Top 10 Applications for Industrial Laser Tube Cutting Machines

Are you looking for a way to improve cutting precision and speed in your operations? Industrial laser tube cutting machines might be the best business decision you make this quarter. They offer unmatched precision for cutting complex shapes used across industries.

Let’s uncover how laser-cutting machines are transforming modern manufacturing.

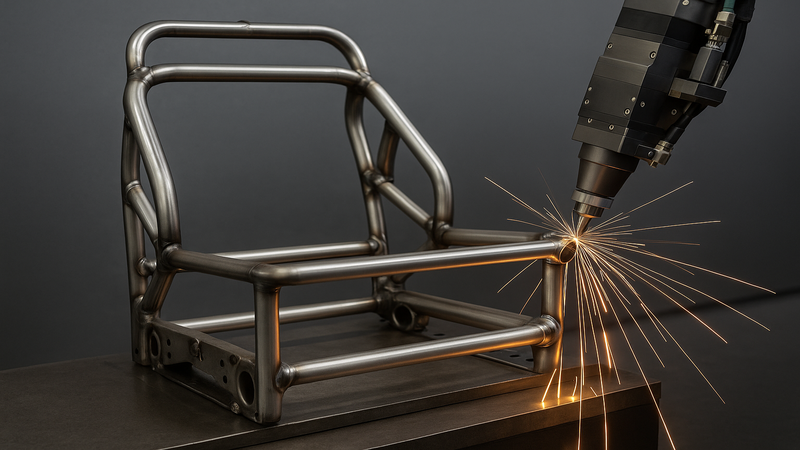

1. Automotive Industry Applications

Laser tube cutting machines have become a central component of automotive component production. Modern laser tube cutting equipment produces lightweight, reliable components with precise tolerances. This simplifies welding and increases structural integrity.

Moreover, the multi-axis modern machines allow for the production of complex parts like exhaust systems and seat frames. Automated machinery also enables repeated creation of complicated designs for mass manufacturing. Thus making your business more efficient.

They are mostly used to develop chassis sections, seat frames, and exhaust systems. These parts require high precision and consistent cutting accuracy to assure safety and performance.

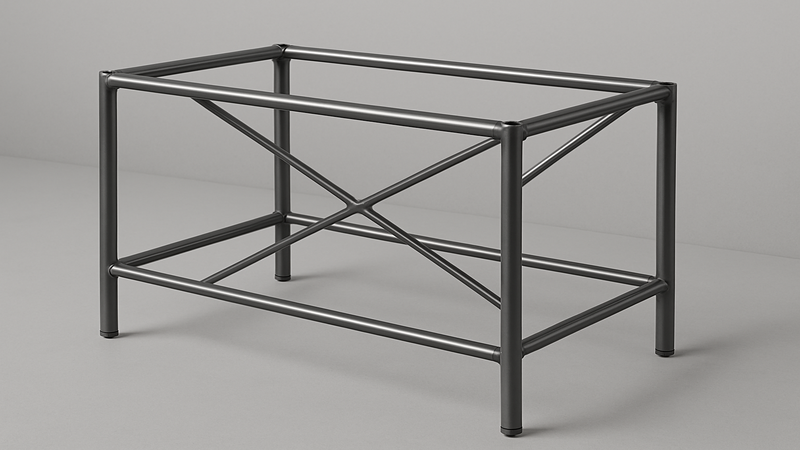

2. Furniture and Fixtures

The entire designer metal furniture industry now depends on laser tube-cutting machines. It is ideal for producing intricate table frames and racks. Modern laser cutting technology enables machines to create clean edges that boost the visual appeal of modern pieces.

The sleek design of furniture is created due to the high-precision cutting process. This process ensures the parts fit together perfectly without extra finishing. Using laser cut machines also reduces material wastage. All while delivering high aesthetic value.

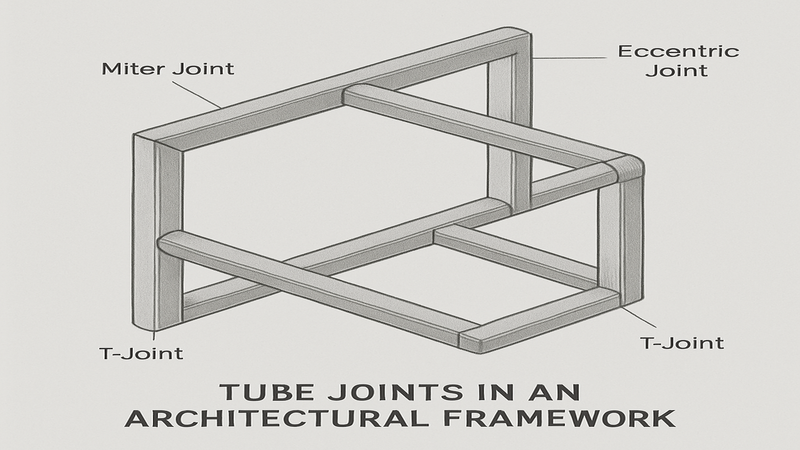

3. Construction and Architecture

The architecture and construction industry has made the most use of laser tube-cutting machines. Modern laser cutting technology facilitates modular building and prefabricated assembly. This speeds up construction operations while reducing on-site errors.

It has become vital for producing structural tubing, curtain walls, railings, and handrails. These parts demand accurate cuts at precise angles for strong and safe connections.

Laser cutting assures accurate lengths and clean joints. Hence, resulting in architectural frameworks that are both durable and visually beautiful.

4. Agricultural Equipment

Laser tube cutting is now required for creating frames for plows, trailers, and irrigation structures. These components must be long-lasting and designed to withstand harsh field conditions.

The method can handle thick-walled steel and aluminum tubes with ease. It provides clean, powerful cuts with no need for additional finishing or rework. Laser tube cutting also enables the rapid production of heavy-duty parts. While maintaining high precision for ease of assembly.

5. Aviation and Aerospace Industry

Laser tube cutting is essential for aerospace and aviation applications. As they require lightweight supports, brackets, and engine parts. These components must meet stringent accuracy and material consistency requirements. And only the most precise technology can create that.

Moreover, the technology can handle titanium, aluminum, and stainless steel tubes with ease. It provides clean cuts that eliminate stress areas and ensure long-term durability. This technology also allows for the complicated designs required for engine components and airplane frames.

6. Medical Device Fabrication

In medical devices, tube lasers are used to manufacture surgical instruments. It is less commonly used to create equipment frames and rehabilitation devices. To comply with high medical standards, these parts must have sanitary finishes and carefully cut edges.

The method is effective with stainless steel and medical-grade metals. It produces smooth edges, which reduce contamination risk and facilitate sterilization. This technology also enables the creation of complex designs for modern medical gadgets.

7. HVAC and Plumbing Systems

Laser tube cutting is applied in both HVAC and plumbing systems. It is perfect for manifolds, pipe fittings, and ductwork supports. It produces rapid, burr-free cuts, eliminating the need for further processing.

Tube lasers also allow for precision hole drilling and unique shapes. This enables complex design and provides easy repeatability across huge projects. The approach helps to develop parts that fit properly in custom HVAC systems, saving time during installation.

8. Fitness Equipment

Laser tube cutting is required for creating exercise machine frames, gym rigs, and racks. These pieces require consistent strength and intricate angles to provide stability while in use.

The procedure produces smooth finishes, which are crucial for user safety. This minimizes sharp edges and promotes ergonomic design. Laser cutting also aids in the production of long-lasting components. Which are capable of withstanding heavy loads without sacrificing quality.

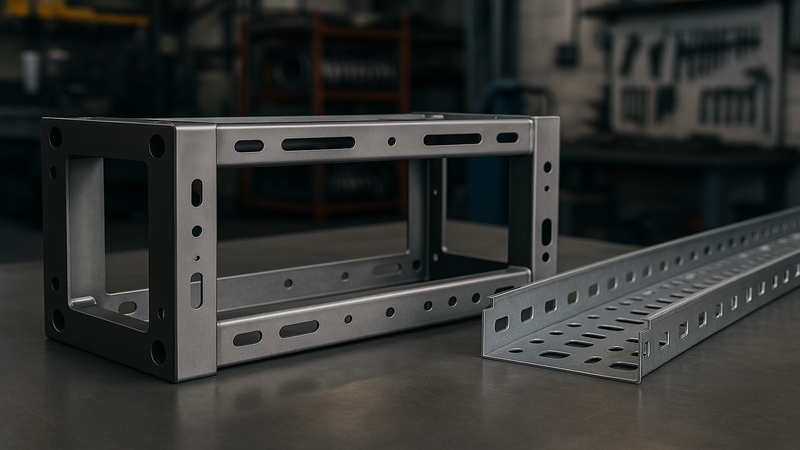

9. Electrical Enclosures and Cable Trays

Laser tube cutting is commonly used to create tube frames for electrical housings, cable trays, and conduits. It features precision slots and holes for easy wire routing.

Moreover, clean cuts eliminate the need for post-processing, which speeds up assembly. This allows producers to achieve short project schedules without sacrificing quality. Laser technology can also create unique patterns that fit complex electronic devices.

10. Industrial Automation Systems

Laser tube cutting is essential for producing tube supports for conveyor frames and robotic arms. These components have to be accurate and repeatable. In order to ensure consistent performance in automated settings.

The technique allows for modular design, making it simple to scale or adapt systems as needed. Manufacturing industries profit from short turnaround times, whether for prototypes or bulk production.

Laser technology enables the production of sturdy, lightweight parts that fit nicely into complex automation setups. Moreover, it has helped replace mechanical drilling in sheet metal fabricating, thus eliminating traditional processing methods.

Why These Applications Benefit from Laser Tube Cutting

Laser tube cutting applications provide significant advantages that apply to many industries. It accelerates production cycles by combining cutting, drilling, and labeling in a single automated phase.

Here is a breakdown of all the reasons why these applications benefit from laser tube-cutting technology.

Faster Production Cycles

Laser tube cutting drastically reduces production times. Cutting, drilling, and labeling are combined into a single automated operation while ensuring processing accuracy. Thus, eliminating the need for manual handling between manufacturing processes.

This means that your business can go from raw material to finished item in a fraction of the time than traditional cutting methods.

Precise and Complex Geometry Cuts

Modern laser tube cutting equipment is excellent at generating precise, burr-free cuts. It does so even for complex forms and tight angles. This level of precision guarantees that parts fit exactly during assembly. Thus minimizing errors and rework.

The technique also allows for the creation of elaborate designs. Achieving these designs would be difficult or impossible with mechanical cutting.

Less Material Waste

Laser cutting maximizes material utilization through intelligent nesting and accurate route control. The end result is less scrap and cheaper raw material prices. This efficiency not only minimizes waste, but it also supports industry-wide environmental goals.

Integrated Cutting, Drilling, and Marking

One of the most significant advantages of laser tube cutting is its ability to perform many operations in one pass. The machine is capable of cutting, drilling, and marking items without the need for any tool or setup changes.

This connection enhances uniformity, accelerates manufacturing, and reduces the possibility of human error.

Lower Labor and Tooling Costs

Laser cutting decreases the need for manual intervention and secondary finishing. Thus lowering labor needs. The laser can also digitally adjust to varied designs and materials. This reduces the requirement for specific tooling. This flexibility allows you to save money on both equipment and labor costs.

Materials Commonly Used in Laser Tube Cutting

Laser tube cutting is compatible with a wide range of materials used in various sectors. Each material has distinct qualities that make it suitable for a given use. Let’s go over all the materials and their specific strengths.

Carbon Steel

Carbon steel tubes are commonly utilized in construction, agriculture, and industrial machinery. They combine strength and cost. Laser cutting can handle carbon steel tubes with wall thicknesses ranging from 1 mm to 10 mm. It can also handle varied geometries such as round, square, and rectangular.

Stainless Steel

Stainless steel is widely used in medical devices, food processing equipment, and architectural components. It offers corrosion resistance and a crisp finish. Tube wall thickness normally ranges from 0.5 and 6 mm, with round and square tubes being the most prevalent.

Aluminum

Aluminum tubes are highly valued in aerospace, automotive, and furniture manufacturing. Due to their lightweight and strength. Laser cutting works well on aluminum tubes from 1 mm to 8 mm in thickness, in various shapes, including rectangular and round.

Titanium

Titanium is utilized in aeronautical and medical applications. They require a high strength-to-weight ratio and corrosion resistance. Laser cutting can handle titanium tubes up to 5 mm thick, usually in round shapes for precise items.

Copper

Copper tubes are used in electrical and HVAC applications due to their conductivity and formability. Laser cutting is used to cut thin-walled copper tubes, which are typically less than 3 mm thick and come in round or rectangular shapes.

Conclusion: Is Laser Tube Cutting Right for Your Application?

Laser tube cutting is a versatile solution used in all industries. It provides unprecedented speed, accuracy, and flexibility. It is also able to produce complicated parts with minimal waste.

Whether you want an impeccable material surface after cutting or want to produce complex hydraulic systems. Tube laser-cutting machines are the future of industrialization.

Laser tube cutting is the best option if you’re looking for ways to optimize your production process. It also works ideally if you need assistance with custom-cutting requirements.

However, it is important to note that the type of tube laser cutting machine can impact functionality. The type (fiber laser vs. CO₂ laser), machine power, and system setup are all critical factors. Any variation can impact the laser cutter’s ability to handle different materials and geometries.

Let’s Build Your Next Project with Precision

At Baison Laser, we help manufacturers achieve outstanding results with advanced tube laser cutting solutions. Our team is ready to guide you if you need help choosing the right machine. Or if you want to explore custom options that fit your production goals.

Contact us today for a free consultation or personalized quote. Let’s turn your ideas into reality.

FAQ

What industries use laser tube cutting the most?

Laser tube cutting is widely used in industries that require precision, speed, and complex geometries. Key sectors include automotive, aerospace, medical devices, furniture manufacturing, construction, and agriculture. These industries rely on laser cutting to produce high-quality components with minimal material waste and quick turnaround. Thus helping them meet strict performance and design standards.

Can laser tube cutting handle thick pipes?

Yes, laser tube cutting can process thick-walled pipes with excellent precision. The capability depends on the laser type and power. Modern machines can cut carbon steel tubes up to 10 mm thick and stainless steel or aluminum tubes up to 6–8 mm. The process ensures clean edges, reducing the need for secondary finishing or rework.

What tube shapes can be cut by a laser?

Laser tube cutting works on a variety of tube shapes. Common profiles include round, square, rectangular, and oval tubes. The technology also handles custom shapes and profiles. Thus allowing you to produce intricate designs and tight-tolerance parts for specialized applications. This flexibility makes laser tube cutting suitable for many industries and design requirements.

Is laser cutting better than plasma for pipe fabrication?

Laser cutting offers higher precision and cleaner cuts than plasma cutting. Especially for detailed or complex parts. It is better suited for applications that need tight tolerances and smooth edges. Plasma cutting can still be preferred for very thick materials or lower-cost projects. But laser cutting delivers superior accuracy and finish quality.