With huge growth in North America, Asia, and the rest of the world, the sheet metal industry benefits many businesses and fuels their revenue streams. A few common industries industrial sheet metal is used are storage, military, plumbing, electrical, pharmaceutical, food, and more. While all use sheet metal, they often use different lengths and thicknesses, requiring different ways to cut sheet metal than other industries.

If you work in an industry that must comply with specific guidelines when cutting metal, you must know the right power tools that suit your operations. Having the right metal-cutting tools can save significant time on your production line, reduce the risk of accidents, streamline your production process, and much more.

What are the different tools for cutting sheet metal?

Various metal-cutting tools can upgrade your processes if you want to use or use sheet metal for your business. They are:

Hand Tools

- Hacksaw

One of the most original tools for sheet metal is the hack saw. You or your employees can use this by hand for cutting sheet metal and other materials (if you wish). The saw comprises a metal handle with a wooden or plastic grip. It has a metal cutting blade in the saw, which is replaceable.

Due to it being manual and portable, this cutting metal tool is often seen as the cheapest and more affordable than others. For this reason, many people use it for small projects at home, as hobbyists, or in shops that only use small sheet metal. If you want to make clean cuts on sheet metal, you should aim to choose a wavy tooth-type blade.

Advantages

- Inexpensive and versatile to use.

- Incredibly helpful for making clean and straight cuts.

- You can easily replace the blades

Disadvantages

- Limited to other cutting types, only good for making straight cuts.

- A lot of elbow grease, energy, and time is required.

- If cutting more than one metal object, there can be a lack of consistent cuts with a hacksaw.

- Tin Snips

Another hand-held sheet metal cutting tool is tin snips. These tools work like scissors and are appropriate for achieving straight cuts; however, they can cut circles and curves. They provide great use for cutting softer metals such as copper and aluminum, proving great use for studs, gutters, and metal roofs. Tin snips are ideal for cutting soft metals like aluminum and copper.

Advantages

- Inexpensive hand tools

- Can cut metal stock thats’ soft, like tin, aluminum, or copper.

- Good for making cuts in tight places.

Disadvantages

- Cannot cut through the heavier and thicker stock

- Leaves unfinished and rough cuts

- Most materials need to be cleaned and filed after using snips

- Only serve practical value for hobbyists

- Chisel and Hammer

A chisel and hammer are one of the simplest and most inexpensive ways of cutting thin sheet metal. This method requires a lot of time and is best suited for small projects at home instead of industrial-level operations.

Advantages

- Inexpensive and portable

Disadvantages

- A lot of patience is required to achieve accurate cuts.

- Slow process and labor intensive.

- Only good for small projects.

Bench Tools

If you want to cut industrial sheet metal on a work surface, then bench metals may be convenient.

- Beverly Shear

The Beverly shear is often called a throat less sheer because it can cut cleanly through different types of metal stock. These tools are usually made from cast metal and have a sharp cutting blade on their handle, similar to a guillotine. They work best when they’re mounted to a floor or workbench. As these blades are subject to a smaller cutting surface and have no throat, you can easily navigate them by making curved and straight cuts.

Advantages

- Cuts through different types of sheet metals

- Easier to navigate than other hand-held cutting tools

- Can guide through tight turns and helps with detailed cutting work

Disadvantages

- Only can be used for sheet metal and not other materials

- Quite expensive for a hand tool

- The tool is not portable and quite heavy to use

Power Tools To Cut Sheet Metal

If your project is bigger, you’ll want to use power tools. They’re less old-fashioned and quicker to make cuts. Here are some of the top metal-cutting power tools:

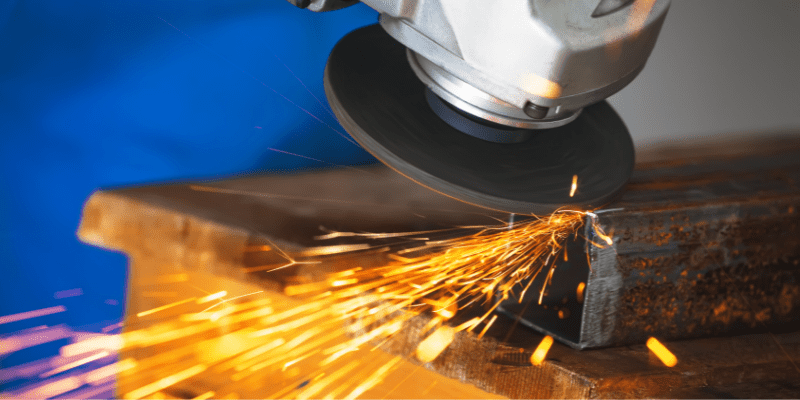

- Angle Grinder

Angle grinders are versatile tools for cutting and grinding metal used in many shops. They’re compact and have a cutting wheel that can be exchanged for different accessories and discs. An angle grinder can be used for many metals, such as bar stock, tubes, sheets, and hardware. In particular, they’re great for cutting through thin stock without no pushback. These power tools work best on rough cuts and help remove cutting welds and seized hardware.

Advantages

- It can cut through different types of metals.

- It can operate in tight spaces due to its compact size

- Compatible with different cutting surfaces and blades

Disadvantages

- The saw blade is prone to overheating during the cutting process. It can easily burn or finish the metal you’re using.

- The cutting wheels can break easily if not used properly.

- Not great for detailed cuts work

- Nibbler

The nibbler is a power tool mainly used by professionals and can help achieve deep cuts using thin gauge steel. They operate similarly to portable micro sheers; they’re pistol shaped, and you hold them by hand and follow a blade along a required path to make small cuts.

If you use a nibbler a lot, it can produce curly metal fillings, which can easily cause cuts if you have exposed skin. Therefore, you must wear safety gear and clean up the filings immediately after use.

Advantages

- Handheld and portable tools

- Compact and can navigate tight turns

- Creates deep cuts in thin steel

Disadvantages

- Make a lot of noise and produces lots of vibrations when using

- Require a strong hand to operate the cutting blades

- It can leave rough edges which need to be cleaned before using

- Circular Saw

A circular saw can help you cut sheet metal frequently with little resistance. They’re particularly beneficial for cutting bar stock and tubes. You can easily pair a cutting saw with specialized blades to cut metal.

Advantages

- You can easily find these power tools

- Produces a clean cut

Disadvantages

- They can’t cut through every type of metal

- Blades can easily break on a circular saw

- Reciprocating Saw

Out of the different power tools, a reciprocating saw is one of the most powerful and aggressive tools for metal cutting. A reciprocating saw is commonly used to cut through thin timber and remove old nails and is regularly used for metals in demolition projects. Typically reciprocating saws achieve a rough cut; they’re not very precise for cutting metals.

Advantages

- Reciprocating saws can cut through many materials

- Can easily attach different blades to them

- Highly powerful and fast

Disadvantages

- Provide rough and imprecise cuts

- Its long blade can easily damage wires and pipes

- Oxy Acetylene Torch

An Oxy Acetylene torch is a powerful tool that can cut many different types of metal irrespective of their thickness. It had compressed oxygen tanks that also stored acetylene which fuels the torches. These tools are great for cutting heavy stock metals like beams, steel bars, and stock materials.

Advantages

- It can be used to help with welding

- This tool can cut through heavy materials

Disadvantages

- Not practical for thin materials

- They take up a lot of space

What are the best tools for cutting industrial sheet metal?

While hand tools, power tools, and bench tools can surely help cut metal, the best tools for industrial-scale operations are the following:

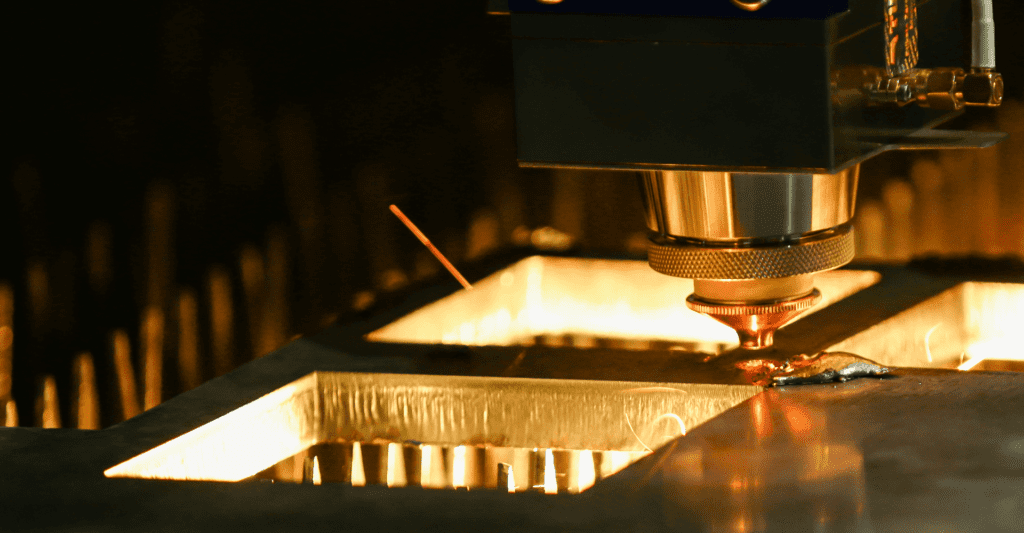

Laser cutting

One of the fastest and most precise methods for cutting industrial sheet metal is with a high-power laser. Different lasers help navigate a cutting head across sheets at high speed with great accuracy. A computer controls these machines, can automate your production, and create custom shapes according to your liking.

Advantages

- Safer to use

- Require less staffing

- Short set-up time

- Creates clean and safe edges

- Plasma cutting

Disadvantages

- Expensive to own

- A lot of power is required to operate

- It needs a skilled operator

Waterjet

These machines use a small amount of water combined with abrasives applying high pressure at high speed into the metal. The water jets help cut metal up to a few inches thick, creating a finished edge. A waterjet uses no chemicals or electrical heat to cut through many types of metals, alloys, and plastic and achieve the same accuracy and finish.

Advantages

- Versatile can cut different types of metals

- Good for cutting thicker stock

- Uses cold cutting methods, making it safer for the operator

Disadvantages

- It can take longer to cut than a traditional laser cutter

- Expensive to use

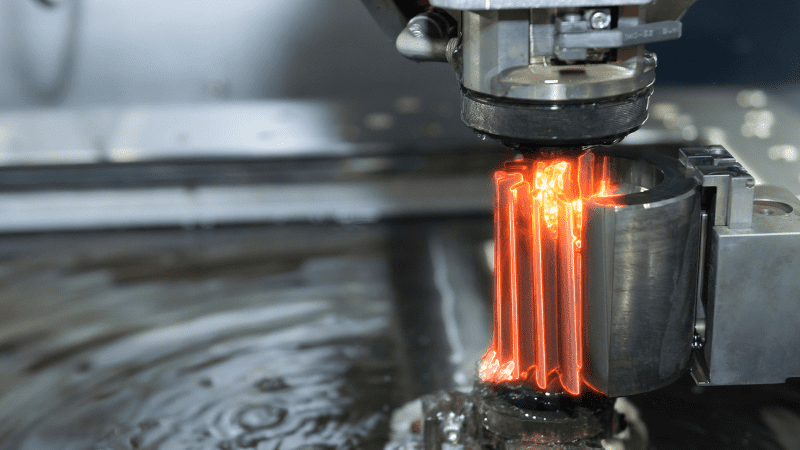

EDM Cutting

EDM cutting uses an electrical discharge for cutting metal. It primarily relies on thermal energy to cut through metal instead of a mechanical machine. To cut through, the machine produces controlled sparks between 8000º C to 12000º C.

Advantages

- Precise to use

- High-quality surface finish

Disadvantages

- High carbon footprint

- Not ideal for large-scale projects

- The materials the machine can cut into must be electrically conductive

Conclusion

There are many different ways to cut metal, especially sheet metal. When buying tools for metal cutting, there is a range of handheld, power tools, work benches, and more.

However, you can’t go wrong with a laser cutter if you’re operating at large volumes and want to cut metal stock with high accuracy, quick timeframes, and fewer mistakes. They help streamline your operations, save you less manpower, and are safer to operate than an angle grinder, power tool, chop saw, hacksaw, and more.

To help decide the right industrial sheet metal cutting tool for your business, you should consider the cut line, desired radius, workplace space, the material’s thickness, and the safety risks involved. If you need support picking the best tool for your business, we can help you. Contact us today, and one of our team will get in touch.