In this blog post, we’ll guide you in choosing a suitable bending machine. You’ll also explore the key factors when selecting a bending machine. So, let’s get into it.

Understanding Types of Bending Machines

Various bending machines are available today to assist you in bending various workpieces. Here are some commonly used types of bending machines:

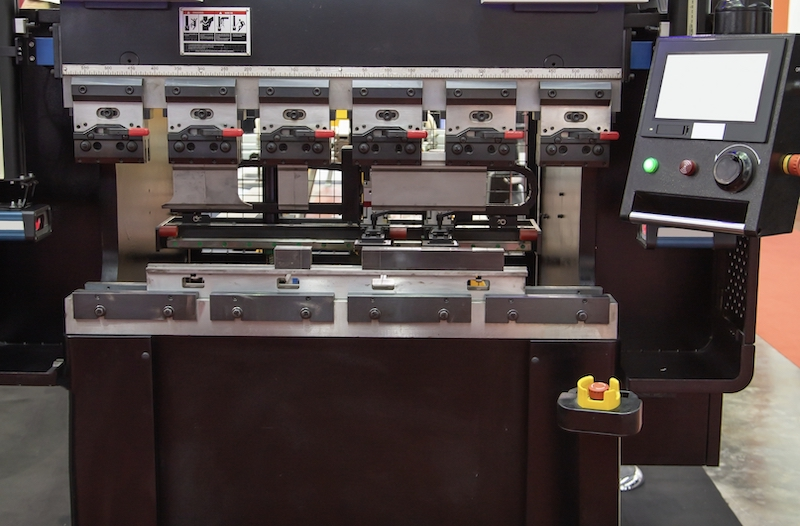

1. Press Brake Bending Machine

According to Wikipedia, a press brake bends metal sheets and plates. It includes a hydraulic or mechanical press to apply sufficient force to bend metals. Its rear gauge has three shafts that give better control over the bending process. You can control the speed and stroke of the machine, making it efficient equipment for metal bending.

This bending machine is convenient to operate. Its easy operation makes it the most suitable bending machine for handling large metal bending projects.

2. Metal Pipe Bending Machine

This bending machine employs friction to bend metal pipes into different shapes. It utilizes hydraulic machines, servo motors, or pneumatic operations as a power source to operate the machine. According to LinkedIn, different metal bending machines enable you to work with various metals, like stainless steel, steel, carbon, titanium, iron, copper, and aluminum.

It works by clamping the pipe so it remains stationary. The machine rotates to bend the pipe in the desired direction. Some machines also have a mandrel to prevent collapsing or wrinkling of pipe during bending. Metal pipe bending machines are used in several industries, including construction sites for plumbing or HVAC systems.

3. Plate Rolling Machine

It is pyramid-shaped equipment that bends metal plates into a round or conical shape to create various shapes.

It employs plate rollers to bend the metal workpieces, which electric motors or CNC controllers control. A plate rolling machine can roll copper, aluminum, zinc, stainless steel, and other metal sheets, making it suitable for heavy-duty metal fabrication.

4. Sheet Bending Machine

The sheet bending machine enables you to bend and shape metal sheets, plates, and panels. The sheet is placed on a lower die, and a slider bends it to the required angle. Many sheet-bending machines can also bend pipes. Some machines are customizable, and you can conveniently create complex shapes using them.

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Key Factors to Consider When Choosing a Bending Machine

Before choosing a bending machine, you should understand the factors that impact its performance. Here are some prominent factors you should consider when choosing a bending machine:

1. Bending Capacity

Bending capacity is a crucial factor that determines whether your machine model is compatible with handling your workpiece size. You can easily fit any workpiece smaller than the maximum capacity of your machine.

However, don’t choose a bending machine with a bending capacity that is too large, as it requires extensive tooling and more energy consumption. It can also reduce productivity, increasing production costs.

2. Material

Each bending machine can handle various types of material. Stainless steel is hard to bend and needs a high-powered metal bending machine. However, you don’t need excess bending force when dealing with ductile metals like aluminum.

Check the manufacturer’s recommendation before picking a bending machine. It will enable you to pick the machine that best fits your material’s strength.

3. Number of Tool Stacks

The number of tool stacks indicates the capacity of a bending machine to install bending dies. Installing multiple dies allows you to handle multiple radii in a single setup. Bending metal pipes in a tube bending machine with a large number of tool stacks allows you to minimize material handling. It also offers you higher design freedom, enabling you to create various designs at once.

4. Bend Quality

Bend quality is another prominent factor that impacts the choice of a bending machine. It determines your machine’s capability to create precise bend angles and lengths of straight portions. The machine assembly and quality of its various components also impact the bend quality it produces.

5. Control System Stability

The stability of a control system involves several aspects, including hardware configuration, functionality, and reliability. It impacts the efficiency of a bending machine. The reliability of controllers is a critical factor in picking the right machine. You also need to focus on the durability of various components to ensure smooth operation.

6. Wall Thickness

Wall thickness is a crucial factor in choosing the right tube-bending machine. It determines the bending force required to bend a pipe or tube to a particular angle. The thickness of the material is also crucial when dealing with metal sheets and plates. Thicker materials required more force. You need to select a highly efficient bending machine to bend thick materials.

7. Power Source

Various bending machines employ different power sources. They use hydraulic, pneumatic, or electric power. Hydraulic bending machines are best for bending tasks that require excessive power. Meanwhile, pneumatic or electric machines are known for their efficient energy consumption and smooth operations.

If you are dealing with workpieces that demand high-powered machines, you should go with hydraulic-powered bending machines. However, if you are looking for an energy-efficient solution, pneumatic or electric machines will be better for you.

8. Maintenance

Maintenance of a bending machine is a time-consuming and costly pursuit. However, without regular maintenance, your expensive machine will be ruined.

Some companies offer you durable machines with exceptional features that require less maintenance. Investing in such machines allows you to be carefree and concentrate on the bending process.

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

How to Choose a Bending Machine Supplier?

Choosing the right supplier is as crucial as picking the right bending machine. A reliable bending machine supplier ensures the success and efficiency of your manufacturing processes. A reputable supplier helps you enhance your production while maintaining high quality. They also enable you to stay ahead of competitors in a competitive market.

Here are some considerations that can guide you in choosing the right bending machine supplier:

1. Search Bending Machine Suppliers

To choose the right supplier for purchasing a bending machine, search the market and find who offers it. Knowing the available options will help you choose the best one.

2. Compare The Cost and Quality

When you have various options, you can easily compare the purchasing costs of bending machines from different suppliers. Comparing the initial investment is crucial to understanding the market rates. However, don’t go with low cost, as it might lead to poor quality.

3. Learn About Customer Support

A responsive and knowledgeable support team can minimize downtime and troubleshoot issues. They also provide the necessary training to operate the machine.

4. Check Supplier Reputation

The reputation of a supplier is another notable factor. You can learn about the reputation of the supplier on the Internet. Customers leave reviews about suppliers on their websites that can help you learn about their services.

5. Warranty

Some suppliers offer a warranty to ensure the durability of their machines. It gives you peace of mind and is a testament to the supplier’s confidence in the quality of their bending machines. However, pay attention to the duration and coverage of the warranty.

How to Evaluate and Compare Bending Machines?

The choice of a suitable bending machine is imperative for effective metal fabrication. However, comparing various bending machines is also necessary. The following aspects will help you compare various options and choose the best equipment:

- Focus on the machine’s specifications. Various parameters, like bending capacity, material compatibility, and material thickness, significantly impact your productivity. Choose a machine that offers high bending capacity and is compatible with a wide range of materials.

- Pay attention to the quality of results. Choose a machine that offers accurate bending angles.

- Various models of bending machines are available. Choose the latest models that offer you automation features.

- Conduct practical tests on various machines. It allows you to assess the ease of setup, programming, and operation.

Ready to Get Your Own Bending Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. What are the different types of bending machines?

Various bending machines are available today. Commonly used machines include press brake, metal pipe, plate rolling, and sheet bending machines.

2. What are the four types of PVC bending?

The PVC bending process includes mandrel tube, compression, rotary draw, and roll bending,

3. What are the three types of bending?

Metal fabrication uses three types of bending. It includes air bending, coining, and bottom bending.

Conclusion

A bending machine is an imperative component for creative, unique products with metal. Various industries are employing this technology. Choosing the right bending machine enables you to streamline your operations and get the required bends and shapes. Take time to search for reputable suppliers to get the best product at the best rate. So, choose the right bending machine and create perfect shapes with metal.

Unleash the Potential of a Bending Machine with Baison Laser!

Choosing a reliable bending machine is a daunting task. Baison Laser offers you high-end bending machines at the best rates. Baison Laser is a reliable bending machine supplier. In addition to these machines, it offers several laser solutions, including laser cutters, welders, and cleansers.

Contact us today to learn about the features of our machines and get one for your project.