Understanding Fiber Laser Machines

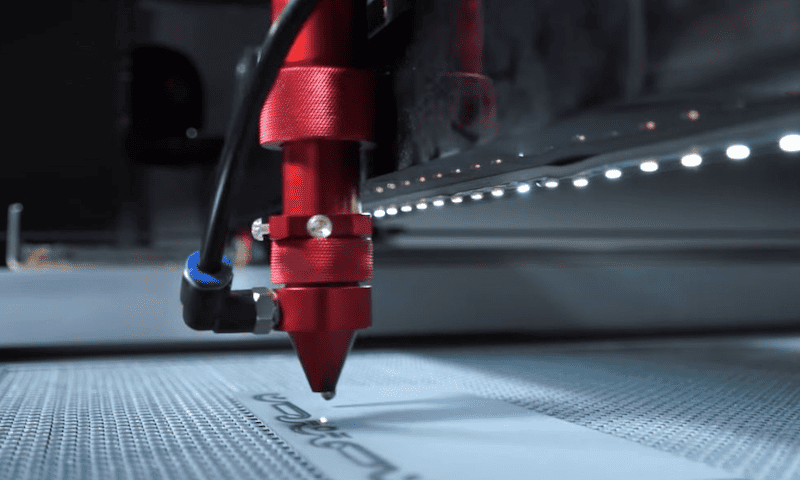

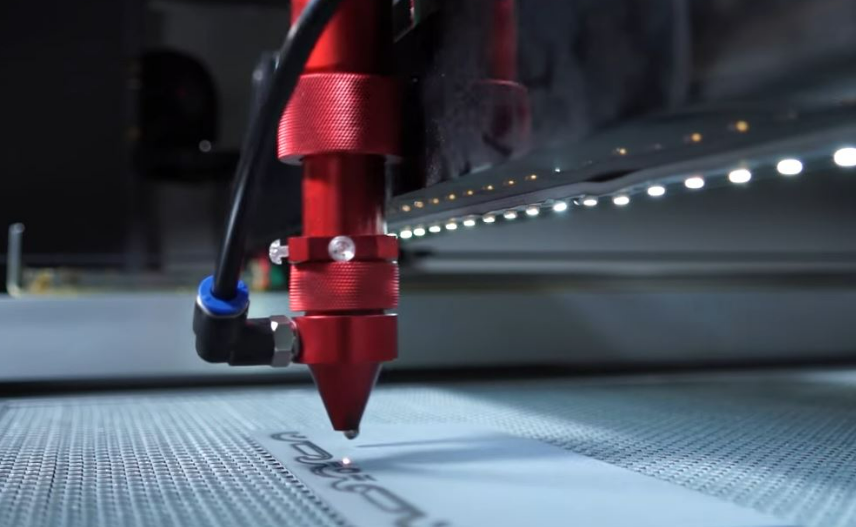

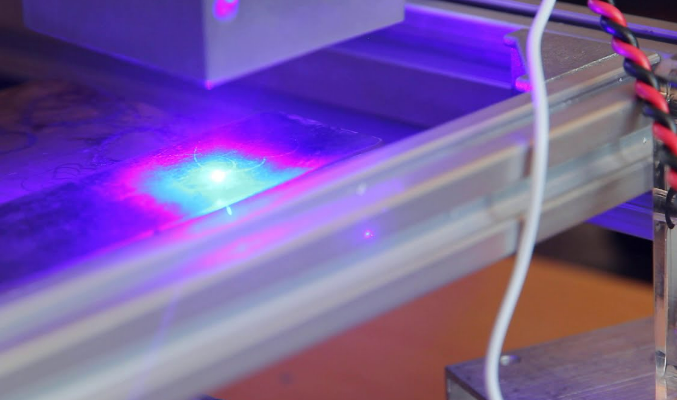

Fiber laser machines are quite the marvel. These machines use an optical fiber infused with rare-earth elements as a gain medium. This supercharges the machine. They employ diode arrays, which work together to create amplified signals.

When pump light from these diodes enters the optical fiber and gets absorbed by the rare-earth elements, it stimulates emissions at specific wavelengths. This creates a powerful laser beam that is perfect for precision tasks such as deep engraving, etching, or marking materials.

Common Uses of Fiber Laser Machines

You might ask where this technology comes into play in real life. Let us tell you about its wide array of applications:

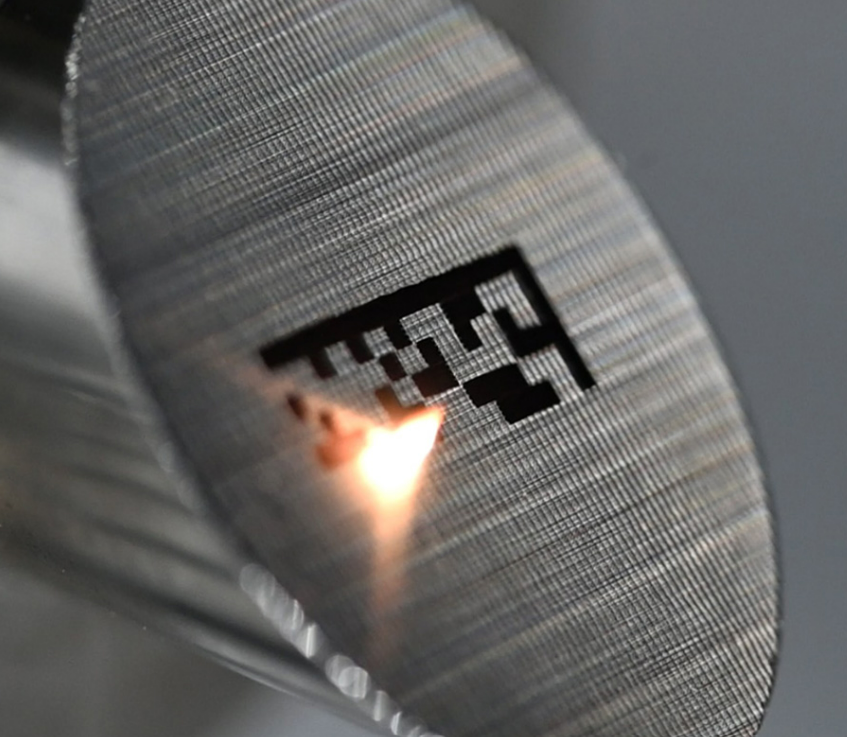

- Fiber lasers excel in engraving tasks because they produce high-quality marks without damaging the surrounding material. It’s like using a precision tool rather than a blunt instrument.

- These machines can easily make permanent marks on hard materials, such as metal identification tags that won’t fade even under harsh conditions.

- Fiber laser marker is also great for etching intricate designs onto delicate surfaces. It offers control and accuracy, making it perfect for custom jewelry or art pieces.

Exploring Green Laser Machines

The world of green UV laser marking machines is fascinating, to say the least. With their unique working mechanism and vast areas of application, they’re truly a marvel in the industry.

How Green Laser Machines Work

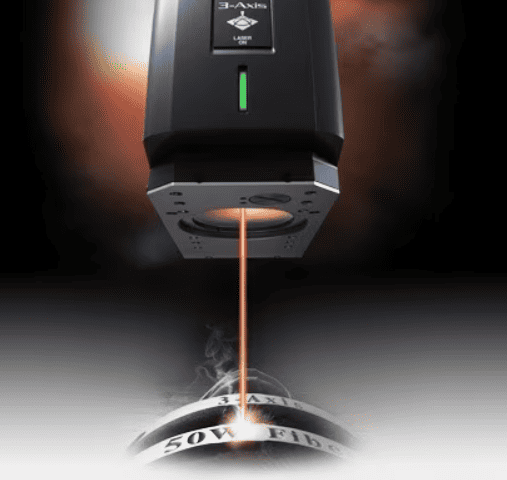

Green laser machines operate using an exciting principle: frequency doubling. This method uses standard Nd: YAG lasers as a foundation. It’s like building a house – you start with strong bricks (the Nd: YAG lasers) and then add another layer on top (frequency doubling).

The result? A robust structure emitting wavelengths specifically in the green spectrum. This process makes these machines incredibly efficient at engraving or etching designs onto surfaces without causing damage due to excessive heat generation—a feat akin to drawing detailed artwork with chalk on hot pavement under direct sunlight.

Applications of Green Laser Machines

A key advantage of these machines is their ability to interact effectively with materials that don’t absorb infrared wavelengths well. Imagine trying to talk underwater—sound doesn’t travel too great, right? But if you use sign language, your message gets across perfectly fine. Similarly, when traditional infrared lasers struggle, green laser machines save the day.

- Glass: In glass processing industries where precision is paramount for beautiful results, green laser markers come in handy because they do not cause cracks during operations.

- Solar Panels: They are also extensively used in solar panel manufacturing for scribing thin-film photovoltaic panels, which require precision and minimal damage to the material.

- Medical Industry: In medical industries, they’re useful for marking high-quality codes on delicate equipment without damaging them. It’s like writing a note on an eggshell—only green laser marking technologies can do it without causing any harm even on organic materials.

Comparing Fiber Laser and Green Laser Machines

The world of laser is as diverse as it’s intriguing. But when you’re choosing between fiber lasers and green lasers, things can get a bit tricky. Here is a quick table that gives an overview of the differences before we get into the details:

| Feature/Characteristic | Fiber Lasers | Green Lasers |

| Core Mechanism | Optical | Nd:YAG |

| Efficiency | High | Selective |

| Wavelength | Infrared | 532nm |

| Best For | Metals | Plastics |

| Heat Damage | Minimal | Minimal |

| Operational Life | Long | Standard |

| Maintenance | Low | Standard |

| Application Focus | Speed | Precision |

Fiber Lasers: A Closer Look

Fiber lasers, known for their efficiency, are champions in the speed department. They use an optical fiber doped with rare-earth elements like erbium to amplify light signals into powerful laser beams. This process lets them mark or engrave materials swiftly without causing significant heat damage – perfect for handling metals.

Beyond that, they boast long operational life thanks to their solid-state design. Less maintenance needs means more time saved – making them quite cost-effective in the long run. Click here to learn how laser marking can help you save money.

A Glimpse at Green Lasers

On the other side of the ring stand green UV laser machines. These systems utilize frequency-doubled Nd: YAG lasers emitting shorter wavelengths around the 532nm range. It also stands out due to its structural and micromechanical properties.

This wavelength interacts efficiently with materials that don’t absorb infrared well – such as plastics or certain metals like gold and copper. The result? Precise markings on sensitive materials minus any serious harm.

Picking Sides?

In this comparison battle, there’s no outright winner; it all boils down to your specific requirements. If your priority lies in speedy operations over a wide range of material types (especially metal), then give yourself a pat on the back because fiber laser machines could be your match.

But, if you’re dealing with materials that demand delicate handling and high precision – green lasers might just win your heart. They also shine in applications where the aesthetics of marking matter.

In conclusion, when choosing between fiber laser and green laser machines, it’s not about which is ‘better’ overall – but rather what’s better for YOU based on your unique needs. So choose wisely.

Industry-Specific Applications of Laser Marking Machines

Laser machines, including fiber and green UV lasers, have become integral tools in a variety of industries. They’ve proven to be invaluable due to their precision and adaptability and make a great chunk of the industrial revenue.

Fiber Lasers in the Automotive Industry

The automotive industry is one where fiber laser machines truly shine. With the ability to etch on both metal and plastic parts, these machines are often used for marking vehicle identification numbers (VINs) or branding components with company logos.

If there’s ever a recall, manufacturers can use the precise laser markings to swiftly identify which units are affected. If there’s ever a recall situation, manufacturers can quickly track down affected units thanks to precise laser markings.

Green Lasers for Electronics Manufacturing

In electronics manufacturing, green UV laser has carved out its niche. These lasers interact well with materials that don’t absorb infrared wavelengths effectively – think delicate circuit boards or sensitive electronic components.

Green lasers mark these items without causing heat damage, ensuring product integrity while providing important information like serial numbers or brand names on each piece.

Aerospace: A Field That Utilizes Both Types

In the aerospace sector – both types find use. Fiber lasers are utilized for creating permanent marks on sturdy materials such as steel alloys used in engine construction whereas green UV lasers excel at leaving clear inscriptions on sensitive optical equipment without any risk of thermal damage.

Choosing Between Fiber Laser and Green Laser Marking Machines

If you’re in the market for a laser machine, two of your primary choices are likely to be fiber laser and green laser devices. Both are top-tier options with unique strengths, but which one should be your go-to? Let’s get into the details.

Fiber Laser Machines – The Efficient Powerhouse

Fiber lasers have gained popularity for their efficiency and adaptability. These machines use an optical fiber as the gain medium infused with rare-earth elements like erbium or ytterbium. This design allows them to generate high-power beams that make quick work of engraving, etching, or marking materials. More on how they can improve the quality of results by setting parameters here.

The versatility of fiber lasers means they can mark various materials ranging from metals to some plastics. They also shine in terms of speed – these machines can complete tasks much faster than most other alternatives without compromising precision.

Green Laser Machines – Gentle Yet Precise

In contrast, green UV laser machines excel when working with delicate materials that might not absorb infrared wavelengths well. Materials such as glass or certain polymers benefit immensely from this type of technology due to its low heat output preventing material damage.

This doesn’t mean it lacks laser power output though. Green UV lasers offer remarkable precision for intricate designs while still maintaining impressive processing speeds—a win-win if you ask us.

So, which one to choose? The answer lies in your specific requirements. If you’re dealing with robust materials and need speed and efficiency, fiber laser machines are the way to go. On the other hand, for delicate materials requiring a gentler touch but still demanding precision, green UV laser machines will serve you best.

Unique Strengths of Fiber Laser and Green Marking Lasers

They use an optical fiber infused with rare-earth elements as a gain medium to create amplified signals. This gives them the ability to etch detailed markings on various materials like metal and plastic.

The strength of these machines lies in their speed and long operational life. Thanks to advanced technology, they can operate at high speeds without losing precision or causing damage to the material being marked.

But what about the green laser marking system? Well, these devices shine when it comes to working with heat-sensitive materials that don’t absorb infrared wavelengths well. Using frequency-doubled Nd: YAG lasers, they generate green light ideal for processing plastics or other sensitive substances.

Green UV laser markers stand out because of their exceptional focus diameter and peak power density—factors critical for achieving fine detail while minimizing thermal stress on your workpiece.

- Fiber lasers excel in engraving metals thanks to their strong interaction with such surfaces.

- Green UV lasers perform exceptionally well with non-metallic compounds due its precise wavelength compatibility.

- The choice between both depends largely on specific requirements like budget constraints, frequently used material types, and desired precision levels among others.

High-Speed Operations & Long Operational Life of Fiber Lasers

The fiber laser marking machine’s nature allows it to work at high speeds without losing accuracy. This means you can churn out more products in less time, boosting your overall productivity.

Additionally, these machines are known for their long operational life. They don’t require as much upkeep compared to other laser types and usually have a longer lifespan, making them an economical option for many companies.

Precision & Material Safety with Green Laser Marking Machine

Green laser marking systems offer exceptional precision when dealing with sensitive materials like plastic or glass. Their ability to minimize heat damage makes them the go-to choice for industries where material safety is paramount.

So what’s the takeaway? Both fiber and green UV laser machines pack a punch with their own unique strengths, making them key players in any operation.

Cost-Efficiency of Fiber Laser Marking Machines

They pack high-speed operations and long operational life into one package, giving you more bang for your buck.

High Efficiency and Long Life

The fast operation speed of fiber lasers allows them to complete tasks quickly, saving time which translates into money saved. The efficiency doesn’t stop there though.

Unlike other types of lasers, the components in fiber laser machines have an extended lifespan that outpaces their counterparts by miles. In fact, research shows they can last up to 100,000 hours before needing any major servicing or replacement parts.

This longevity reduces downtime from maintenance and repairs over the machine’s lifetime – another win for your wallet. But let’s not forget about energy usage; these machines use significantly less power than others on the market – helping keep those utility bills down too.

To bring it all together:

- The high-speed operation means faster job completion times,

- The longer lifespan leads to reduced need for expensive repairs and replacements,

- Lower energy usage means savings on utility bills.

It’s no surprise that businesses are increasingly opting for fiber laser marking machines. With their blend of speed, longevity, and energy efficiency, they’re a smart investment in the long run. Learn more about laser marking machine prices here.

Ensuring Accuracy and Material Safety Using Green Laser Marking

When it comes to precision in marking, green laser marking machines steal the show. Their unique ability to provide precise markings makes them an ideal choice for delicate materials that might be damaged by other types of lasers.

The beauty of a green UV laser marking machine lies in its wavelength. Operating at 532nm, this type of machine is perfectly tuned for sensitive materials like plastics and certain metals that can’t absorb infrared wavelengths well.

Safety First: Less Heat Damage

The potential heat damage from more intense lasers is a concern when dealing with delicate or temperature-sensitive materials. But here’s where green UV laser markers shine. They operate using less heat than their counterparts – ensuring safety without compromising on quality.

This means you get sharp, clear laser marks every time without worrying about damaging your material due to excessive heat exposure. Now isn’t that something?

Incredible Precision: Detailed Work Made Easy

Apart from being gentle on sensitive surfaces, these machines are known for their incredible precision too.

- Detailed work? Check.

- Fine engraving? Double-check.

In short, they let you perform intricate tasks with ease. This level of accuracy has made them popular across industries such as jewelry making and electronics manufacturing.

A Practical Solution: Versatility Meets Efficiency

Green laser machines are not just safe and accurate; they’re also highly versatile. From PVC to glass – if you have a range of different materials lined up for processing, these machines have got you covered.

So, if precision and material safety are on your checklist, it’s time to give green laser marking technology a closer look. With their reduced risk of damage and high-precision operation, they’re the unsung heroes in the world of laser marking.

Conclusion

Both fiber laser and green UV laser marking machines bring their own unique strengths, catering to a broad spectrum of industrial applications. Whether it’s the adaptability and speed of fiber lasers or the precision of green UV lasers for delicate tasks, the right choice often hinges on your specific needs. As you chart the course of your business’s future, remember that equipping yourself with the right technology is a game-changer. In case you want to learn more about laser marking, here is our guide!

Unleash the Potential of Advanced Laser Solutions with Baison Laser!

Are you prepared to elevate your operations with unmatched laser cutting and welding efficiency? At Baison Laser, we are committed to providing top-tier laser solutions tailored to your unique requirements. Take a deep dive into our offerings by taking advantage of our free sample proofing!