, but the speed of the laser should be slower than 1m/min.

4. What Can a 1500W Handheld Laser Weld?

If you are looking to weld thicker materials, you need to increase the power of the welding machine. A 1500W laser can weld stainless steel with a maximum thickness of 5mm.

5. What Can a 2000W Handheld Laser Weld?

If you want to weld an 8mm thick stainless steel, opt for a 2000W laser. A 2000W laser welding machine offers enough energy to penetrate the material, creating a thicker weld.

Handheld Welders vs. Other Methods: Thickness Capability

Welding is a vast field where you can employ several methods. Compared to traditional methods, laser welding is a more precise and cost-effective technique. Moreover, the welding rate of handheld laser welding is much faster than other methods, including traditional argon arc welding, gas metal arc welding (GMAW), shielded metal arc welding (SMAW), and flux-cored arc welding (FCAW).

The maximum thickness each method can weld varies. A handheld laser welding machine can weld a material up to 8mm. Traditional argon arc welding can weld up to 4mm thick materials. According to the Quora, gas metal arc welding (GMAW) can weld various thicknesses. You can weld any thickness with this technique. You can achieve a maximum thickness of several centimeters. Shielded metal arc welding (SMAW) and flux-cored arc welding (FCAW) also weld materials that are several centimeters thick.

| Welding Method | Maximum Welding Thickness Capability |

|---|---|

| Handheld Laser Welding | 8mm |

| Argon Arc Welding | 4mm |

| Gas Metal Arc Welding (GMAW) | Several centimeters |

| Shielded Metal Arc Welding (SMAW) | Several centimeters |

| Flux-Cored Arc Welding (FCAW) | Several centimeters |

Welding Effect of Handheld Welding Machine

Handheld welding is an advanced approach. The following are the welding effects of a hand-held laser welding machine:

- Handheld welding enhances convenience as you can carry the welding equipment anywhere. These portable machines enable you to weld materials at places where large equipment is not accessible.

- It offers you flat and sleek welds while working with different metal thicknesses. Handheld laser welding machines offer better penetration of the heat energy and lead to thicker welds.

- Handheld laser welding minimizes pollution by limiting the emission of hazardous gasses. It promotes a safe working environment.

- Handheld welding machines lead to weld formation rapidly. According to the Fabricator, the high power and speed of laser welding enables you to create welds in a short time.

FAQs

1. How thick will a laser welder weld?

A laser welder can weld various thicknesses. You can weld up to 8mm thick materials with a high-powered laser welding machine.

2. What are the limitations of laser welding?

Laser welding is an expensive technique that requires considerable investment. Moreover, the reflective nature of some metals also requires additional processing.

3. Are handheld laser welders any good?

Yes, handheld laser welders are a better option than traditional techniques. It is an efficient approach that offers more productivity.

Conclusion

Handheld laser welding is a fantastic approach that enables you to weld various materials conveniently. The high energy and efficiency of laser welding allow you to achieve deep welds. Moreover, you can boost production quality and productivity with this method. It offers you a wide range of options and precision that traditional welding methods may not be able to provide.

However, it is necessary to get proper training before dealing with handheld laser welding machines. A slight mistake can lead to severe injuries and damage to equipment. In addition, you should get a reliable laser welding machine. Baison Laser offers you durable laser welding equipment.

Get a HandHeld laser Welding Machine With Baison Laser!

A high-end laser welder is crucial for achieving deep welds. Baison Laser offers you the best laser equipment, including laser welding, cleansing, cutting, and marking machines. Contact us today to learn about our laser welding machines. Our experts will guide you in getting a suitable laser machine for your needs!