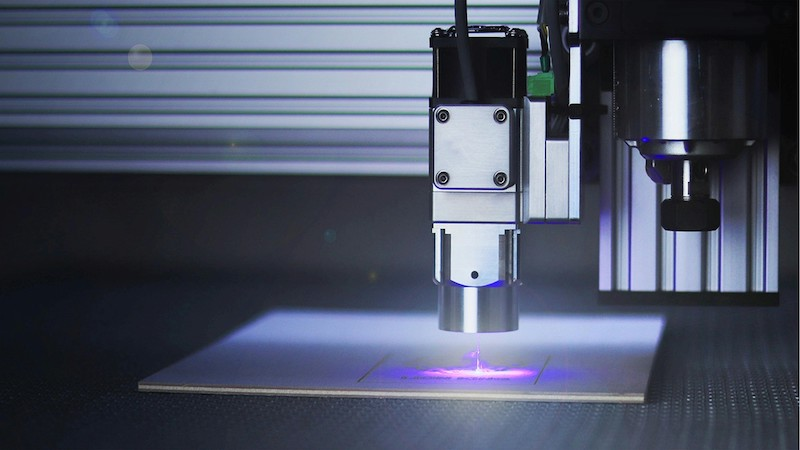

Even though in the vast area of laser cutting, the focusing lens is a seemingly small component, it plays a vital role in directing the laser beam and ensuring its energy is concentrated on the cutting area. Selecting the right focusing lens can significantly impact the quality, efficiency, and even cost-effectiveness of your laser-cutting projects.

This article delves into the intricacies of choosing the ideal focusing lens for your specific needs. We’ll explore the key factors to consider, including material type, key functions, and different focal lengths. By the end of this guide, you’ll have all the necessary knowledge to set up a focusing lens and also how to maintain it properly.

What Does a Focusing Lens Do?

The laser beam fires in an unfocused state as it leaves the laser tube. The laser tube’s beam must be focussed to the right degree. The beam must interact with the material correctly. Without a laser focus lens, the laser beam can still leave markings on your materials; but it will look like an uneven burn mark. A convex lens must focus the laser tube’s beam to a spot at a predetermined distance.

The distance at which the laser beam interacts with the material will depend on the focal point of these lenses, which ranges from 1.5 to 5 inches. Smaller details can be engraved with a shorter focal length, but cutting depth will not be possible with shorter focal lengths. On the other hand, finer details cannot be engraved with longer focal lengths, but focal lengths will be increased easily.

Key Functions of a Focusing Laser Lens

A focusing laser lens plays an important role in laser cutting. Besides cutting thick and thin materials and laser engraving, a focusing lens can also be used to achieve accurate, clean, and efficient cutting results. Some of the key functions of a focusing lens are given below.

1. Focusing Laser Bea

In laser cutting, maintaining a focus position is very important because it prevents the repeatability of the cutting parameters. It also helps to maintain a consistent quality of the material edge.

2. Focusing on Exothermic Reactions

The intense energy of a laser beam is prone to vaporization when an exothermic reaction takes place. A low or high-pressure point and volume are used depending on the position of the focus point.

3. Focusing on Endothermic Reactions

During an endometrial reaction, a proper cut channel needs to be made with the help of the raw energy of the focused laser beam. Besides, this reaction needs a high degree of pressure and volume so that it can support the rapid evacuation of the materials that have been melted.

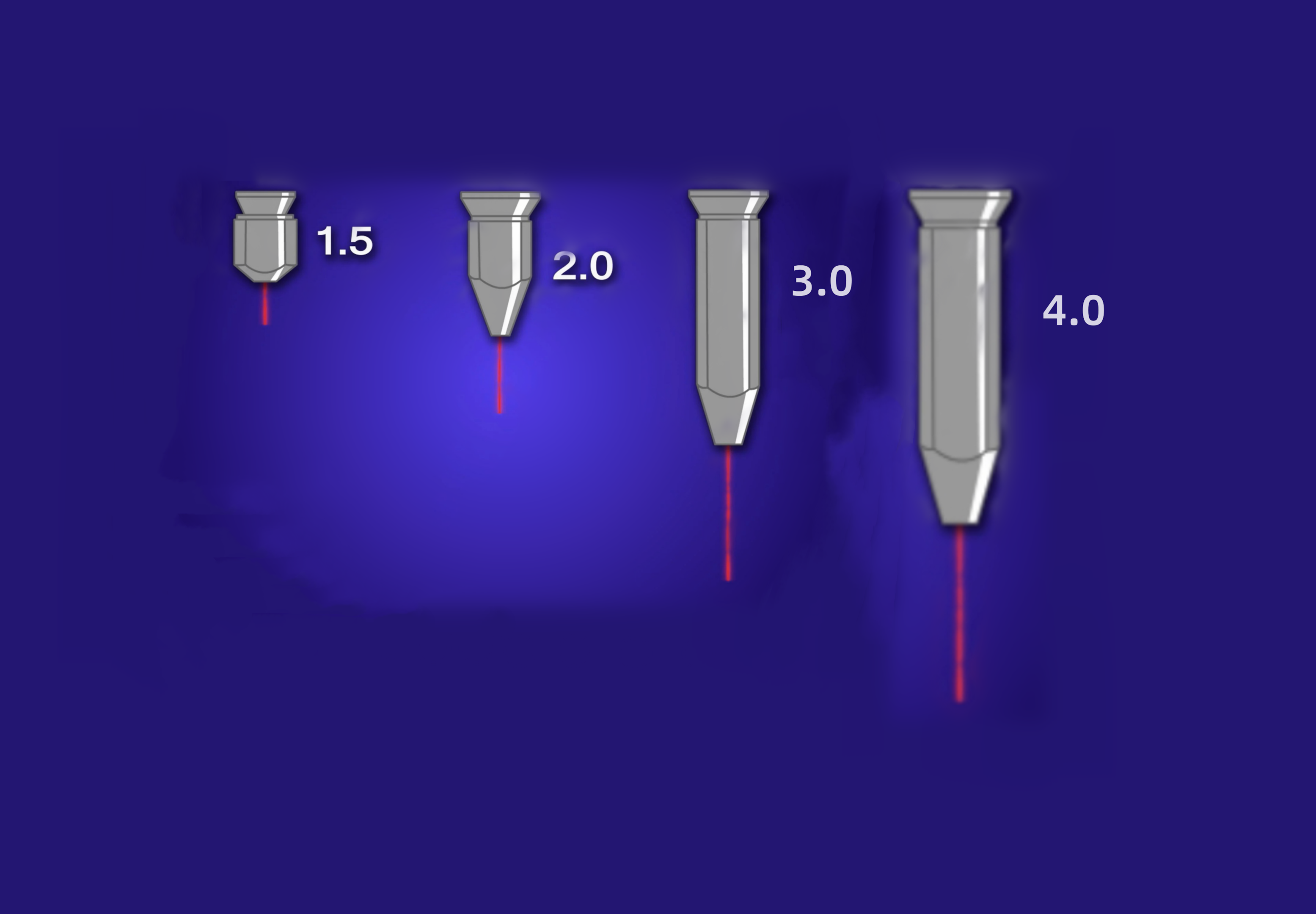

Different Focal Lengths of Laser-Focusing Lenses

There are different types of focal length sizes available for laser-focusing lenses. Some of the most common focal lengths are the sizes of 1.5’’, 2’’, 2.5’’, and 4’’. These sizes are suitable for both laser engraving and cutting. These focal length sizes of a laser-focusing lens are discussed below in brief.

1.5-Inch Focal Length Lens

- It comes with the highest possible resolution.

- One of the major drawbacks is it can easily fall out of focus.

- Works best in a laser engraving machine for small details and cutting thin materials.

- It has the highest power density.

- Works on delicate small materials, like plastics.

2.0-Inch Focal Length Lens

- Widely used for laser engraving.

- This lens is used for cutting thick materials.

- Offers a good balance between the depth of etching and the focus sharpness.

3.0-Inch Focal Length Lens

- Popularly used for cutting thicker materials, like acrylic, timber, and many more.

- It comes with high-grade components, accuracy, and precise cuts.

- This type of lens is also known for its reliable results.

- Offers an optimal focal length for a wide range of cutting.

4.0-Inch Focal Length Lens

- Used to cut the largest depths.

- Usually requires high power to measure focal distance.

- Comes with a large spot size.

- Can be used for engraving materials with curvature.

- Popularly used for cutting thick materials.

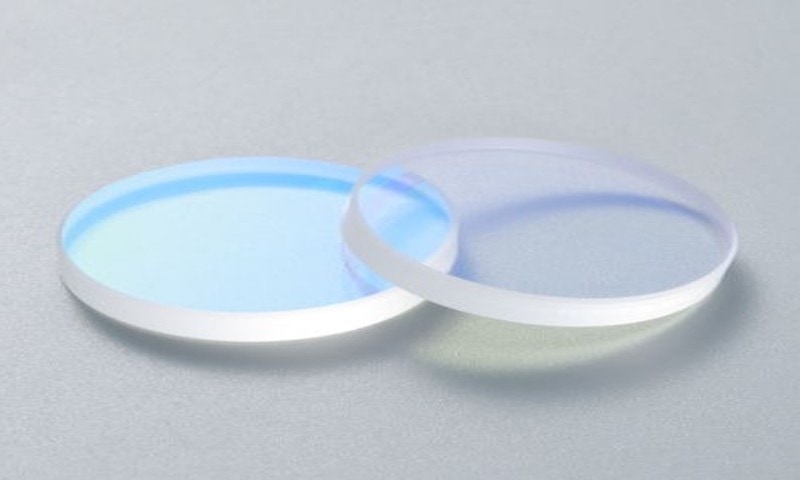

Common Types of Laser-Focusing Lenses

Some common types of laser-focusing lenses are given below.

1. Spherical Lens

A spherical lens has two spherical surfaces with equal curvature. It is the most common type of CO2 laser focusing lens. It has a curved surface, which can be either convex or concave. A convex lens converges light rays to a focal point, while a concave lens diverges them.

Function: Focuses a laser beam into a small spot and provides a good balance of cost and performance.

2. Aspherical Lens

It comes with a non-spherical surface resulting in a smaller spot size and higher efficiency. These lenses have a non-spherical surface. Aspherical Lens helps correct aberrations and achieve precise focusing of laser light.

Function: Improves cut quality, and reduces heat-affected zone.

You can also learn the difference between Spherical Lens and Aspherical Lens in this article.

3. Cylindrical Lens

It has two cylindrical surfaces and is widely used to focus a laser beam into a line. Instead of being curved in both dimensions, cylindrical lenses are curved in one direction either concave or convex. These lenses are used in altering the shape of laser beams, like turning circular beams into lines.

Function: Enables cutting long, narrow features and is used in applications such as slitting and scribing.

4. Powell Lens

It comes with a cylindrical lens that is designed to create a straight laser line with uniform intensity. It is a specialized cylindrical lens designed to transform a laser beam into a uniform line beam.

Function: Known for improving the accuracy and consistency of the cutting processes.

5. Axicon Lens

It has a conical surface and is used to focus a laser beam into a ring. Axicon lenses are valuable in applications requiring ring-shaped laser beams for specific interactions with materials. Their unique ability to produce these ring-shaped beams has made them important tools in various scientific and industrial settings where precise control of laser beams is necessary.

Function: Creates holes with smooth edges and minimal heat-affected zone.

Considerations for Choosing Laser Focusing Lens

The choice of your laser focusing lens mainly depends on your needs and requirements. The selection of the appropriate lens varies from person to person. However, there are some major factors that play an important role in the selection process.

1. Graphic Design Complexity

You need to be careful while choosing a laser focusing lens because there are specific focusing lenses with special features made based on the complexity of the Graphic Design.

Simple Designs

For a simple design with minimal detailing, you can choose spherical lenses or standard Plano Convex Lenses.

Complex Designs

For a complex design, it would be a wise decision if you get Aspheric lenses. These lenses are supposed to have a good focal tolerance and are more suitable for intricate designs.

2. Laser Equipment and Lens Properties

You need to consider laser wavelength, focal length, and beam diameter while buying a laser-focusing lens. You also need to carefully consider coating, laser beam wattage, surface quality, and Numerical aperture (NA).

For example, a high-quality surface will offer reduced aberrations which will ensure a precise and correct focus point. On the other hand, anti-reflective coated lenses will reduce unwanted reflections and will improve the transmission.

3. Lens Material

Different materials have different levels of transmission and absorption at different laser wavelengths. Choosing a focus lens material with high transmission at your operating wavelength ensures maximum energy delivery to the target area. For example, fused silica is excellent for CO2 lasers due to its high transmission.

4. Lens Applications

By carefully considering lens applications and their specific requirements, you can choose a laser focusing lens that optimizes beam distribution, and energy density. This ensures efficient, safe, and high-quality results.

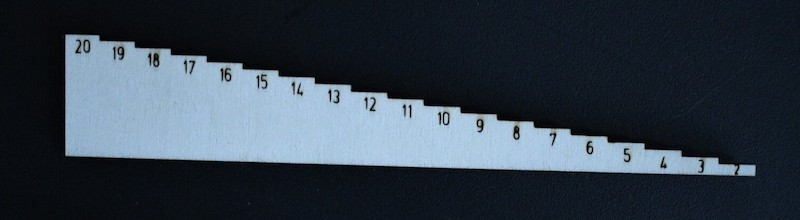

How to Set up the Laser Focus Lens?

Before you start setting up the laser focus lens, you need to understand a few important things. The first thing you need to know is that the real laser system does not focus on an exact point. Rather the system produces more of an extremely tight hourglass-shaped waist.

Theoretically, a lens with a shorter focal distance can not be able to cut too deeply and will always have a short length. On the other hand, a lens with a longer focal distance comes with a longer length and high power density.

Tools Needed for the Setup

The necessary tools needed for the setting up of the focus lens include a focus lens, lens holder, focus gauge, and some adjustment tools.

- The focus lens is the main tool that helps the laser beam to concentrate on the material so that it can be cut.

- The lens holder has the function to hold the focus lens in place.

- The tool that helps to measure the distance between the focus lens and the material is known as the focus gauge.

- Lastly, some additional adjustment tools include screwdrivers and wenches.

The Setting Process

The setting of a laser focus lens and laser light is a very easy and flexible technique. This method of setting a laser focus lens is particularly useful When you are working with different materials.

- Firstly, the operator will need to hang the focus tool on the end of the laser head. The lens holder is needed to be placed in the laser cutter. This process is known as Mounting the Focus lens. The operator is recommended to use the manual for guidance while placing the lens holder.

- After that, it is time to install the focus lens into the lens holder. The lens needs to be tightened securely in place.

- The next step involves setting the focus height. The operator needs to position the focus gauge over the lens and lower the laser head until the focus beam is centered. The focal point should be centered on the crosshairs of the gauge.

- The working table needs to be moved manually until the working surface touches the focus tool.

- The height of the laser head also needs required adjustments. The ideal distance between the focal point and the material depends on several factors, such as the type of laser being used, the thickness of the material, and many more.

- At this point, the focus point is set. The operator may need to review the manual that comes with the laser cutter for recommendations related to the height of the focal point.

The operator needs to check the focus by simply cutting a small piece of material with the intention of testing. After the laser cutting, the cut edge is needed to be examined thoroughly to check if the edges are clean and free from all kinds of burrs or rough edges.

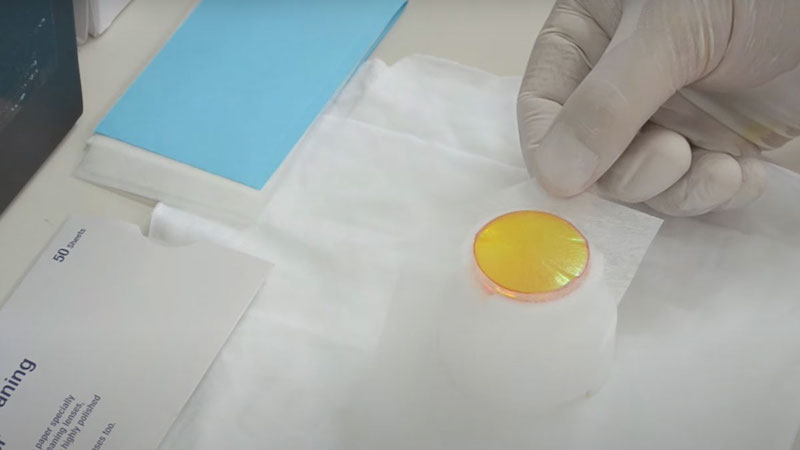

Cleaning and Maintenance of Focusing Lenses

For the best performance and image quality, it’s essential to regularly maintain and clean focusing lenses. Since these lenses are delicate and costly, proper care is crucial to extend their lifespan. The following are key tips for their upkeep.

- The material of the focusing lenses is made of a brittle and fragile element. So, it is recommended to pay extra attention when handling the lenses, especially when disassembling or assembling them.

- The surface of the focusing lenses is very sensitive to some pollutants and moisture. Besides, scratches and oiliness can cause some serious damage to the lens.

- While cleaning, it is advised only to use the recommended equipment for lens cleaning.

- Proper air pressure must be ensured while dealing with the equipment. You need to check the air nozzle of the focusing mirror to ensure the perfect air pressure before you start working.

- You need to check the focusing lens and laser head every once in a while to make sure it is free from all kinds of pollutants and dust particles. You will need to clean the lenses immediately if you find any abnormalities.

- For proper cleaning, you will need to use a blower. The blower will help to remove the dust particles from the lens surface. Besides, you can also use paper soft cotton balls only the laboratory grade is acceptable.

- You need to clean both sides of the lens in a clockwise direction.

- You are recommended to use acetone or any sort of high-purity alcohol for cleaning purposes.

- You will need to replace the focusing lens if you find that the lenses are too polluted to get cleaned and damaged by any chance.

- You need to follow certain criteria when installing a new laser lens. For example, don’t press the laser lens too hard while installing it into the device otherwise it will crack and cause serious damage to the equipment.

FAQs

1. What is the difference between a focusing lens and a collimating lens?

A focusing lens superimposes the laser beam to a small, focused spot for cutting, while a collimating lens straightens a diverging laser beam to make it parallel. Both can be used in laser cutting but the functions differ from each other. For specific information, click here.

2. How does laser power influence the selection of a focusing lens?

Laser power has an impact on the choice of lenses. High-power lasers require lenses with higher damage thresholds to withstand the intense energy. Additionally, the focal length might need to be adjusted for different laser power levels.

3. Does the material type affect the choice of focusing lens?

Different materials absorb and reflect laser light differently. For that reason, the chosen lens material should be compatible with the material being cut to ensure optimal performance and prevent damage to the lens.

Conclusion

A successful laser cutting project relies heavily on various machine components, particularly the focusing lens. The right lens choice is crucial for high-quality cuts, making it a valuable investment for precise and efficient work. Understanding important factors, considering various options, and maintaining the lens well is key to selecting the best lens for your laser cutter.

Improve Your Laser Cutting Projects with Baison Laser!

Are you looking to improve the quality of your laser-cutting projects? A focusing lens and good craftsmanship are both needed for that, as well as great quality machines. At Baison Laser, we provide answers to any of your laser cutting industry-related questions and find solutions to help make your business a success. Contact Baison Laser today for any inquiry you have.