The demand for high-performance, heavy-duty cutting solutions is growing rapidly in a variety of industries. For businesses working with materials like stainless steel, carbon steel, aluminum, copper, titanium, and more, efficient and precise cutting technologies are paramount.

In this post, we’ll explore the advantages of Baison’s fiber laser cutting machines for heavy-duty applications across multiple sectors. Let’s get right into it!

What Is Fiber Laser Cutting Technology

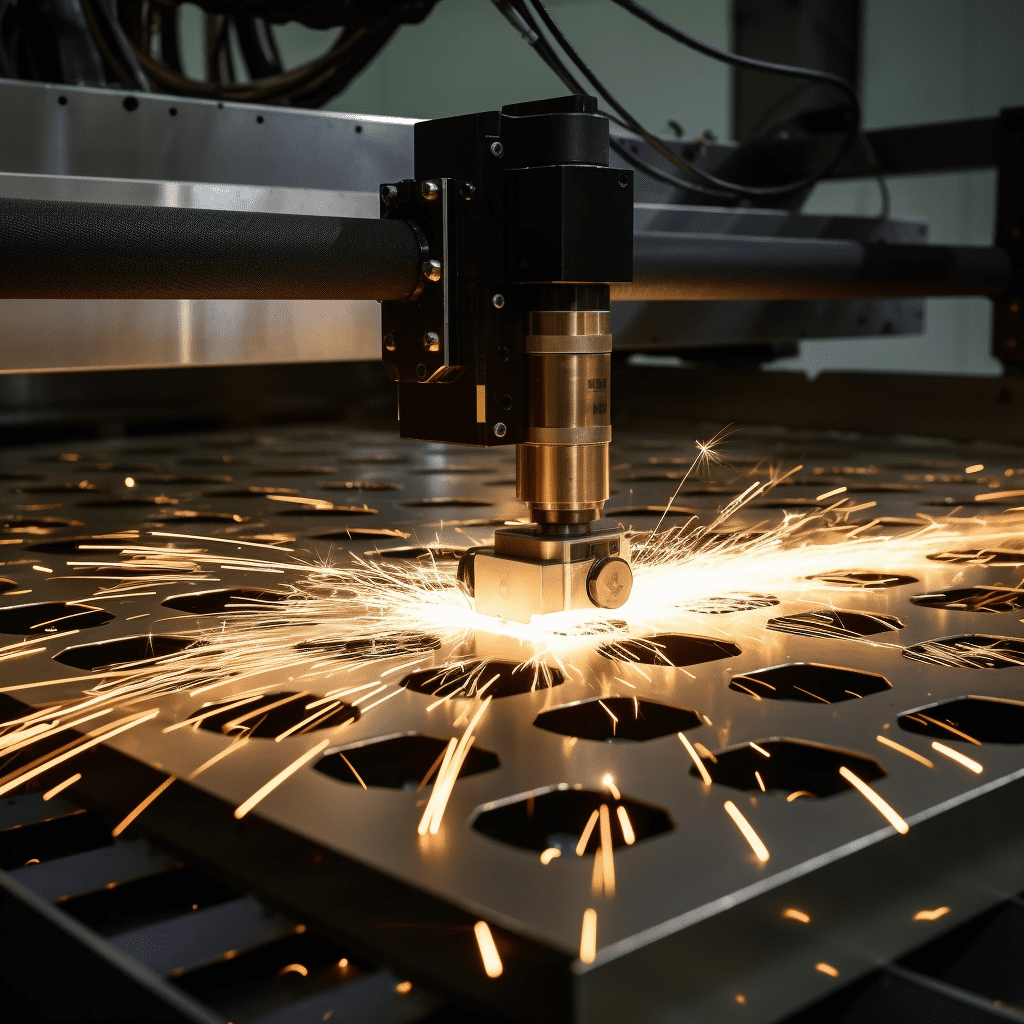

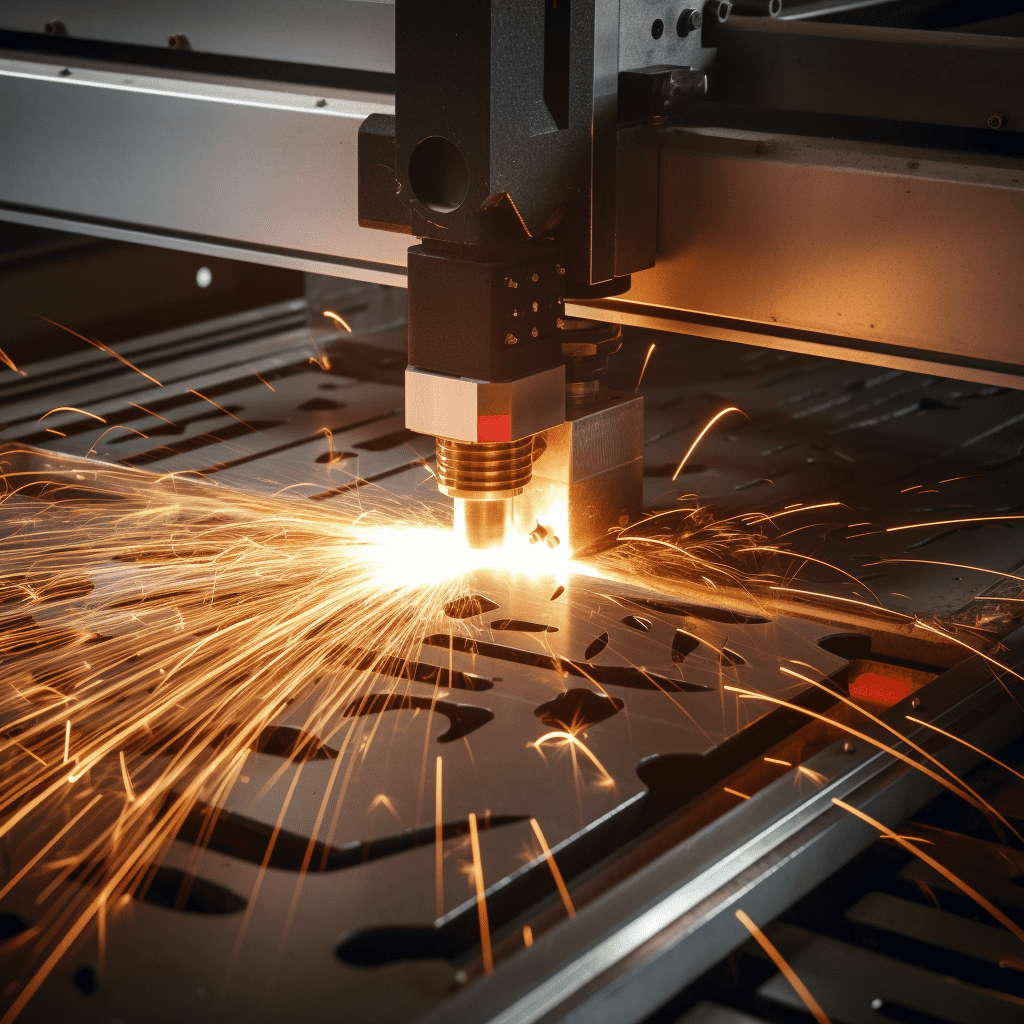

Fiber laser cutting technology uses a high-powered laser beam to cut through materials. It is known for extreme efficiency, precision, and focus when it comes to cutting a wide range of materials. Moreover, this technology has revolutionized the manufacturing industry by offering a superior alternative to traditional cutting methods, such as plasma or waterjet cutting.

Fiber lasers use a flexible fiber optic cable that emits laser light to achieve precise cuts. This allows for greater control and accuracy in the cutting process. As a result, this innovative technology boasts numerous advantages, including faster cutting speeds, minimal heat-affected zones, and reduced material waste.

Factors That Determine Cutting Thickness

Here are some key factors that determine cutting thickness:

- Laser Power: This is one of the most important factors when it comes to determining the cutting thickness. Higher laser power generally enables cutting thicker materials, as the increased energy output allows the laser to penetrate and vaporize the material more effectively.

- Beam Quality: The quality of the laser beam has a direct impact on the cutting thickness. A higher-quality beam, characterized by a smaller focus diameter and consistent power distribution, can cut through thicker materials more efficiently while maintaining precision and minimizing heat-induced distortion.

- Material Type: Different materials have varying properties that can impact cutting thickness. For instance, materials like aluminum or copper alloys, which have higher thermal conductivity, may require more laser power for cutting compared to materials like carbon steel or stainless steel.

- Cutting Process Specifics: The specifics of the cutting process, such as the type of assist gas used, the nozzle distance, and the cutting speed, can also influence the maximum cutting thickness. Optimal settings for these factors vary depending on the material being cut and the desired finish.

Laser Power Cutting Thickness

Here’s a table comparing the cutting thickness capabilities of 2000W and 1000W fiber laser cutting machines. These values are approximate and may vary depending on the machine’s specific configuration and cutting conditions.

| Material | 1000W Cutting Thickness (approx.) | 2000W Cutting Thickness (approx.) |

| Stainless Steel | 3-4 mm | 6-8 mm |

| Carbon Steel/Mild Steel | 6-8 mm | 12-16 mm |

| Aluminum and its Alloys | 2-3 mm | 4-6 mm |

| Copper and its Alloys | 1-2 mm | 3-5 mm |

| Titanium | 1-2 mm | 4-5 mm |

| Nickel Alloys | 2-4 mm | 6-8 mm |

Please note that this table is for reference only, and actual cutting capabilities may vary depending on the specific laser cutting machine model, beam quality, cutting process specifics, and material properties.

The Most Common Materials are Processed and Cut Using Fiber Lasers

Some of the most commonly processed materials include:

- Mild Steel: Similar to carbon steel, mild steel is frequently processed using fiber laser cutting machines due to its extensive use in manufacturing and industrial applications.

- Stainless Steel: Known for its corrosion resistance, stainless steel is often cut using fiber lasers in sectors like food processing, medical, and aerospace industries.

- Galvanized Sheet: With a protective zinc coating, galvanized sheets are often cut using fiber lasers for applications in HVAC, automotive, and construction industries.

- Carbon Steel: Widely used in construction and automotive industries, fiber laser cutting machines provide precise cuts and minimal material waste for this popular material.

- Aluminum: Fiber laser cutting machines process aluminum, a lightweight and highly conductive metal, for various applications in industries such as electronics, automotive, and aviation

Advantages of Fiber Laser Cutting Machines for Heavy-Duty Applications

Looking to take advantage of fiber laser-cutting machines for heavy-duty applications? Here is what you will get:

- High Processing Speed: You can cut through at faster speeds using a fiber laser cutter compared to traditional cutting methods. On top of it, increased processing speeds translate to higher productivity, shorter lead times, and the ability to meet tight deadlines, providing businesses with a competitive edge.

- Lower Production Cost: What business does not like lower production costs? Fiber laser cutting machines bring this to the table as they require less maintenance compared to traditional cutting methods. Moreover, reduced production costs contribute to higher profit margins and enable businesses to offer competitive pricing to their customers, creating a win-win situation for all parties involved.

- Stable Operation and Precise Control: Fiber laser cutting machines deliver consistent, stable operation with precise control over cutting parameters, as a result. With enhanced control, businesses can produce intricate and detailed designs while maintaining consistent quality and minimizing errors or defects.

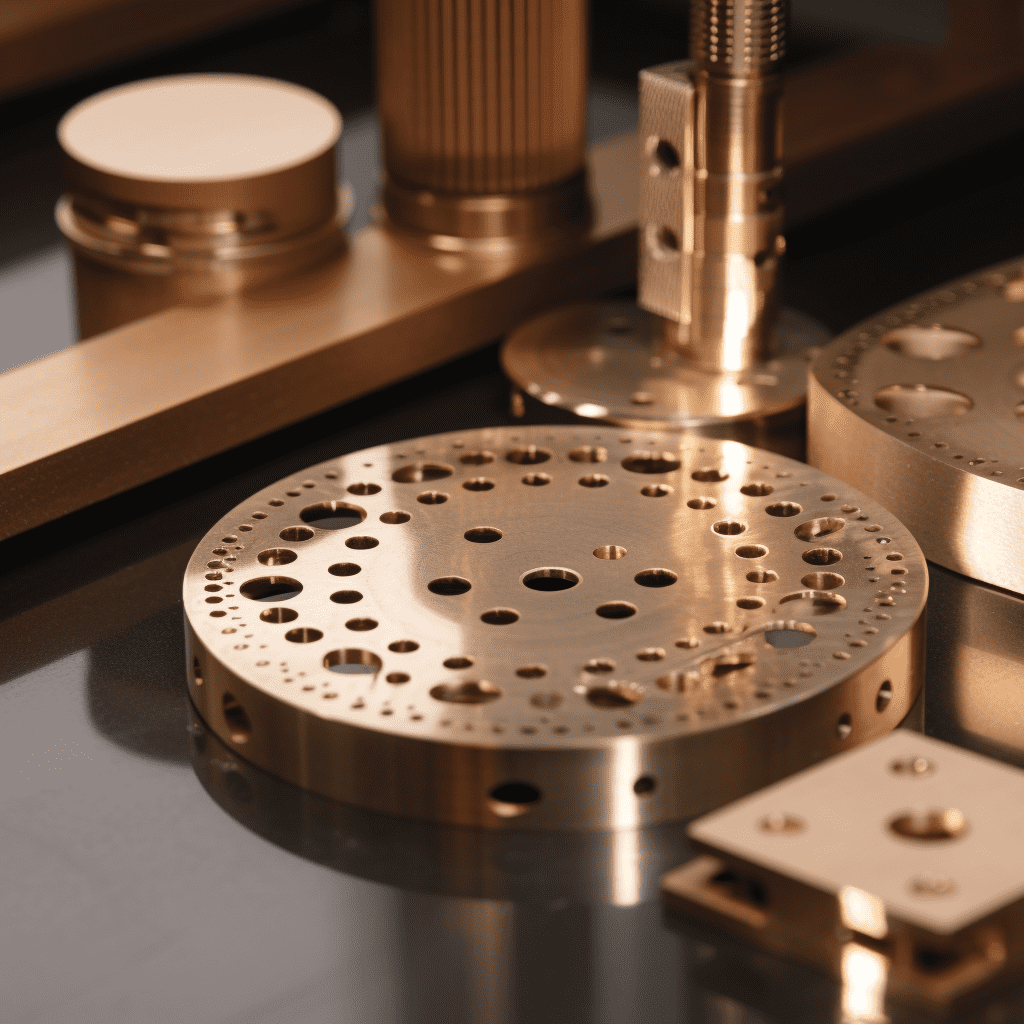

- Precision Cutting: Fiber laser cutting machines offer unmatched precision when cutting complex shapes and intricate patterns. Therefore, this high level of accuracy results in superior finished products, reducing the need for secondary operations and enhancing overall product quality.

- Flexible with Various Materials: Fiber laser cutting machines can process a wide range of materials, from metals like stainless steel and aluminum to non-metallic materials such as plastics and composites. Hence, this flexibility allows businesses to expand their range of products and services, catering to a broader customer base and increasing market opportunities.

Industries that Benefit from Fiber Laser Cutting Technology

Even though a wide range of industries uses this technology, we have only mentioned those which benefit from it the most:

- Construction: Fiber laser cutting technology is highly beneficial in the construction industry, where precision and efficiency are crucial. Fiber lasers enable rapid production and superior quality for various construction applications, from cutting structural steel beams to creating intricate decorative elements.

- Shipbuilding: requires the processing of large, thick metal plates for constructing hulls and other structural components. Fiber laser cutting machines provide the necessary precision and power to handle these heavy-duty tasks while minimizing material waste, ultimately reducing production time and costs.

- Heavy Appliance Industry: Ever seen those refrigerators sitting around? Fiber lasers in fact help cut through several components of home appliances, including air conditioners, washing machines, and fridges. The precision and efficiency of fiber lasers ensure that these components fit together seamlessly, reducing assembly time and improving product quality.

- Aerospace: This is another industry that heavily relies on the use of fiber laser cutting machines. It allows industry experts to cut through complex parts with high precision. On top it, since the industry needs to use durable and lightweight materials such as aluminum alloys and titanium, the machines easily cut through them as well.

- Automotive: Fiber laser cutting technology is widely utilized in the automotive industry for the production of various parts, such as body panels, engine components, and exhaust systems. The technology’s ability to handle a diverse range of materials and provide precise cuts ensures that parts are manufactured efficiently, reducing production costs and enhancing overall vehicle performance.

The Growing Importance Of Fiber Laser Cutting Machines In Heavy-Duty Applications

1. Advanced Manufacturing Techniques

Adopting advanced techniques, such as Industry 4.0 and automation, is driving the demand for fiber laser cutting machines that integrate seamlessly with these rapidly evolving systems.

2. Environmental Sustainability

With a focus on reducing environmental impact, fiber laser cutting machines offer an eco-friendly alternative to traditional cutting methods, contributing to greener manufacturing processes.

3. Customization and Complex Designs

The increasing importance of customization and intricate designs across various industries has led to a higher demand for cutting solutions that can handle complex geometries, which fiber laser cutting machines excel at.

4. Versatility Across Industries

Fiber laser cutting machines are becoming increasingly important due to their versatility in handling a wide range of materials and applications across various industries, allowing businesses to expand their product offerings and explore new market opportunities.

Conclusion

In conclusion, fiber laser cutting machines have become an essential tool for heavy-duty applications across numerous industries, offering unmatched efficiency, precision, and versatility. As industries continue to evolve and adopt advanced manufacturing techniques, fiber laser cutting technology will play an increasingly vital role in driving productivity and maintaining competitiveness.

Discover the Future of Manufacturing with Baison’s Cutting-Edge Fiber Laser Solutions

Experience unparalleled efficiency, precision, and versatility by harnessing Baison‘s advanced fiber laser cutting machines. Our commitment to excellence and continuous innovation ensures that you’ll stay ahead in the competitive manufacturing landscape. Reach out to our team of experts today, and let us help you unlock your business’s full potential.